-

Posts

976 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by iMustBeCrazy

-

Unfortunately yes, I didn't have any bent trees It's simply a bit big and as it turns through almost 90 degrees the cross grain would be just as obvious as the laminations, or that's my excuse. All the floors and futtocks have been shaped, next I have to drill and 'bolt' them. Keel has been scarphed:

-

HMS Renard 1872 by Draque - 1/24 - POF

iMustBeCrazy replied to Draque's topic in - Build logs for subjects built 1851 - 1900

Michael, you might look at using this schooner as a template, she is roughly the same size and date. She has a room and space of 24 inches versus your 22. Scaling the timbers and spaces (sided) down to suit gives: Floor ..................... 5 5/8" 1st Futtock ............5 3/8" 2nd Futtock............5 1/8" 3rd Futtock.............4 7/8" 4th Futtock.............4 1/2" Top Timber.............4 7/8" Stanchions Heel.....4 7/8" ...................Head...4" -

HMS Renard 1872 by Draque - 1/24 - POF

iMustBeCrazy replied to Draque's topic in - Build logs for subjects built 1851 - 1900

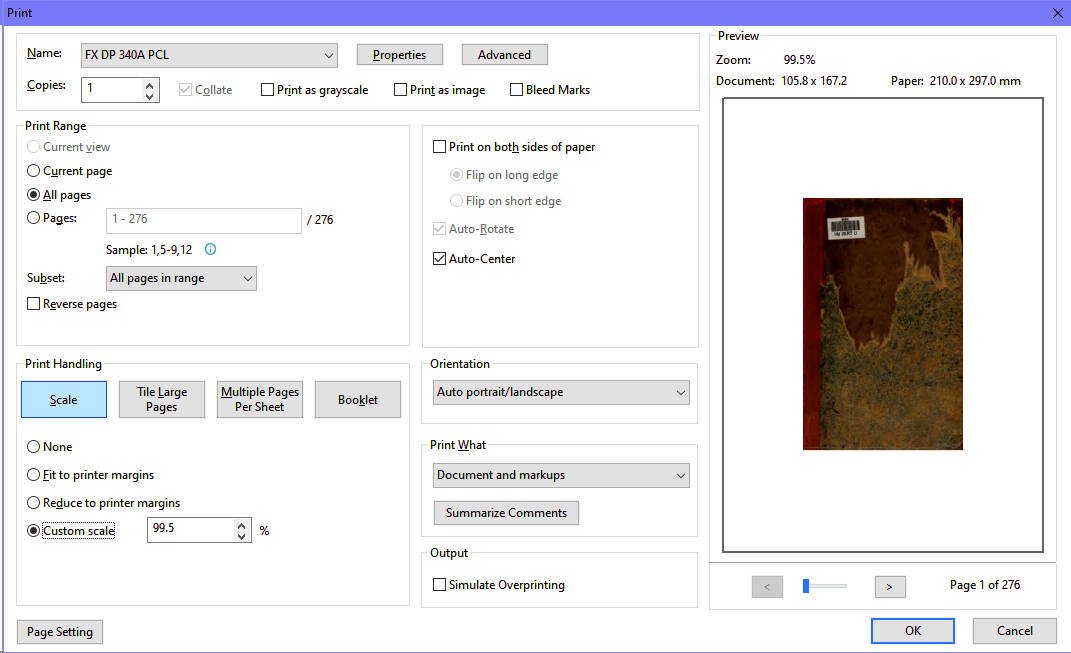

Michael, when you go to print there will be a size or scale option. The default is probably something like "Fit to page" or "fit to Margins". You want the option that allows you to set a percentage like the "Custom scale" option in the screenshot. Print first at 100% and check the print for size. If it's wrong then "measurement I want" divided by "measurement I got" times 100 should give you the percentage to print at. -

Yes yes, yet another Bounty Launch. This will be the third being built at the moment. Allan's at 1:48 https://modelshipworld.com/topic/33539-23-foot-launch-by-allanyed-bounty-late-18th-century/ Tim's at 1:24 https://modelshipworld.com/topic/33565-hms-bounty-launch-by-oakheart-scale-124-%E2%80%93-18th-century-based-on-drawings-from-national-maritime-museum/ And this one at 1:16. As far as I can see these are the first scratch built Bounty Launches on this forum excluding those built for Bounty models. Allan has been asking lots of questions in preparation for his build which has driven much research and given us some facts to work from. https://modelshipworld.com/topic/33217-bountys-ships-boat-details/?do=findComment&comment=945945 We have settled on building based on ZAZ7361 with some minor tweaks: https://modelshipworld.com/topic/33217-bountys-ships-boat-details/?do=findComment&comment=947122 https://modelshipworld.com/topic/33217-bountys-ships-boat-details/?do=findComment&comment=948363 We have each done our own drawings and I have now reached the stage where I can start building in earnest. I have made a few pieces but wanted the jig designed before starting this log. We shall see how it goes.

-

Ok, I thought it would be that one. It's one of the diagonals. Measurements in the table of offsets (which we don't have) give the length along the diagonal from the centreline to the station line this is sometimes longer than the (half) width of the hull. On my drawings I (try to) make the same reference line the same colour wherever it appears.

-

HMS Renard 1872 by Draque - 1/24 - POF

iMustBeCrazy replied to Draque's topic in - Build logs for subjects built 1851 - 1900

Michael, I produced a PDF with some scale rules sometime back, you may have to adjust your printer scale to get them right but they are the right price:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.