-

Posts

205 -

Joined

-

Last visited

-

Cleat reacted to a post in a topic:

Making Slings

Cleat reacted to a post in a topic:

Making Slings

-

Cleat reacted to a post in a topic:

Making Slings

Cleat reacted to a post in a topic:

Making Slings

-

Cleat reacted to a post in a topic:

Making Slings

Cleat reacted to a post in a topic:

Making Slings

-

cotrecerf reacted to a post in a topic:

Making Slings

cotrecerf reacted to a post in a topic:

Making Slings

-

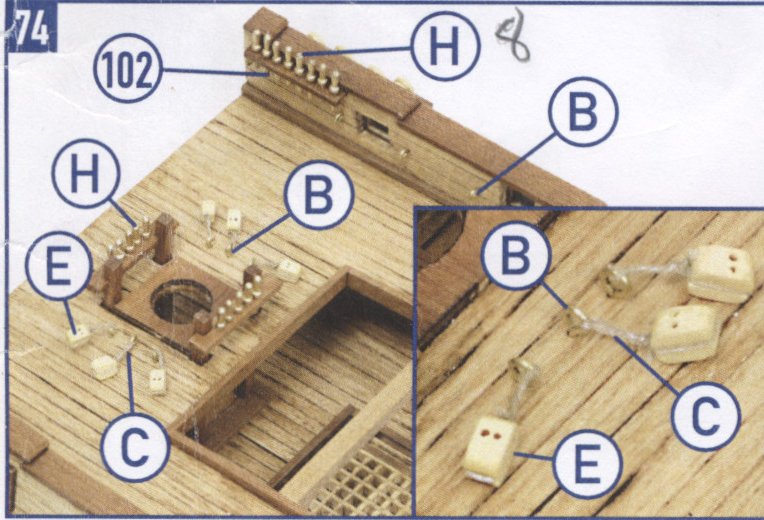

I've reached a point in my build where I need to make a lot of slings to connect blocks & pulleys. I don't know how to make a sling. The picture in my document isn't clear enough to determine how to tie a sling (item C in the picture). I would also like to know what knots I need to learn for rigging in general.

-

RossR reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

RossR reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

-

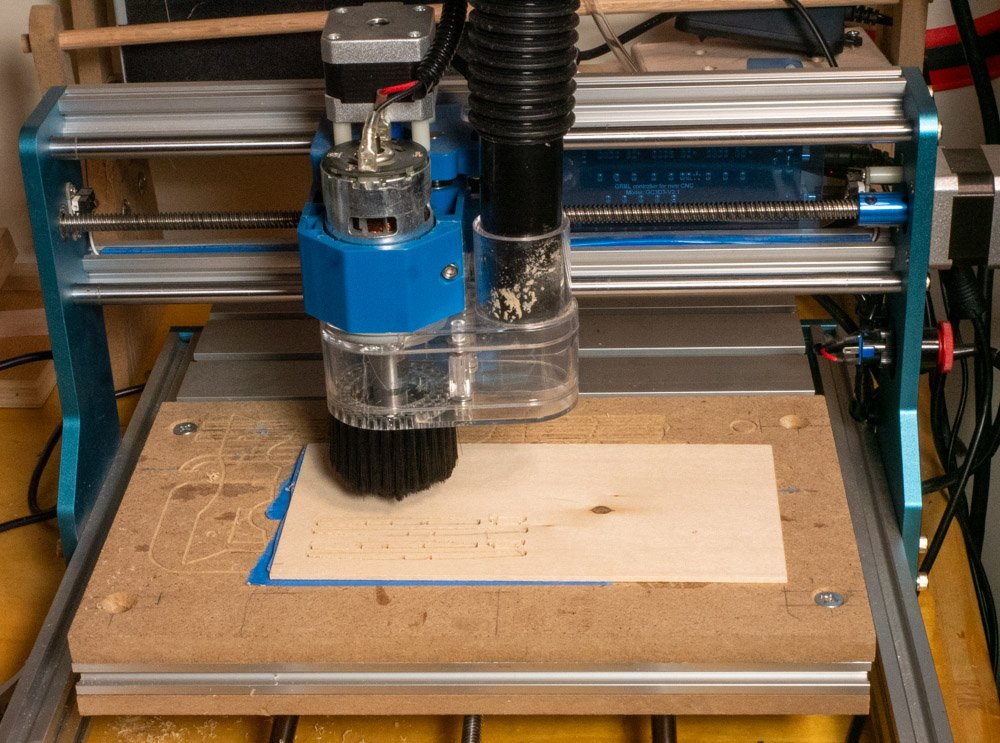

I had trouble with the bracing under the mast platform. I broke one piece while handling it after I cut it from the laser cut plywood parts. I broke another piece while assembling the structure. I kludged the pieces together glueing them to the platform, then I discovered and had installed it backward. I dissolved the glue and removed the structure. While disassembling the structure I broke a third piece (leaving 1 piece I didn’t break). I had to make replacement parts. I removed the original cutouts from the plywood skeleton to make measurements, then I scanned the originals to create a file to cut the parts on my CNC spindle machine. The first set or pieces I cut matched the originals exactly, unfortunately the material I used was a different thickness so I had to modify the notch dimensions for my material. (I made a pile of mistakes). Now I have to figure out how to shape the mast from round to a square end. Now I have to figure out how to shape the mast from round to a square end.

-

Geordie Tyne reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

Geordie Tyne reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

-

RossR reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

RossR reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

-

The lower deck stairs were longer than they need to be because the height of the two decks is different. The instructions call out 1x4 mm stock for the treads but I didn’t have any, the stringer slots measured 5 mm. I glued 2 pieces of 0.4 x 5 mm planking from a previous kit together, cut the treads and they slide smoothly into the slots. I cut the completed stairs to size. I made the canons. I use an airbrush like a can of spray paint, mine has a pistol grip and a pull trigger. With a fan nozzle it covers a good area. I painted the canon black and put a coat of matte clear coat on it because I was going to try and use a brush to apply a bronze color to the rings and if it didn’t work it might be easier to remove. It turned out OK but I had to touch up with black to cover errors with the bronze brush. I used CA glue to attach the wire axles; when dry, I attached the wheels with CA glue, then I clipped axle wire as needed. I added the exterior steps and installed the gun ports. I continue to process various parts. I’m reaching the end of the picture steps. I’m scoping out the mast drawings to determine a procedure.

-

RossR reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

RossR reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

-

RossR reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

RossR reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

-

Russ2025 reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

Russ2025 reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

-

Geordie Tyne reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

Geordie Tyne reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

-

Geordie Tyne reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

Geordie Tyne reacted to a post in a topic:

Santisima Trinidad by Cleat - OcCre - 1/90 - cross-section

-

I’ve transitioned from my garage shop to my indoor hobby shop. I evaluated the work I did last winter and the interior turned out darker than I wanted. The stain applied on the bottom of the hull turned out how I wanted but when I applied stain to the other levels, the wood turned out darker because the wood absorbed the stain differently from the stock used in the bottom. I’ve been looking at other build logs and I might add some lights to the interior (I had drilled pilet holes for lighting during construction). To ease back into the project, I’ve been working on processing various smaller pieces. I’ve been doing some painting, staining, and assembling sub-assemblies.

-

Cleat started following Show pictures of your work area

-

Kevin-the-lubber reacted to a post in a topic:

Lazer cutting

Kevin-the-lubber reacted to a post in a topic:

Lazer cutting

-

I got my hobby machine from Sainsmart a few years ago, they have a variety of products of good quality. My experience with their support has been good. Based on what I learned from my hobby machine I got a Onefinity Machinist model (with a router) for the garage.

-

I use a 5.5 W laser for etching, it won't cut much. I use a device with 2 computer fans with a charcoal filter and it does a pretty good job, a smoke detector is 12 feet away and I haven't tripped it yet. My hobby machine lets me change the laser to a spindle and I've cut parts and routed jigs with that configuration.

-

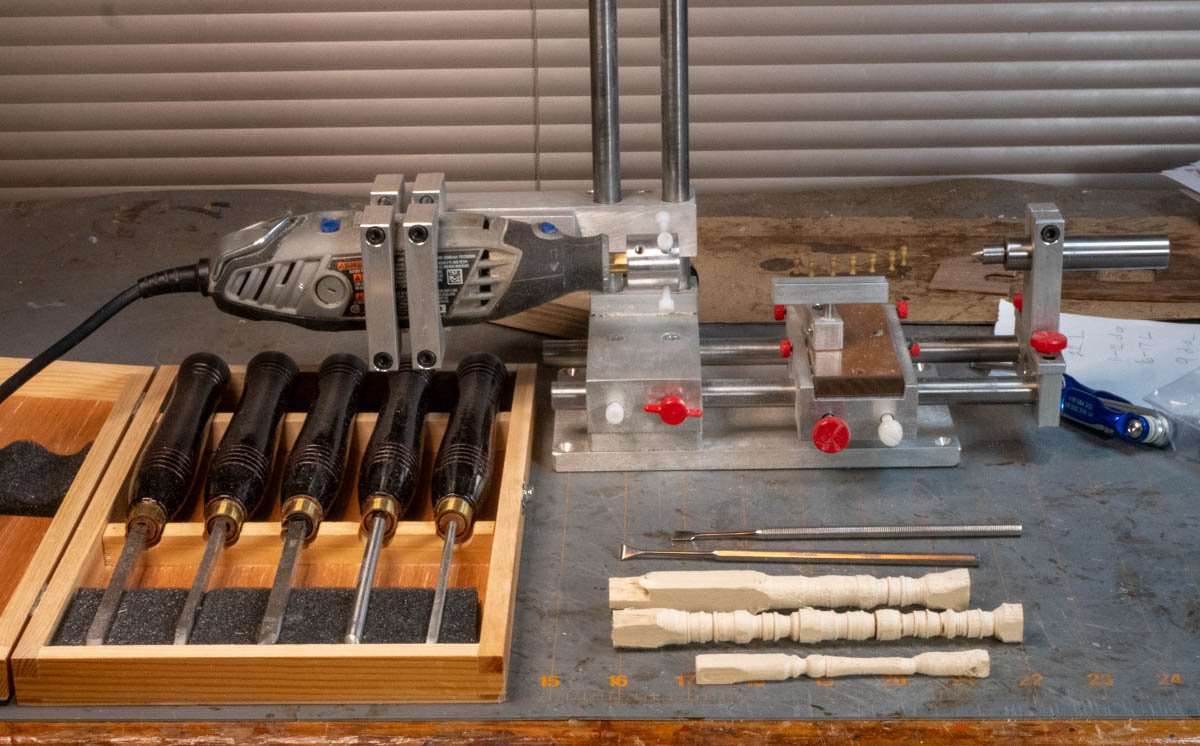

I got the Vande-Lay drill press configured with an adjustable X-axis (Acra Mill Plus). The micro lathe is very light duty. It takes a little time to switch configurations (about a half hour). Vanda Lay web site

-

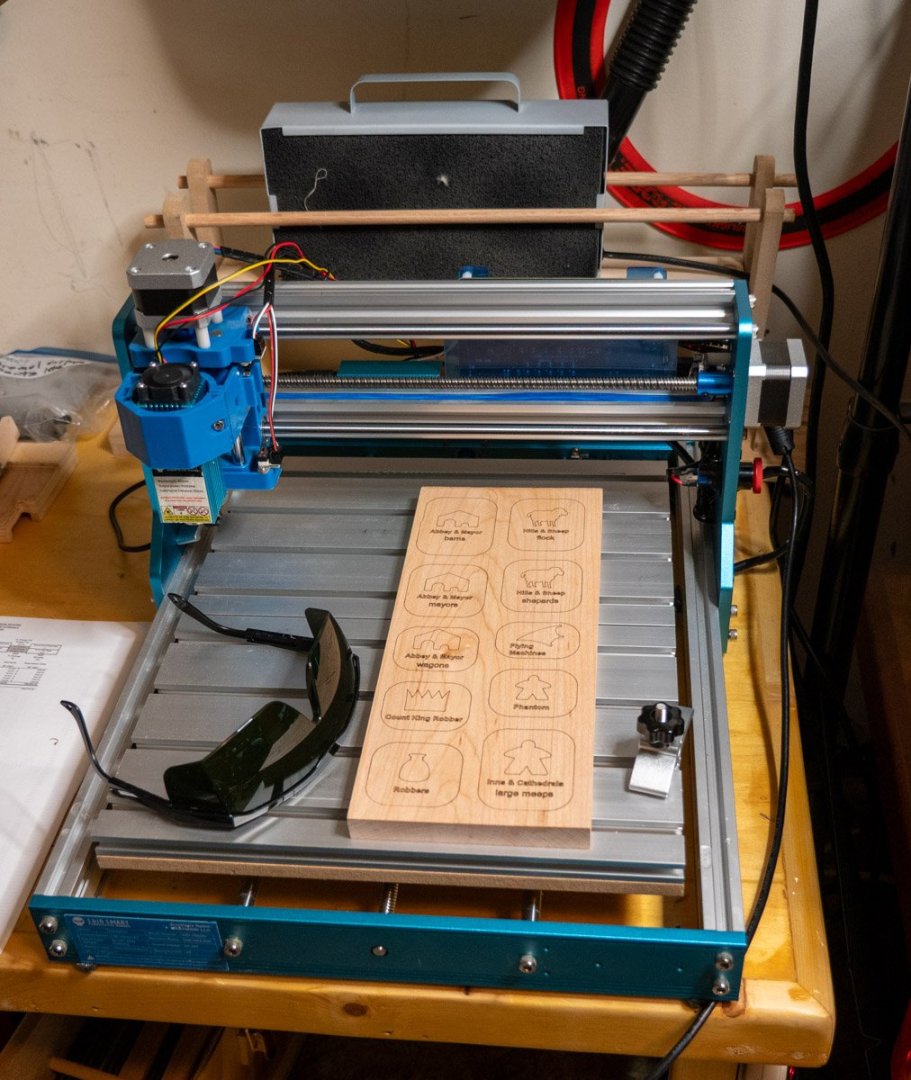

I bought a Genmistu 3018 PROVer several years ago. It can be configured to use a laser or a spindle motor; I bought a package that included both. I had a project that could use the laser to burn graphics in wood (a fancy wood burner). I upgraded my machine with an expansion kit to increase the work envelope of the machine. The Genmistu is a good learning machine and they also have good support. I discovered the spindle configuration is helpful in model ship building. The first thing I made was stairway sections to replace broken pieces. I took measurements, drew it up in CAD software, converted the file using CAM software, and ran the G-code file using controller software to operate the machine; I was able to duplicate the original parts. I made a jig by routing a shape for railings, I used the jig to bend brass wire and made railings that all turned out the same. I scanned a plywood piece and created pieces to cover the plywood by cutting walnut veneer with the spindle. Learning a hobby CNC machine requires that you learn a variety of software. I found the laser configurations with Lighburn software was easy to learn, Lightburn is probably the preferred laser/machine control software; it can be used to design and control your machine. For the spindle configuration I used free software but you need to know how to troubleshoot different software working with each other (I experienced frustration until I figured it out). Based on my experience with the Genmistu I bought a Onefinity CNC router for my garage, a bigger, more powerful machine. I also got VCarve software to produce G-code files for my Onefinity. it is a complete product like Lightburn except it is for routers (I can use it for both of my machines). VCarve can also produce carvings using clipart. I wrote manuals to operate and service industrial CNC machines so I have the basic knowledge of how G-code works and how CNC machines work. This is useful knowledge but it isn't necessary if you have good software like Lightroom or VCarve. I bought my first hobby machine to perform a specific project but I knew there is potential for other uses. I considered the cost to be tuition to learn CNC software and processes. Manufactures often have forums that I've used to help solve problems. I use my garage CNC router more often than my bandsaw now.

-

My model ship building is my winter hobby and I've transitioned to other hobbies. I found time to process the barrels I made with the Vanda-Lay Micro Lathe with needle files. The four barrels on the left are from the kit, mine are on the right, they turned out so-so. I'll probably try again next fall after I sharpen the turning tools and prepare a hardwood spindle.

-

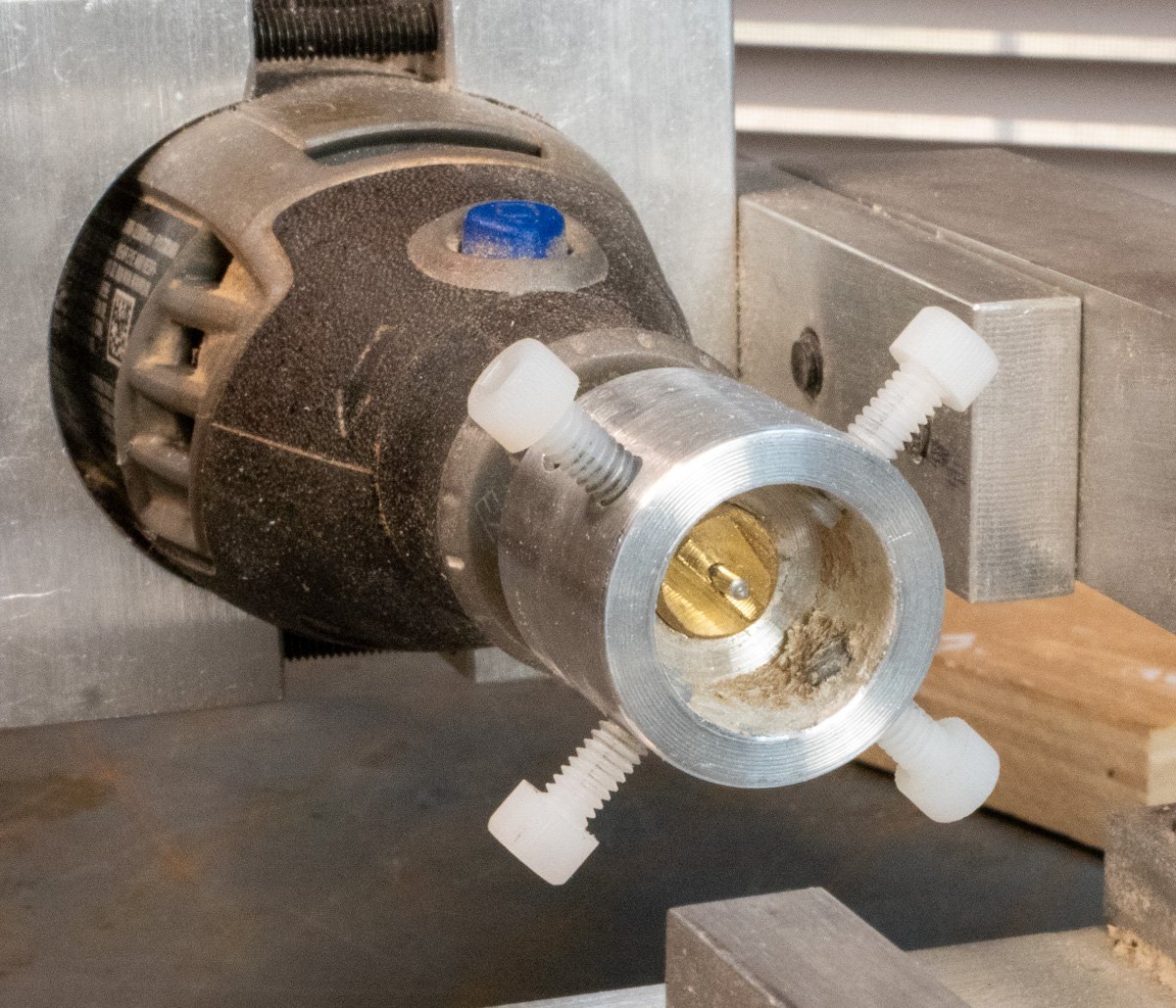

I have the Landa-Lay micro lathe attachment. I’m proficient with my 1221 mini lathe and thought the micro lathe might be something I might use. I configured my Vanda-Lay drill press with the micro lathe attachment, it is not difficult but it takes some time. I’ve used it a few times and it is a very light duty lathe. I picked up a cheap set of small lathe tools (I can always use them with my mini lathe) and I used a couple Micromark chisels. The chuck has a 1/16 inch pin to help align the spindle stock, you need to drill a hole in the stock to be able to slide the stock into the chuck. The chuck has four nylon thumbscrews to hold the stock in place. I also drilled a 1/16 inch hole to align the stock with the live center. The live center fits into a bearing in the tail stock. I had a couple pieces of ½ inch pine spindles to try, I had to knock off the corners to make the spindle fit in the chuck. The pieces I used were probably as large as the lathe can handle. My goal was to see how the system worked and see how the small lathe tools worked, I also tried to make some barrels for a current build (I got a couple that might work with further processing). I used the Micromark chisels as turning tools for the smaller piece. It makes a mess: I used the micro lathe to make some beam supports. The 31 mm supports were as small as the lathe could handle; I turned one half of each support, removed and reverse the stock to turn the other half. The turning tools weren’t very sharp, the chisels I tried were sharp and they worked better (made a smooth bead). I had to run the Dremel at a high speed because when you are too aggressive with a turning tool it will slow the rotation speed down (you could stop the Dremel). With a light touch the system works. If you don’t mount the stock properly, it will fly off (happened to me twice). I'll be returning it to the Acra mill drill press configuration which has more uses for me.

-

I've been making progress. I figured the lower decks would be dark places but I think my staining turned out darker than I intended. Before I installed the exterior planking I drilled pilot holes in line with the rear cross beams in case I want to add lighting in the future (I have not looked into lighting). I'm trying to decide about painting the canon doors. My fancy frame covering will probably not be noticed but I know it is there - I had fun making it.

-

OHOH I discovered two mistakes I made earlier in my build and some wood shortages in my kit. When I was cutting the 4x4 mm stock for the black planks I came up short 8 pieces. When I made the deck supports, I noticed they were light colored wood (limewood) and I used the walnut; I figured the kit may have changed – I was wrong. I found the 4x4 mm limewood while looking for more walnut and used it for the black planks but I was still 4 planks short (I found a piece from a previous build that worked). I installed the plywood gun ports backward. I knew the ports were offset on each deck but after I installed them, I realized the gun ports in top piece were aligned with the gun ports of the lower deck. I had to cut the tops off and glue them on the other end of the pieces. I discovered that my kit had no 2x5 mm limewood stock for the light-colored planks. I used basswood instead. I also discovered that the 2x7 mm sapelli wood (item 91) included in my kit is too short for the gunwales (a new chellenge). I’m making progress. I applied some finish to the planks before I paint the planks black to help prevent the paint from wicking to the light wood.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.