-

Posts

607 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Stockholm

Recent Profile Visitors

-

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Canute reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Canute reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

chris watton reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

chris watton reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

thibaultron reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

thibaultron reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

BenD reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

BenD reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

JeffT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

JeffT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

mtaylor reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

mtaylor reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Ryland Craze reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Ryland Craze reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Beef Wellington reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Beef Wellington reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

SighingDutchman reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

SighingDutchman reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

James H reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

James H reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Caldercraft hasnt done anything to their Nelson Navy series since the beginning of the 2000s so I dont think we can expect anything from them at all. They have a great line-up of kits but IMHO they are in desperate need of updates but they simply gave up on product development. Just take the plans and manual for the Diana kit as an example. Without seeing others builds on this site, I would be completely lost. The Harpy look indeed very interesting. Taking a first glance at the plans it indeed looks very much as Speedy... but it is much bigger in size. I really need to start the rigging of my Speedy but been caught up in plastic models for a long time now.

-

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Yes, but in this case the price range goes from just buying separate blocks to the MS edition. If I understand correctly, there are also various of blocks available to other ships and they dont have it on the same page. My point was simply that Flirt seem to be listed abit differently than the other kits that seem to follow a certain style.

-

Sorry for being a Besserwisser, but I just noted an anomaly on your webpage when checking out the latest releases.... instead of "HMS Flirt - 1782" it has been listed as "Order 1:64 HMS Flirt". And it also has a odd price range since you could order block through it. Order 1:64 HMS Flirt – VANGUARD MODELS I know you are a perfectionist so I thought I would point it out 😛

-

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Interesting concept, she looks great! I think several of your old design deserve revisits. Just look how far you have taken this since the Diana days. When I compare my Snake to Speedy for example it looks so "bulky". Its nothing wrong with the old Snake but just imagine how it would look like/and build with your new design style and mtrl.

-

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Speaking of sales and perhaps this is company secrets... but just out of curiosity. You now start to have a very good lineup, what kits are doing well and is there any kit that has suprisingly low numbers for some reason? People have expressed lots of suggestions on what you should develop next but what is actually selling in practice?

-

There she is! I am glad you went with her, its such a weird ship. And she actually looks better than I imagined. Kind of the opposite to Speedy which has the most beautiful and proportionate lines. Perhaps you should sell it as a pair under the name "the beauty and the beast"? I think it will sell just because it stands out to basically everything else on the market.

-

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

The content of the kit is clearly explained at the website so that customer hasnt read what he is buying.... However, I think he just had gotten the wrong idea what Vanguard is all about. Shipmodelling has for decades been very traditional. Plywood, walnut and cast metal that many times looks quite bad. Even though a metal barrel might feel more genuine.. its not like you are going to fire them. As I understand, Vanguard is about re-inventing shipmodelling, using new materials and solutions in order to make models more accurate and also more easy to build where most companies just give you instructions how to carve out things from rectangular wooden blocks. I cant say I like all of your soilutions. But I definitely enjoy seeing the constant new designs. And when it is time to buy a new kit, I cant really see me going for something else than a Vanguard kit again.

-

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Vane reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Vane reacted to a post in a topic:

HMS Indefatigable 1794 by Kevin - Vanguard Models - 1:64 - Feb 2023

Vane reacted to a post in a topic:

HMS Indefatigable 1794 by Kevin - Vanguard Models - 1:64 - Feb 2023

-

The first kit people buy is usually something they find to "look good" on the shelf. However, the more they build the more they start to look for doing something different. From a general selling point of view, I think you will benefit from having a variarity of Royal Navy kits to offer your customers. And so far I think you have managed that quite well! And it is always exciting to see what comes next.

-

Just a question on the upcoming rigging. Have the conversion to "razee" affected the rigging and masts in some way? Or can we expect everything to basically look the same as on HMS Agememnon?

- 473 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

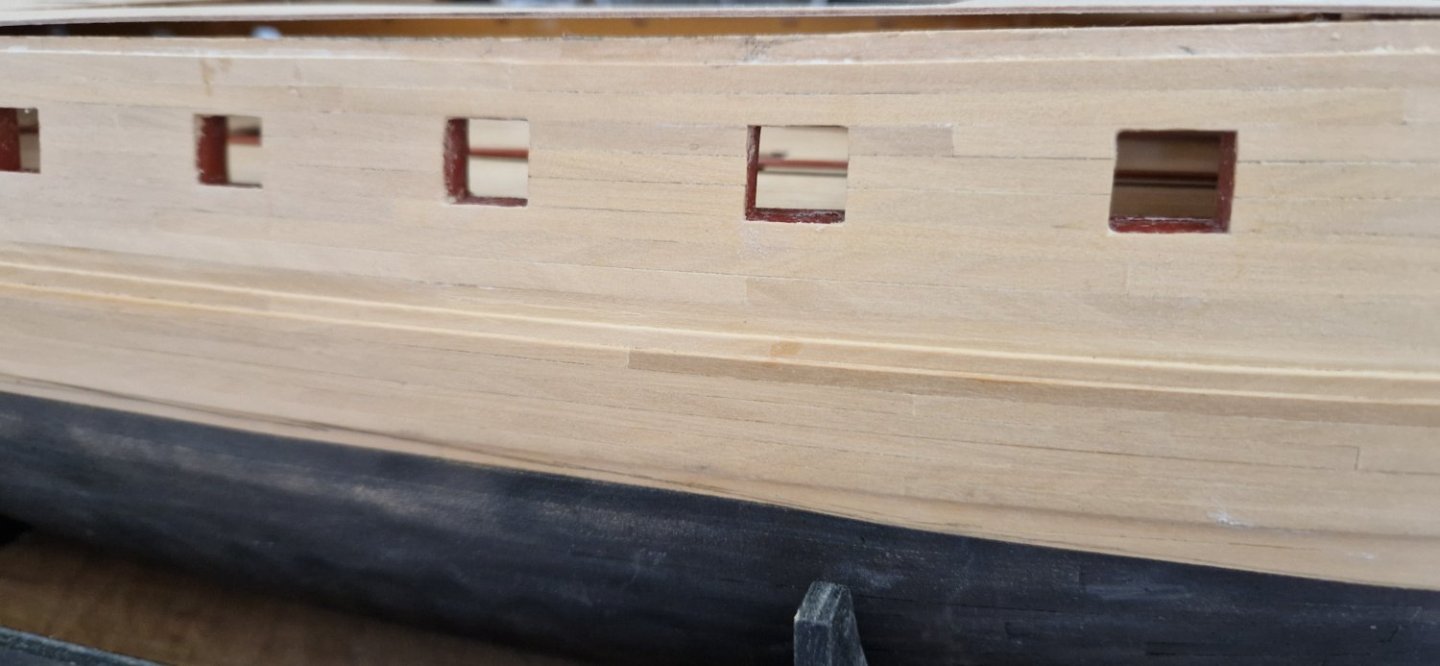

Some progress on my Diana. 2nd planking almost done on both sides. Did some small mistakes but overall happy how it turned out. Gunports are not perfect. Difficult to get them right when everything needs to be scratchbuilt. Chris has definitely improved his solutions in the kit design since he did this like 30 years ago when everything is up to the builder. Cant wait to do another hull with MDF and build it like Lego 🙂 . I cut the upper deck in 3 parts. I think it will require too much tweeking to get it in place in one piece. I am not yet sure how if I am doing the quarterdeck with walls or open rails which looks more beautiful but requires some scratchbuilding. As I said before, progress is slow due to numerous of parallell projects. In summary: Hms Victory: rigging started Hms Snake: yards under construction Hms Speedy: rigging to begin Hmbv Granado: deck details and guns ...and various plastic kits in different stages.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.