dunnock

NRG Member-

Posts

519 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dunnock

-

Thanks Al. I'm sure that you'll enjoy building Speedy. It makes a fine model and there is scope to make it your own.

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

Great build and log with lots of useful tips and ideas I'll be interested to see the results of your CA and Superphatic tests BE David

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Supplies from Canada and Czech Republic arrived so quickly that I didn’t get time to begin Harpy, although work on Speedy, did involve the Harpy kit. I decided the wooden cutter was no longer salvageable. Instead I’ve raided Harpy’s box and made up the 3D printed version. I made up the boat cradles from the Speedy kit and have hit a snag. It maybe an unforeseen consequence of adding rounding to the hatch coamings but the cutter rests on the ledges rather than the cradles. It wouldn’t do for Cochrane to be banging is head every time he came on deck so I’ll have to cut some new ones to make the boat sit above the hatches. With new supplies of rope and blocks, I can continue with the rigging. Topmast backstays are added using 0.45mm rope. The shifting backstays are also completed using 0.45mm rope for the pendants and 0.25mm for the falls. It wasn’t clear to me where they belayed but I have used the nearest convenient belay pin. The falls are not fixed so they can be moved if necessary. I'll add ratlines, finish lanyards and trim ropes once the topmast stays are completed so it's on with those now. The likes are much appreciated and thanks for looking in. David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

I had begun to fit the booms before Daniel’s @Thukydides tip on fitting the topmast shrouds next and as I couldn’t see any reason not to, I finished fitting the lifts and halliards. I have fitted the pendants for the vangs but not completed the falls. I was unsure where the peak hallliard should belay. For the moment I’ve tied to the aft starboard shroud. I now turned to the topmast shrouds. As for the lower shrouds, the forwardmost shroud is fully served and the others to about 4ft, scale 18mm below the halfway point. I used 0.45mm dark brown rope.. The shrouds were set up with deadeyes in the usual way. I thought 0.1mm looked a bit thin for the lanyards. According to Steel they are 2” corresponding to 0.25mm. Next up are the stays and backstays but I failed to order enough of the finer brown rope from RoS so I can add the ratlines, futtock staves, catharpins and sister block but then I will wait for new supplies. The good news is that meanwhile, the Master of the Shipyard has ordered a start on Harpy and thanks to all the blogs already on MSW @Blue Ensign, @Glenn-UK and @Richard44, there is some great advice and tips that I will benefit from. 😊 David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

Thanks for the heads up Daniel. For some reason, I'm finding it difficult to put together a plan for rigging Speedy so I will follow your advice and move to the topmast shrouds before continuing with the yards. If I find that they are getting in the way I can unrig them as they're not glued in. David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

I’ve been working on the lower yards. I’m a bit short of the smaller diameter ropes from RoS so I’ve used 0.4mm Gutterman thread for most of the strops. While the yards are not fixed to the masts, I thought it easier to add the ropes for the jeers. The plans do not show any yard tackle pendants but I assume that they must have been present. I used 0.7 mm rope and 7mm long tackle blocks. They will eventually be rigged with falls and hooked to the futtock shrouds. I prefer the look of rope stirrups rather than the PE brass ones supplied. They are made from 0.35mm rope. An eye is spliced in the lower end and the other end attached to the yards with three wraps and then glued. The eye hangs 15mm below the top of the yard. The horses are 0.45mm rope and are first to go onto the yardarm, followed by the yard tackle pendant, the combined sheet and lift blocks and finally the brace pendant. The yards are pinned to the mast but not glued. I thought I would see if I could hold them in place using only the trusses. I may come to regret this but for now, with the falls in place, it seems to work. The I want to continue with the running rigging of the lower yards as far as possible but it occurred to me that it might be worth adding the driver boom and gaff while the main mast is still accessible. David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

Sorry to hear about your health problems. Hope you're on the way to recovery and can get back to Sparkler in the spring David

- 35 replies

-

- vanguard models

- Adder

-

(and 2 more)

Tagged with:

-

I’ve been making progress on the yards. The octagonal sections for the lower and topmast yards were marked, roughly cut with minature chisel and then sanded to finish. I find it pretty difficult trying to get even sides to my octagons starting from round dowel. I think that next time I will try harder to find some square section. Smaller sizes are readily available but anything above 6mm seems more difficult to come by. After finishing the octagonal sections, the tapering is done in the lathe. I followed the plan sheets’ dimensions in most cases. Having cleaned down the lathe and all the dust, I assembled the yards for this photo and then realised that I had only made 4 stuns’l booms and need another 4. I also need to make two boomkins so the lathe will have to come out again. But first I’ll finish dressing the yards. The gaff and boom jaws needed a bit of tweaking. I first cut them in two and filed a groove along the inner edges to fit around the booms and glued them in place. I sanded in a lot more taper to the jaws and then rounded off the edges. They were finished off with three ‘iron’ bands cut from black card. All the yards and booms are painted matt black ready to start adding the blocks. Thanks for the likes and for looking in David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

Looking forward to following your build Glenn.

- 241 replies

-

- Vanguarrd Models

- Harpy

-

(and 1 more)

Tagged with:

-

I completed the planking of the cutter and was quite pleased with the result of my first attempt at clinker planking. The only problem I ran in to was that I put too much pressure on the transom when fitting one of the planks and it split in half. I glued it back together and completed the planking. I trimmed and sanded the planks at the stern and all looked well until I removed the frames and then structure just fell apart. I have begun to put it back together but the transom has split again. I have put it to one side for now while I consider whether to continue with repairs or abandon in favour of a 3D printed version. I went back to finishing the shrouds, adding futtock staves, catharpins and ratlines which are now completed. I've begun work on the yards having marked them up and filed and sanded the octagonal sections of the lower and topsail yards. They are now ready for tapering on the lathe. David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

Lower Shrouds and Stays The new jig is made and both fore and main mast shrouds set up. This jig worked much better than messing around with the bits of brass rod that I had used previously. The lanyards are made from 0.4mm thread and will be finally tensioned at a later stage when the standing ring for the lower masts is completed. Moving on to the stays. Based on Steel, the fore mainstay should be scale 8mm and preventer 7mm. I had no 8mm rope in my stock so used 1mm cabled rope. The main stay is given as scale 1mm rope but to maintain a differential between fore and main stays, I’ve used 1.2mm and 0.8 for the preventer stay. Lees says that stays are served to 6’ below the mouse, which in my case meant I served the top145mm of each stay. I’ve started making the mouse (mouses, mice?) for each stay, turning them on my lathe from 4mm dowel. They still need a little more work with the file to achieve a better shape. The other bit of news is that I received this the other day. I’ve been allowed to look at the box but it has now been put away and not to be seen again for another 2 weeks. 🧑🎄🙁 Thanks for the like and comments David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

First piece of rigging to add is the gammoning. I used 0.45mm dark brown rope as the nearest I had to 0.5mm from RoS. I was able to get 9 turns in the slot but only 8 frapping turns before I thought they were getting too close to the bowsprit. I also used 0.45mm rope for the stays and shrouds all set up with 3mm deadeyes. Final trimming is left until latter in case I need to adjust tensions. With the bowsprit well lashed down I moved on to the shrouds of the masts but first the pendants of tackles needed to be added. I used 0.7mm rope served along their whole length. According to Lees thimbles had replaced blocks ffor the tackles I messed about using drilled out 4 and 5mm trucks for the thimbles but decided they were oversized and went with 3mm brass thimbles I had from HiS Model. The shrouds are 0.6mm rope. The foremost is fully served and the rest served down to the level of the lower catharpins. I decided that a served length of 50mm looked right. I cut a length of 400mm for each pair of foremast shrouds. The first pair are served for 250mm and the second for 100mm. The main mast shrouds needed to be a little longer and I used 450mm for each pair, The main mast has five shrouds each side and the final swifters are rigged singly to each side. All the shrouds were prepared in one session of serving followed by seizing them around the mast head. It would have been easier to slip the shrouds over the mast if I had not added the cleats and blocks but at least I was able to remove the blocks temporarily. I’ve started turning in the deadeyes – I’m using cable laid rope so the deadeyes are turned in right-handed. Going back to the three shrouds that I did yesterday, I think that they are slightly too close together so I will make an new jig and redo them. Thanks for the likes and for looking in David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

I put in my pre-order for Harpy this week but there is still plenty to do on Speedy and in any case, I have to pretend I don’t know what it is until Christmas 😄 🙄 Bowsprit and Booms The bowsprit is turned from 6mm dowel. The maximum diameter is 1/3 of the length along from the step. I cut a square tenon for the fitting into the cap rather than round. Apart from the gammoning, there seemed to be no way of preventing the bowsprit from moving back through the bitts with the kit arrangement, so I have added a heel. Actually a false heel. I had glued the bitts into the deck so had to remove them to make it easier to work on. I filled the hole in the bitts with a scrap of dowel and glued a second short length of dowel to the after side. The heel piece was sanded and filed to shape. The bitts were refitted and the bowsprit is pinned and glued to the to the forward side. I don’t know if this arrangement is correct but it looks better to my eye than the bowsprit fitting flush into the bitts. Prior to fitting, I added all blocks and cleats. I decided not to use the PE brass fittings for the blocks and instead they are stropped with 0.45 rope. I served one piece of rope in sections of between 40 and 8omm depending on the position and number of blocks in the strop. I was a little puzzled by the rigging plan here because the PE rings showed all the deadeyes on one ring but the plans definitely show at least two strops. For simplicity, I decided to rig the bowsprit stay deadeye on one strop, the two side stays on another and the fore stay on a third. I used a similar arrangement for preventer stays and 3mm blocks. Thank goodness for quadhands... I used the PE parts for the fairlead and jibboom saddle and just forward of this I added the spritsail yard saddle I made from a wine bottle capsule. I hope it looks similar to the lead sheet used in real life but may need toning down. I wasn’t able t modify the bowsprit cap to take the squared tenon and made a replacement from boxwood sheet. I have also scratched the dolphin striker from a piece of 1mm walnut which looks a more substantial piece now. Jib and flying jib booms are made from appropriate sized dowels. The jib boom has an octagonal section 14mm long at the after end and a 3mm length at the forward end. I cut a heelrope sheave and hole for the lashing on the inboard end and a sheave for the outhauler at the outer end. The flying jib boom gets very delicate on the lathe when working it down to 1.4mm on far end. There is a short octagonal section on the inner end. I’ve not been brave enough yet to cut sheaves in this thin spar but I may attempt it when it’s time to fix it in place. The bowsprit is now pinned and glued in place and it’s time to start rigging. jib and flying jib are loosely fitted but they look pretty vulnerable out there so will be removed until later. Thanks a lot for looking in, the likes, comments and general encouragement. David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

Thanks to everyone for the likes and comments. I’ve added all the blocks and deadeyes to the lower masts before they are finally fitted to the model. I’m using the latest ‘boxwood’ resin blocks from Syren which are very nice and detailed. I’ll use the deadeyes supplied with the kit although some sorting is needed to pick those with the best distribution of holes. I’ve used dark brown RoS cotton ropes, served with Gutterman thread for the strops for all the blocks and deadeyes around the mast. The blocks below the tops are shown suspended from eyebolts in the crosstrees on the plans. According to Lees and Petersson, they would be suspended from wooden pegs on the floor of the tops. This arrangement is quite fiddly and space is tight but easier to do before the tops are fitted on the mast. Strops are 0.4mm Gutterman polyester thread. They need to be long enough to pass through the floor of the top and leave the blocks clear of the crosstrees. A couple of coats of matt varnish stiffen the long strops and fix the pegs in the eye of the strop. I’m leaving the guard rails off until the rigging is almost complete to make access easier and because I'd probably break them if I fitted them now That completes the fittings on the lower masts. I’ve made a start on making the bowsprit, jib and flying jibbooms which I’ll complete before beginning the standing rigging. David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

It's been a while since I posted. I have been working on the masts but I've also had a short break in Norfolk looking for birds that proved elusive. Anyway I've now completed the fore and main mast sections According to Lees’ and Petrejus’ plans for topmasts and topgallants, all have a square section heel and are octagonal between top and cap. The top mast was made from 8mm dowel and topgallant from 6mm to enable the 5 and 4mm octagonal sections to be made. The excess was planed square to begin and then finished with files, sanding sticks and then the lathe for the round sections. I wish I could start with square sections for masts and yards but I can't find any that cover the full range of sizes needed. Top rope sheaves are drilled through the octagonal sections from starboard through to port faces. The topmasts, like the lower masts are finished square at the cap. I thought about whether to make the caps from scratch but found I didn't have any sheets of the right size so decided to modify the caps supplied. I plugged the round hole with a piece of dowel and then cut a new square hole using a 0.6mm drill to perforate around the edge. A scalpel was used to roughly cut out the hole and then I finished it off with a file. The corners are rounded off. I’ve still to add the four eyebolts around the underside. I was taking some photos after I had finished but before painting when I had a little accident. I dropped my camera on the foremast and smashed the bibs and crosstrees. Luckily they were salvageable and the parts glued together well. I liked the way that the tops for the topmasts are made up. Using PE brass crosstrees and pearwood trestletrees, they are simple to put together and the holes in the brass for topgallants stays and shrouds are more robust than if they were in wooden components. I’ve dry assembled the masts and put them in place to get a feel for the finished size of Speedy and to check she’ll fit on the new shelves. Thanks for looking in and the likes and comments David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

Nice planking Andrew. I bought some proportional dividers a while ago but couldn't get on with them. Maybe I'll give them another try. David

- 35 replies

-

- vanguard models

- Adder

-

(and 2 more)

Tagged with:

-

Lower Masts I will make all the masts and yards from ramin dowel stained or painted as appropriate. The lower masts are both made from 8mm dowel. I first marked out, planed and filed square the head sections. Then using my Proxxon lathe, tapered the round sections according to the proportions at each quarter given in Lees. Both lower masts were stained antique pine before adding the hoops. According to Lees, the diameter at the hounds is 4/5 of the diameter at the deck equal to 6.4mm. This is slightly less than given on the plans, so the hounds needed a small amount of trimming before they were fixed. I also scribed a false scarf joint to indicate the presence of the bibs. It's not apparent in the photo but can just about be seen with the naked eye. The main mast is canted aft but the top must sit parallel to the waterline so the hounds are set at an angle. The foremast is vertical, so in this case the top sits square to the mast. Should a front fish and cheeks be added to each mast? I decided to follow the plans and leave them off. I have, however added hoops and battens to the mast head. For the hoops I used heat shrink tube and the battens are made from 1x1mm boxwood strip. Adding these before the crosstrees was a mistake though. If I made up the trestletrees and crosstrees, they would not now go over the mast head. I had to glue together one trestletree and crosstree and complete the assembly around the mast: a bit awkward but it works. The cap should have a square hole for the lower mast according to Lees. I made the tenon 4mm square rather than round. If I were following Lees exactly, it should be 4.5mm across and 4mm front to back but I’m happy that 4mm square is a sufficient approximation. Thanks for looking in David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

Thanks Andrew. They are all only brush painted using Admiralty paints There is a camber on the combings and gratings and I added a couple of bands to the elm tree pumps. A fuller description of making up the fittings is in post#19 David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

The centre line fittings are all in place using the kit parts. The only modification I made was to the skylight, although the mast partners and stove chimney benefit from a little rounding. According to Chris’s narrative at the beginning of the manual, so little headroom in his cabin that Cochrane was in the habit of opening the skylight and poking his head out shave. I thought I would have a go at simple modification and create a sliding skylight. I hope that this is the correct arrangement. I used 5 x1.5mm strip and cut a channel for the skylight to run in then replaced the kit sides with the modified ones. I don’t have a mill so used scalpel and file to create the channel. I bought some Micro Kristal Clear to glaze the lights. It’s the first time I’ve used it so the glazing is not perfectly flat but I’ve convinced myself that from a distance it looks like blown glass. Thanks for looking in David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

-

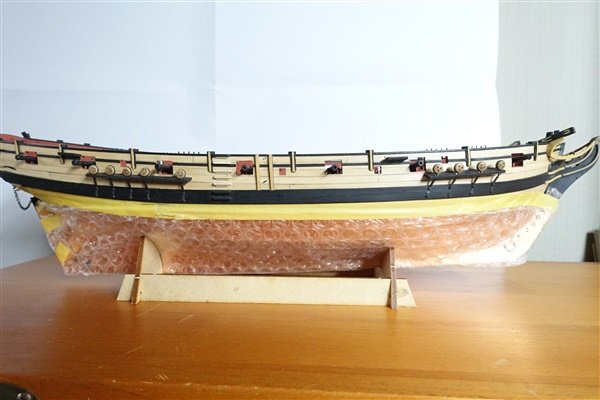

The guns are now in place. I have pinned each one to the deck using lengths of 0.6mm brass rod. The RoS breech ropes lie nicely without any real manipulation and without need to spot glue them in place. A broadsides worth of 'random' coils The falls of the tackles have been left loosely flaked on the deck. Unfortunately the dilute matt varnish that I used to hold the coils together has darkened the ropes but there’s not much I can do about that and it’s not easy to see the contrast between tackle and fall. Speedy is now beginning to look like a ship now that all the guns are on board. Adding the deck fittings is the next stage. David

- 114 replies

-

- Vanguard Models

- Speedy

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.