-

Posts

976 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by iMustBeCrazy

-

At the rate you're going this might be too late but: On an open boat sand everything on the inside before fitting, sanding later is a pain. Dang, you just posted, I knew it would be too late.

- 23 replies

-

- boston whitehall tender

- rowboat

-

(and 3 more)

Tagged with:

-

Well, I failed with the ply. It's just too stiff. So I sanded a piece of paulownia (which I used/am using on my Bounty boats and for everything except the bulkheads on Kitty) down to 0.65mm to match the ply and fitting it was a piece of cake. Paulownia is very like double density balsa. Once it's filled and painted no one will know.

-

Well, as I expected the bow sections are a bit more of a challenge. Both the long edges change from overlapping the keel or side to a butt joint to the stem or side add to that getting the curve working and you can see it's going to be fun. The shape wasn't too hard, templated in card. And I think this will achieve the curves. It has been warmed with a heat gun but I do not know yet if it was warm enough. And yes, that's another stringer gone.

-

A rubber band and a piece of scrap wood will create a reference you can measure from. You can also square it up from one of the transoms to align things lengthwise.

- 72 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

Make a 'V' block as shown, if the brass is too short put a bit of wood through it and clamp both ends.

- 24 replies

-

- 18th Century Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

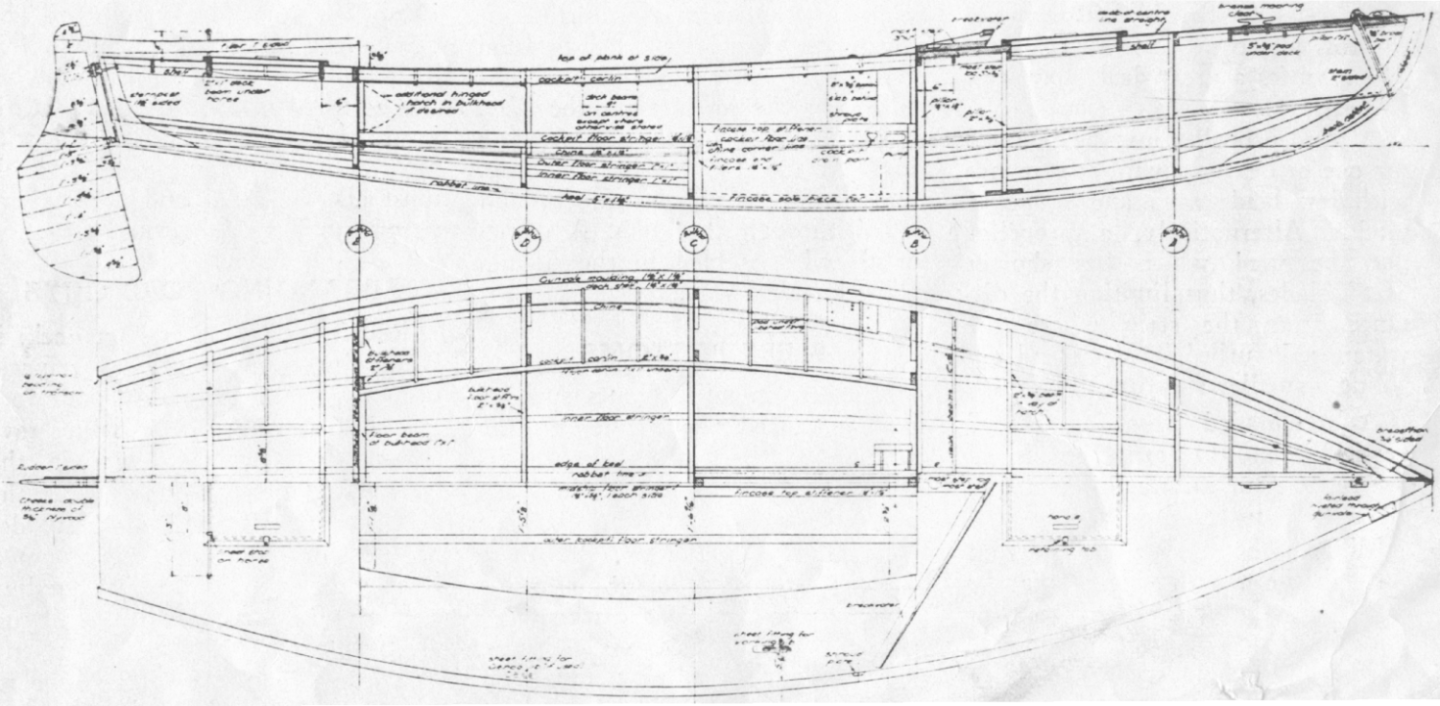

Something a little different. Hopefully this will be a quick build at least up to a painted hull, I only have until Easter to get that far. Some may be wondering why I'm not working on my Bounty launch. Kitty was built in 1949 by my father and three mates and was going to be my next build after the launch but the son of one of the builders will be visiting at Easter so the launch is on the back burner. I have been playing with drawings for a few months based on photocopies of photocopies of the 'plans' in a magazine, some incomplete drawings my father did in preparation for making a model, some photographs of the build and, fortunately, the materials list.

-

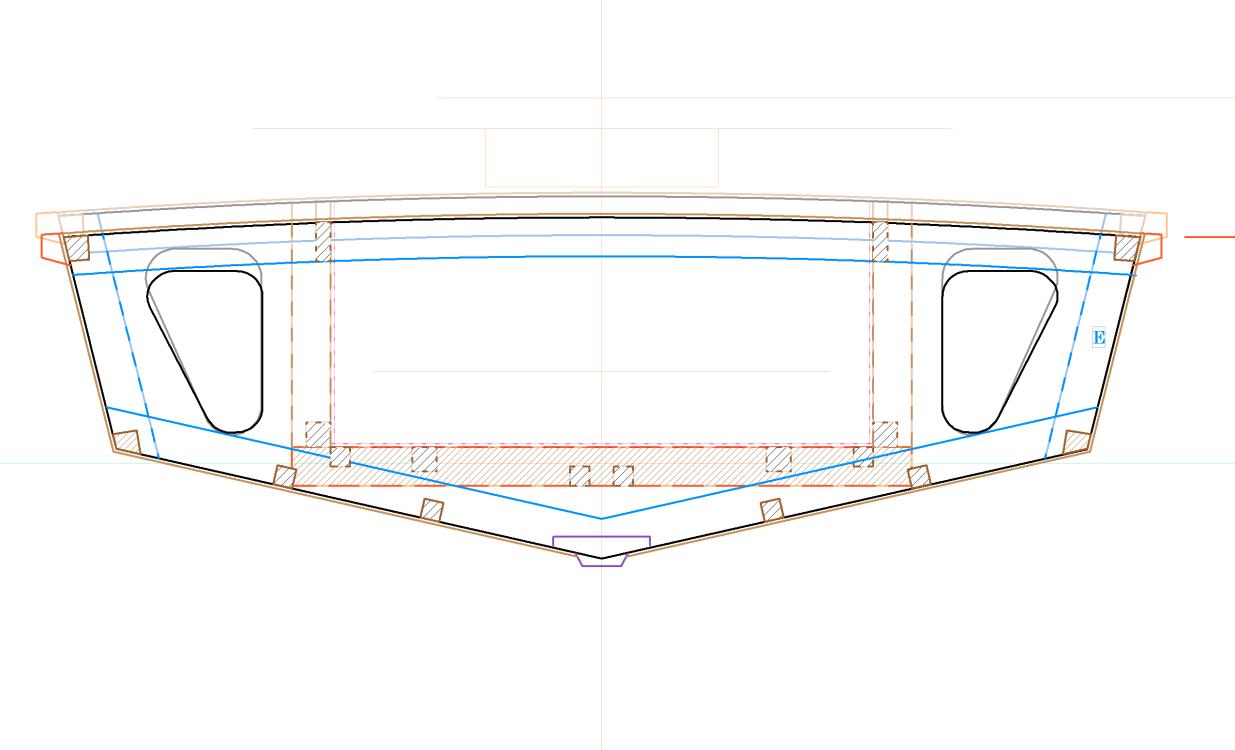

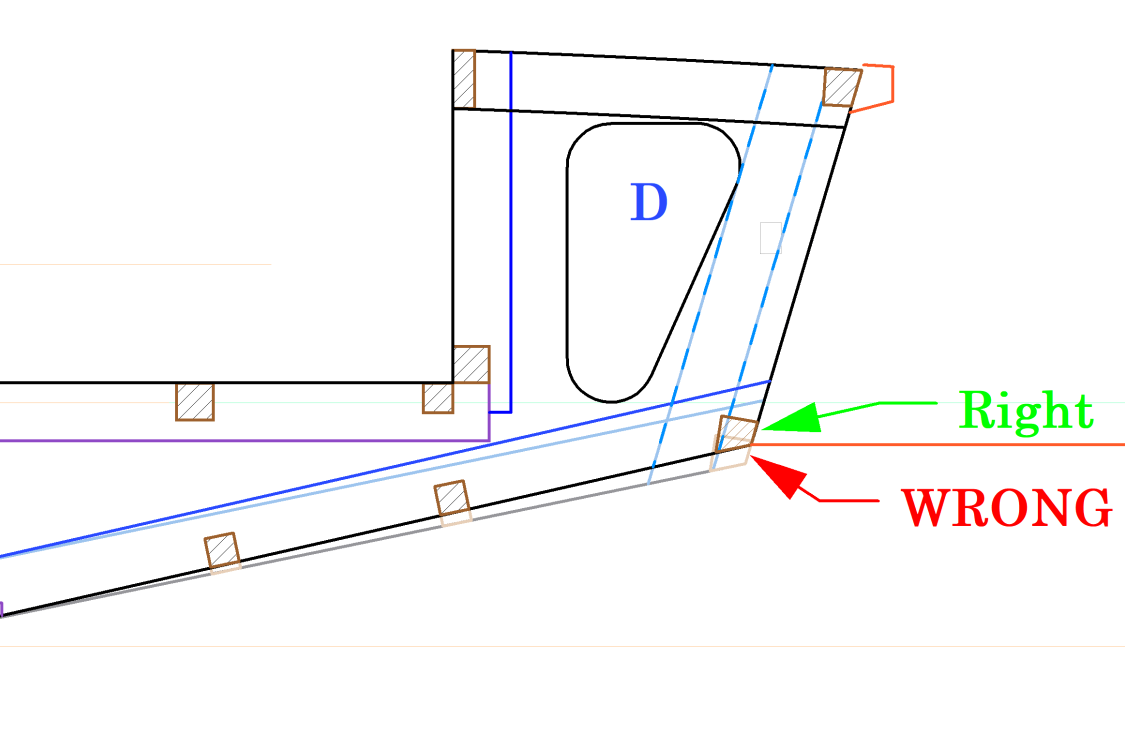

Unfortunately I stuffed up either my measurements or my gluing of the landing strakes and the sheers don't overlap the landing strakes properly. There should be a 1" (scale 1/16") overlap the full length but I finished up with zero overlap at E, F, G and at the transom. The stem and midships are fine. I Ummed and Ahhed for some time and finally decided to add some packers to make the sheer sit at the same height it would be if it overlapped and then when I fit the fender it will hide everything.

-

Ok, I'm back. I got some insect repellent in my eyes and couldn't focus well enough for close work even with magnifying glasses. Better now. Prior to that I fitted the landing strakes. These are clinker as mentioned above. This time I used a stepped rebate for the gains rather than the 45°s that I used on the small cutter. I glued depth stops to a pair of blades (you need a left and a right) and cut rebates going down to half the thickness of the planks. It worked well and was easier than the 45°.

-

I'm not that old! The only real problem is you need to come up to the forward thwart. Some examples: https://www.rmg.co.uk/collections/objects/rmgc-object-66671 https://www.rmg.co.uk/collections/objects/rmgc-object-67761 Based mainly on the above and other contemporary models, the quarterdeck was likely solid (no gaps between planks), the foredeck either solid or a grating. Based on experience, the rowers need somewhere to brace their feet. Either raised floorboards or footrests. There will be exceptions.

-

Just a minor update, planking continues slowly. Although I've decided that the originals hull was most likely painted white I'm going leave mine natural with a coating of shellac, the timber is quite pale so it's 'close' to white and it will show off my work. And a better visualisation of Allan's project

-

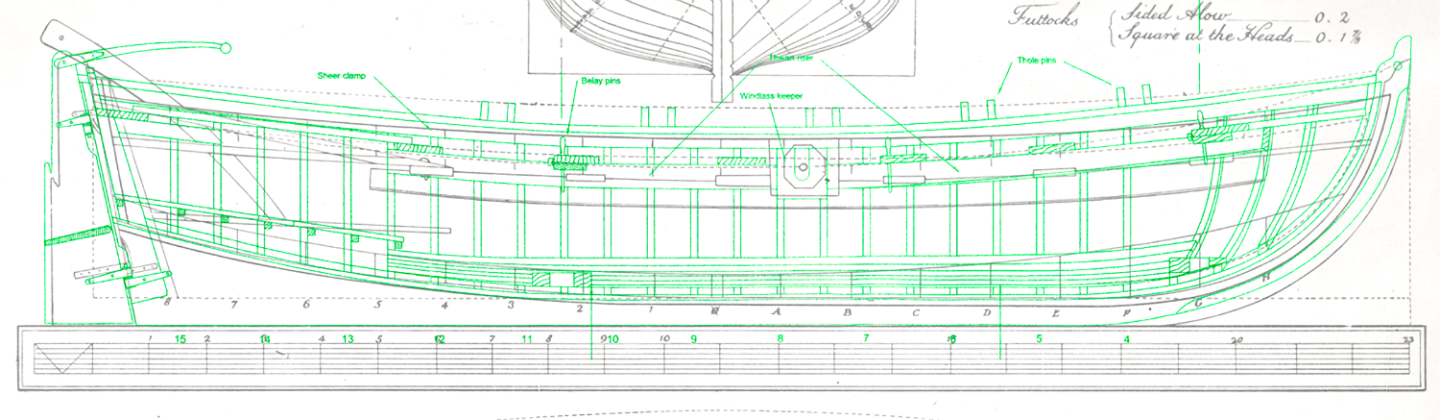

Haven't we all? Taking a stab at it, from the comment about being short of white (paint) for the small cutter I'd guess all the boats were painted white (impress the natives) with the sheer probably painted in a colour that somehow matched the Bounty. Sometime before leaving Tahiti the bottom of the launch was painted with half pitch half tar (probably coal pitch (black) and pine (or Stockholm) tar (anything from light amber to dark brown)). The effect was probably a brown/black wash over the white leaving the launch rather dirty/shabby in appearance which would do little to impress the natives and may have increased the chance of being attacked. Model Shipways kit (green) v ZAZ7361 the drawing from the books:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.