-

Posts

222 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Long9Ron

-

I was thinking of building myself a waterline marker and was wondering if any of our members had a good design that I might be able to follow in some way. I did a search on MSW and the web, but didn't come up with much. I would like to build one that is not mickey mouse, one that will last be for some time to come. So, if anyone has some pictures of their DIY waterline marker, could you please post them here. Thanks

-

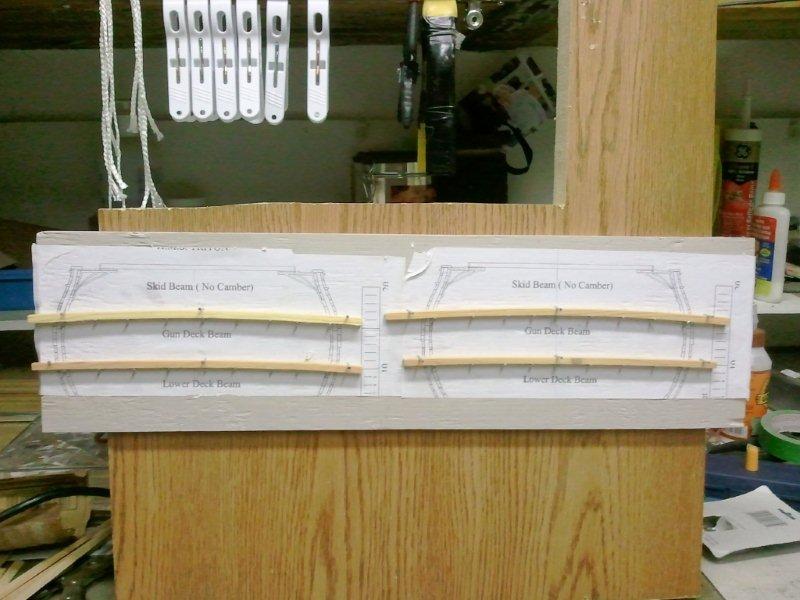

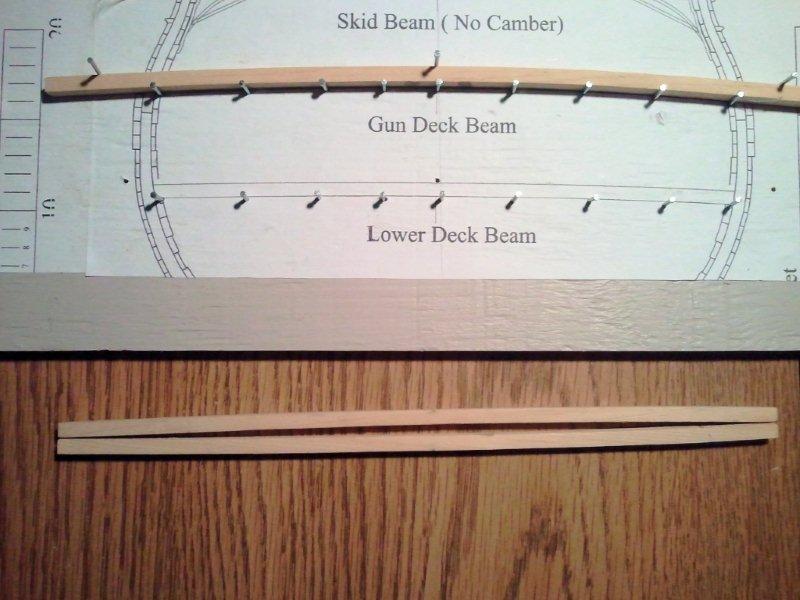

Mark Nice answer.. Grant I made the new limber boards and drilled holes every 5 feet and then sawed a line across them for drainage and handling. I think they will look okay. Next step is to apply Danish Oil to this point once I have masked the areas off that will require glue. Question: I have the Lower Beams ready with the right camber and was wondering if it is best to glue them in place first before cutting s the notches for the carlings or should I cut the notches first and then glue the beams into place?

-

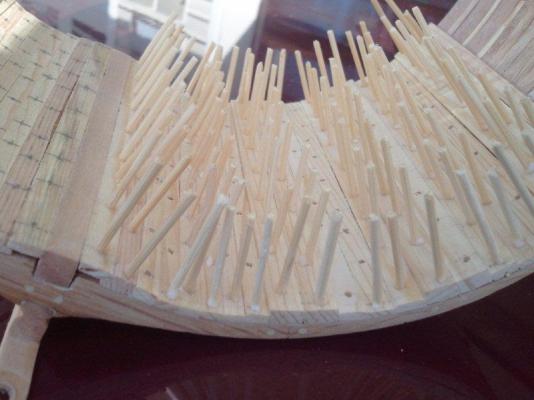

Thanks everyone on how to cut and sand. I first cut the toothpicks at the base and then I started to sand the them down by using my Dremel tool but quickly stopped as it was not the thing to do. I then did as Snowmans suggested I used a small block of wood wrapped with 150 grit and sanded each board. Slower process but it worked just fine. Learn as you go.. Mark I already had the treenails installed in the limber boards, so I used Isopropyl alcohol to loosen the wood glue and then removed them. I will be making new ones soon. But. thanks for the suggestion. Question: Do you think that when I make the new limber boards that I should make them to scale as you suggest (3 to 5 feet long) or just one single piece? All the ones that I have seen are one piece.

-

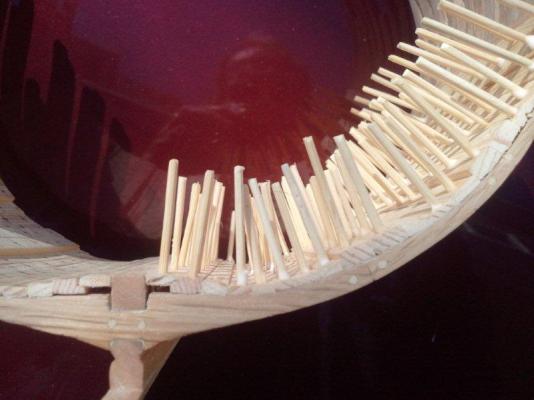

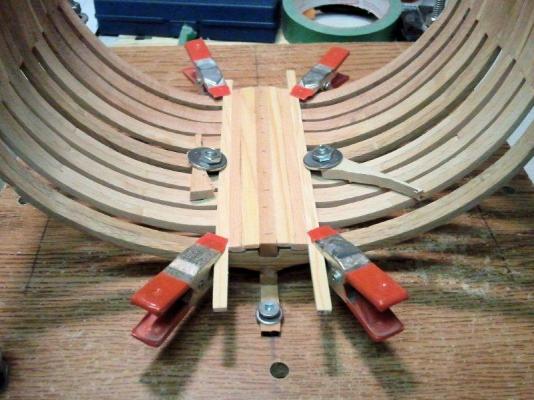

Checked on the second batch of bending the beams. They turned out okay. Meanwhile, marked the treenails holes (360 holes). Drilled 180 holes by hand and installed natural colored toothpicks in most of the holes. Toothpick forest. I'm almost halfway on the treenails... Will be installing toothpicks for a while and then sanding them all down flush. Will take a while. Found out that my frames are made of Oak and the planking is Douglas Fir. The wood was from an old recliner that was taken apart. Meanwhile, my neighbor has given me some solid maple and some nice looking Yellow Cedar. He says that I can get all the wood off of him for free, he is a cabinet maker. Cool. I like saving money.

-

Making gratings

Long9Ron replied to marius's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Marius You might want to check this site out. http://gabierschimeriques.free.fr/modelisme/caillebotis.htm -

Thank you everyone for your kind words. I have learned from my mistakes and the mistakes of others. I will most likely make more along the way, but oh well, that's the learning process and that's how I will end up making a better model next time. Right? So, when I get my corrections done, I will post some more pictures.

-

Thanks for the kind words Pete and Paddy. I believe that my build will be a build for other ship modelers to learn --- WHAT NOT TO DO ---- I have done some planking and it will be a while before I will be doing any beam work. I will be doing some treenails first among other things. But, meanwhile I have found that when I temporarily laid the beams across for the lower deck to see how everything lined up, I noticed that one corner was higher than the other three. Oops I contribute this to my making of bad frames and rushing the job. . I considered starting all over, but have decided against it due to the fact that this is my first build in 50 years and I will be able to correct this by adjusting one of the planks. Also, after I have finished the model, it will be a reminder to me of the things that can go wrong unless you take the time to think things through. Lesson # 2 Think twice before doing anything. Lesson # 3 Follow the plans closely and anticipate what is ahead. Anyway, A few pictures of what I have to this point. No pictures of the beams out of alignment because I'm in the process of correcting the mistake (or covering up my mistake).

-

Yes very nice frames Marius. Just make sure when you mount them that you line them up with a very good jig. Otherwise you might be out a bit like I was on my frames and now I have to make an adjustment to correct it. My frames were not that great because I rushed the job and was not paying attention to the future alignment of the planking and beams. But, that's another story.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.