-

Posts

243 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Blue Mountains, NSW, Australia

-

Interests

Building stuff, electric mountain biking, kayaking, travelling.

Recent Profile Visitors

-

FrankWouts reacted to a post in a topic:

Royal Louis 1780 by EJ_L - Mamoli - Scale 1:90

FrankWouts reacted to a post in a topic:

Royal Louis 1780 by EJ_L - Mamoli - Scale 1:90

-

FrankWouts reacted to a post in a topic:

Royal Louis 1780 by EJ_L - Mamoli - Scale 1:90

FrankWouts reacted to a post in a topic:

Royal Louis 1780 by EJ_L - Mamoli - Scale 1:90

-

FrankWouts reacted to a post in a topic:

Royal Louis 1780 by EJ_L - Mamoli - Scale 1:90

FrankWouts reacted to a post in a topic:

Royal Louis 1780 by EJ_L - Mamoli - Scale 1:90

-

FrankWouts reacted to a post in a topic:

Royal Louis 1780 by EJ_L - Mamoli - Scale 1:90

FrankWouts reacted to a post in a topic:

Royal Louis 1780 by EJ_L - Mamoli - Scale 1:90

-

Eugenio Treviño reacted to a post in a topic:

HMS Victory 1805 by DarkAngel - Corel - 1/98

Eugenio Treviño reacted to a post in a topic:

HMS Victory 1805 by DarkAngel - Corel - 1/98

-

popeye the sailor reacted to a post in a topic:

Wasa by md1400cs - FINISHED - Corel - 1:75

popeye the sailor reacted to a post in a topic:

Wasa by md1400cs - FINISHED - Corel - 1:75

-

md1400cs reacted to a post in a topic:

Wasa by md1400cs - FINISHED - Corel - 1:75

md1400cs reacted to a post in a topic:

Wasa by md1400cs - FINISHED - Corel - 1:75

-

BLACK VIKING reacted to a post in a topic:

Wasa by md1400cs - FINISHED - Corel - 1:75

BLACK VIKING reacted to a post in a topic:

Wasa by md1400cs - FINISHED - Corel - 1:75

-

EJ_L reacted to a post in a topic:

HMS Victory 1805 by DarkAngel - Corel - 1/98

EJ_L reacted to a post in a topic:

HMS Victory 1805 by DarkAngel - Corel - 1/98

-

EJ_L reacted to a post in a topic:

HMS Victory 1805 by DarkAngel - Corel - 1/98

EJ_L reacted to a post in a topic:

HMS Victory 1805 by DarkAngel - Corel - 1/98

-

Hull 2nd coat Haven't used any filler as yet, I want to see how the stain fills up the gaps first. May get away without using filler Before First coat has dried and cured, leaving a mat finish. However the more layers of stain, the more of a satin like finish it has. After Still wet with a nice glossy look.

-

I've been following your excellent work Mark, very impressive. Thankyou, your build will be very inspirational and useful when it's time for me to build the Wasa.

-

Hull update Time to stain the hull thus far, just thought it would inspire me to continue my build. I used the same japan black stain I have been using on the whales. This is the first of 3 - 4 coats. Takes 12 hours to cure in between coats. Enjoy the pics edit I'll take another pic after the stain has dried and cured before the next coat.

-

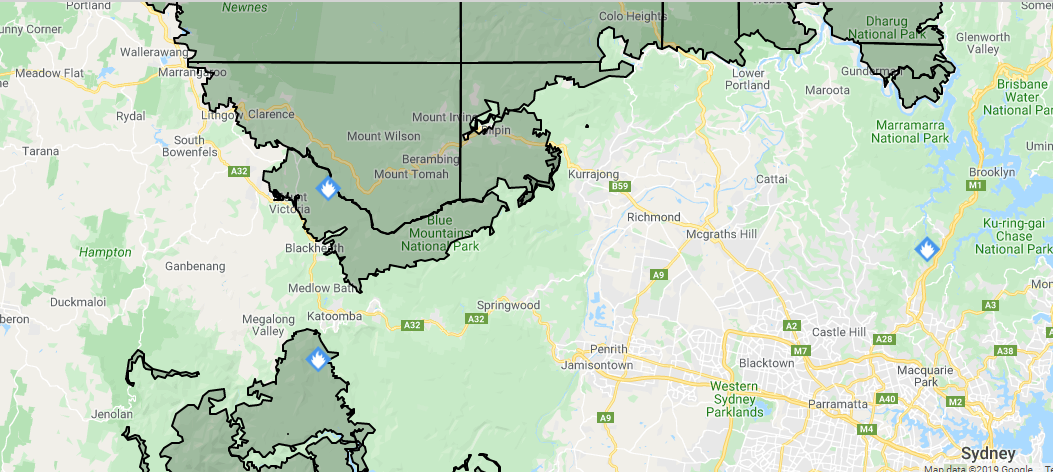

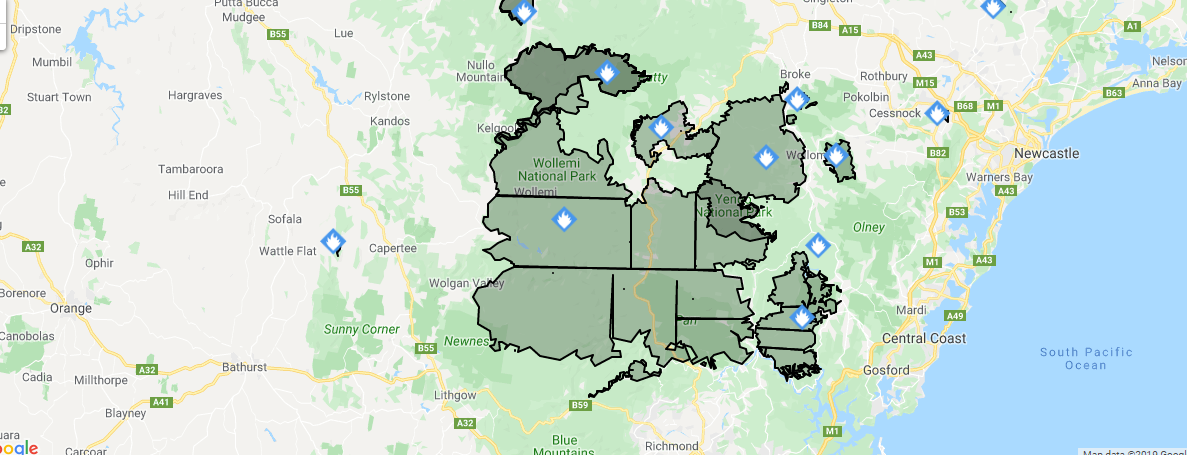

Fires NSW update... fires have come through my town with ember attacks destroying about 10 houses. I have been looking after my friend and his dog after they got evacuated. Fire has been stopped for now as backburning around the mountain hill's of Lithgow has been in effect for over a week. Several fire's have merged, and there is another major fire on the way from the south. However I think everything is ok for now.

-

Thanks everyone for your kind thoughts. The guy in hospital in the bed next to me works in the command center for the local NSW Rural Fire Service and is a good source of information about the local fires. When he was a teenager he remembers Lithgow surrounded by fires in the hills on three fronts and the town in the valley of Lithgow survived ok. So that gives me a bit of confidence as we only have one fire front to consider at this stage Maybe the house will be ok, just need to prepare for ember attack from the massive pine tree's near the highway a couple of streets away.

-

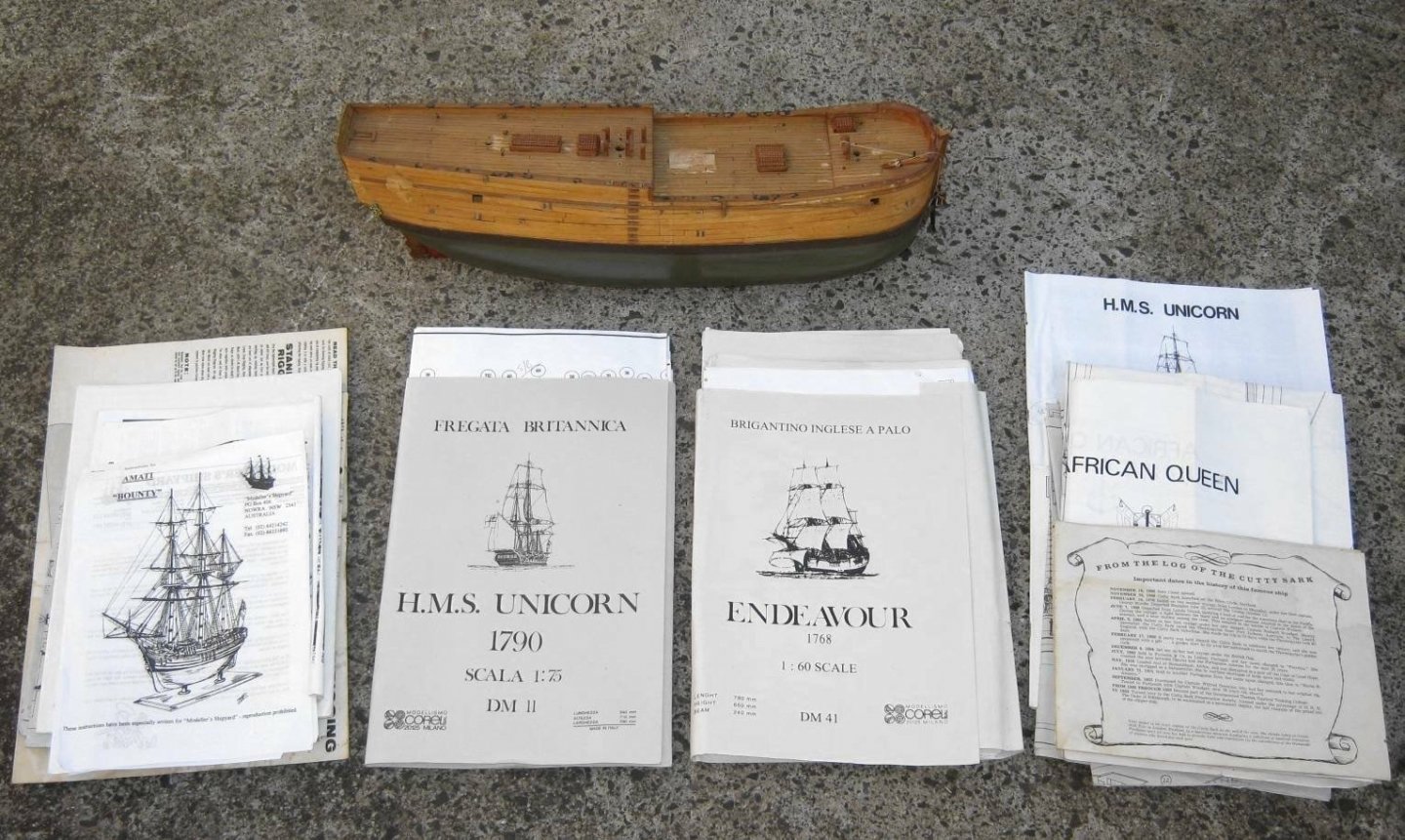

Hey Mark, welcome back. I hope your missus is ok. Currently I'm in hospital on morphine probably for a few days with a Chrohn's disease complication and there is a huge fire slowly burning towards my town and I am a bit pre-occupied with thinking about evacuation plans, I may not even take my HMS Victory model with me.... I have the Wasa still unpacked in the box... so I'll probably take that as priority as is. My Victory build stuff is everywhere and not convenient to pack up quickly. On the plus side I have acquired quite a few plans for some nice ship builds.... Like the Royal Caroline 1749 by Panart... Lancia Armada 1803 by Panart... African Queen by Billings Boats.... HMS Unicorn by Corel.... HMS Endeavour by SM 4 Corel and Artesania Lantana... HMS Bounty by Amati So that is nice. I also acquired a finished hull for the HMS Endeavour in 1:60 scale to complete the opened box Corel SM 4 I have. So I may put that in the 4wd too if I have room.

-

DarkAngel reacted to a post in a topic:

HMS Victory 1805 by DarkAngel - Corel - 1/98

DarkAngel reacted to a post in a topic:

HMS Victory 1805 by DarkAngel - Corel - 1/98

-

Sanding and Sealing the hull. Q. Does anyone have any suggestions on how to deal with fine gaps between the planks on the hull. I have noticed sanding is great for adding dust into any cracks, however the process of cleaning the timber to prepare it for staining will remove most of this wood dust and reveal cracks once more. The stain I'm using over a few coats will fill small gaps, I'm also thinking of dripping the stain along the plank joins as they are full of dust and then sanding smooth each plank before staining the cleaned up surface of each plank... Does anyone have any suggestions they have found works well ? Using a glue / wood dust slurry has it's own issues as the stain doesn't coat glue and leaves clear glue. So I'd have to somehow stain the wood dust before adding the glue slurry... Also the stain is spirit based and does not mix well with PVA glue, infact PVA does not stick well to stained material.

-

New Purchase I found a sale on some old ship building plans for the Corel Endeavour 1:60 DM 41 Corel HMS Unicorn 1:75 DM 11 Billings Boats African Queen 1:12 Amati HMS Bounty Also a Corel completed hull of the Endeavour... this goes great with the Corel HMS Endeavour 1:60 DM 4 kit I bought without the Bulkheads I wouldn't mind building the HMS Unicorn and Bounty later if I can source the right raw materials. My friend is keen on the African Queen.

-

Shipwrights Journal Build Plan Calendar December Complete hull planking underneath the waterline on both sides Stain outer layers on hull Add staircase leading to 3rd deck behind stairs near middle mast and above Ships Galley Consider opening up Upper Gun Deck floorplan to increase floor space (and add more fittings incl. complete long 12 lb'er cannons with carriages) Design and build prototype carriage 64 lb'er Carronade's from wood to accomodate new Brass 20mm Carronade's. Design stern cabin floor plan, dedicate lowest level for electronics setup and maintenance access. Design circuit diagram for ships electronics and input area's for charging micro usb port(s) for battery cells. Test lighting system and install once lanterns crafted New Supplies Bluetooth circuit relay 12v x 4 to activate with smartphone Brass 3mm x 0.5mm OD tubing for crafting lantern's Wood turning knives

-

December update Here's a look at where I am up to currently... progress has slowed last month and still working on planking the hull and another redo of the Upper Gun Deck and Quarterdeck. Hull progress Filling in another section, once completed with one more filler plank I shall add the Japan Black stain and see how that looks Upper Gun Deck Redo I'm redoing the stairs leading down from the Upper Gun Deck after discovering they were positioned in the wrong position, the stairs should lead down from the top of the pic, not the right as they had been previously. This positioning may be due to the ships galley below... I thought to make the ship as accurate as possible to the real thing required me to make the change. After making the grill above in the Quarterdeck larger around the chimney from the Galley, there will be an opportunity to see below into the Upper Gun deck which enables me to add the ventilation grill from the Galley one more level down, and the chimney pipe.

-

Taking a break It feels like Summer is here, and today I think it is. People are out and about and friends seem to be coming out of the woodwork. My build has slowed to planking one strip of wood per day. Things are looking good Egyptian Barge doco I saw a documentary on a 3500 BC Egyptian barge that was uncovered next to the Great Pyramid, and a marine archeologist decided to try and rebuild a replica to see if it could transport a 2.5 tonne block of limestone. What was interesting is that the boat was only held together with rope sewing the planks together... also they discovered in order for the barge to be watertight they submerged the barge underwater so the wood fibres would swell and seal up any joins to make the ship watertight. The rope also swelled and tightened making the ship super strong. This smallish barge carried 13 men or up to 19 tonnes of cut pyramid stones down the nile following the currents when the Nile was in flood during it's hayday.... Amazingly it was also disassembled after the flood season and stored in caves underground until the beginning of the next seasonal flood, when it would be joined together again !

-

Cannon update The 30mm Corel cannon's arrived and I have noticed they are the same cannon's in the Corel Wasa kit. These cannons are perfect dimensions for the 12 lb'er long cannons, and I'm thinking of cutting the barrels down for the Short 12 lb'ers. I like the look of the wider cannon barrels and how they sit on the stock carriages for the Short 12 lb'ers on the Quarterdeck. I think the cannon wheels could be slightly bigger and thicker... will relook at the spec's Mark gave me. The width of the barrel on the Corel 30mm cannon is a bit wider than the stock 12 lb'er cannons and also match nicely with the 4mm x 18mm Billings brass half cannon's to finish the cannon layout for the Upper Gun Deck. Here's some pics

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.