-

Posts

976 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by iMustBeCrazy

-

The shape of the hull Possibly the easiest way is the tape trick (see pic) the tape shouldn't have any kinks and should lay flat BUT it should approximate the outer surface of the plank you are trying to make (inner surface for clinker). Mark the edge of the previous plank at each frame and the stem and transom. Use the tape to make a template with your curves, use your calculated plank widths at each station to get the other edge.

-

This bit is easy to explain, the fan is just a way of marking off your divisions on your tick strip. On the fan mark your lines 0 through 8. Mark the measured distance on the tick strip. Hold one mark on line 0 and the other on line 8 (it doesn't matter how skewed it is) the other lines give your equal divisions. Remember that your planks will need to be slightly larger than that indicated by your division as you are measuring the inside arc. This is more relevant in real life but be aware.

-

It depends on what you are modelling. Fincham (ca1820) gives us this description. The transom in launches and clincher-built boats has its aft side on one surface, and well with the rake of the after part of the post; but in barges and pinnaces it is in general in two parts, the upper part lapping over the aft side of the lower, and projecting abaft it, to form a moulding on its lower part, well with the lower part of the land strake; and in addition to this mouldng, formed by the projection of its lower edge, one is likewise worked above by another projection, worked out of the upper piece, well with the lower part of the sheer or upper strake. The transom in launches and clincher-built boats are therefore always let in their thickness from the after part; and in barges, pinnaces, and yawls, from the fore part, it is in general fastened to the post with nails, in addition to the ring bolt and gudgeon. So the transom of almost any boat other than a Barge or Pinnace will look like one big slab but was probably made up of two or more pieces.

-

I've decided to make a change to the jig. Instead of just gluing it to a board as I have previously I'm going to glue a notched strip either side of the false keel and notch the moulds to fit. This should allow better access to the inside during construction. Please forgive my attempt at 3D, the false keel........:

-

You are not alone. It's a very confusing subject. Sort of. I think. It won't be. Many of the descriptions you read are authors opinions stated as fact, even though there is often evidence to the contrary. Eg. there are contemporary sketches of six oared jolly boats. Function would have varied depending on the size of the ship and probably the Captains disposition. And as always, There will be exceptions. Fincham (ca1820) gives us this description. It's certainly not 100% correct but it's a start. The principal boats for attending upon ships are: launches, long boats, barges, pinnaces, cutters, yawls, jolly boats, life boats, and gigs or galleys. The launches, long boats, barges, pinnaces, and yawls, are carvel-built; and cutters, jolly boats, galleys, gigs, and life boats, are clincher-built. Launches are in general from 34 to 59 feet in length. They are for watering and carrying stores to the ship, and are sometimes armed and equipped for cruising at short distances; they are mostly fitted to carry one twelve-pounder carronnade, and sometimes fitted with swivel stocks. Long Boats are seldom or never employed for the use of British ships of war; they are sharper and wider than launches. Barges are generally 32 and 35 feet in length. These boats are for accommodation, pincipally for carrying flag officers and captains; and are lined and panelled above the thwarts, all fore and aft, that they may be richly decorated, if required. Pinnaces are 28 and 32 feet in length. These boats are for similar purposes as the barges, but to carry officers of less rank; they are not therefore fitted up in quite so neat a style, as they are lined and panelled no farther foward tnan the stern sheets. Yawls are in length 26, 25, 18, and 16 feet. These boats are for carrying light stores, provision, and passengers, to and from the ship. To the smaller class of ships,they answer all the purposes of a launch. Cutters, Jolly Boats, Galleys, Gigs, and life Boats are clincher-built, that they may be made as light as possible. Cutters are in length from 32 to 16 feet; they are used for various purposes that are common to ship's duty, though sometimes 32 foot cutters are supplied to ships instead of a barge, and used for the same purposes; and sometimes the shorter boats are called and used as jolly boats. Galleys are from 28 to 36 feet in length; they are used in enterprises and expeditions against the enemy, and against illegal trade. Gigs are in length from 16 to 27 feet; they are for swift rowing, and are supplied to ships when light boats are required. Life Boats are from 16 to 22 feet in length; they are for landing in surfs, performing enterprises and boarding ships, and for saving men that fall overboard,

- 24 replies

-

- Small boats

- cutter

-

(and 2 more)

Tagged with:

-

Roger, when you add the 'hole' in the seat with the hole in the transom it really looks like it. Oops, just found this one, same artist same time same rig.

- 24 replies

-

- Small boats

- cutter

-

(and 2 more)

Tagged with:

-

Mark, I have no doubt that every shipwright had his own way of doing many things but these are Admiralty drawings presumably saying 'we want it built this way'. So the question might be 'did every draughtsman have his own way of doing things?' or was there actually a reason for the variations? I don't know. I think these eight are the only launch drawings that show any planking details and they basically fall into two groups, sheer strake and sheer wale (thicker sheer strake) with more or less detail/accuracy. As for the Bounty launch short of the wayback machine or discovering that the Tahitians had invented photography we can only make educated guesses about much of it. What we're aiming to do is get as close as we can without the commercial considerations of kit manufacturers. Ultimately it is extremely unlikely we'll get it anywhere near 100% right but hopefully we'll avoid obvious errors.

-

Canvas catches the wind, often in undesirable ways. I would guess the canvas screen was around a foot high with another foot below. And the rain catcher, a canvas sheet held by four men in the shape of a scoop. They probably had a low piece of canvas as a sun shield that they used to catch water when it rained.

-

No, it's pretty much this rig. I think the odd one out is the main thwart.

- 24 replies

-

- Small boats

- cutter

-

(and 2 more)

Tagged with:

-

Allan, I don't think you're wrong. However there are a few strange things in the drawing. First off I think it should be titled Boys Painting a Jolly Boat given their height, second, there are two row locks missing and it probably should be single banked, third, do I see provision for three masts? But it was actually a very good fit when I overlaid my 16ft Cutter: https://modelshipworld.com/topic/33083-16ft-cutter-by-imustbecrazy-finished-small-116-bountys-small-cutter-jolly-boat/page/2/#comment-950515

- 24 replies

-

- Small boats

- cutter

-

(and 2 more)

Tagged with:

-

I guess I may as well post the rest of this: The thwarts of boats are loose, and fixed ; generally three are fixed, and are called the fore, main, and after thwarts ; those fixed are commonly kneed at each end; to carvel-built boats, in general, the main, with two iron knees, and the fore and after, with one, which have two nuts and screws or forelock bolts through the side, one of them through the gunwale, and two up-and-down bolts through the thwarts. When the knees are wood, which is most commonly the case in clincher-built boats, they are fastened with nails, which are in general rivetted on roves or washers. To strengthen the fore part, and unite the bow's, two hooks are in general placed across the bow, one on the gunwale, and one at the upper part of the wash strake; in large boats, when they are attached to the gunwale, they are generally fastened with two bolts on each side; and in others, commonly, with nails; if wood hooks are used, the nails are driven from the outside, and rivetted on roves. And abaft, to strengthen the quarters, knees are likewise brought against the transom, one on each side, commonly at the gunwale and wash strake. The internal fittings of boats are different according to their class and service. In launches, the footwaling generally extends from the keelson to the rising; to some boats, to about the height of the floor-head; while others have bottom boards, only to fix and unfix. The bow and the stern sheets are likewise not only fitted differently, according to the class of boats, but frequently according to the taste of the captain, officer, or person for whom they are intended; some times with regular platforms, and frequently with gratings only. The internal fittings of boats generally are of too trifling a nature to require description; and to explain their detail would be more extensive than important; since a very moderate attention paid to them would be sufficient to become acquainted with all the particulars relating to them, and would fully answer the requirements of the student. It's a pity he never guessed that future students would be unable study a genuine contemporary boat.

-

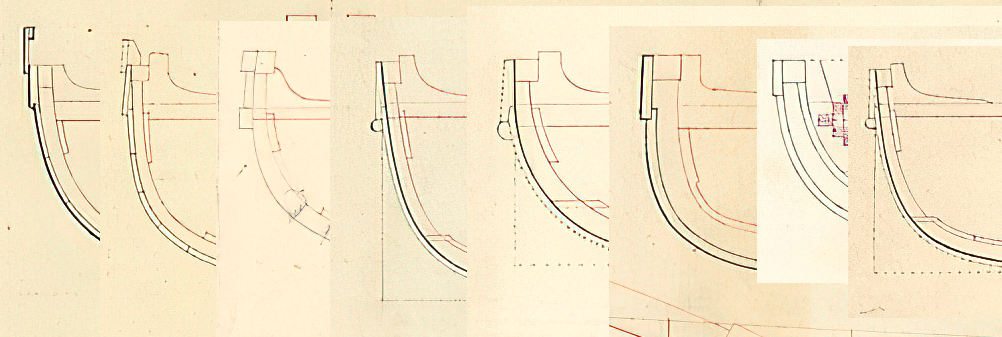

Turning my head to thoughts of planking. John Fincham has given a description of building a Launch in his various books (ca1820) and I've been trying to get my head around his description. The garboard strake is layed into the rabbet of the keel, and is fastened as other strakes, with two nails in each timber, except when it widens aft, when it has sometimes three. The binding strake is placed to be a parallel distance up from the lower edge of the landing strake, and has its upper edge reduced in thickness, for this strake to lay upon it. The landing strake is then brought on, and the sheer or upper strake, when the gunwale is on, the upper edge of Which corresponds with the upper part of the gunwale, to lap on the landing, according to the breadths, as in general shewn on the draught. The space between these strakes and the timbers, which is left by their lapping on each other, is in general filled up by small fillings; and the strakes are fastened with two nails in each timber; and the upper edge of the upper or sheer strake is nailed to the gunwale. The gunwale, which is the upper boundary of the permanent part of the boat, is in general composed of two or more pieces, scarphed together with a vertical scarph, from about 9 to 12 inches in length; and has its upper side well with the sheer or upper strake. The heads of the timbers are shaped on the inside, from the lower side of the gunwale to about one-eighth of an inch at the upper part, and the gunwale is scored over them. Above the gunwale is fixed wash strakes, sometimes permanently, and at other times to fix and unfix. When permanently, chocks are let through the gunwale, to extend down to the upper part of the landing strake, inside, and up to the upper part of the wash strake, for fastening them to the chock, and are spaced so as to form the rowlocks, with additional ones on the bow and quarter, according to the space. The wash strakes lap on the outside of the sheer or upper strake, and are fastened to it, in addition to the fastenings in the chocks. They have likewise to support them, sometimes, a narrow strip, called a feather band, nailed to their upper edge, inside; but most commonly they are lined quite through. On the outside, close under the wash strake, is fixed a piece, rounded to form a fender; and likewise a similar piece, only smaller, is fastened on the land strake, close to the lower edge of the sheer strake, called a land rail. Inside, to a proper height and for supporting the thwarts, is fixed a strake, called the risings; this strake is in general nailed to the timbers, and the thwarts are let in a small distance. I made the following drawing based on Finchams description and ZAZ7344 which I think is right except Fincham suggests the Landing strake laps over the Binding strake. I then attempted a drawing based on ZAZ7361 and found that the curvature requires that overlap (NOTE. I've left the washboard off). Given how much the planks would need to be hollowed out I think I'll redraw it with 8 x 5 7/8" planks. Oh well, back to the drawing board. Edit, it looks better:

-

Jolly boat is more a nickname than a description, the smallest boat on the ship and usually a cutter. But there will be exceptions

- 24 replies

-

- Small boats

- cutter

-

(and 2 more)

Tagged with:

-

All sorts of things. The drum is two (more or less) bits of MDF cutout with a hole saw, drilled and tapped, epoxy applied to the bolt and mating surfaces, screwed on to the bold and lightly tightened together like lock nuts. The head of the bolt is cut off. Once cured it is fitted to the drill and sanded while spinning with a bit of sandpaper on a square block. Sandpaper is then glued to the drum with contact cement, you could do two different grits at different heights. No overlap and as small a gap as you can. The fence must be square, a bit of aluminium extrusion would be nice but wood will do if square. A vacuum to suck up the dust and clean the drum and you're done.

-

It was fiddly enough at 1:16, I had to nest several pieces together, sand the inside of the top one on a spindle sander, cut the top one off then proceed to the next. Then I had to sand the outside of each piece on a disk sander without sanding too much off my fingernails, I only had 3mm to hold on to. All done now but it's a tiny pile of matches for a lot of work.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.