-

Posts

68 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Seamanpeter

-

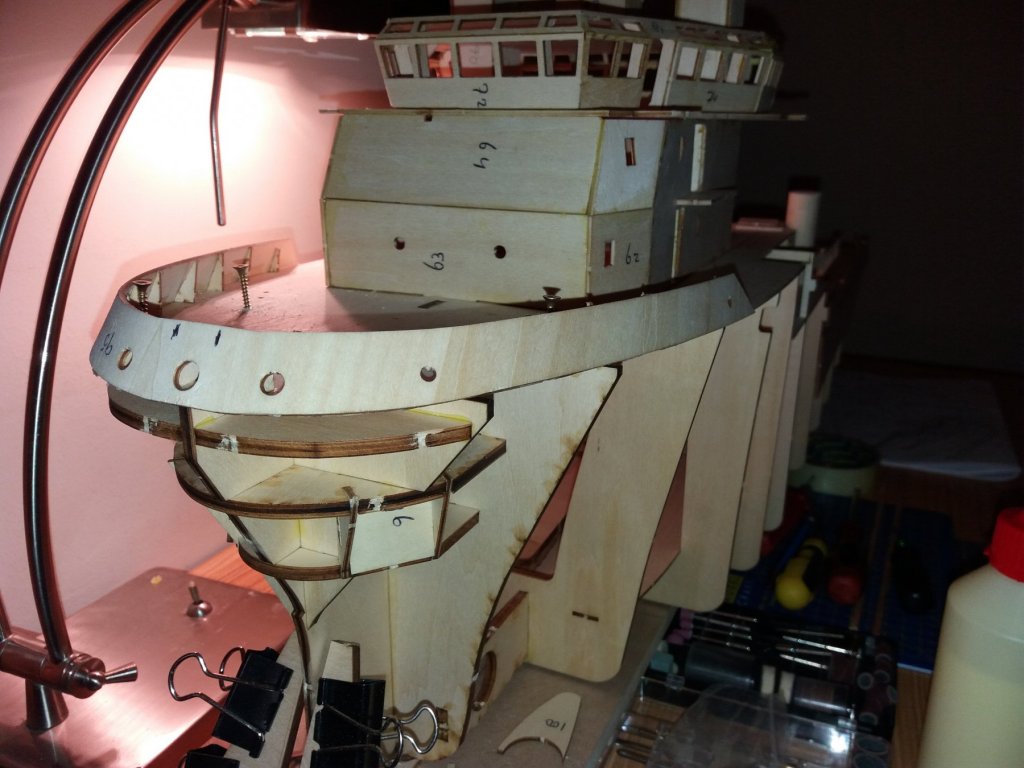

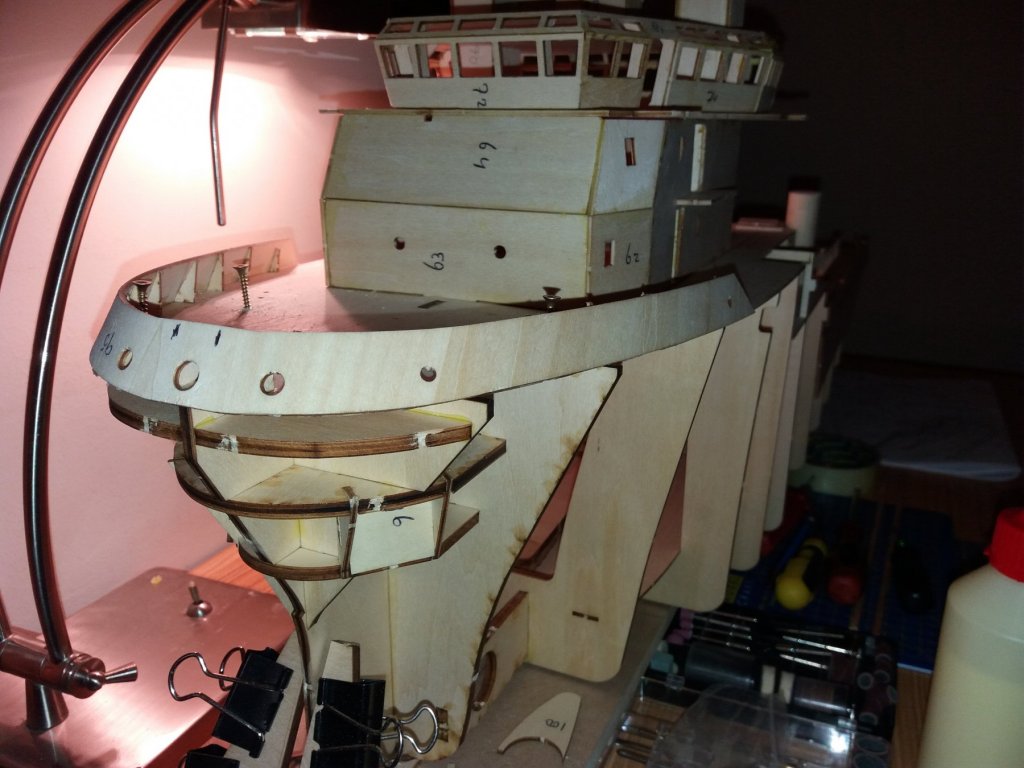

Just finished up the works to the helideck, now have to make the "catch net" around it. Also need to make it nice, smooth etc so it looks for the eye more realistic! Have a great weekend you all.

- 35 replies

-

- fairmount alpine

- billing boats

-

(and 1 more)

Tagged with:

-

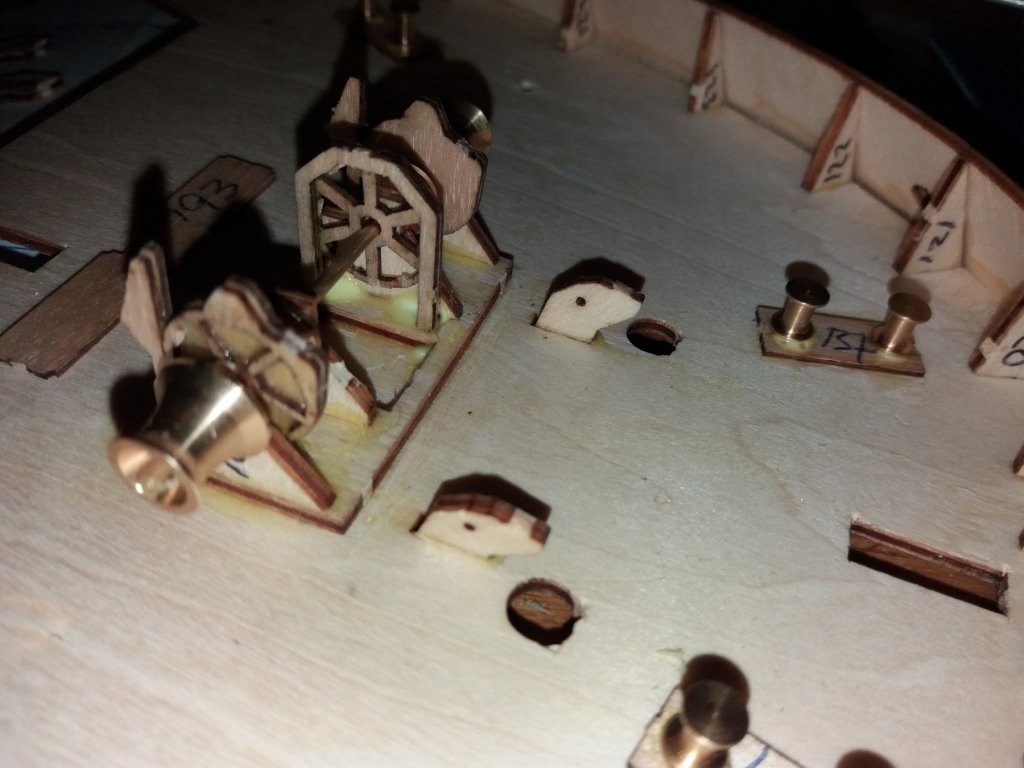

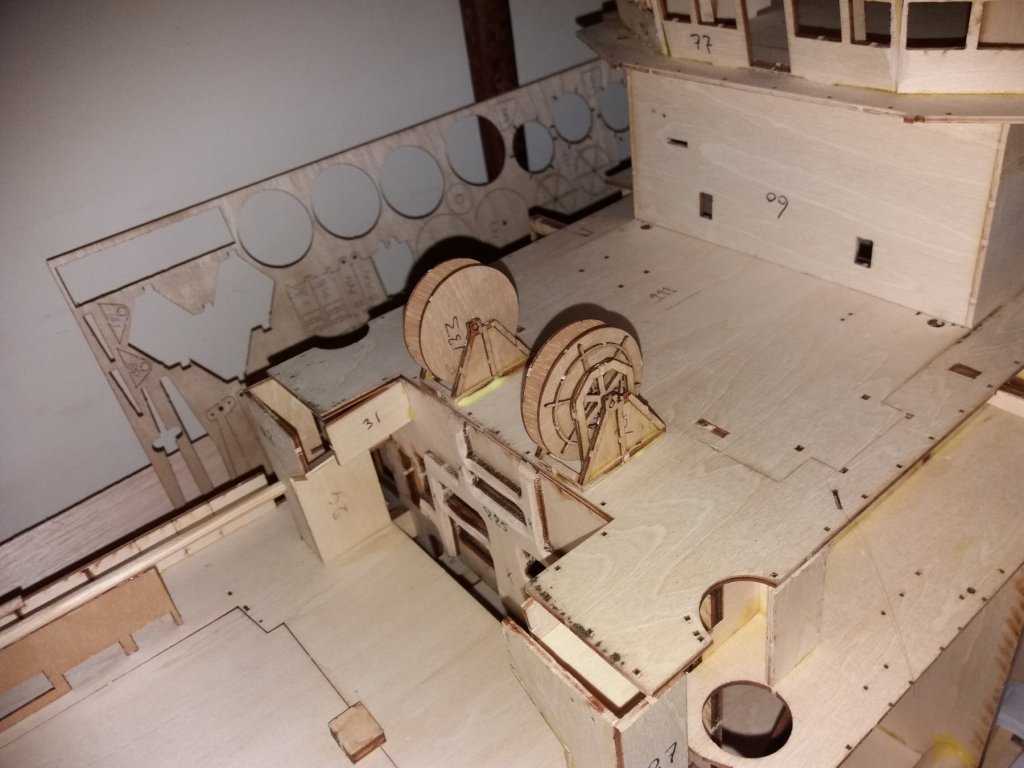

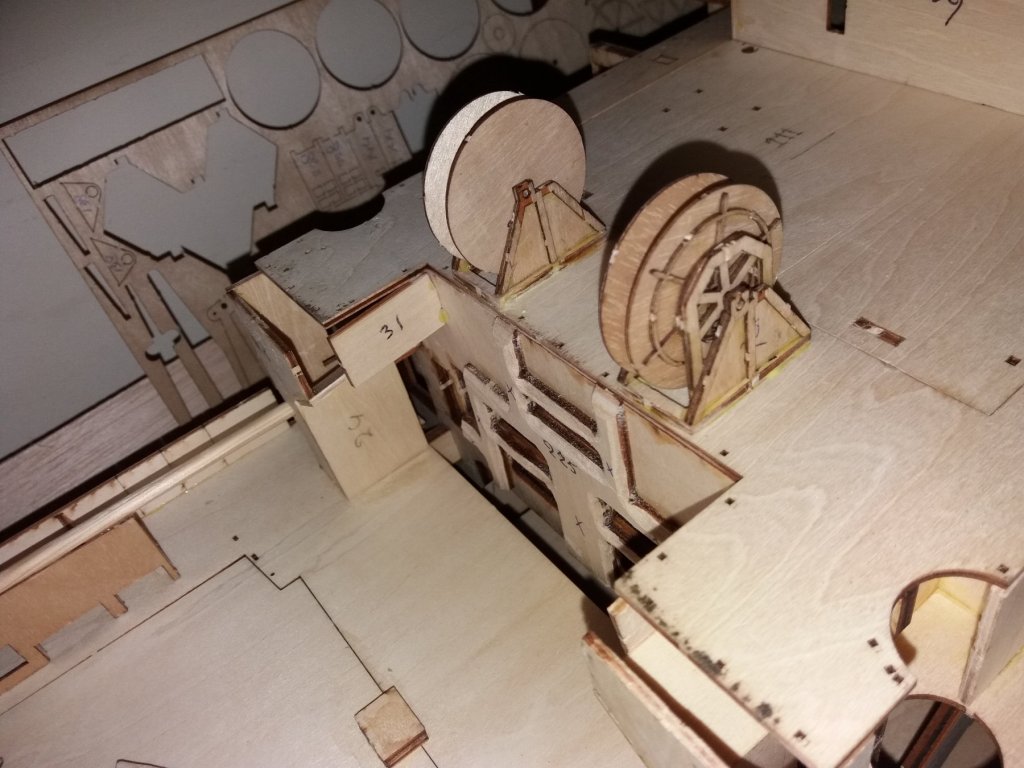

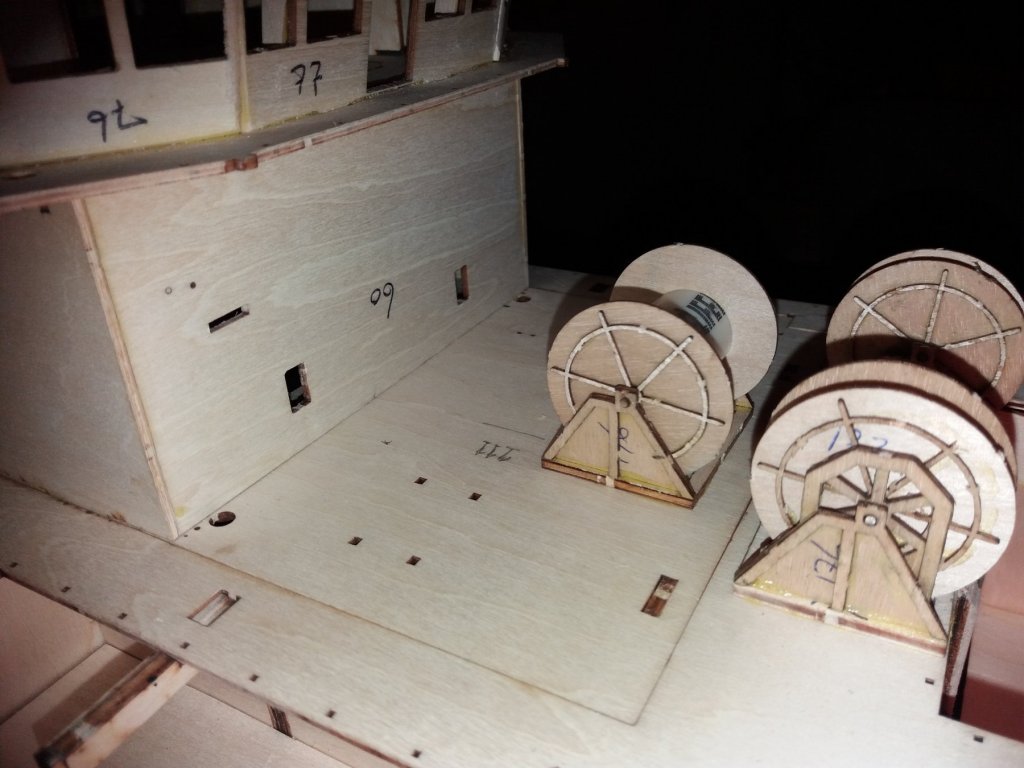

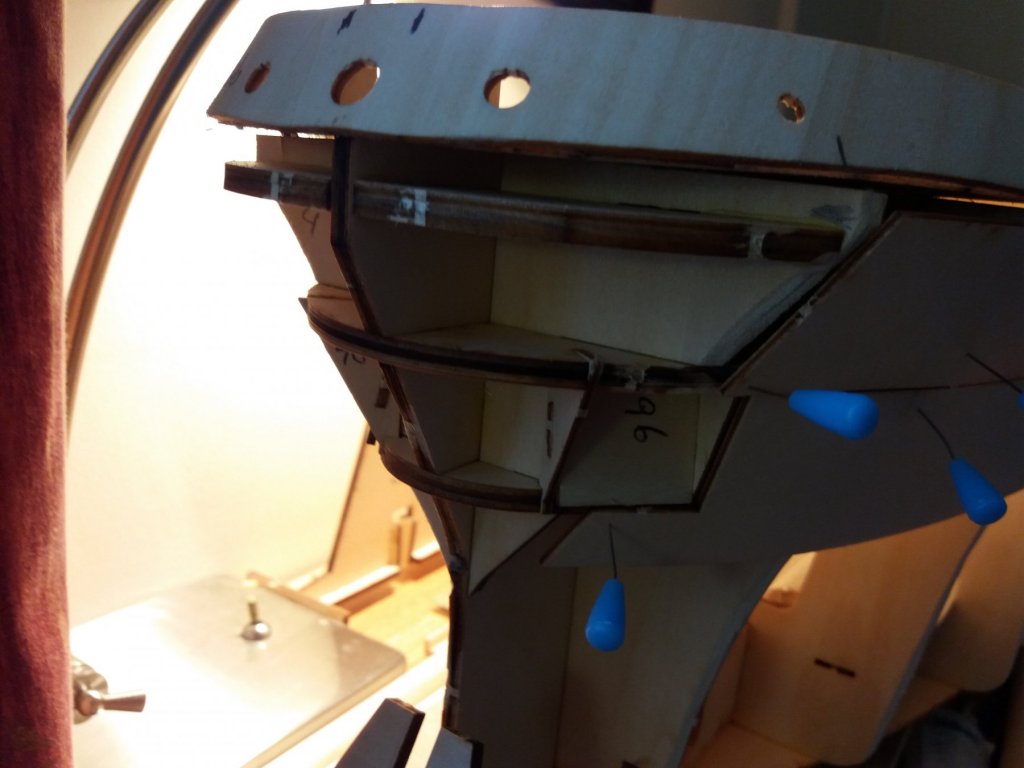

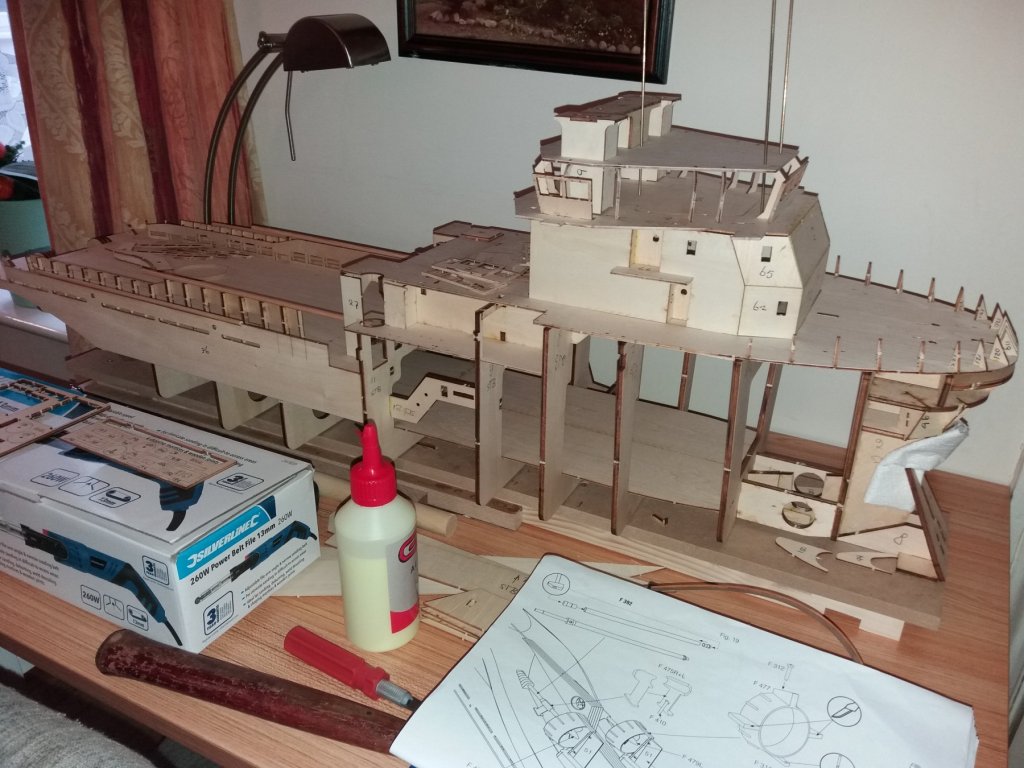

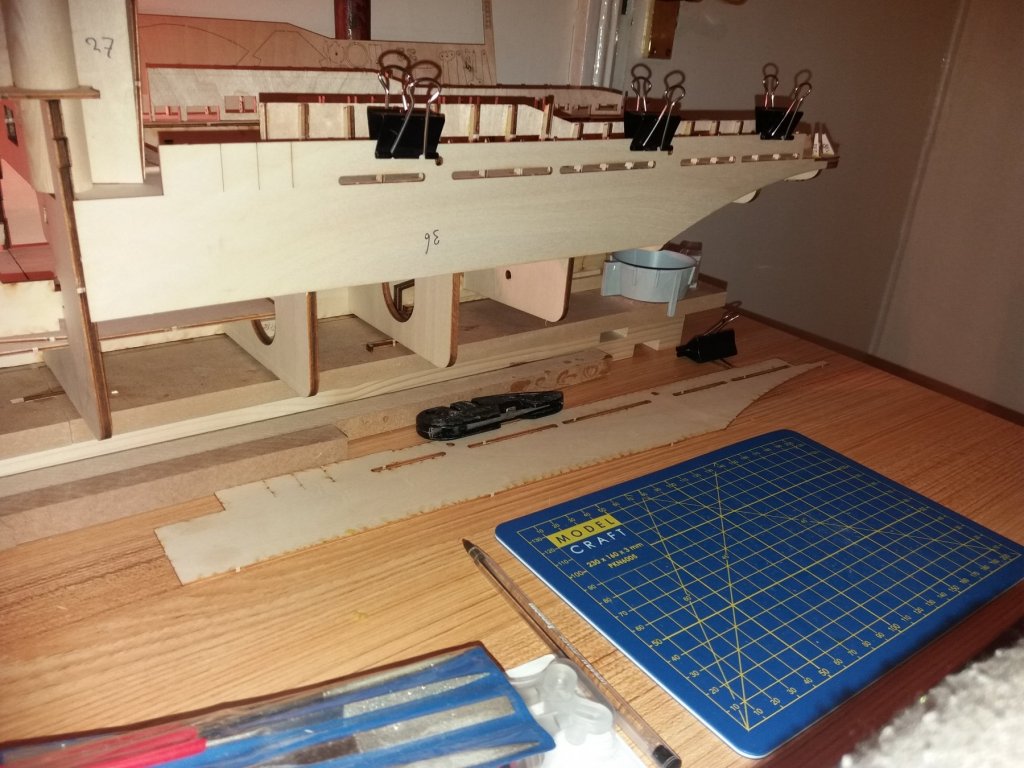

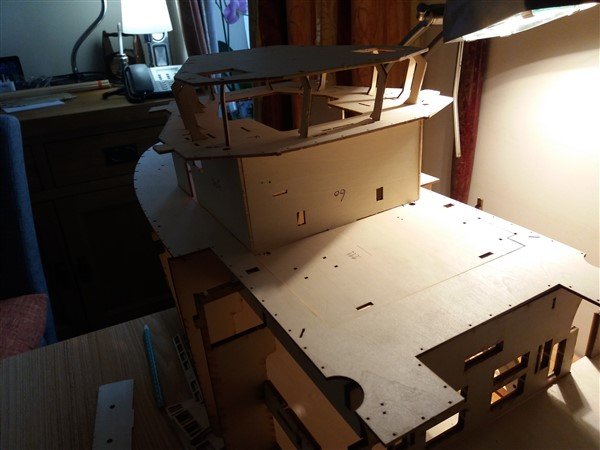

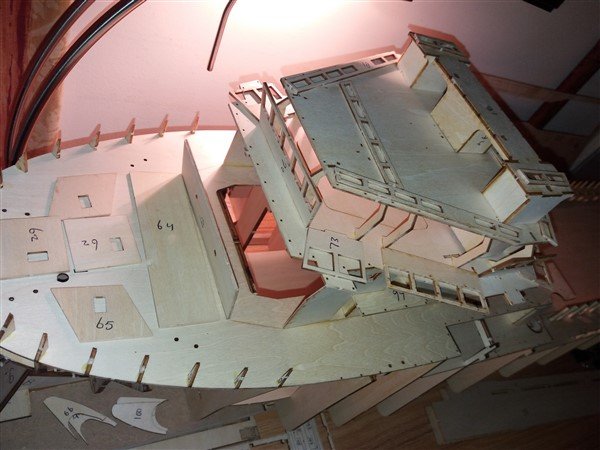

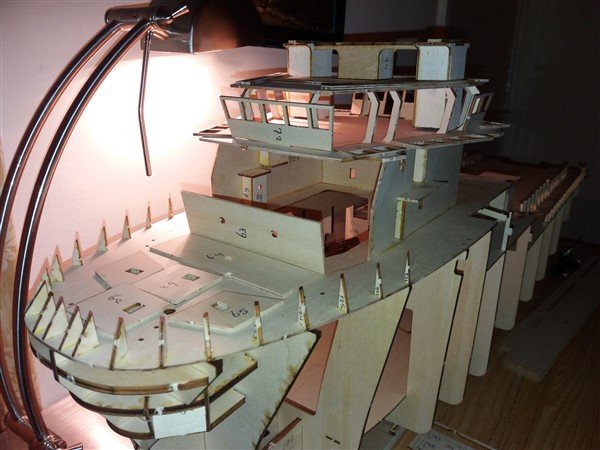

Not to think that I stopped here, nope just goes a bit slower then I thought as needs to alter the building. I'm the first one that is building this tug with Azimuth's without stern truster and also NO rudders. The Azimuth's can turn 360 degrees so no need for them, also the stern truster is closed and will not be used. Now here comes the tricky part as I have to do that a bit different then the "NORMAL" propulsion and need some more supports to have the strength into the building. Also due to the Azimuth's I altered the keel and raised her 12 mm to have more space underneath her and there where the Azimuth's are coming. I made side (bottom) supports on both sides, also in the middle from the last frame until the midships frame a support. Personally, Billund Ships are ok but if you alter the propulsion I think that this building is to weak for that and made those supports. You can see on the pictures below that I struggle a bit with the stern top side small plates to have this in 3 corners bent and also the aft outside corner. Managed it with help of hot water and steam to pre-bent them and stick it to the building, leave them for a day before finally glue them in place. Presently the aft part is 90 % finished but still in a fashion that I can take of the top deck aft to enable me afterwards bringing in on the bottom the epoxy making her watertight, secondly in the event that I have to alter the stern in way of the Azimuth on top I can more easy alter the deck. So far so good and now will start further with front part, doing a little more to the frames to guide the shell plates more and then the bow itself to be bent and glue to the frames with the anchor pockets. Planning is to have the bow trust in before finalise the bow but could be that I change that plan depends on the status of the shell plates who have to be in place and glued. I made some plates under the building there where the Azimuth's are coming to have a good strong support. Also I still use the slip-way as due to the raising of the keel I managed to have her on the "BLOCKS" As I don't need anymore the original propulsion + rudders, I did give it away to a friend in Holland that is presently making the same building but 10 years old and rebuilt her and was in need of those parts. Wish me luck to start with the bow and shell plates! Been some time now but slowly we are coming there. Had some other work to do at home so the building was second in line so to speak.. Anyway today we have the 12 April and done with the helideck and her supports for that, thought that material I ordered did arrive but apparently they are still on their way to me. Yes I did make a helideck, this days it is a MUST to have one if your vessel want to keep up with competitors so looked around to find some ideas and the result is not to bad if I may say so. Also on the forward part bow all fittings done and the winches behind the accommodation as well the 2 x boilers ER put in place , the MOB fit and also the second fast rescue boat. I ordered 2 x cranes to be mounted on the aft part as where the pillars are presently as well an Atlas crane on the aft deck below. The 2 x tucker winches as all supports aft deck done and in place. As you may have noticed the supports ps and stb side are done below bottom are glue inside so we have more strength into the vessel itself. As still in discussion with Cornwall for the Azimuth delivery we came to an option to have an el. motor for the 360 degrees continue running and no stop and go back, did that as with real Schottel you can do that so why not in a model? You only have to use an el motor that runs with a slow movement (or gearbox, reduction) in order to have the steering movements by means of belt and the el motor (vertical mounted) to be done. Means having inside 4 x belts, 2 for the propulsion and 2 x for the independent steering. So in the end there will be not so much el motors or other parts like an original and have due to that more space underneath the deck. Having said that the height under decks iwo the Azimuth was only 24 mm so not much space left for the 2 wheels mounted on top of the Azimuth where as the belts are running from to the el motors for the previous named movements. Still the weather here in the UK is not so good to work outside, still have zero degrees at night so have to wait for the shell/hull plates and bow until this goes better. Anyway, did work enough in the mean time and still can manage to take off all parts such as complete aft part and bridge / accommodation as well to make it more easy for painting and putting epoxy afterwards. Also it is more practical when I'm building in the lights and other parts as under deck (midships) I want to have a working towing winch so made already a platform where as this is mounted later on. Enjoy the pics and if having questions willing to answer them, until then have a great one. As told before, the aft part was glued together as a section but still could be removed from the tug until such time I was finished works below deck I only had 24 mm under the deck plate but as found out after info I got from the maker this would be enough. Made all what was needed on the fore castle like anchor winch and bollards Looking good after have them done Also behing the superstructure where the spare drums are mounted done Was not an easy job but managed it. Still they all can turn too. Both spare drums mounted / glued to the superstructure deck aft Also the heavy big drum for the spare towing wire done and glued, can also turn too. All 3 drums together, now still need to turn around the plate 60 as not done until now. the 2 small tucker winches for the aft deck, turning too. Made a mast but not content with it so this will be changed afterwards Getting there but need much more. I also changed the no 60 plate from the superstructure. Boxes placed on ps deck Here I start to make a helideck for the tug not looking bad and need some more works now how to go there on the helideck! made the stair way to the helideck but is to complicated so will change afterwards Not to bad the direct uptake from monkey island to helideck Safety net to be made and also start with railings complete supports for the helideck other view supports helideck

- 35 replies

-

- fairmount alpine

- billing boats

-

(and 1 more)

Tagged with:

-

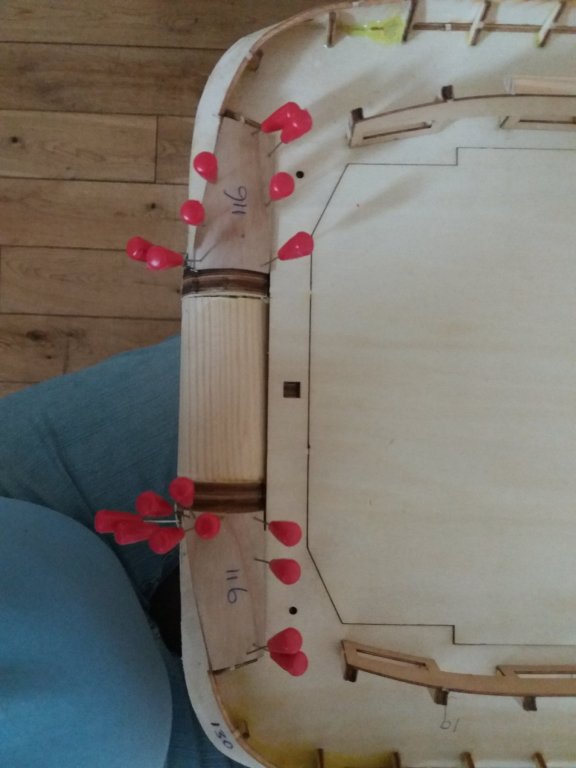

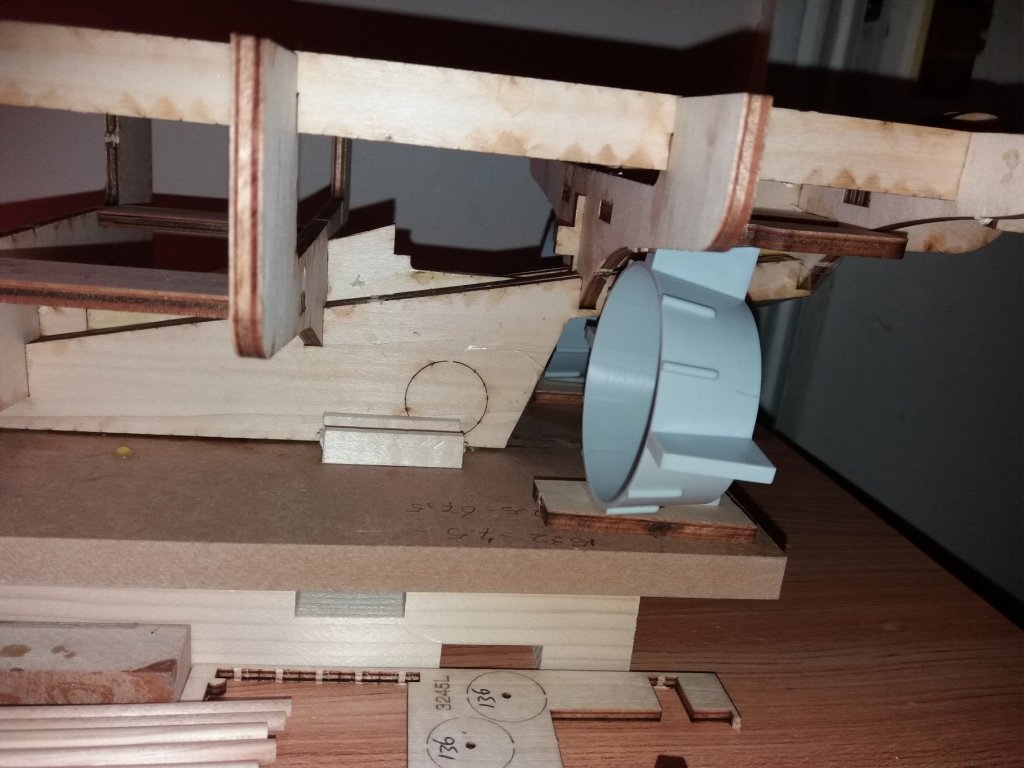

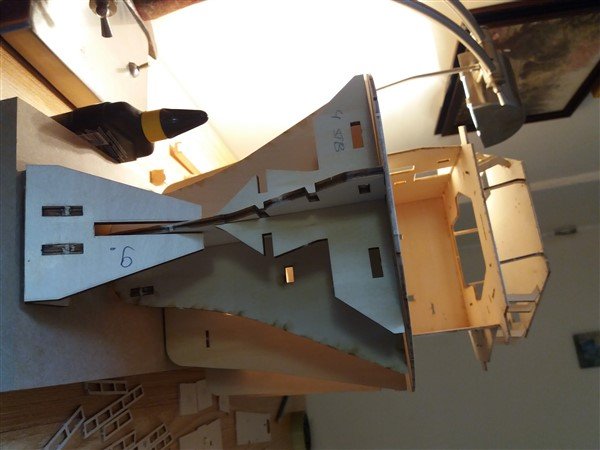

Not to think that I stopped here, nope just goes a bit slower then I thought as needs to alter the building. I'm the first one that is building this tug with Azimuth's without stern truster and also NO rudders. The Azimuth's can turn 360 degrees so no need for them, also the stern truster is closed and will not be used. Now here comes the tricky part as I have to do that a bit different then the "NORMAL" propulsion and need some more supports to have the strength into the building. Also due to the Azimuth's I altered the keel and raised her 12 mm to have more space underneath her and there where the Azimuth's are coming. I made side (bottom) supports on both sides, also in the middle from the last frame until the midships frame a support. Personally, Billund Ships are ok but if you alter the propulsion I think that this building is to weak for that and made those supports. You can see on the pictures below that I struggle a bit with the stern top side small plates to have this in 3 corners bent and also the aft outside corner. Managed it with help of hot water and steam to pre-bent them and stick it to the building, leave them for a day before finally glue them in place. Presently the aft part is 90 % finished but still in a fashion that I can take of the top deck aft to enable me afterwards bringing in on the bottom the epoxy making her watertight, secondly in the event that I have to alter the stern in way of the Azimuth on top I can more easy alter the deck. So far so good and now will start further with front part, doing a little more to the frames to guide the shell plates more and then the bow itself to be bent and glue to the frames with the anchor pockets. Planning is to have the bow trust in before finalise the bow but could be that I change that plan depends on the status of the shell plates who have to be in place and glued. I made some plates under the building there where the Azimuth's are coming to have a good strong support. Also I still use the slip-way as due to the raising of the keel I managed to have her on the "BLOCKS" As I don't need anymore the original propulsion + rudders, I did give it away to a friend in Holland that is presently making the same building but 10 years old and rebuilt her and was in need of those parts. Wish me luck to start with the bow and shell plates! Closing up the holes for the tail shaft penetration as not going to be used, also made iwo Schottels the ground plates and you see the keel I raised having more clearance under the tug for the Schottels Here you see the plates made for the Schottel penetration later as need more strength in the bottom another view of the fixed penetration plates for the Schottels Having built Billing boats in the past and noticed the weak points in their buildings making re-enforcement into the building as want more strength in the tug having a different propulsion. Made the strength of the tug in the bottom and top from stern to bow. starting the top of the aft deck Not looking to bad but need some sanding to be done to the top back side / stern the plates using hot water and afterwards model pins to have it all in place until dried after glue Looks a bit funny but no other way to support those small plates with bending etc stern roller temp mounted as want to alter this. prior fixed the penetration plates for the Schottels made some altering for the correct place of those penetration plates starting making the strength in the tug Secured the tug on the slip as it is 5 mm higher on the keel mounting the hull plate iwo the anchor pocket Have to shape the frames where the hull is touching to have the same angle It's coming there, most parts now in place forward view of the tug Nothing much to say about this then parts are slowly coming to be in position, next step will be the hull. those parts I did not need and give them away to a friend in the Netherlands that was making a restoration of same built and was in need of those parts.

- 35 replies

-

- fairmount alpine

- billing boats

-

(and 1 more)

Tagged with:

-

Congrats with this building / project!! Seen a lot in my life but this is an exception and the works / effort to built this one is one of a kind!!

-

Done a major progress until now. Finished the bridge, did the penetration for the towing wires making smooth and glued, supports for the cranes cut and on the bow deck did all the frames and the top "sheet" what was a bit difficult too. Tomorrow want to start with the aft part of the project and doing railing works on deck and on the stern the 2 bend plates next to the roller. It takes form to it and looks like a strong tug! starting to glue all on the bridge deck superstructure to be glued superstructure and other relevant issues there glued not easy the windows under 2 angles both funnels done inside the bridge the funnels afterwards all the furniture to be placed going to take shape with the superstructure already nearly done superstructure nearly all done glued also the bow nearly all glued going to look good with most parts already glued

- 35 replies

-

- fairmount alpine

- billing boats

-

(and 1 more)

Tagged with:

-

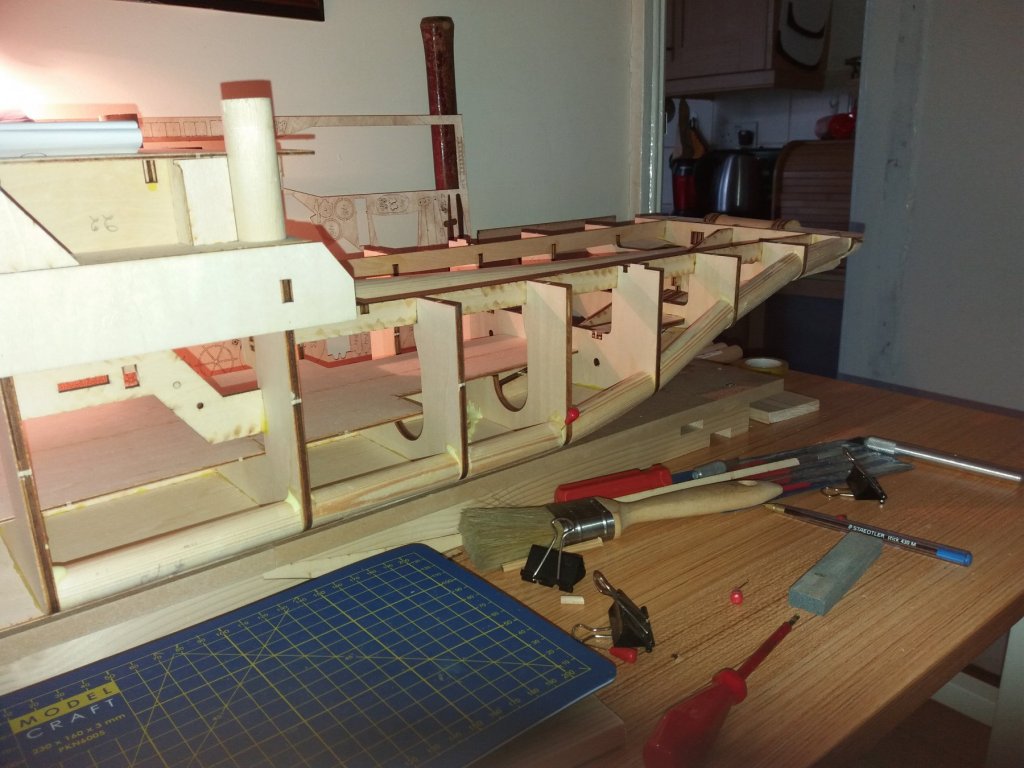

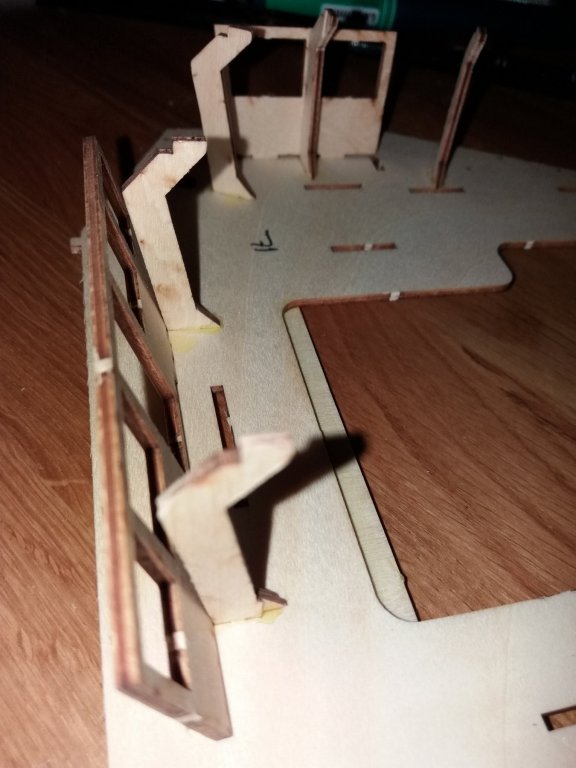

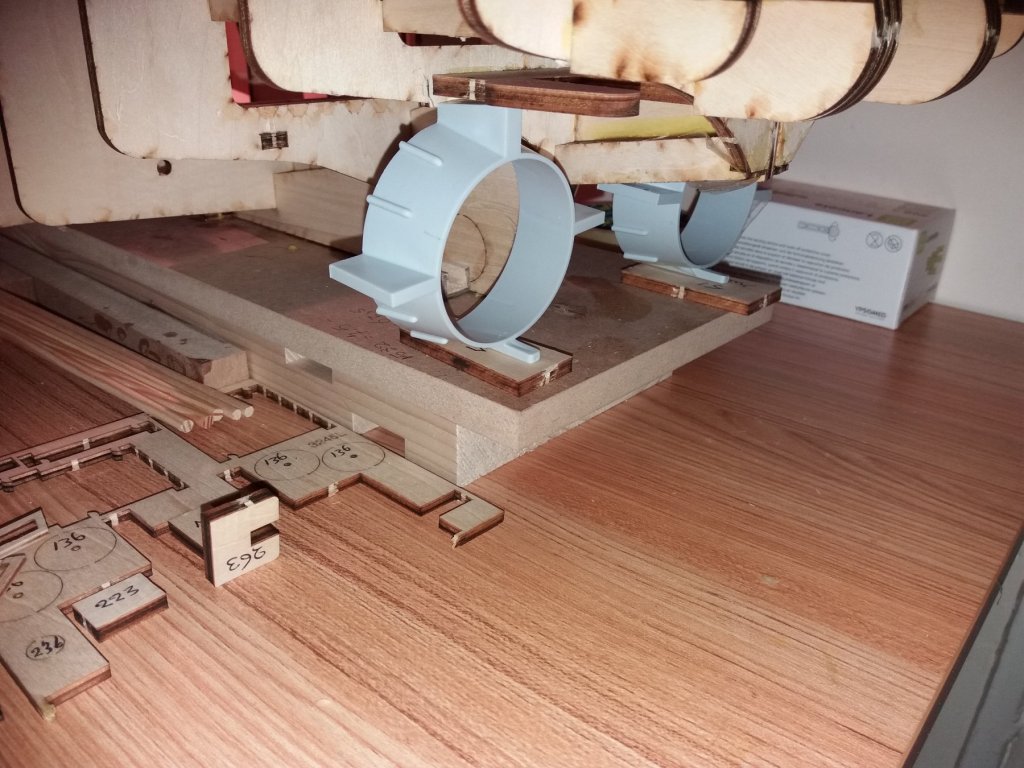

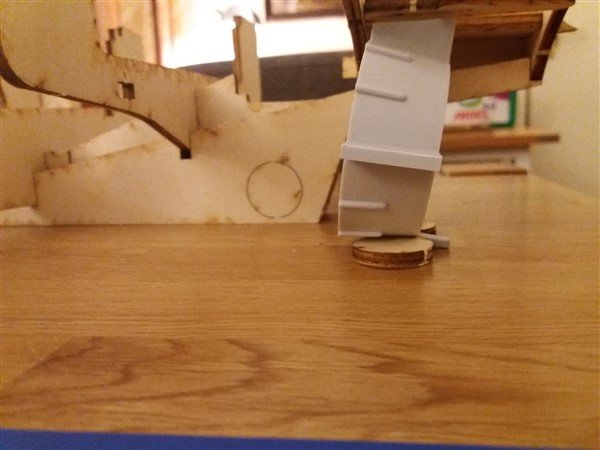

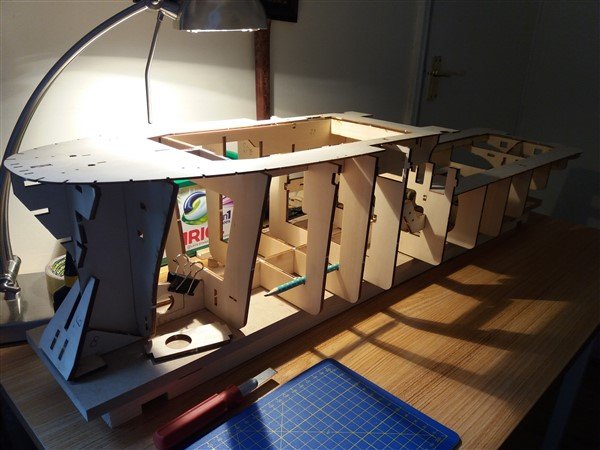

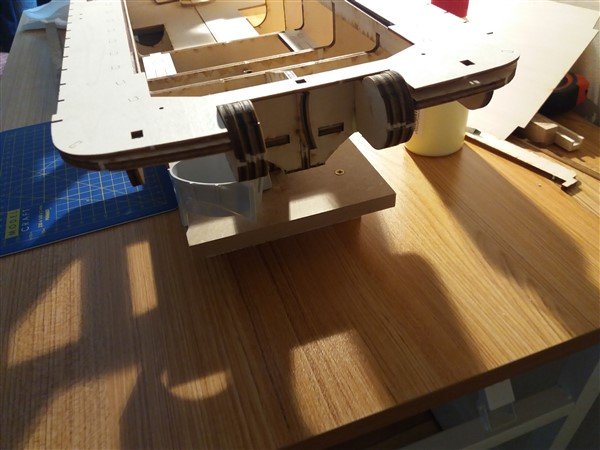

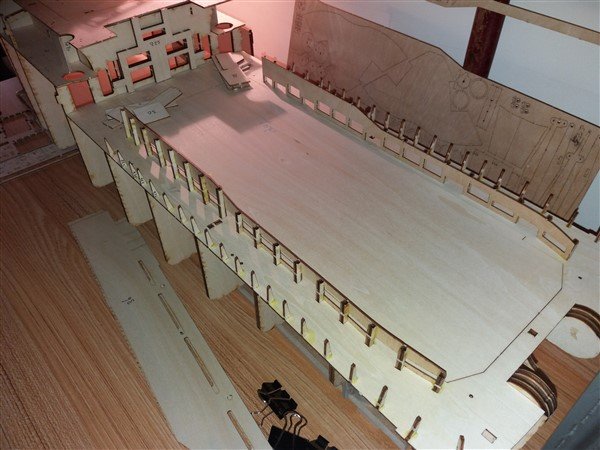

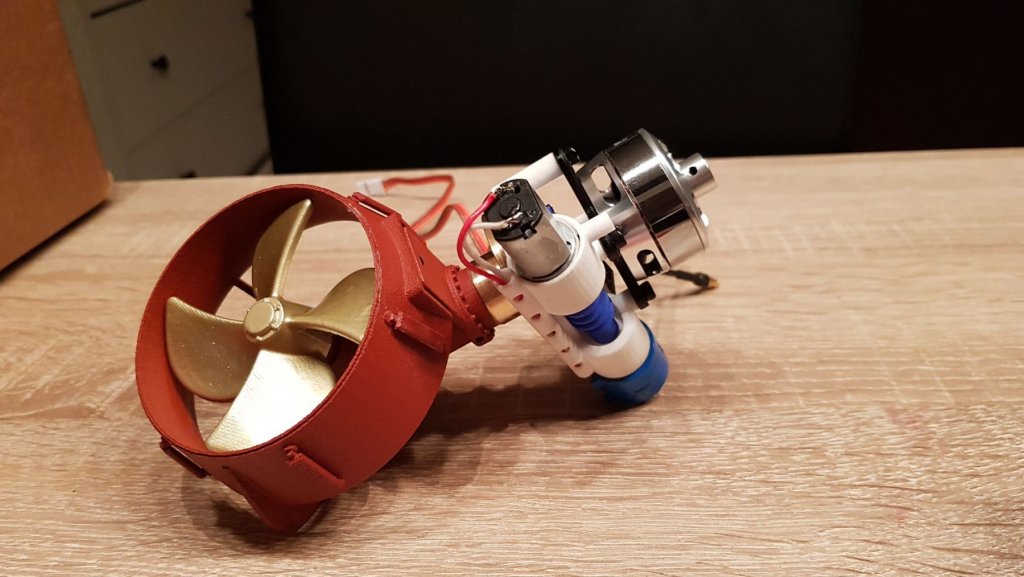

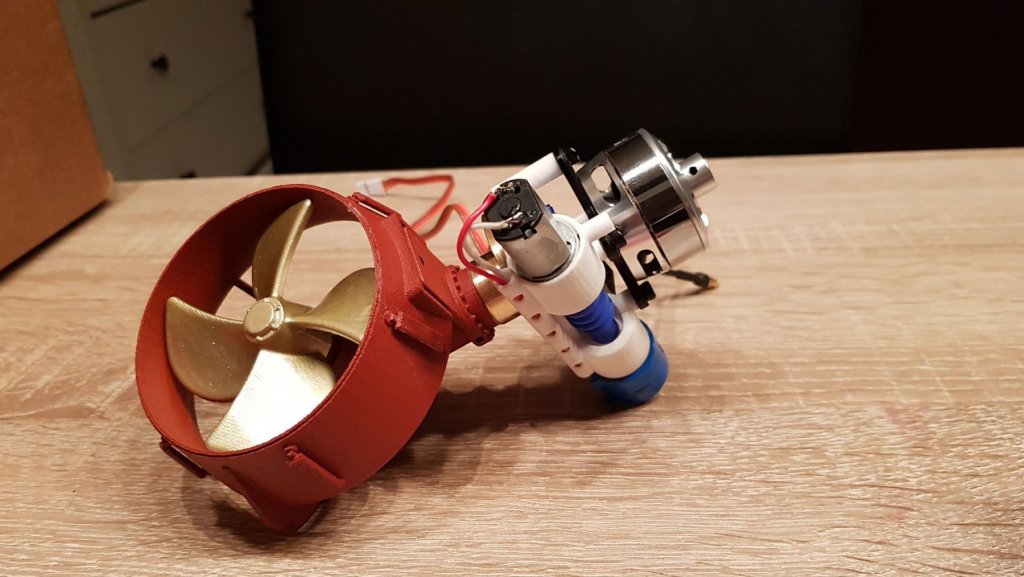

Thanks Kevin, still not sure if I put all this in the right place but until now did not get any comments about it. Well here we go, starting to take all apart for the glue option and use the Aliphatic waterproof/sand-able glue. Now here is the tricky part! Glue the parts is not a bad/difficult job but to do that in a fashion that all will get in the right place you have to think logic as 1 mistake and the whole built is going to be funny!! To keep it strait I use the slip-way what gives me a good indication if all is correct and 90 degrees on each other specially the frames. Anyway, presently half way, back side is finished the frames and some other parts, topside of the deck railings is done, where as the roll comes on the stern is also done but can still take the top of the backside off in order to have better access underneath what I like to have other equipment mounted later. Means only the top shell is glued, rest will follow when my reinforcements are in place between the frames. Now just started the front part and bow what is now drying before put it on. Need to cut the centre connection as otherwise the bow trust cannot be mounted. I also did find the spot for the Azimuth props in the backside where as the tail will go through the shell, used the original ones as still waiting to receive them and the bow truster. Also the accommodation and the bridge will start today with windows bridge as the rest already done. Wish me luck, pics are doing later. Aft part glued together in a fashion I can still take it complete of as having to make some more strength in the built view from top aft deck Just to give the impression how the Schottels will be put on later other view Schottels and here I saw that have to lift the building ca 5 mm to have more clearance under the kort nozzle Just an overview of the frames (not lined up yet and glued)

- 35 replies

-

- fairmount alpine

- billing boats

-

(and 1 more)

Tagged with:

-

I must admit that until now I did not glue all the frames from the hull as she is still on the slip-way and needs to make reinforcements in between the frames but having her on the slip is much more easy to do that as it's a great stability tool to work with on this relative big kit's. Glad I have this slip-way built and make her on this. For the price you don't have to spare as it is relative cheap and during the building it can be easy moved from 1 to another spot without damage vital elements of her. Also some of the bridge parts already glued but in the sense that the <roof> of the bridge can be removed for making inside her bridge the consoles for the nav equipment and the towing winch on her back side of this bridge. Funnels are glues but still not on the bottom as need to have this off when I make the pipes in there. Did not make comments under the pics, sorry for that but must be clear enough looking at those pics.

- 35 replies

-

- fairmount alpine

- billing boats

-

(and 1 more)

Tagged with:

-

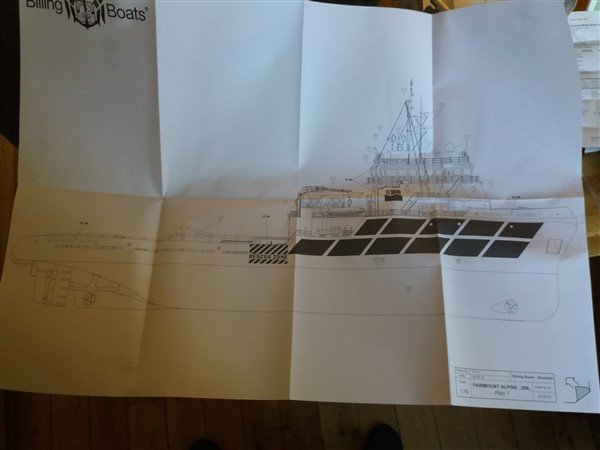

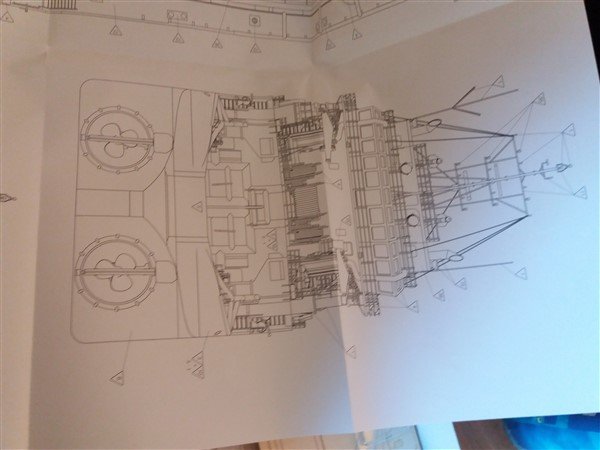

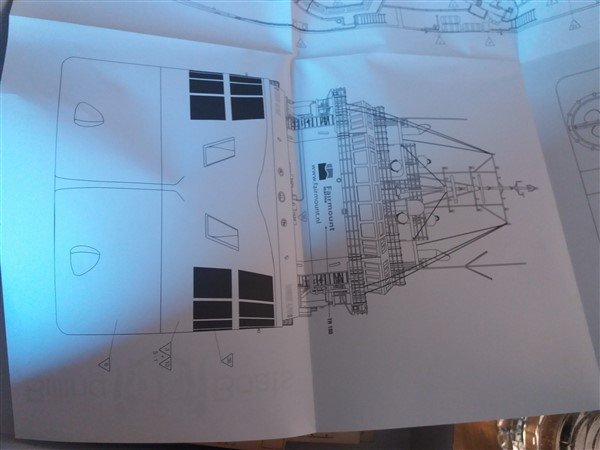

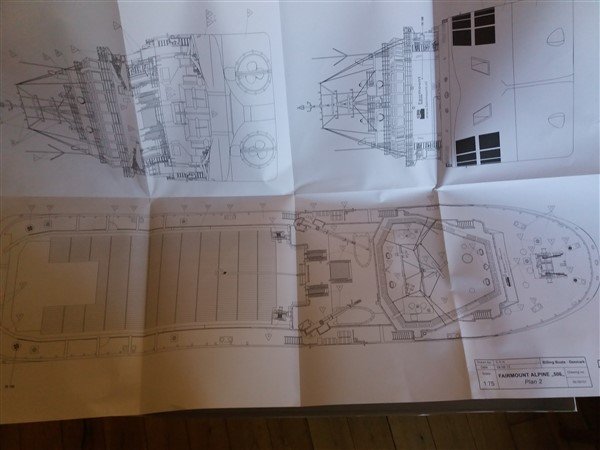

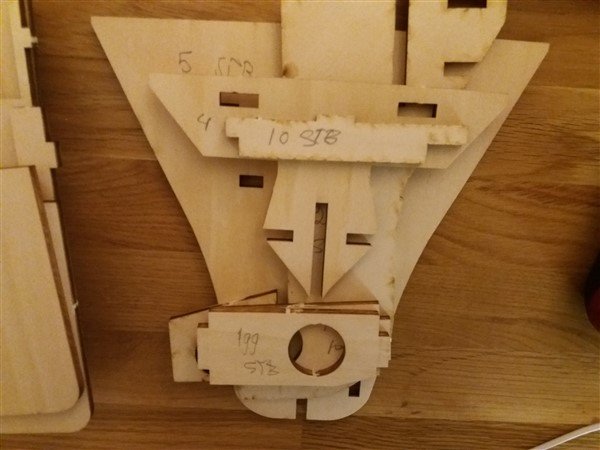

Good day all, Not sure if I'm in the right place on this forum but if not, sorry then it has to be moved. Well here I am with my building side from the sea going tug the "Fairmount Alpine" what with today's name Boka Alpine still runs across our Oceans. This is not my first kit to built but did not do this for the last 20 years+ but being pensioned now the misses wants me to have something to do, maybe keep my brain occupied who knows. Anyway, did start this building from Billing Boats and want to make it different then original, means want to have a Schottel prop stern with 360 degrees rotation. No rudders of course, no shafts, no stern trust so leaving a lot of weight behind what has to be compensated with ballast afterwards but so far I am not yet. Also the bottom will be changed as don't like those small <planks> on vital shell places as go for "massive" shell all the way in the bottom and want to make kim keel's as did see with the sailing models that she is moving to fast when giving a little course changing. Not sure if the <fixed> keel is low enough in the water but if not will extend that also and maybe with ballast in there too. (example the Damen tug in pic) So this project will take some time with having all this in place but no rush, got time. Sequences I use is not the same as Billing boats gives in the manual but this is my system and to my humble opinion is much better. Also waiting for the propellers and bow trust to arrive so I can finish the hull. Having a lot of wishes for this project such as working fire fighting equipment, anchor winch that is working, towing winch and winches on the deck in working condition, lights accommodation and navigation, smoking funnels and more of that stuff. Hope you like the pics here and if comments no problem, will respond to them all. Have a great day you all. First built I made +25 years ago! On this vessel to see the Azimuth propellers, not sure if they are Schottels Birthday present from my wife to keep me busy opening the box all the goodies and more goodies all the brass stuff I will most likely need drawing scale 1:75 Well mine will be different then this Yep, just the forward facing drawing as I made altering to it. same here, altering will be made by me on this built here comes the first raw set-up not to bad but waiting for the "slip" looks massive already now comes the nummering part! position of the propulsion and NO stern trust on mine not to bad looking for the kort nozzle but to my knowledge to low so need to raise the hull / keel. top position stern what I have to alter with ref to Schottel penetration using the tiny hole as ref for the Schottel coffee is a must have building this massive tug here it comes, nummering all parts numbers, this is an absolute must otherwise you get last same here, stb and ps separated as mistakes are easy made part of the keel stern where as normally stern trust is situated midships keel frame got the slip what is an easy help to keep the built strait already raw until the bridge even aft deck already set up looking at it now see the aft accommodation with no 60 is upside down! bow frames clearly see bow trust position having the slip you can secure the built with the bow securing he built on the slip bridge deck and monkey island with funnels starting bridge windows to be mounted / glued stern with stern roller (not mounted yet) inside after stern part what needs to be altered for Schottel propulsion and most likely also for the towing pins. side frames aft deck installed some works accommodation done protection plate aft deck iwo supports glued side sub frames hull mounted / glued further with bridge and superstructure all sub frames forward deck glued taking shape on aft deck still working on windows bridge Schottel propellers I am going to use diam 70, for exact measurements I put later here. bow trust but mine is 24 mm

- 35 replies

-

- fairmount alpine

- billing boats

-

(and 1 more)

Tagged with:

-

Jo, no problem but RC means Radio Controlled. So with a remote control, the ship in the water and having all electronic built inside you then control the vessel by this control unit and by means of batteries connected to electric motors you can sail the ship. Lights are lights inside your building, you have a little deck house there and could easily built in 1 or 2 small led light and of course a battery + switch on/off. But that is all up to you, if you will follow me you can see there how I will do it with my building (when the postman it will deliver). As of now I only have the slip-way what is when you built a ship like mine I rather use a slip-way to built the hull and frames inside as it makes sure they are in line and correct distance from each other. Beside you have a strait keel line and if not strait you will see it afterwards and cannot correct it anymore unless you break off some vital parts and rebuilt. I used it before and happy with it but will show next week when my first data comes into force so to speak. Ok have fun there and if you need some info don't hesitate to drop a line. have a great evening. Peter

-

Mark, thx for the advice but still waiting for the built to arrive by post. The one we ordered with did not have it in stock so now did find another one here in the UK that has her. Already got the slip and can built that together. But you right, soon I have the tug I will open a built log. Thx for your patience and will revert in the building site. brgds Peter

-

Thx Mark from a cold UK! Will do and as soon I have the vsl in hand I will open a building site and if you want yo can follow it there. Presently still waiting for the e-mail from them but already find one where they have it in stock so just depends on that one. Cheers for now, Peter

-

Just an update here. Good job I asked "Premier ships" what happen with my wife's order and just now got the mail stating that this boat is s<sold out> so I asked here to refund and I will buy the boat where they have it in stock!! This will be "Howes Models UK. Then it will take some days before I will receive it all. Now just got my "slip" from Billing boats, at last something is there, gives me also more time to organise all like table and tools. Also I will change this model to 2 x Azimuth Veith VZ 1250 - 70 mm, forget about the stern truster and rudders as those Azimuth can turn 360 degrees. Also have to modify the keel as can be seen on the picture from a Damen tug with 2 x Azimuth's mounted. So I will be the first one to built it in this fashion and to be honest, as I look into the keel of this model it is easy to do. I will upload some pics here so you can image how it will look like.

-

Still waiting for the postman to come with the tug Fairmouth Alpine.

Have been thinking about the prop and will make 2 Azimuth Veth VZ 1250 - 70 mm type in it instead of the 2 props and rudders! It will save me a lot of work to props and rudders, also less electronica as props are 360 degrees. Can also forget about the stern truster as no need for that either. The only thing I have to make is an additional keel as showed here on the pic below from another tug with same props. Will be great for sure but again need some adjustments to make in the underwater part.

Just got the confirmation that the slipway will be delivered today.

-

Well Jo, same as me joined this forum and must say found a lot that could be a help for building mine. I'm not saying that I'm a beginner but yes, this will be my first "BIG" building so to speak in wood. Also mine is somewhere in the pipeline and should come this week. It is a complete wooden kit and I will be supriced how it looks like. Then again, reading here and looked at the 2 others that already did make it but not completed the whole, at least I can see how it will be just the hull and other parts. So yes, it will be reorganising my brain as did those buildings before and the biggest one I built (20 years ago) was from Billing boats the Zwarte Zee. We will look into your building progress and also you can see mine , guess we will be finished nearly same time and then we are the proud owners of some lovely model ships. Not sure if yours is RC but could be nice if it was also with illuminated lights etc. Anyway good luck when the postman will deliver yours, will follow your goal to built it and if we can help just let us know. Success for now.

-

great building so far. Anything done more since last year? Interested to know how the hull is presently, complete or not. looking forward for more details.

- 90 replies

-

- fairmount alpine

- billing boats

-

(and 1 more)

Tagged with:

-

Good day dear readers,

Is there anyone in or near Luton UK that is also building a boat (any kind) so we could do that together? Got a nice place this summer in the garden with a tent that is 3x3 so having enough space there. Always nice if you can do that with others and you can learn from each other too.

Waiting for some replay,

wish you all a nice day and pleasant reading as this side is made for that and can find any enquiry you need.

-

Welcome here, also me new on here but don't have the same experience as you have with Billing boats. Built in the past several ships, Passive and RC controlled, all billing boats. Sure you must have some imagination through to complete all but personally, coming from shipping I did not have any problem. But here on this forum there are nice guys and will give you a hand or advice if you get stocked. Presently I built the Fairmouth Alpine and start to have the slip-way installed, the actually boat comes this week but will place some pics later. Success with your built and hope we will see when completed.

-

Dan, good day to you. Just got a question and you can maybe give an answer. What has coming to my mind and correct if I'm wrong but from the "to built" projects a lot of them are not finished as not noticed here, just the hull with some and that's it. Now having said that, it looks to me that a lot of members are starting a building but due to what ever reason not finishing it. Bit off a bad idea but then again, we don't know the reason why and maybe we never will know. Is this the normal behaviour from those members (and I went back to 2014) that just they disappear and nothing afterwards. Even I start building the Fairmouth Alpine, there are 2 members that also started the vessel but none of them finish it? Anyway, I will keep you updated in another part of this forum with my building progress and hopefully I will finish that after some time. If any member reading this and cannot or will not finish this/her building I'm willing to finalise it if they send me what is left/done to me. I will not keep it but will send it back in final state. Waiting yours, brgds Peter den breejen.

-

As I'm not familiar with the "sail"boats from Billing, I must admit that the one I built was from Billing Zwarte Zee and this one was accurate as it can be! Now I'm starting with the Fairmouth Alpine but haven't got it yet and will be coming in my position this week. What I can see and also been there in Denmark with Billing boats, the models they have presently are very accurate as been on board on both in my years, also when the Zwarte Zee was built and must admit, the kit you will get is just the kit, any detailed parts such as compass, lights, winches, anchors etc not even talking about the options such as "burning" lights all have to buy separate to the kit during or later on so in a way you are right that the kit is <incomplete>! But all parts are available on the market to upgrade your built as you want, all depends how much money you want to spent! Normally when a kit cost £350 you have to add basics another £500 and then again if you want all, another £400 - £500 to make it complete and accurate as it can be. So make a long story short, bearing in mind that the building time also is around 6 - 12 month, the investment to finish all cost around £1500 but then you are the proud owner of a vessel (even on scale) what last for years and gives you the satisfaction showing it around!

-

Just looked in to it and can see that 2 persons already have this boat built? as far I can see they did not finish it? or are still building it. Never mind, I want to be then no 3 with the same building but I will finish it and sail with it also. thanks again for the link and as soon I have my first frame up (using the <slip-way> I will post it there and make the dock/building file.

-

thx and will do. Have a great weekend there down under!

-

thanks Cabbie, if you can tell me where to open this building log I will put in there the progress.

-

good day all, Thanks for accepting me here. Just some info, retired technical fleet manager so lots of time to pick-up my hobby again. My first model (ca 20 years ago) to built was <Zwarte Zee> van Smit Rotterdam, was complete with steering (single prop and no truster), used it with my kids in Denmark and was towing a rudder boat with me inside to control the tug. Now start to built the Failmouth Alpine and just got the "slip-way" where as I will built her on. During the fases of building I will put some pics here for those who want to follow this project. Again, thanks for having me here and sure we will enjoy the time building and looking/reading here.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.01eb78ddd26fe9e56368b6bc83844e8c.jpg)