-

Posts

618 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Vane

-

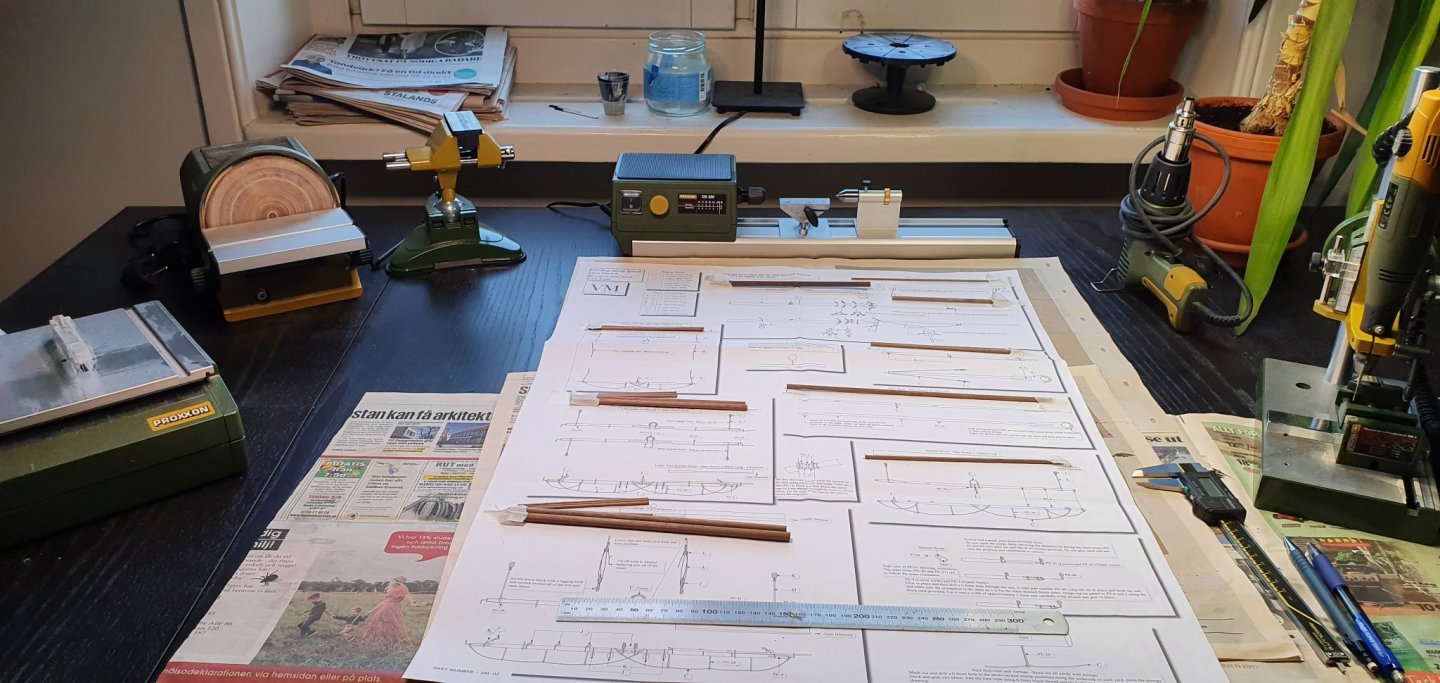

I work on serveral kits in parallel and I must say its really difficult to go back to the older Caldercraft kits when working some time with the Speedy which goes together so much more easy and the plans and instructions are on the spot. Actually, last couple of days I been working on my Diana. Well, not ON her but rather putting number on parts and removed them from sheets and placed into boxes instead. And I have also done an enourmous amount of sanding until my fingers couldnt take it anymore. There is nothing wrong with my Diana kit, but compared to the Speedy you will have to spend alot of time preparing all parts. Vanguards lazercutted parts fits often directly with no or very little adjustments. And then the material is also much nicer than the traditional walnut and ply combo.

-

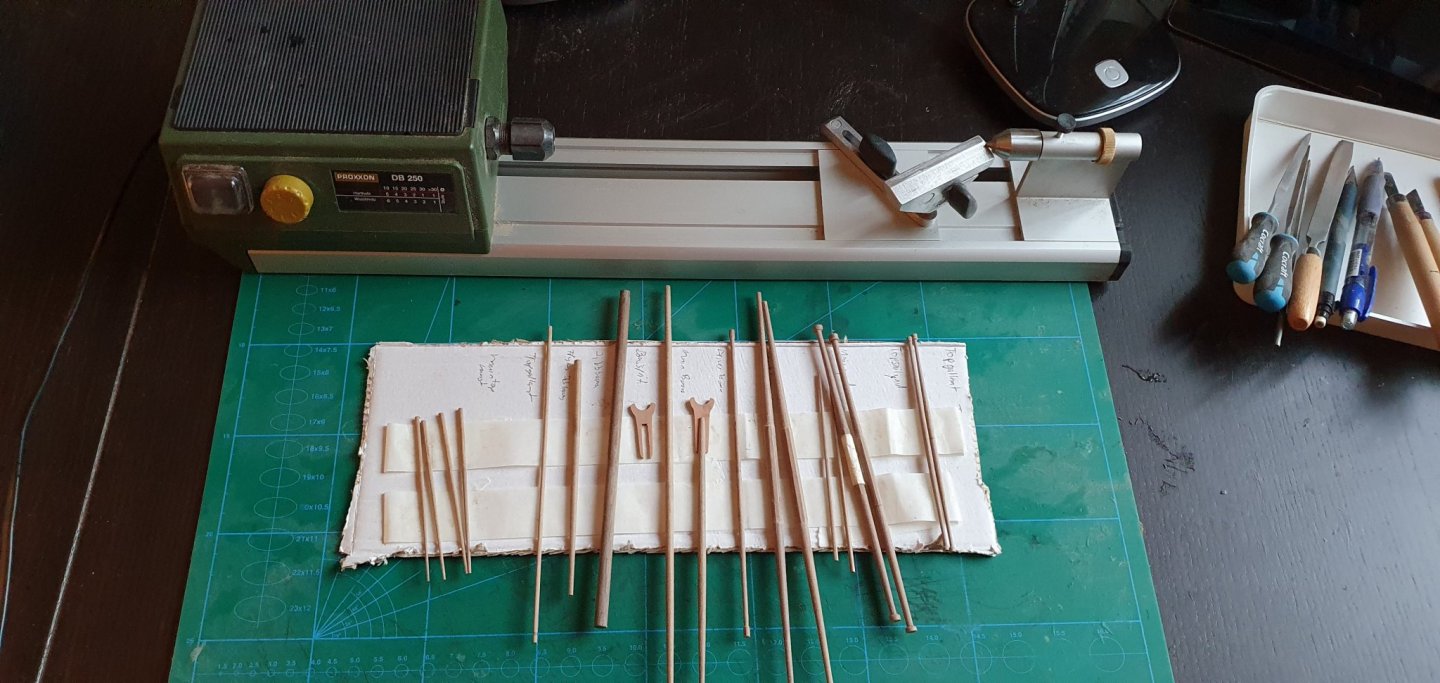

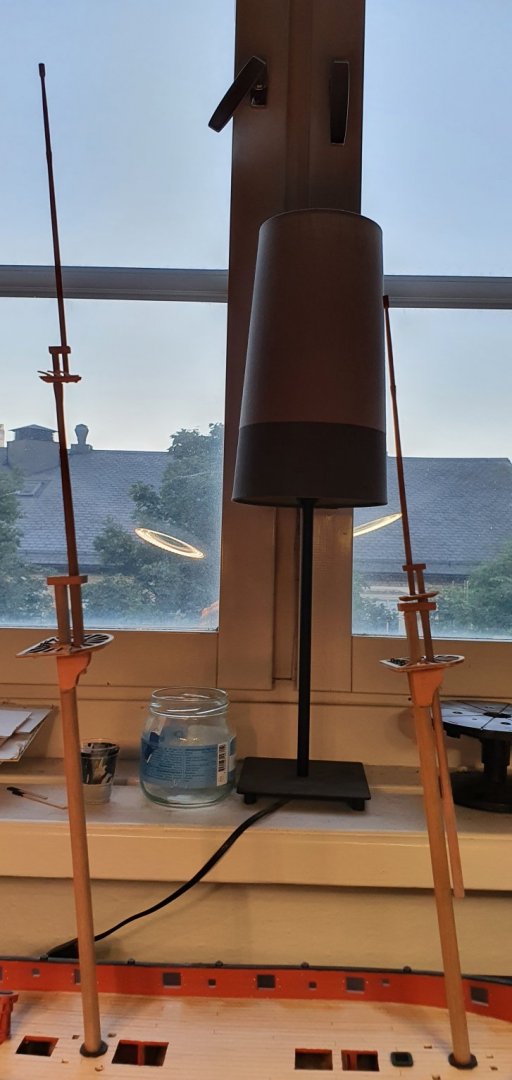

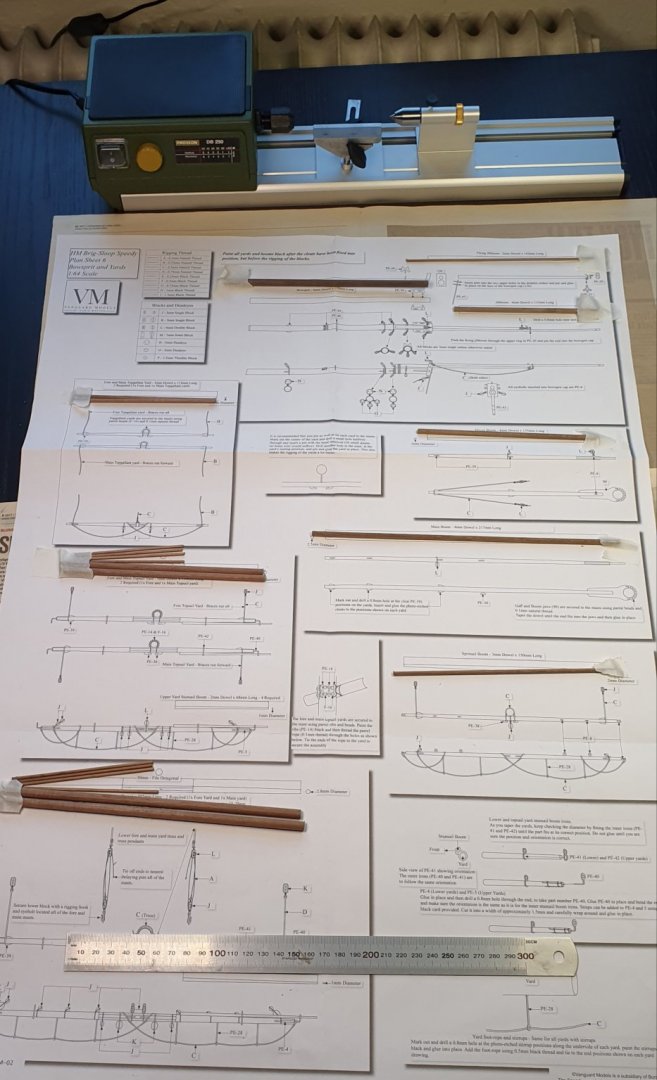

The Proxxon lathe really delivered! A couple of evenings and now all dovels have been sanded down to the right dimension. I also tested putting up the masts and suddenly she got way bigger. This will become a very beautiful ship! Hmmm... I am not sure where the rest of these dovels is suppose to be mounted on the ship... ? i feel like after IKEA and you dont have a clue if the leftover screws are extra or vital to the furniture... 😛

-

The whole Nelson line is very nice and my style of ships. However, Caldercraft has, as far as i know, not developed anything new for nearly 20 years. Their kits are now way outdated and in real need of being upgraded. But they seem not to care at all about that and live on old successess. Comparing the Caldercraft Diana kit with my Vanguard Speedy is like an old Volkswagen Beetle to a Lamborghini Avantor in design, kit details and instructions. So basically, I would rather wait for Chris to develop something new than order kits that dont cut it anymore.

-

I am very excited to see the progress and new models coming up. Once i have finilized some of my current builds (including the Speedy) I am looking for a new Vanguard ship to take on. In my view, when it comes to the next models, I would argue that it should simply be a business decision for getting Vanguard models to grow and not so much about individual opinions here. Design a model that fits and expand the line up you have. Also think about what kits your competitors already have on the market and do something unique. Finally, always keep in mind your brand. Stick with the certain style that you want Vanguards to be rather than just developing randomly projects that has nothing in common. My 50 Cent

-

Once u release air the pressure starts dropping and then the compressor starts after a while and build it up again. Its not an exact science. The key is to find an airpressure where the paint flows nicely on to the model. Just try on some scrap and adjust until it works fine. Its like showering in the old Days when you had to knobs: one for Cold and one for warm and you needed to adjust until you got a nice flow with the right amount of heat.

-

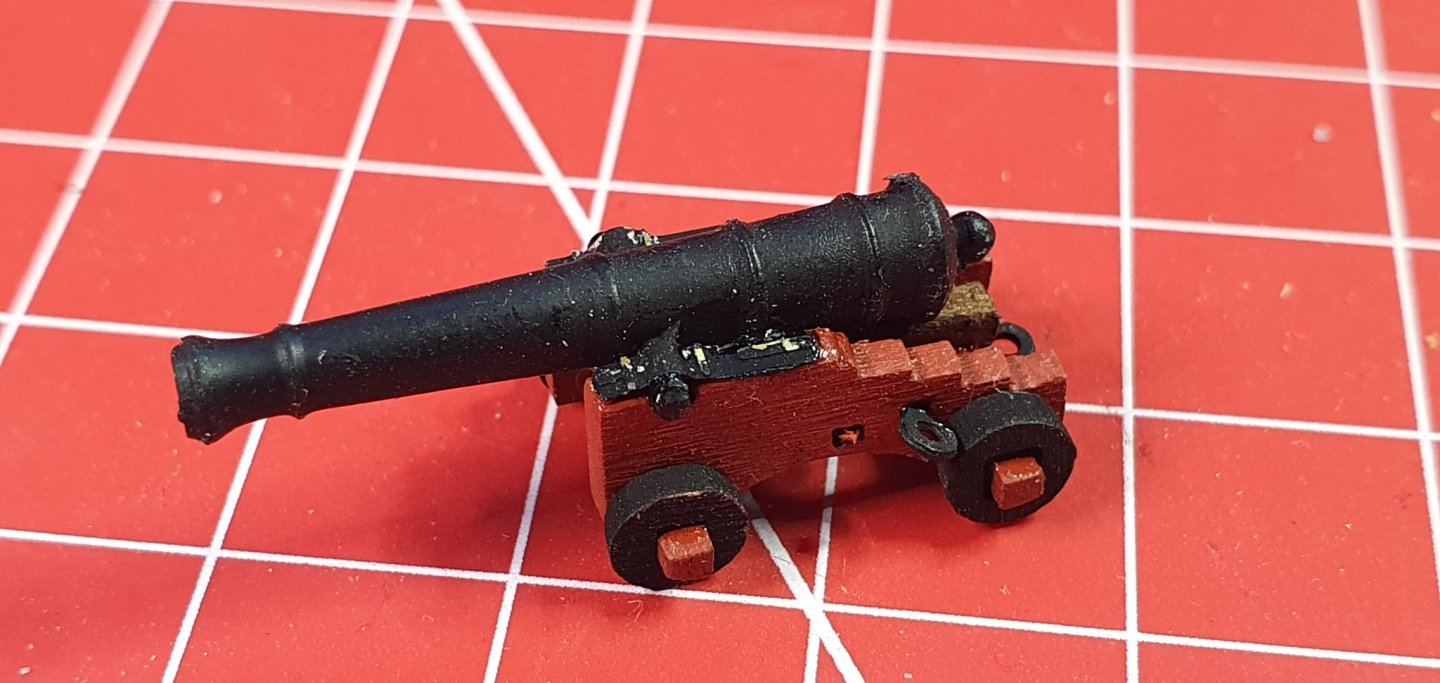

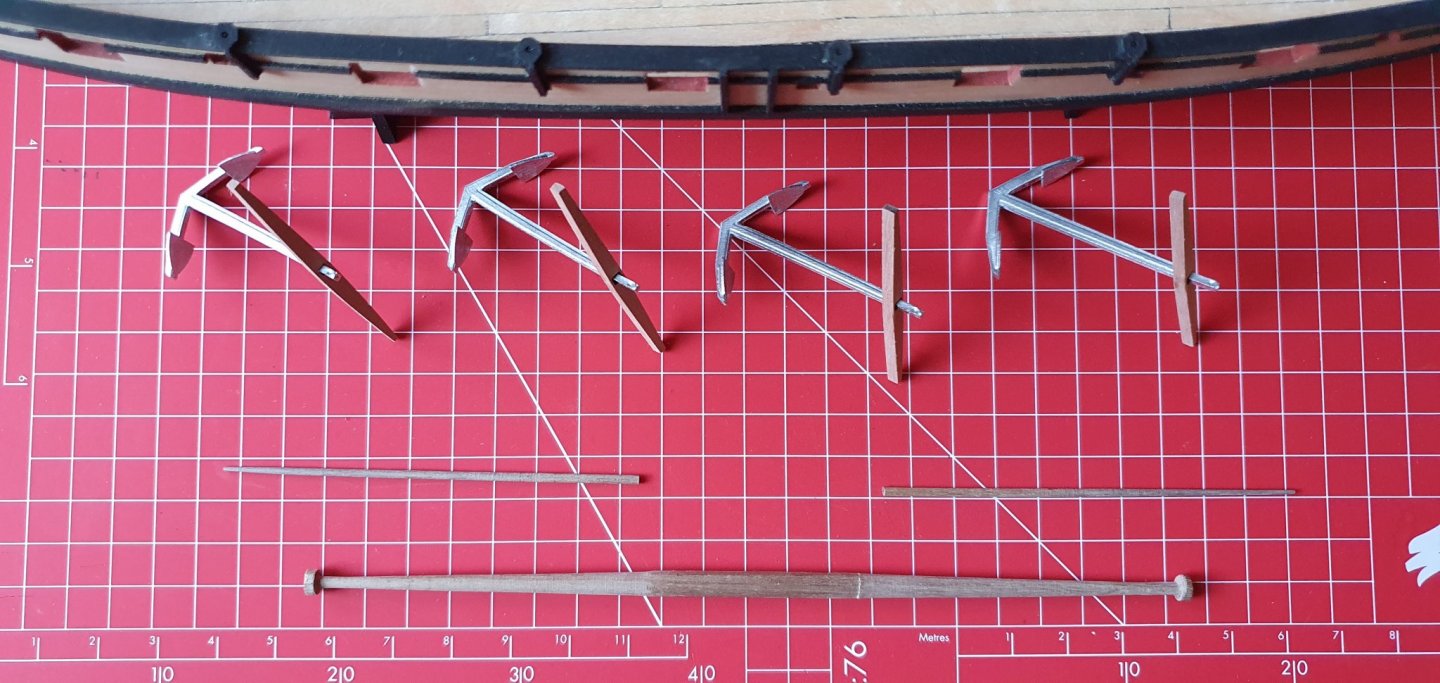

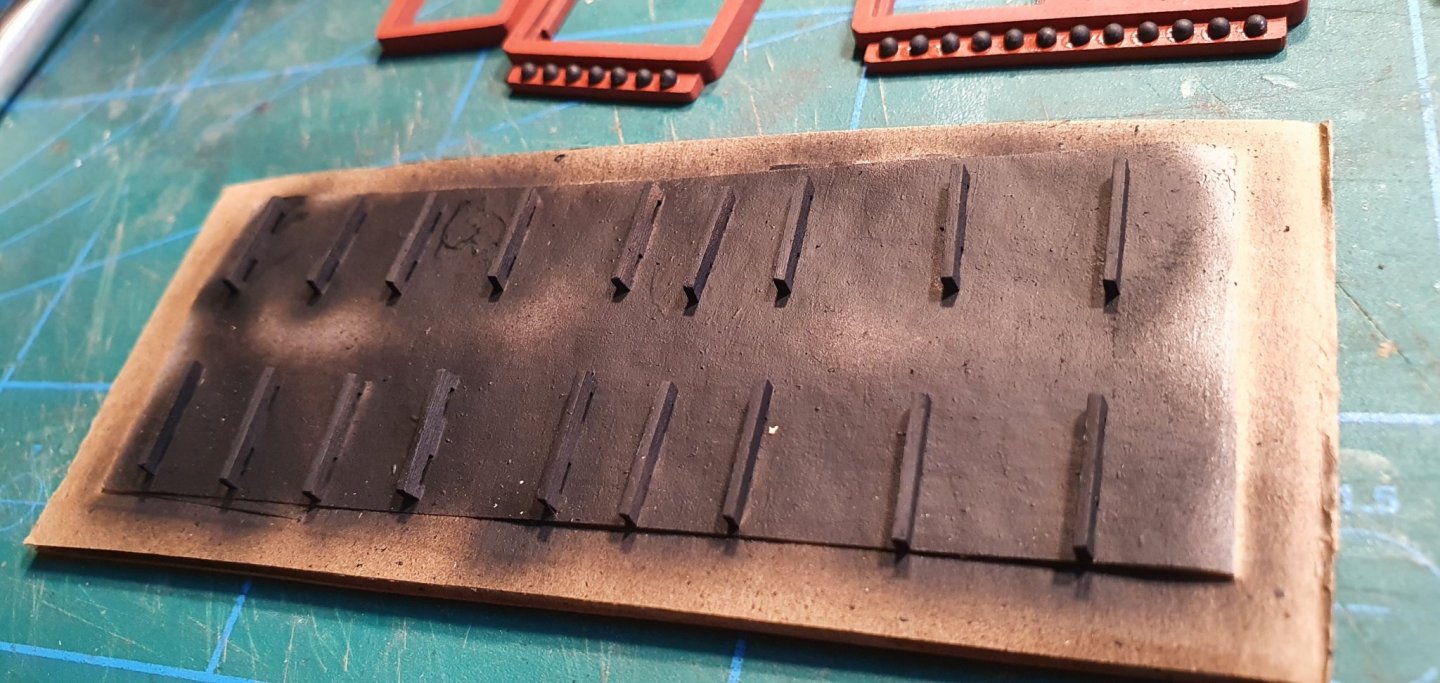

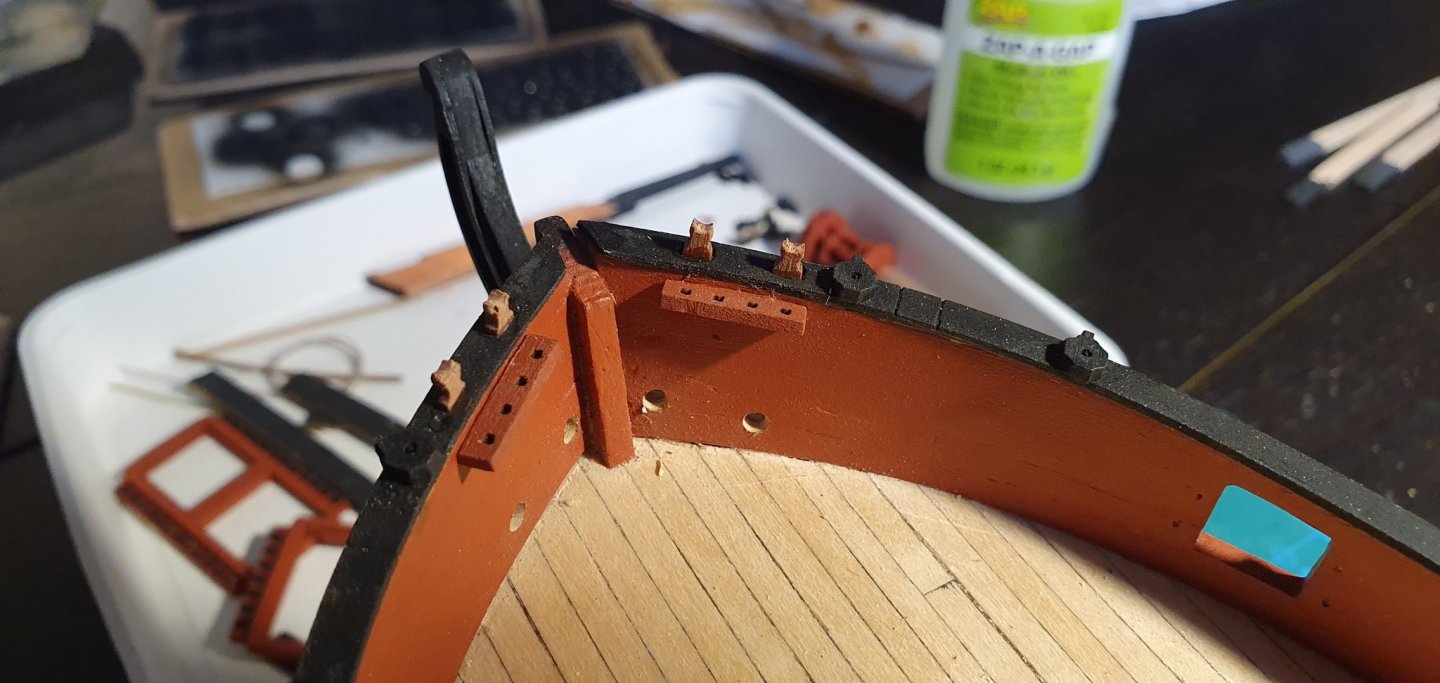

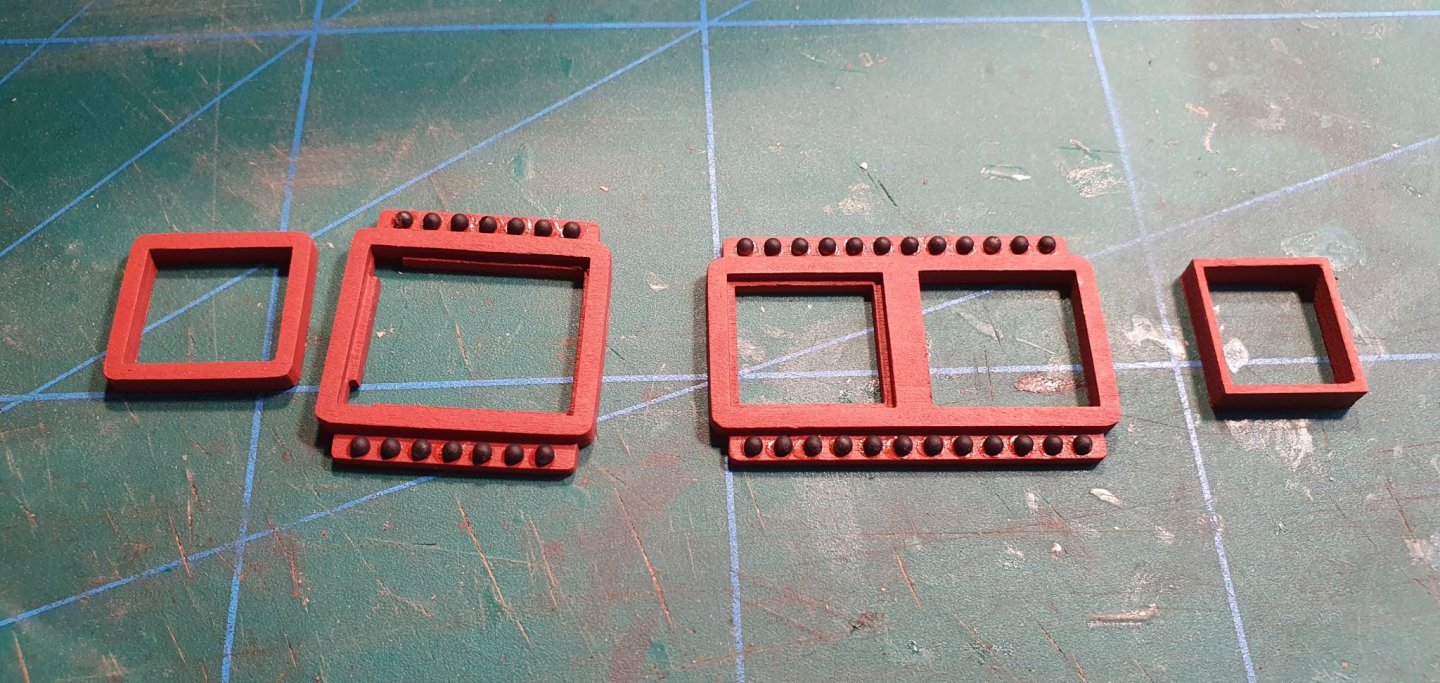

After some time off from my Speedy, I have started to work on the tiny parts. Some are really difficult and perhaps not of the best quality (!) but I think it mostly depends on outsourced lasercutting. I got one of the first kits and looking at the upgrades and what Chris have done with his own lasermachine I think they are way better now. I decided to plint these black but i might do a few of my own in boxwood to match the colours. Most of the precut stuff are great and make the work much easier. I also start to be friends with my airbrush but still have alot to learn. I still havent decided about rigging the canons. They are really small so it will require some hard work.

-

This is really impressive. These guns are really small. I have not yet decided on the ones on my speedy yet.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

Regarding the extensions, i put PVA on mina. No problem breaking them of later and with some sanding.

- 101 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

-

You can do things in various order. I guess its just preference. Cutting out the holes in advance might work well. The only thing is that you still need to cut holes from the second planking. Avoiding planking the gunports is one thing but its more difficult with small holes. I use both CA and PVA. Depends on what drying time that is most suitable. 1st planking which is not visable, I prefer PVA and pins. But if you are not going to paint the 2nd planking, you need to use CA to avoid pinmarks.

- 101 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

-

Nice woodwork there. Its all about preference: if you want to paint or not, what kind of wood that has the best colour and texture for you. The best material to work with is boxwood but hard to get and expensive. I have built a couple of hulls in walnut. But those I painted. I dont mind the dark colour of walnut. My main problem with it is the variation in colour and tones so I would have to carefully select the planks to work with so the all are basically the same.

- 101 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

-

The problem as a beginner is that usually the airbrush works fine just as you put some paint in it and press the trigger. Then after a while, the fine flow of paint suddenly is not so fine anymore. It might even not come out any paint at all. Then you need to figure out whats wrong and correct it. Sounds easy? Well, everything needs to be balanced right. That is what requires practice. Spraying is not that difficult, but so many varibles affect the flow of paint have making sure everything has the right setting is key.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

I need to add another layer before its finished but its so much more smoother and have no brushstrokes. It takes times to become friends with your airbrush, cleaning is one thing but also airpressure and thinning, various types of paint etc. I would recommend to look into plastic forums to get better tips because its a world of its own.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

You have a great build there! I can really recommend airbrushing. I got myself one a few months ago and everything looks so much better. Only problem is I also got myself some plastic kits to practice on and now I just got so many projects that is slowing down the progress on my boats. :-P

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

I dont think the first planking is that important since its only about getting the shape right. But in the second you really need to pay attension to details, especially if you are not going to cover it all with paint. I hope to be able to do some work on this later this summer but I have too many Projects going on so I will try to finalize some before going back to this ship.

- 101 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

-

I doing several build at the same time so I might not remember it exactly right. But I used the blocks in the kit in the front but did not add any extra balsawood that some do in the front. I did a annoying mistake at the stern and glued the end piece before the tappering so I had to carve/dremel it out… it would had been easier to follow the intructions and just sanded it down first. :-P

- 101 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

-

We are all different and spend various amount of time on our Projects so planking can look very different. On my first model i just used pins, hot water and PVA on my walnutboards. It looks decent with paint on. After several hulls i have improved alot. Now I replace the walnut with much higher quality Wood, I am prebending with heatgun, CA, tappering and alot of sanding. And no painting over the final result. Way better but i still dont come close to scratchbuilders like Sloane and his HMS Bellona.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.