-

Posts

618 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Vane

-

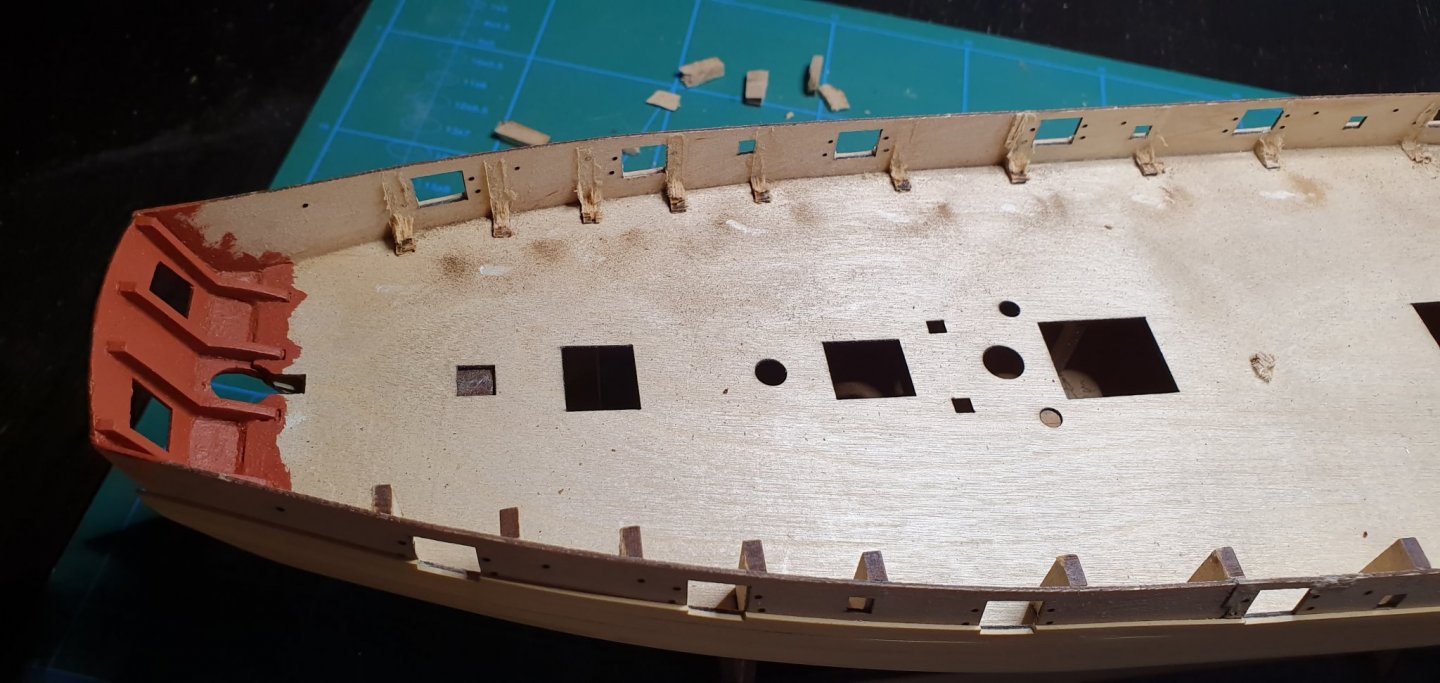

Thanks for a good points all of you have raised. I dont think any of you are right or wrong, just different ways of looking at the problem. The interesting thing with the whole kit is all of the new design solutions using latest technology and with an idea of speeding up the build process. Some of those may not look as good as an advanced and highly skilled scratch built solution, but its saves time and some people my not have the needed skills. Even though some details are important, I dont think they are as important on wooden ships as on plastic models where u spend lots of time on weathering effects. The rigging is what stands out.

-

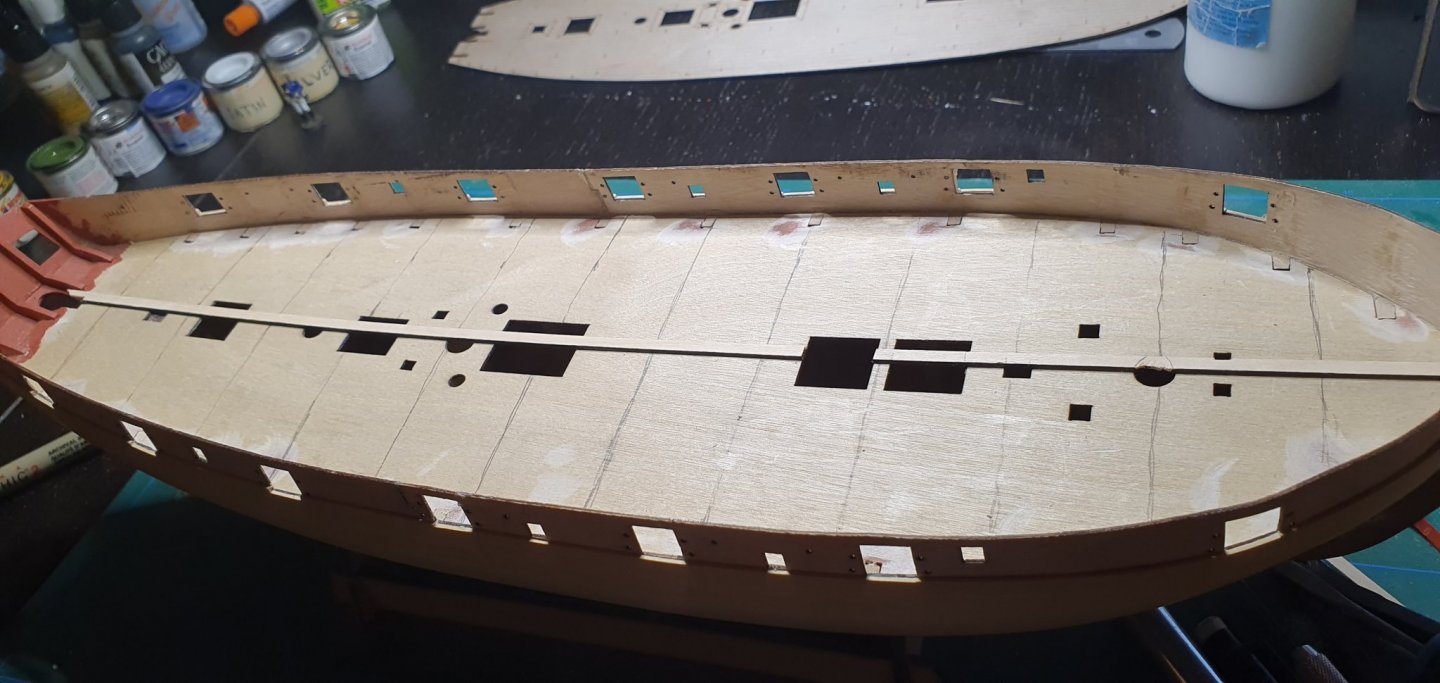

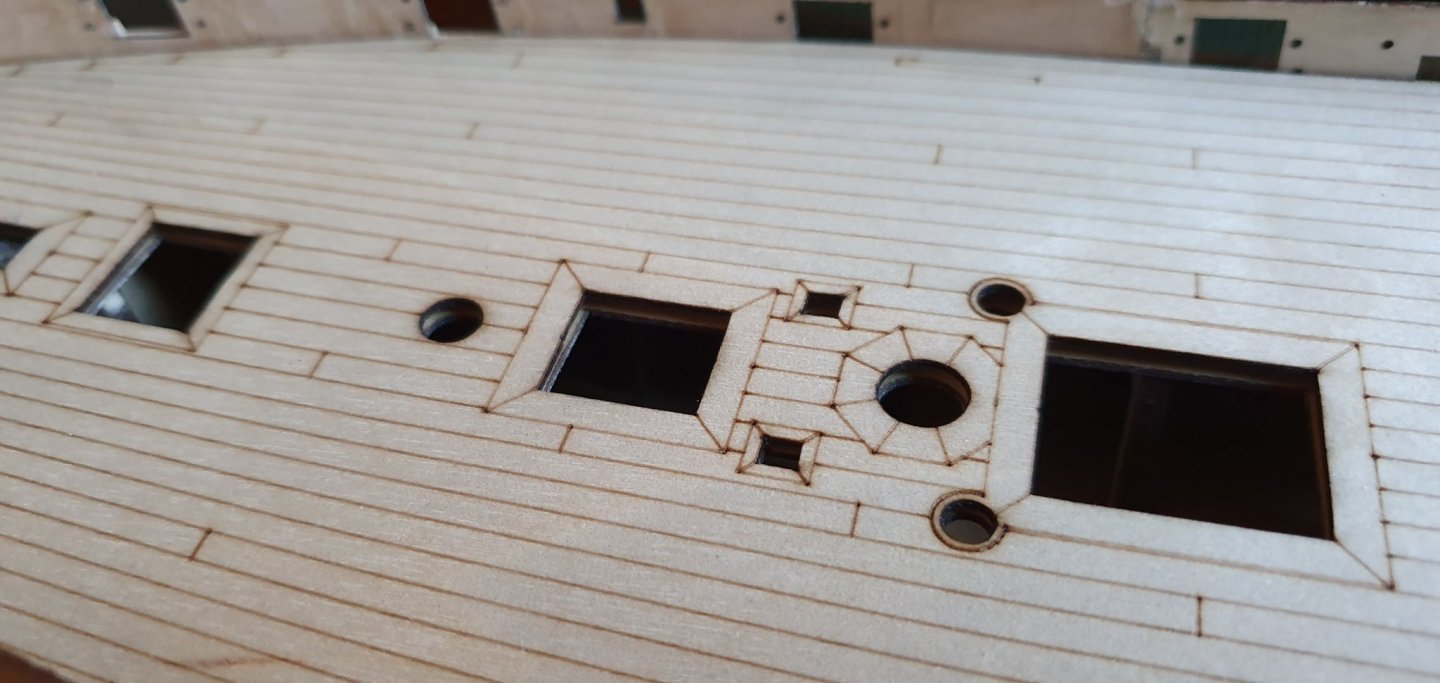

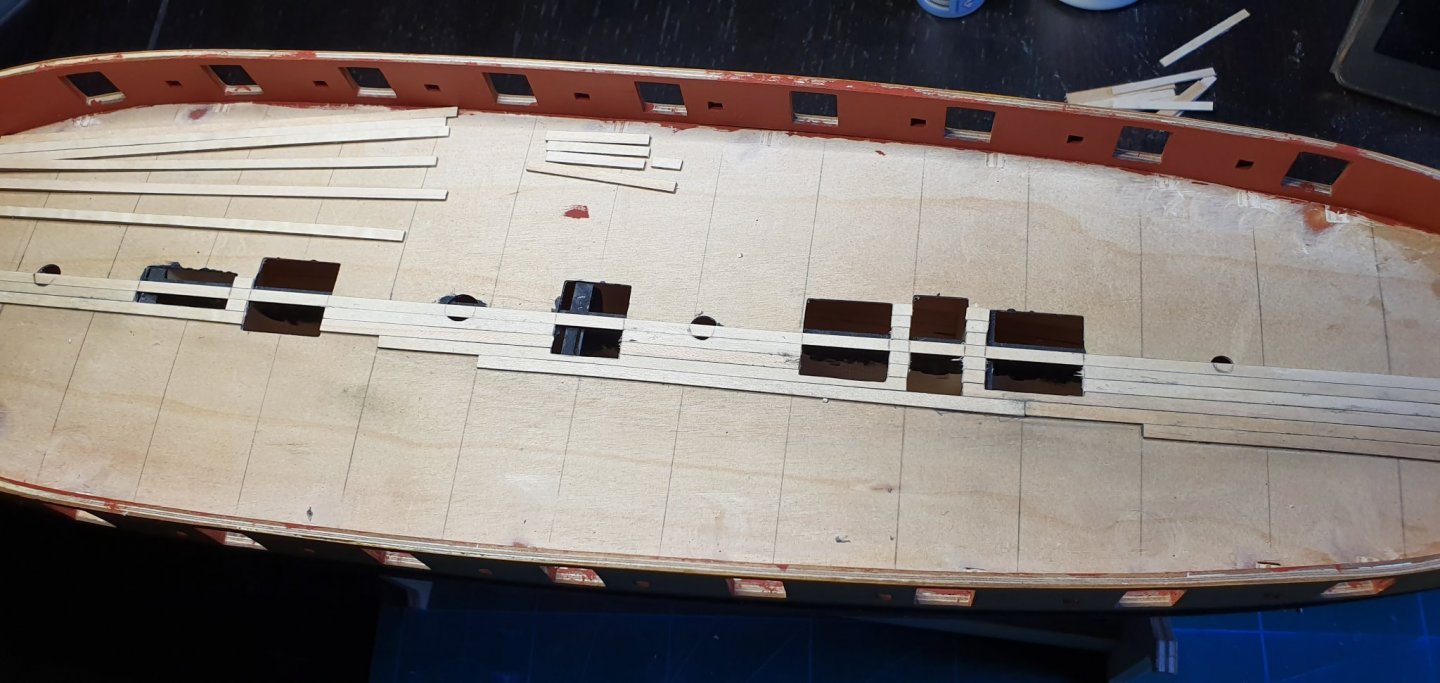

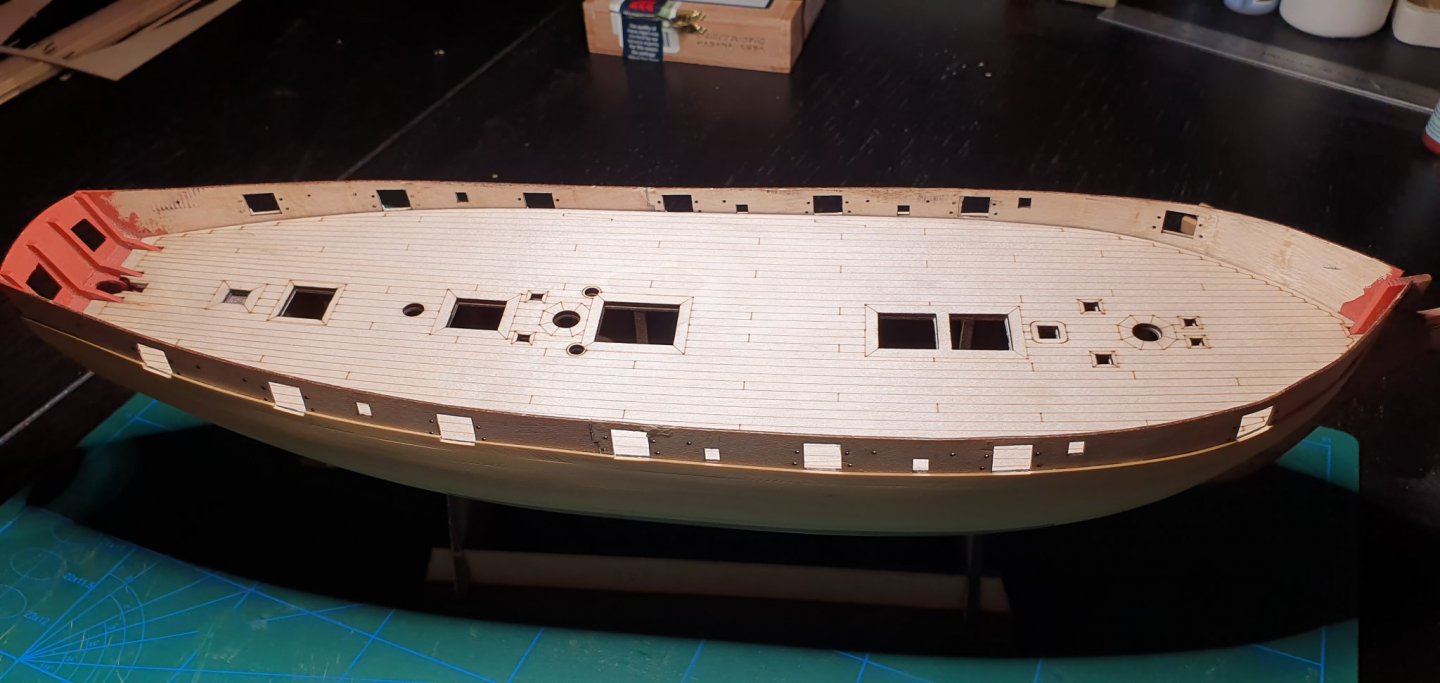

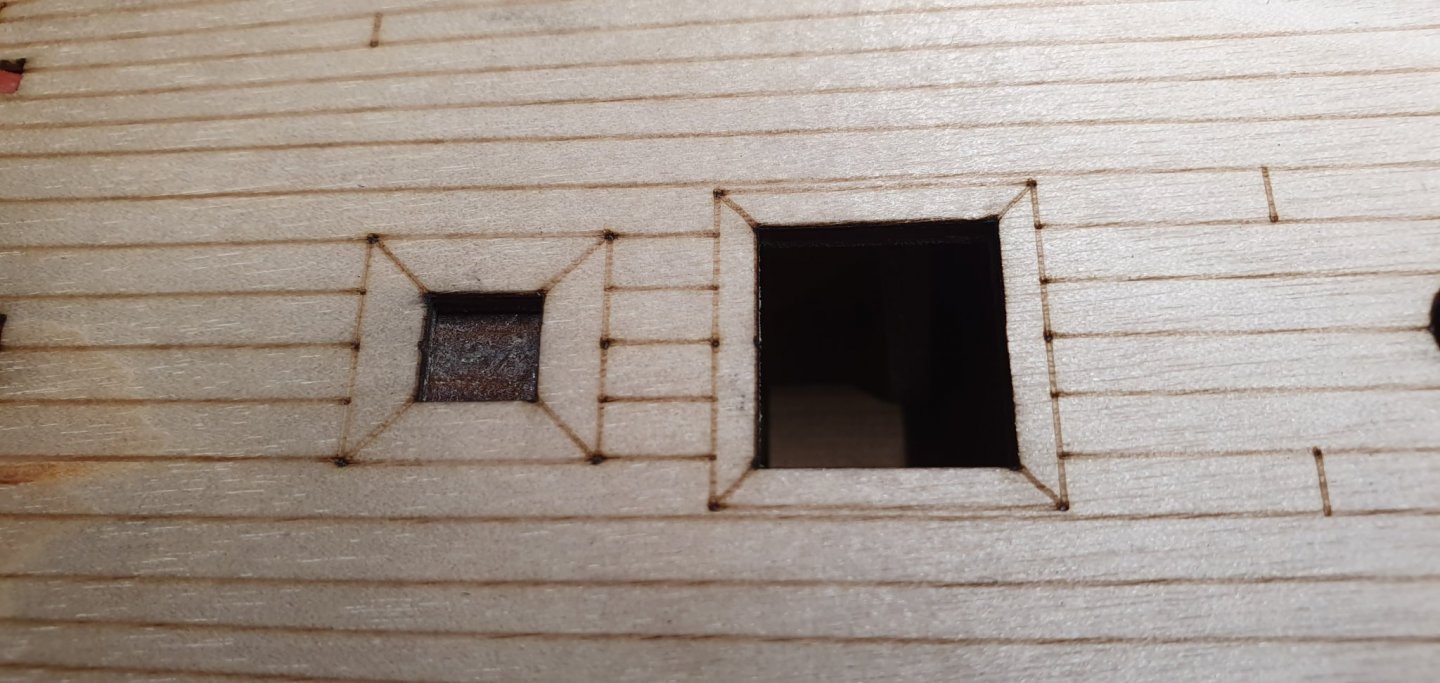

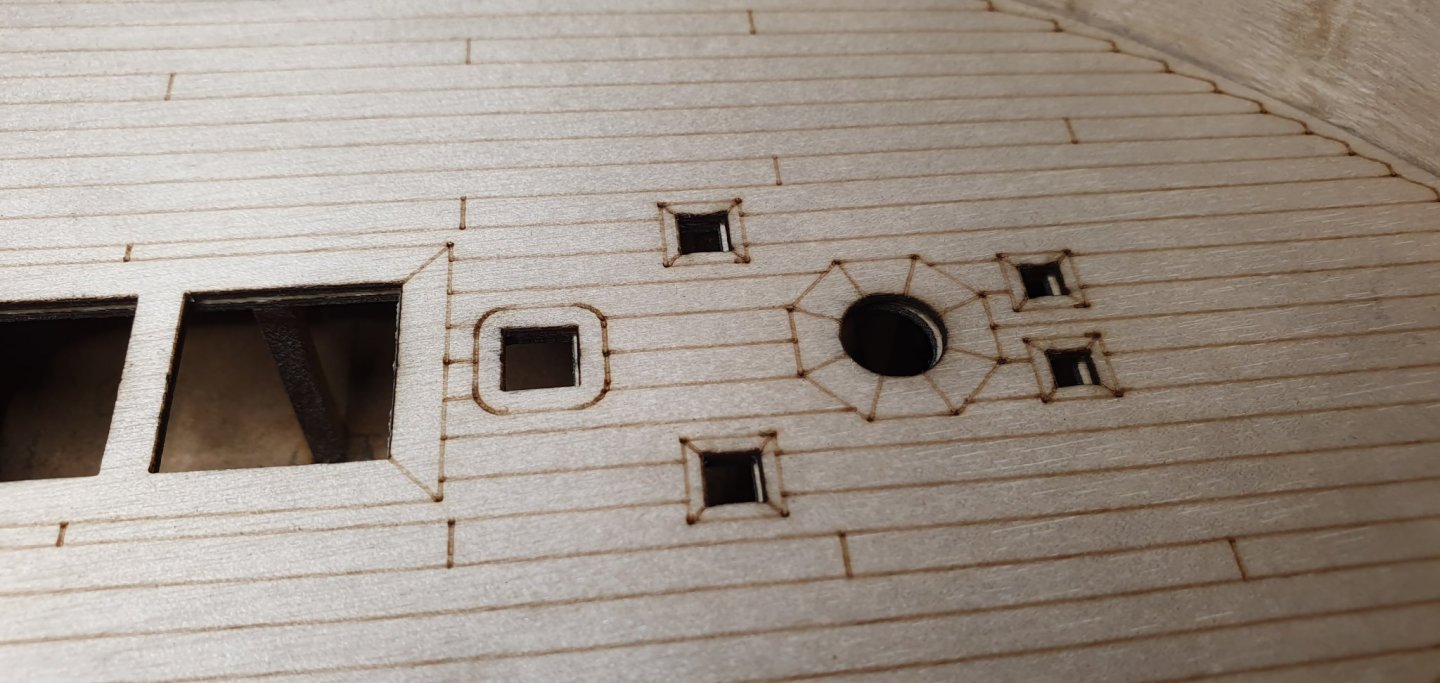

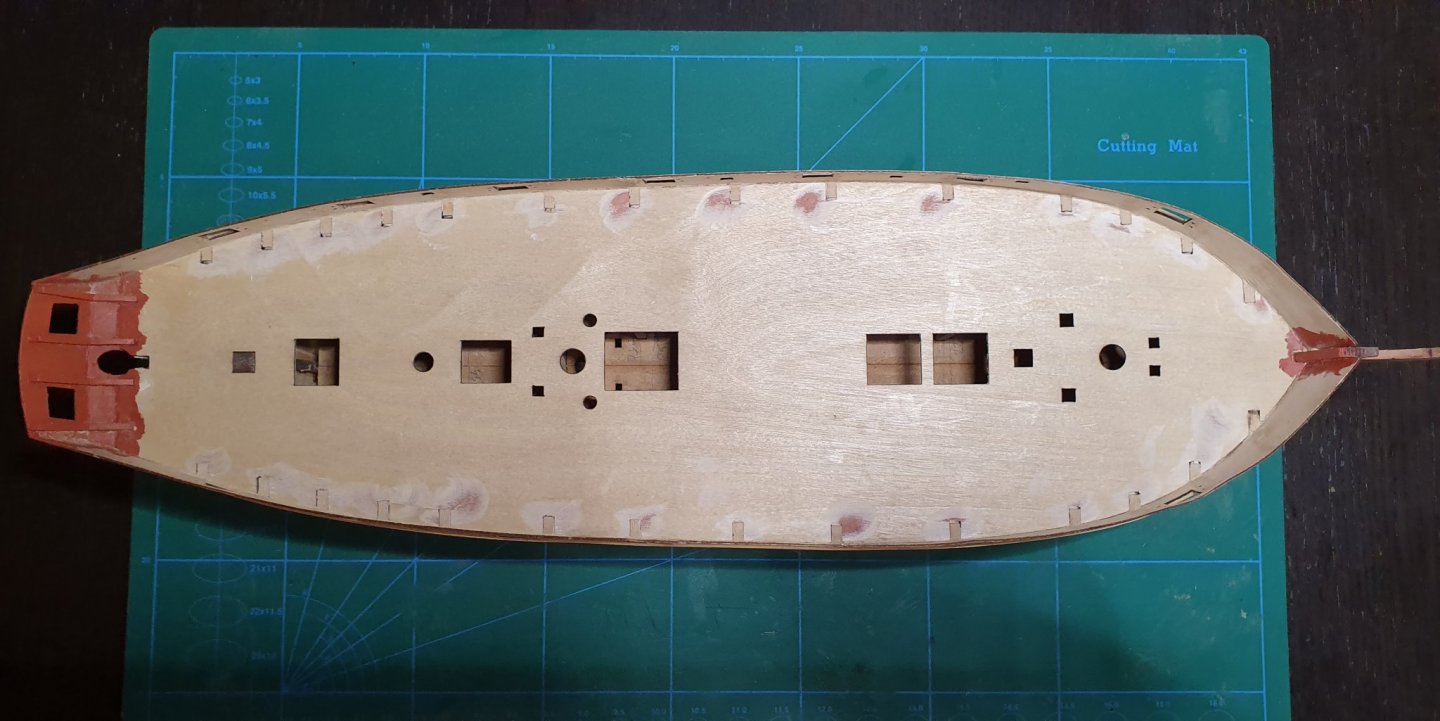

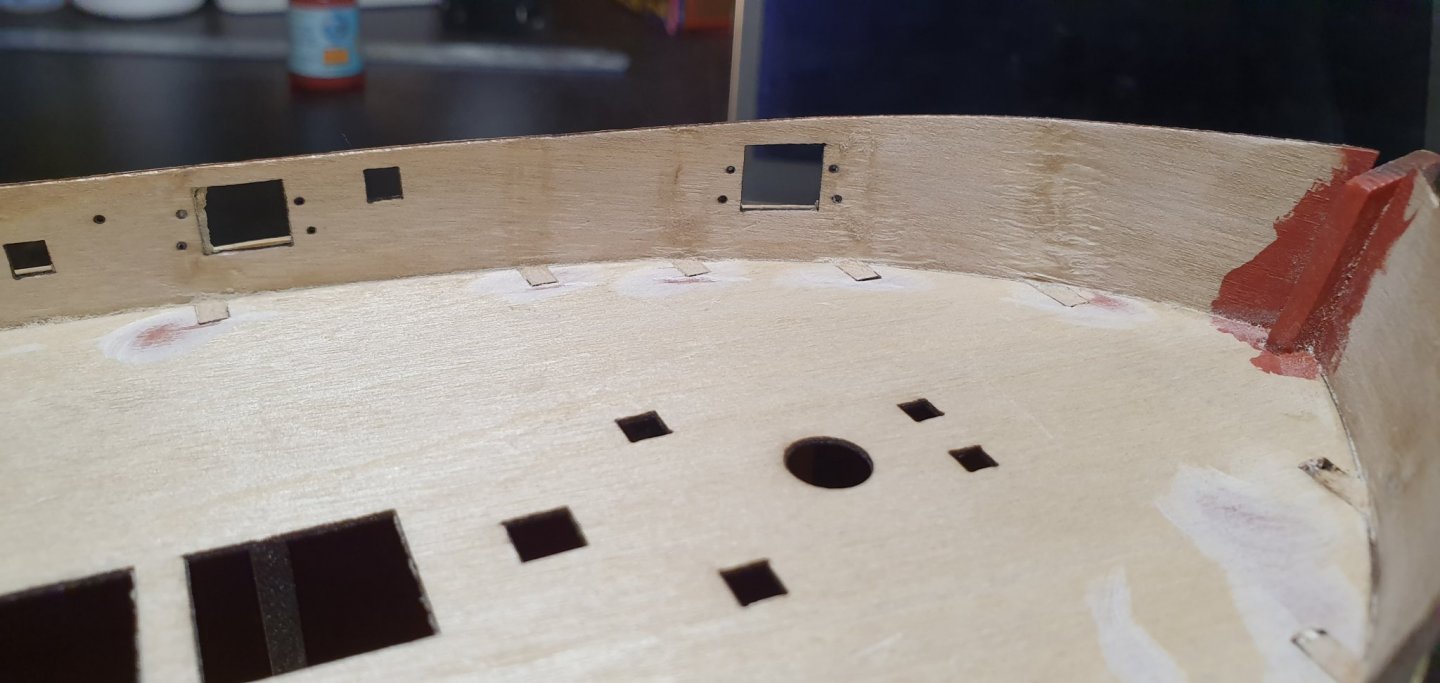

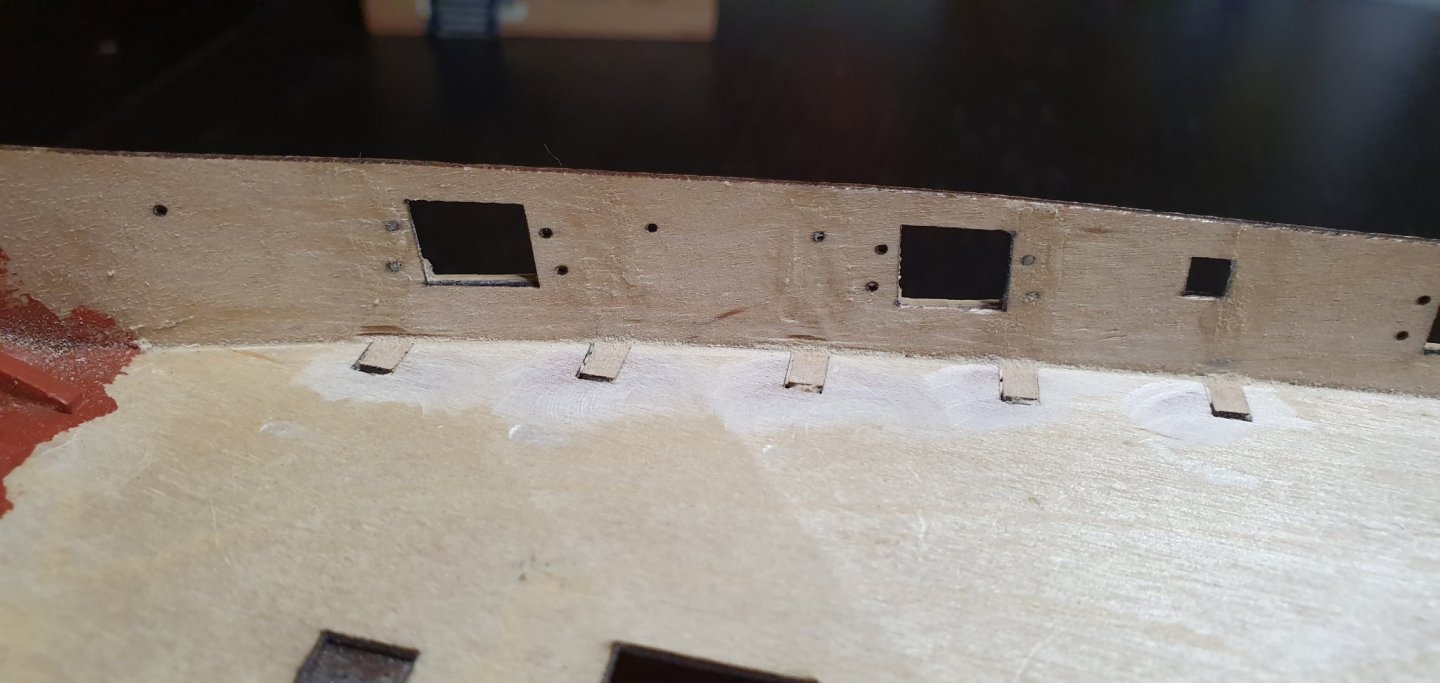

This was quite alot of work... Unfortunately my maple is really rough and each plank require alot of side sanding. My Proxxon has been invaluable to fix the tips of the planks. Each plank is 15cm long and i am doing a 3cm pattern. I am using a pencil for the caulking since i thought that a Black pen made it to harsh. Hopefully i Will finish this i a few days. The laser engraved pattern feels very tempting for my Speedy now...

-

While trying to decide about the deck i did a mini project: swivelguns. Here i also got to try out my new airbrush which was quite fun but also abit of a challange to use. Once again, the design with resin guns with photo etched parts made this not that difficult. Everything is very small but came together nicely. It was even easy to drill out the guns with a 0.8mm drill.

-

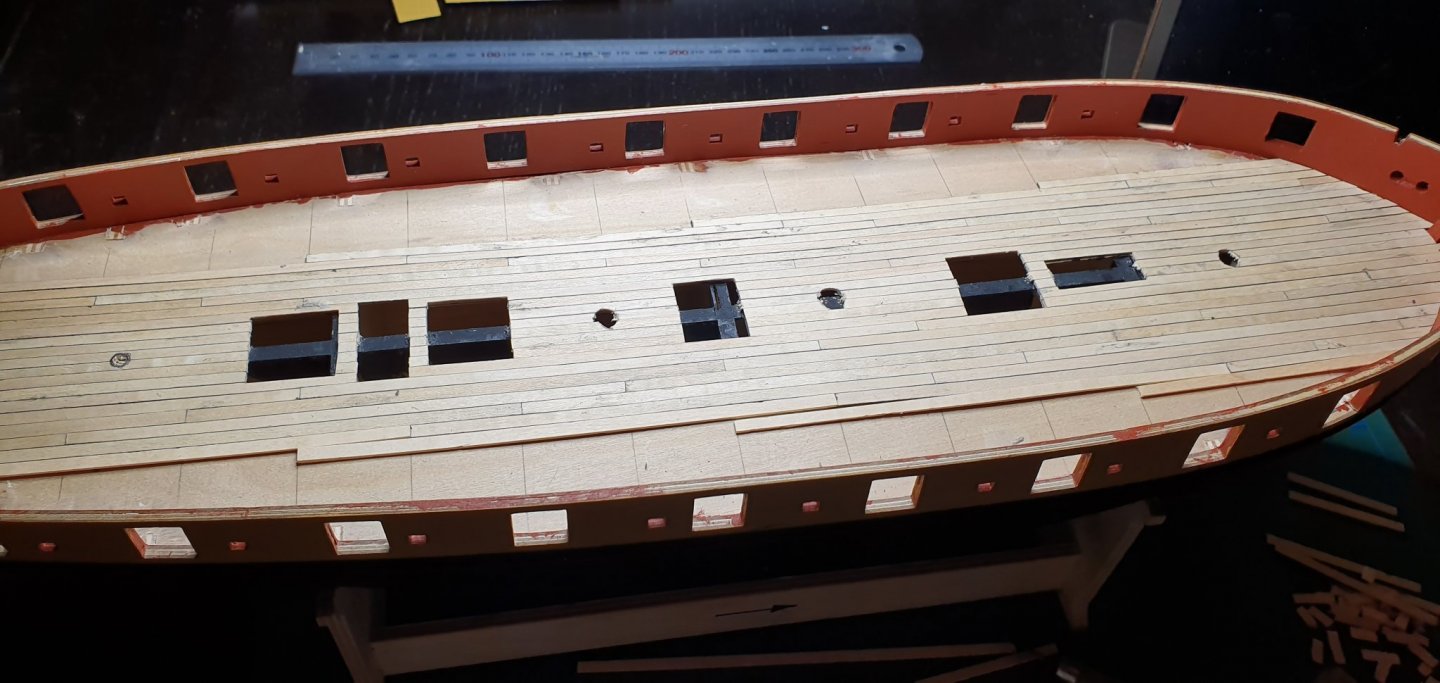

I definitely think the new Speedy deck look better than the original. I still havent decided whether I should use mine or not... will do some deckplaning on my other models Before I make my final decision. Today I put together the Swivel guns which was a much easier job than expected. Great design there as well!

-

The number lime planks where fine in my kit.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

Very nice! I think sanding is one of those things that people do very differently and its probably because we build for various reasons and aim for completely differnt result. There are many logs here which basicaly dont sand at all. Pieces are just glued together. Others, especially scratch builders in larger scale, can sand a single piece for several hours ensuring that there wont even be a Micrometer gap anywhere.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

On the one hand, I think a properly laid plank deck in maple would look best. But on the other hand, the laserdeck would same me tons of work and it also includes some details difficult to make. And it would be really interesting to try it out and see if this works. This kit has so many New solutions so perhaps its just right för this build.

-

Agree, the tight frames made this step easy. It looks much better than my first planking!

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.