-

Posts

618 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Vane

-

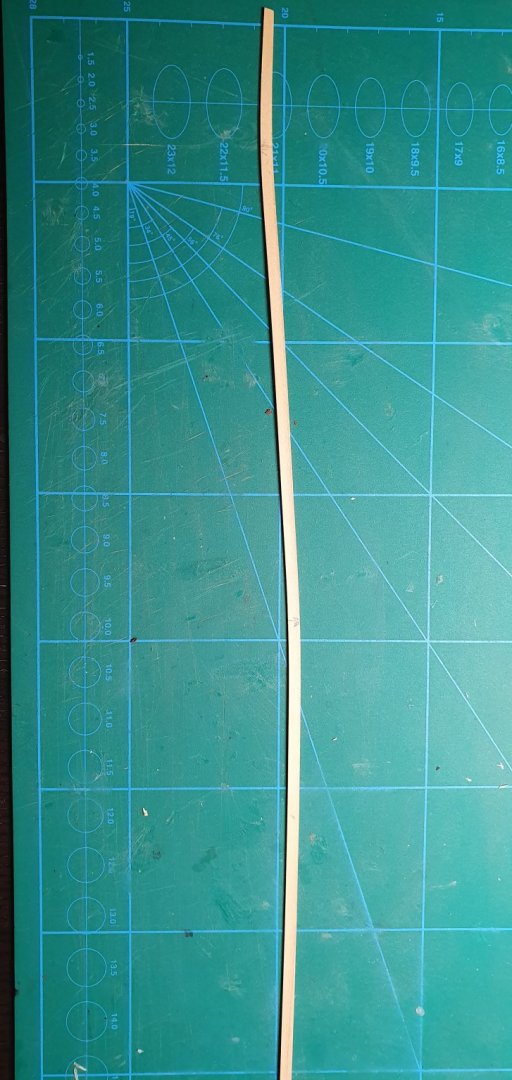

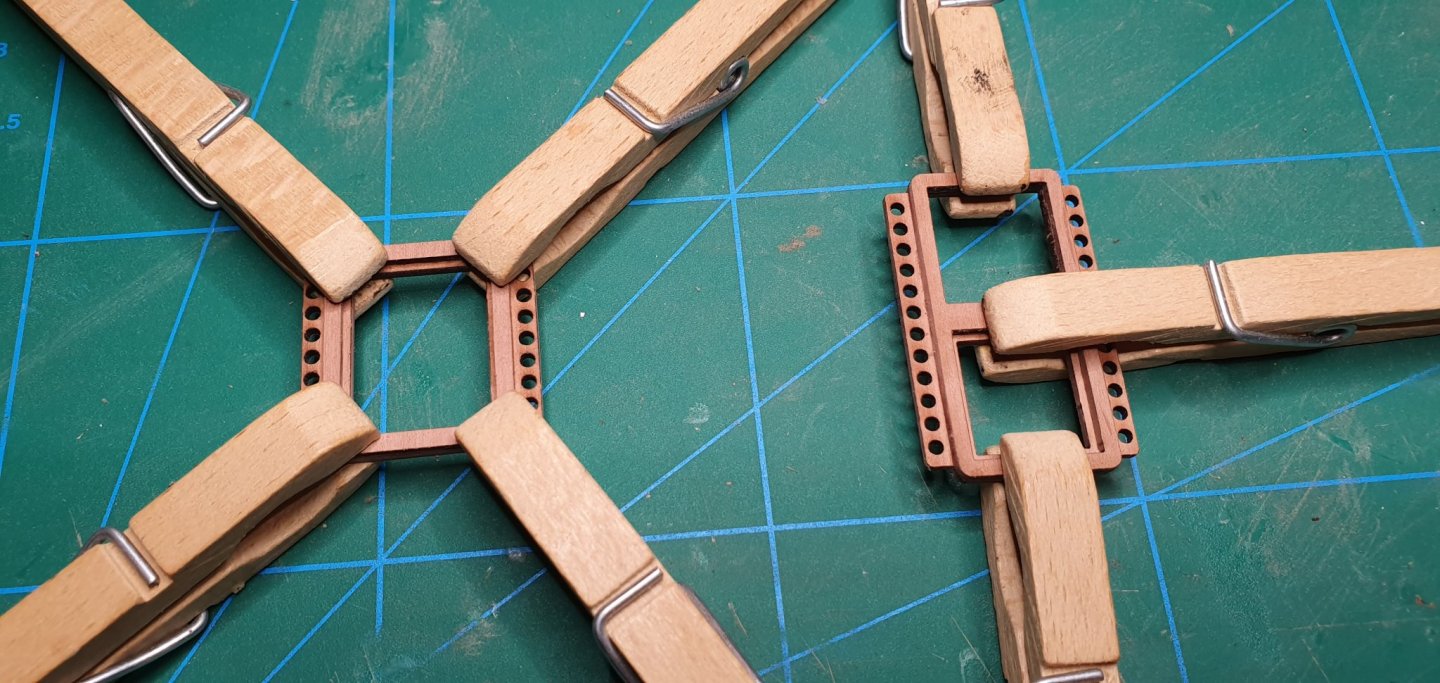

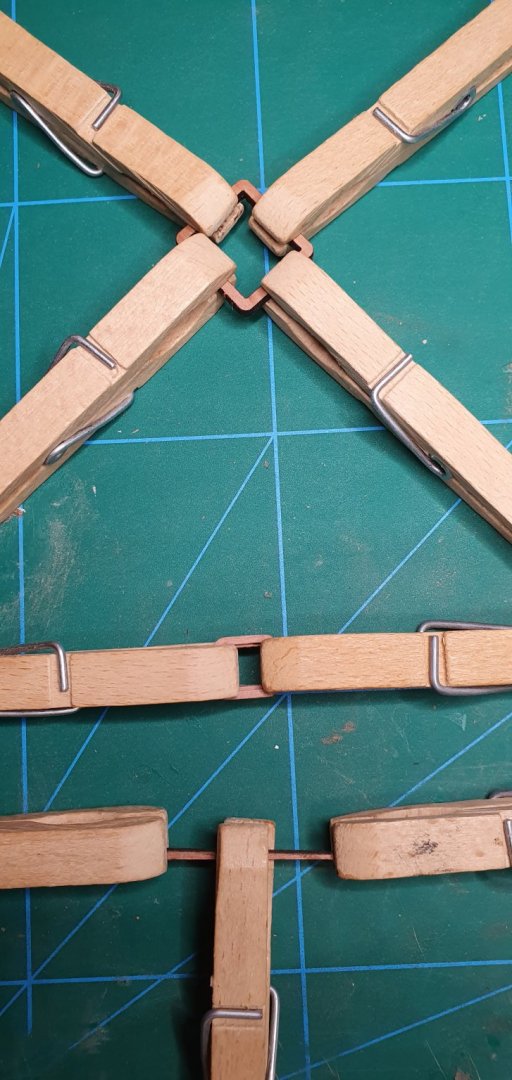

When i did this the first time I used boiling water, PVA and pins. That is ok if you will paint the hull completely and can use woodfiller afterwards. Nowadays, especially on models when the wood will be visable, I have upgraded my technique and go with the "Chuck method". Instead of bending and pinning down the plank, I spend much more time on preparations. This involves two things: i prebend the plank in the "wrong direction" using hot air and clamps. I also spend some time on sanding to make sure it will lie flat against the previous plank. The final result is an S-shaped plank.

-

This is optional according to the manual. But I decided to attach the keel elements before starting the 2nd planking simply because its kind of a slippery hull when everything is sanded smooth. With the keel my fingers gets something to grab when holding the ship. We will see if it was a good decision i guess...

-

The problem with fabrics is that it wrinkles and much more difficult to get right than for example paper or just a painted wall. But there are some fabrics that can work if it hangs correctly and dont take too much attension. Looking forward to see more photos of ur excellent ship!

-

I simply love seeing photos with numerous ships in the same scale. Your "Diana" looks amazing. Cant wait to start building mine but have too many ships in the shipyard at the moment. My other hobby besides shipbuilding is actually photography. Two simple recommendations to make them better. Place the boats daytime near a large Window so you get more light. The Main problem in Most photos in this forum is just too little light. And also fabrics dont really make a good background. Better to use a simple wall instead with a neutral colour.

-

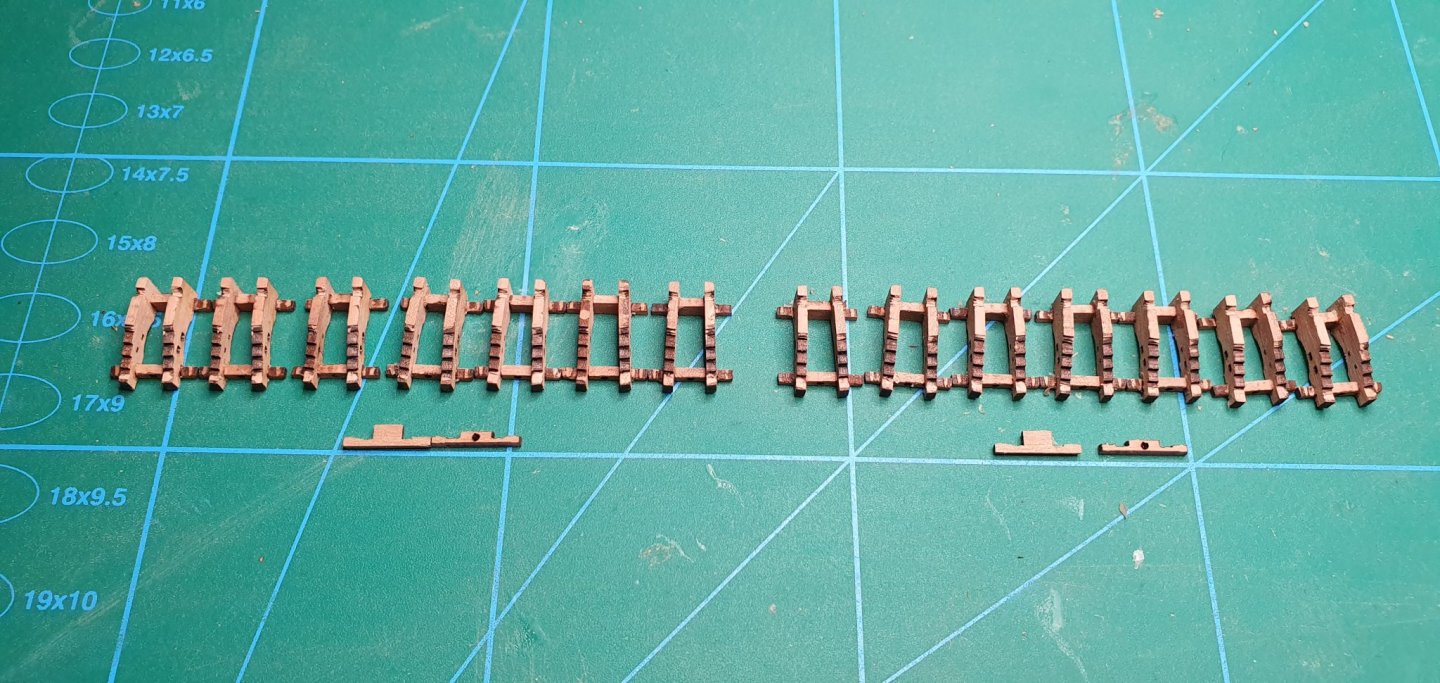

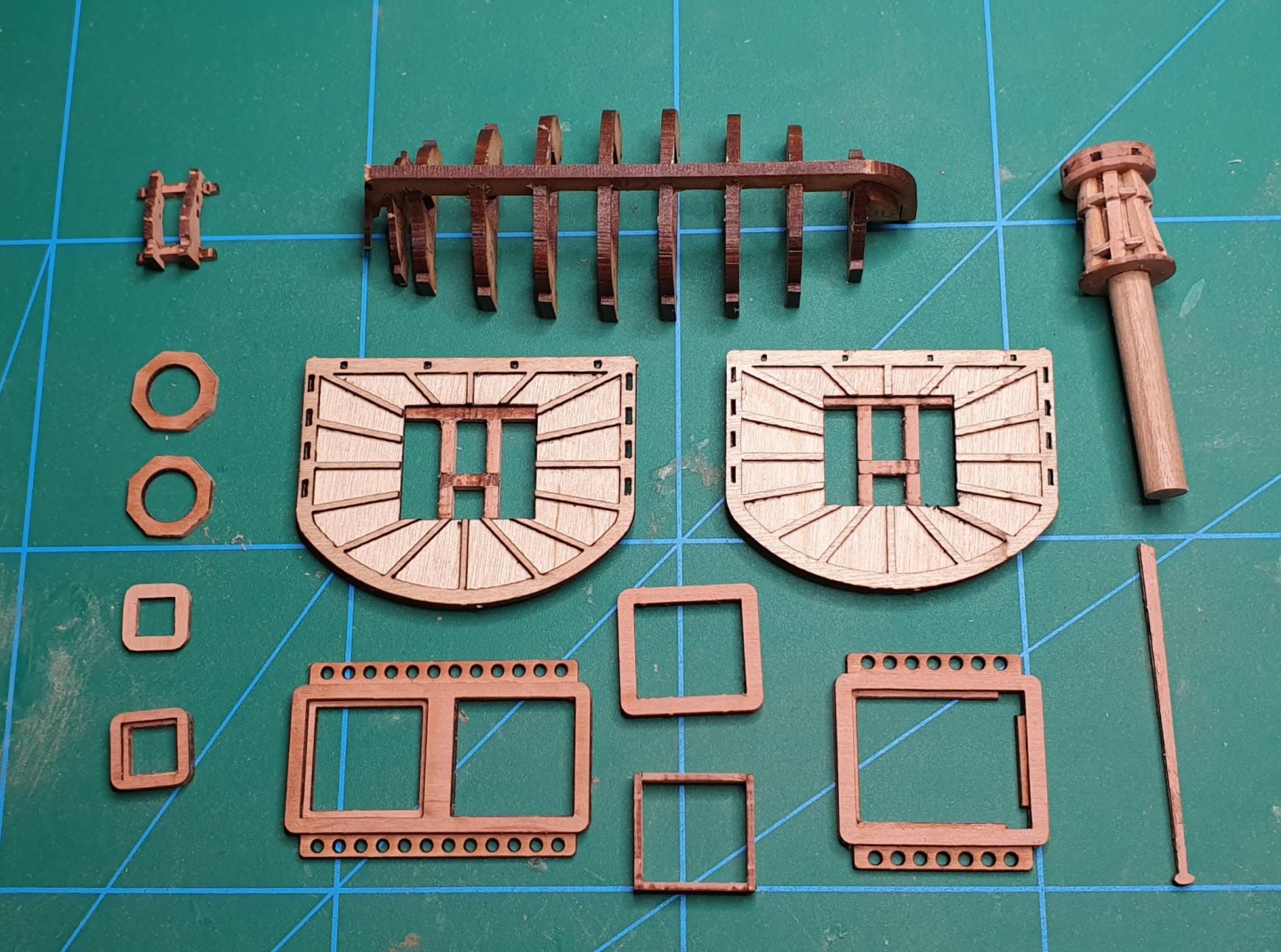

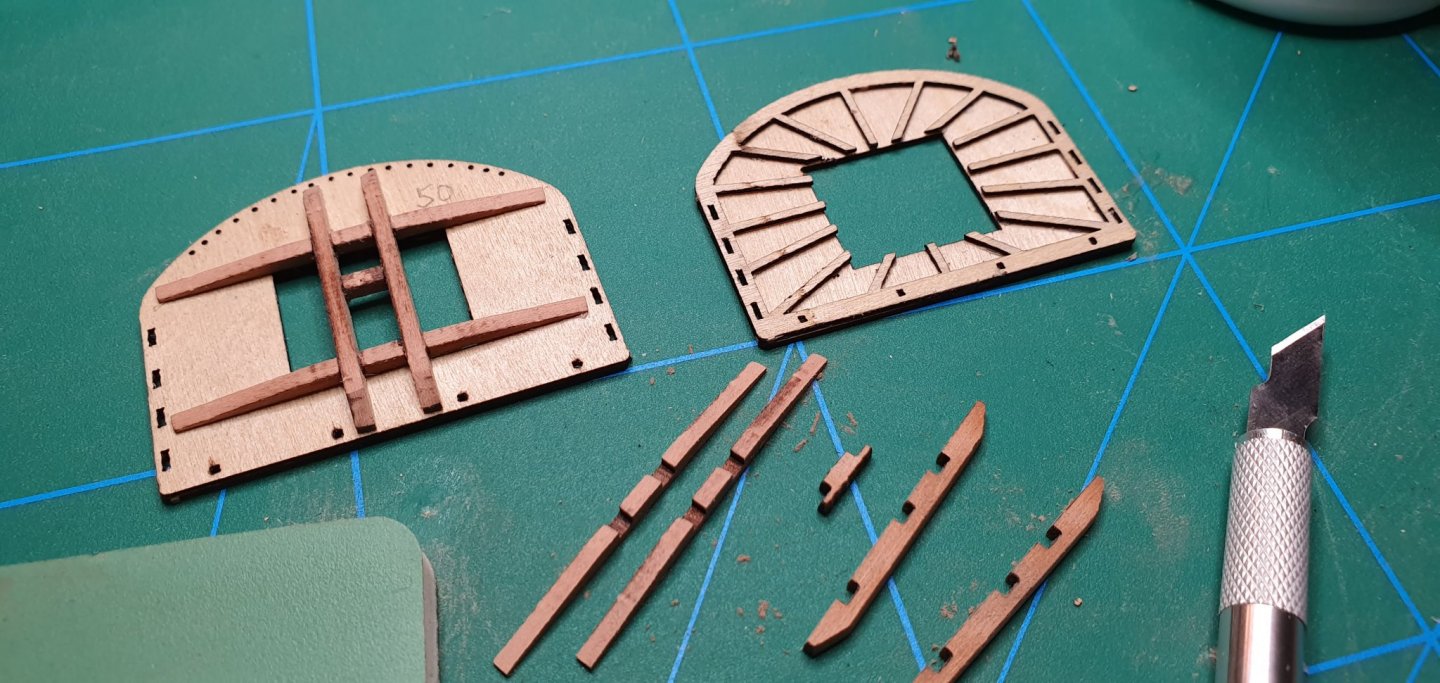

Well, they turned out ok and the proportions looks great. Just need to be very careful here. The MDF design is very different from all other kits I come across. It would be interesting to try it out for a much larger ship. The skeleton of your 1/64 Victory looks really impressive. I guess you will have that design for your upcoming Bristol as well?

-

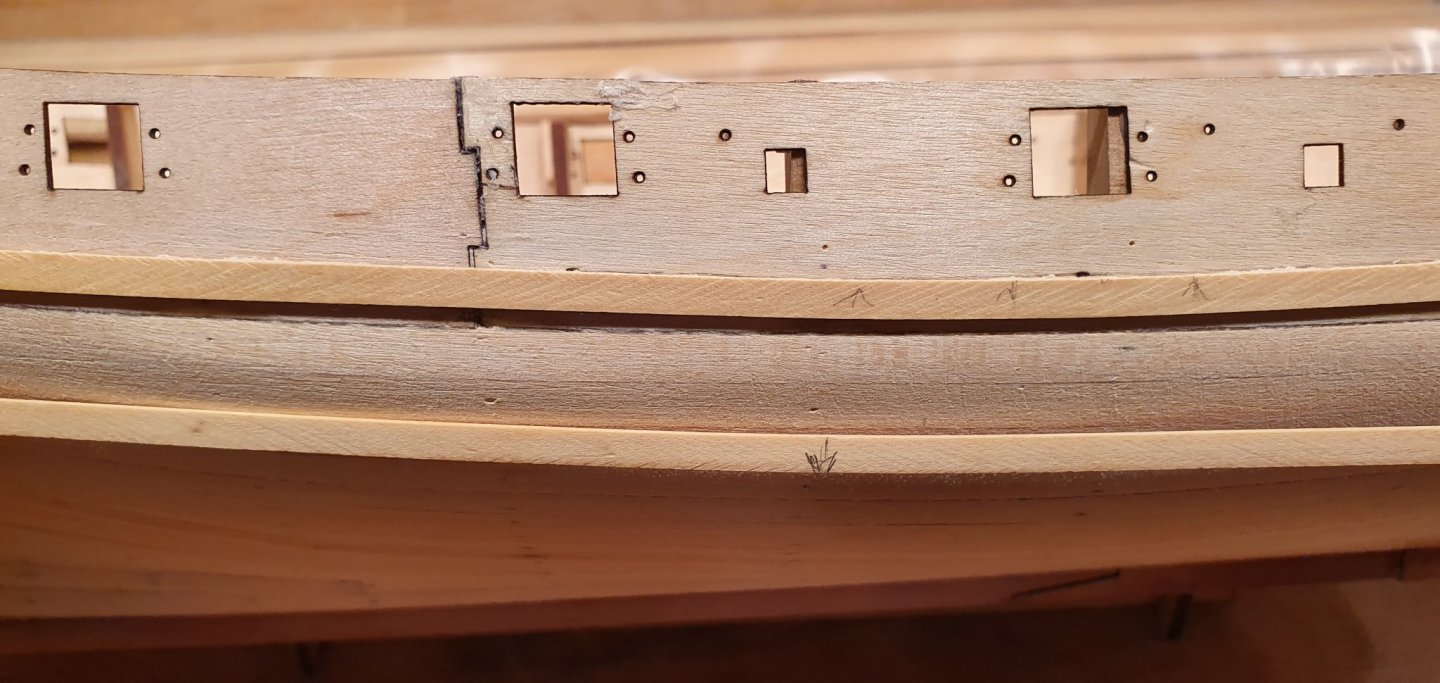

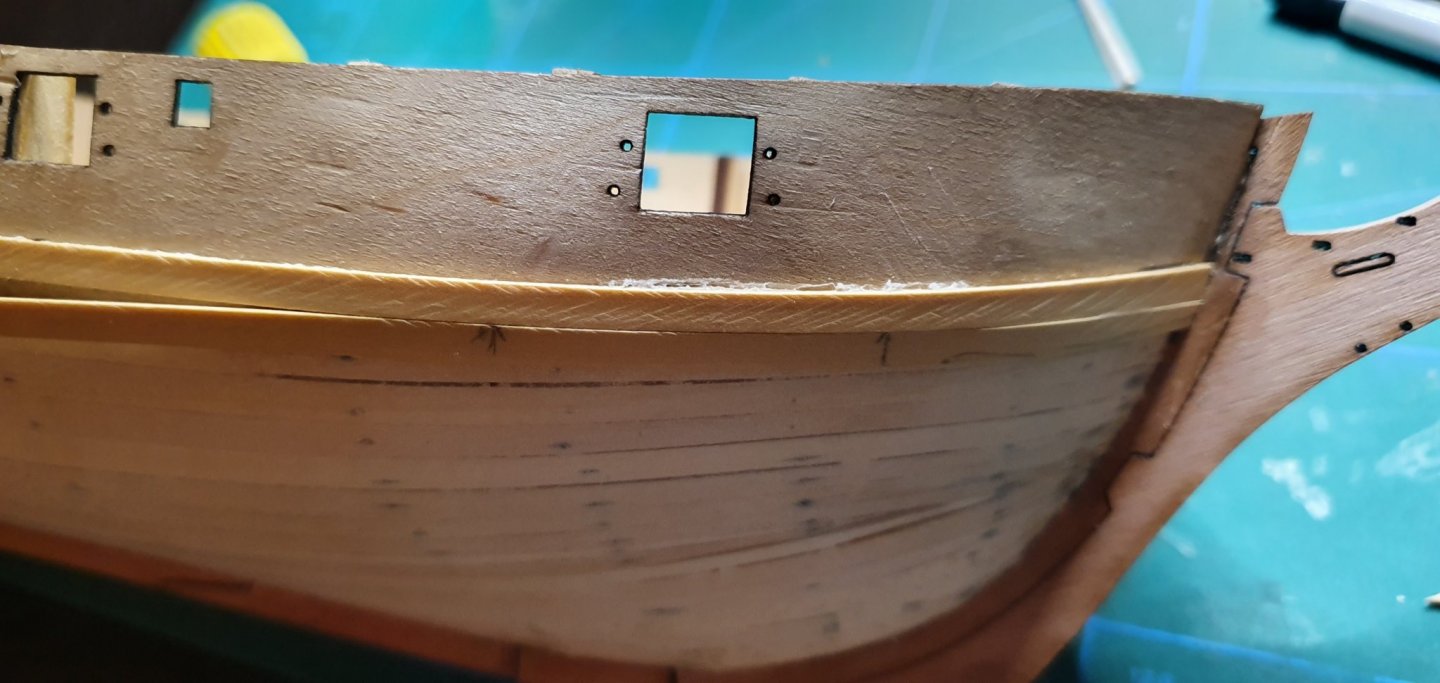

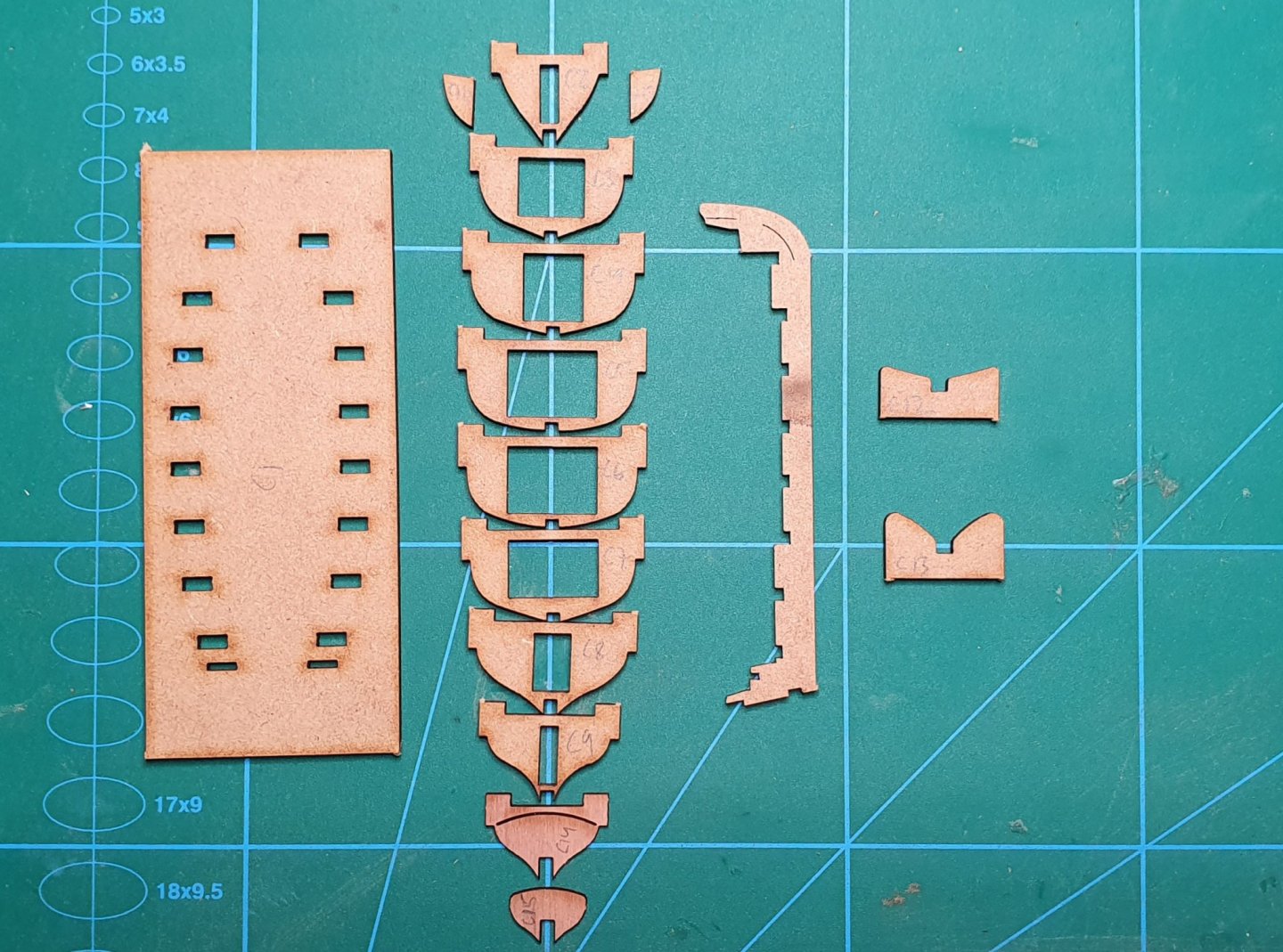

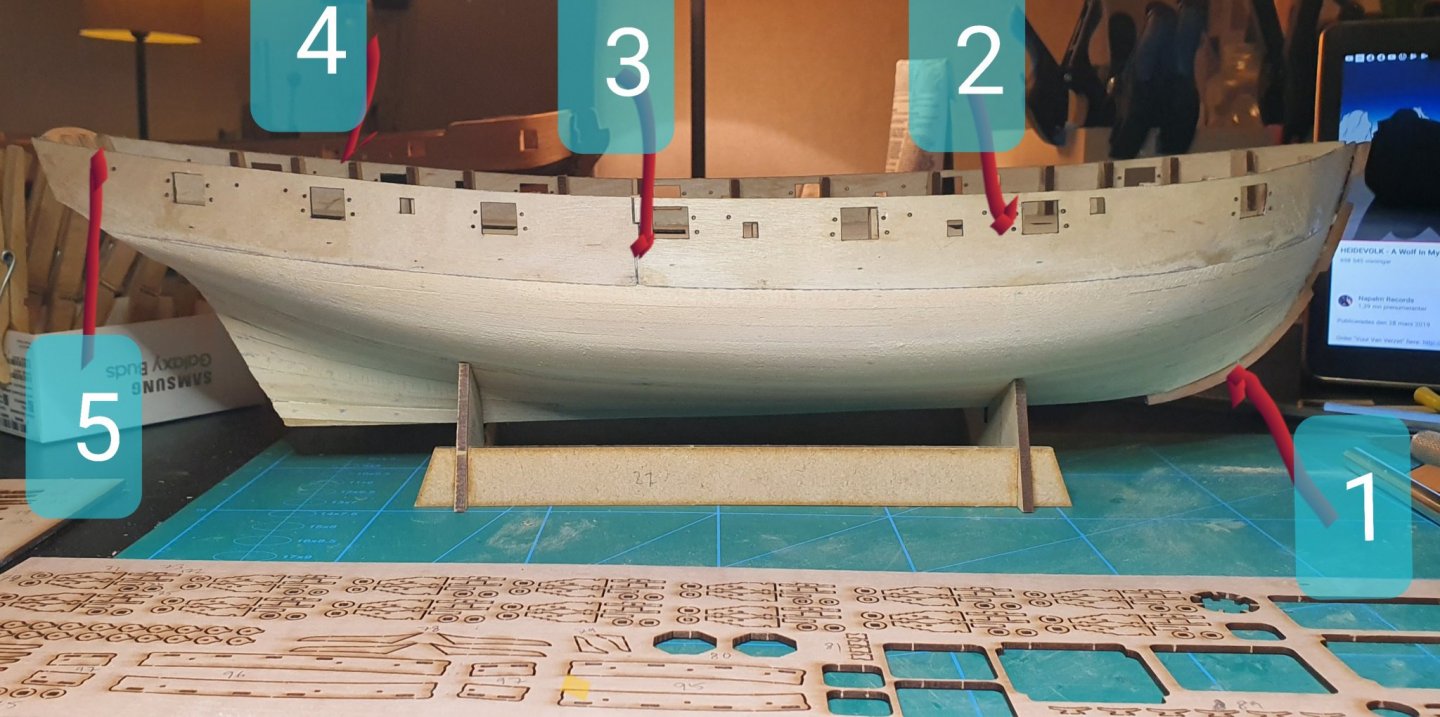

First planking done and I have just had the kit abit more than a week. What I like about Speedy is that Chris have made many new design solutions that really make it easier and faster to build. A few observations so far: 1) Pre-made rabbit to support the first planking. 2) Laser cut holes from "the wrong side" so you dont need to measure 3) The precut walls comes in 2 pieces 4) MDF skeleton with many very close bulkheads 5) Only identified weakness so far are these 4 very fragile pieces that easily break during assembly. The would perhaps be made in a different mtrl than MDF? Now its time to start with the 2nd planking in boxwood. Here he has also clear markings on where the first board should be placed so nothing to measure... 🙂

-

I am very grateful for this log since its a great inspiration for my own Granado build which are quite behind. I have finished my hull and managed to clean up all gunports. Next is to start with the big guns. I have done mine in Tanganyika so it will be interesting to see the difference in style later.

- 421 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

-

Yes its a very different style. We will see how the Boxwood turnes out on my Speedy. But boxwood is much different to work with. The Tanganyika is abit soft and splinters. I am definitely happy i didnt stay with the supplied walnut.

- 101 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

-

I finally got my hands on some Boxwood. I have already done the 2nd planking in Tanganyika but here you can see the difference in colour and grain.

- 101 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.