-

Posts

2,834 -

Joined

-

Last visited

-

md1400cs reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

md1400cs reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

md1400cs reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

md1400cs reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

md1400cs reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

md1400cs reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

Hubac's Historian reacted to a post in a topic:

TITANIC by Force9 – Trumpeter - 1/200 - PLASTIC - White Star Liner

Hubac's Historian reacted to a post in a topic:

TITANIC by Force9 – Trumpeter - 1/200 - PLASTIC - White Star Liner

-

mtaylor reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

mtaylor reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

-

Mike Y reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

Mike Y reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

-

Mike, Yikes --- just catching up - 🙂 your work is so good! Cheers,

- 943 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Baker reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

Baker reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

Old Collingwood reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

Old Collingwood reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

mtaylor reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

mtaylor reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

Evan, I am very much enjoying following your build You’re also doing some great extra detail work as well. As a kid, and as a teenager I grew up, of course, with plastic cars and airplanes. Looking at your work in this medium is inspiring, and adding great personal memories. Excellent work and log. Your Titanic will be awesome indeed. PS in my opinion this ship does need to be built from plastic — PS 2 are you going to install real wood decks that are available for this kit? Cheers

-

I've had both of these for years - always perfect - I also, more recently, bought the large Proxxon Fet saw - probably "overkill" for my needs. Still mostly use the KS 115. But the larger saw is fabulous for angle cutting as the table swivels as well! Your work is so excellent you might also want to consider the Proxxon MF 70?? a very excellent addition. Regards,

-

I - so many of us - have been waiting for “half as long” as it took Nat. Geo. discover where the Vasa had sunk to actually be able to buy this stunning kit, which looked (past time) to be too amazing indeed. High on so many “buy” lists indeed 😔 Expensive, PROBABLY, but too hard to ignore, and not buy- IMHO. PS: Forget about this one

-

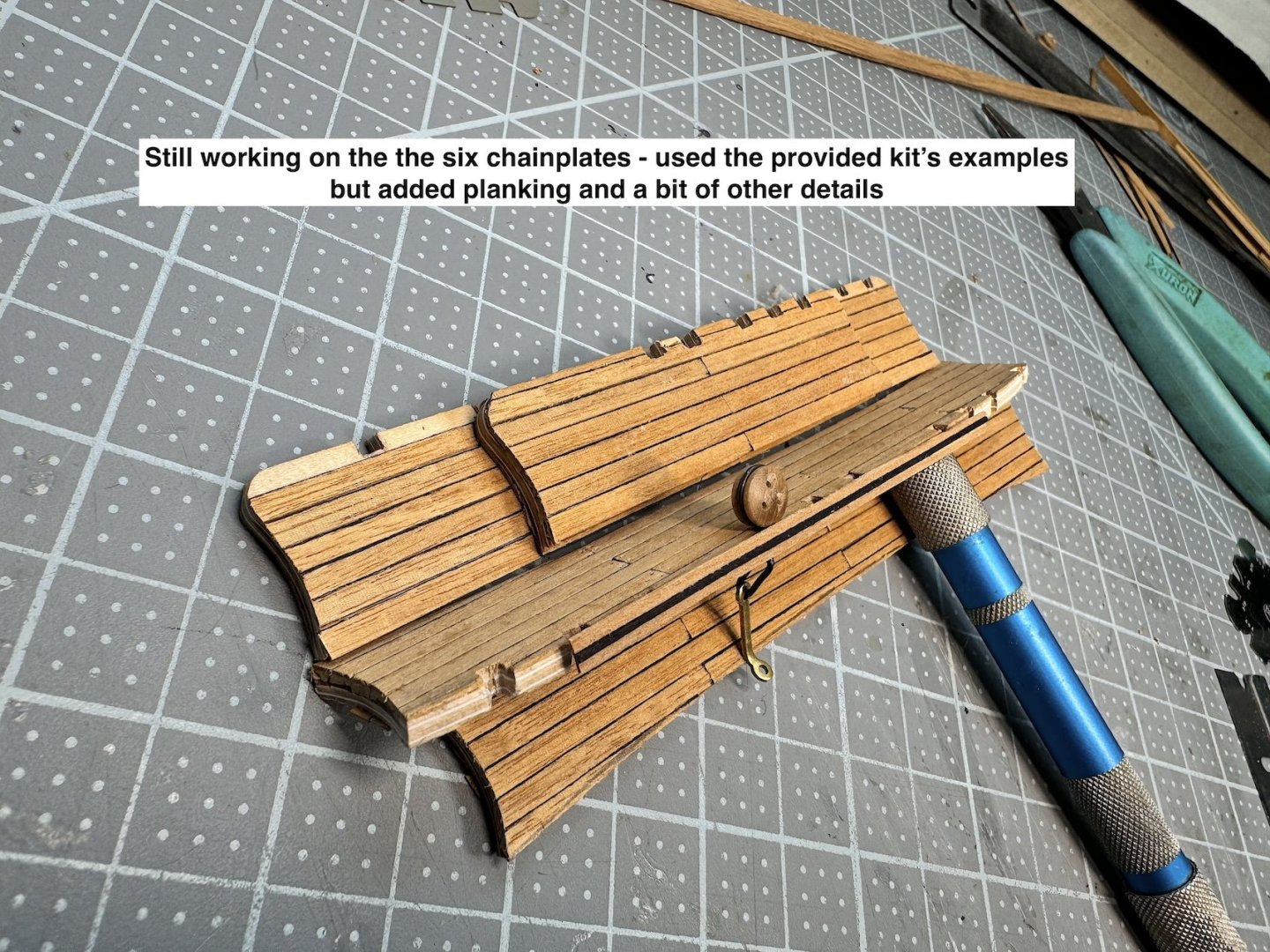

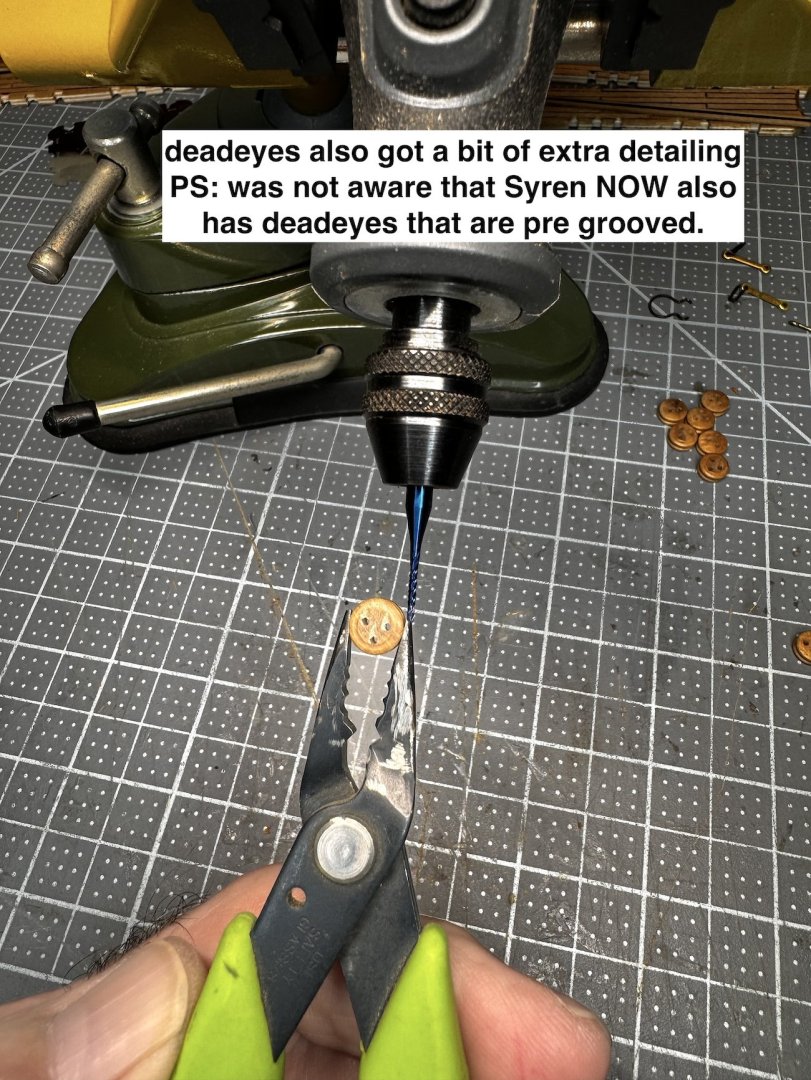

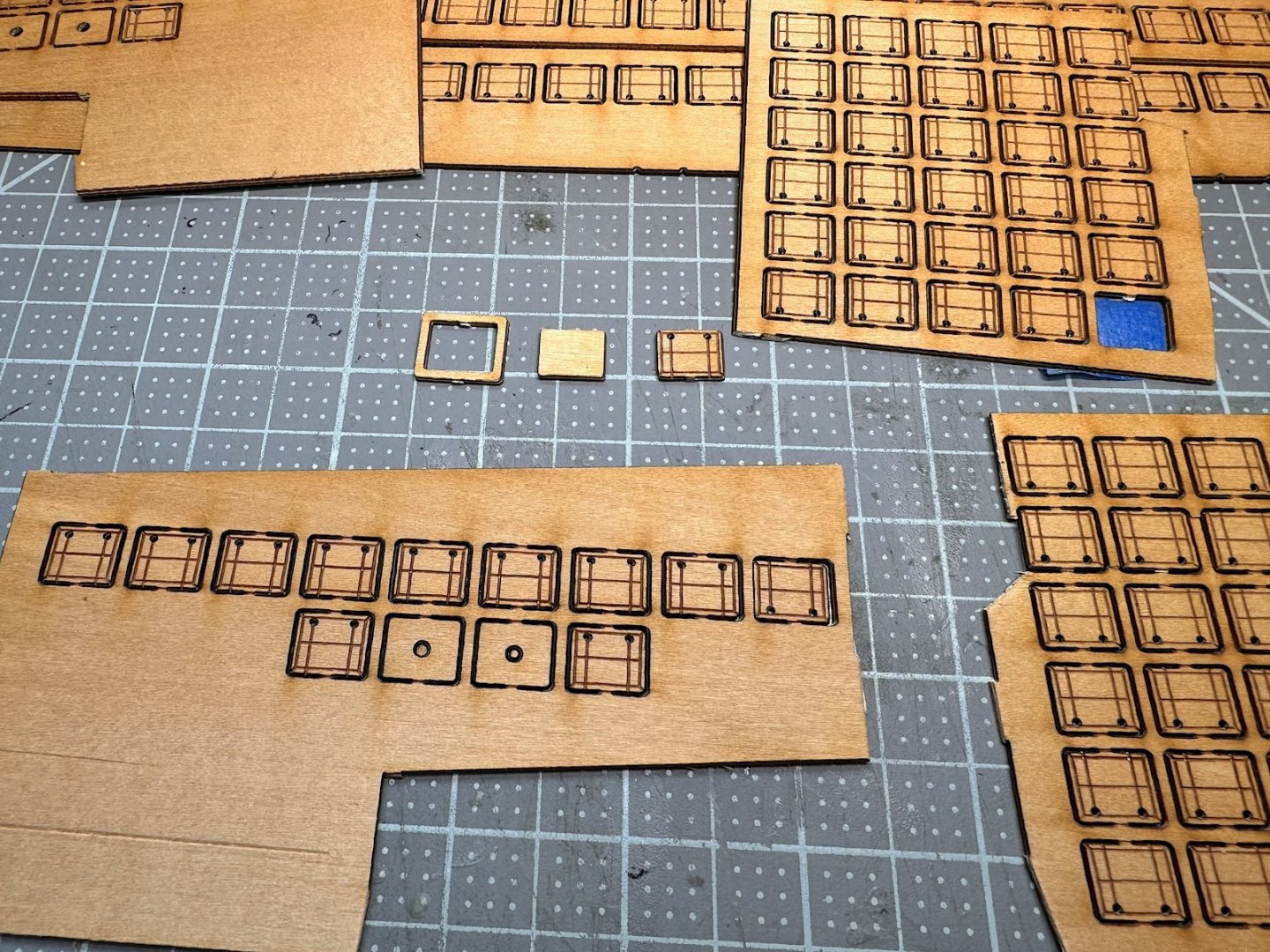

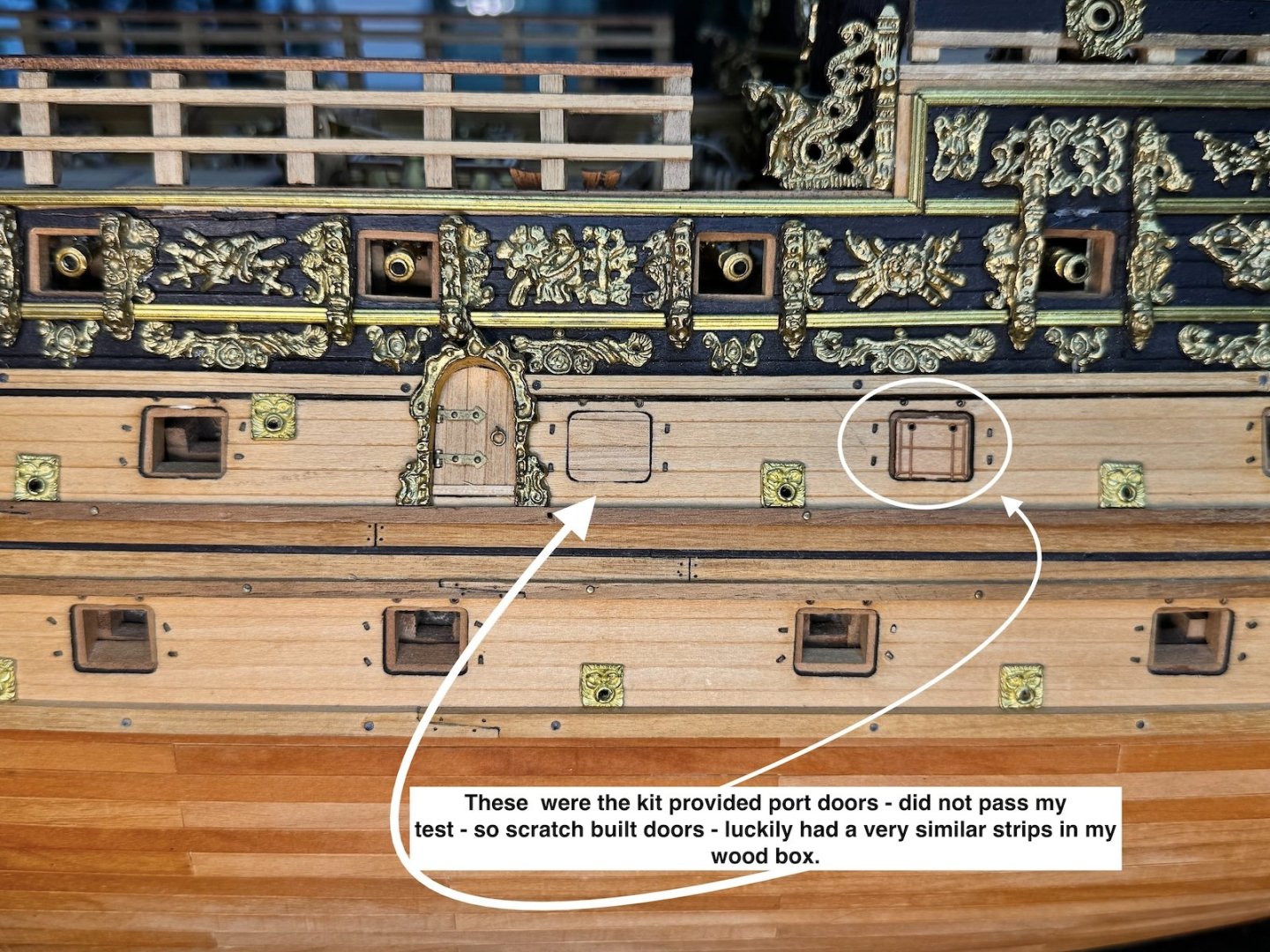

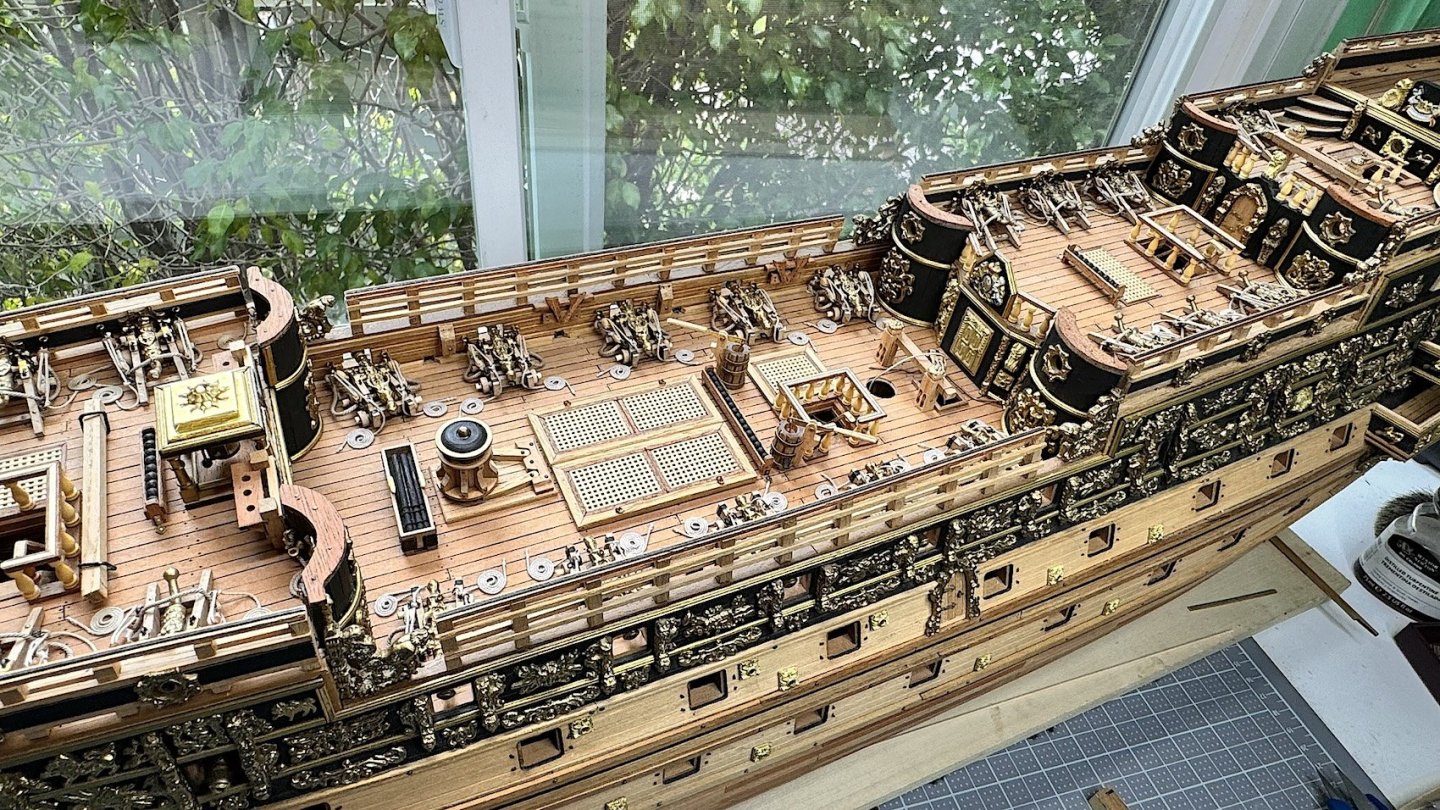

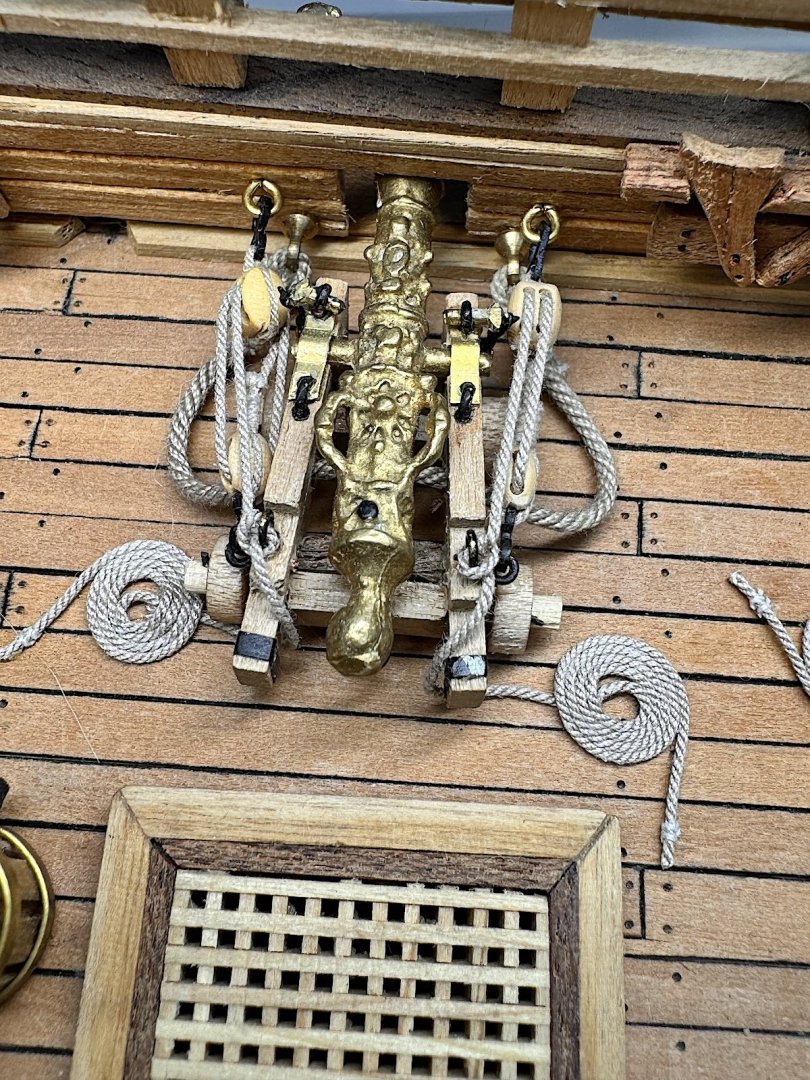

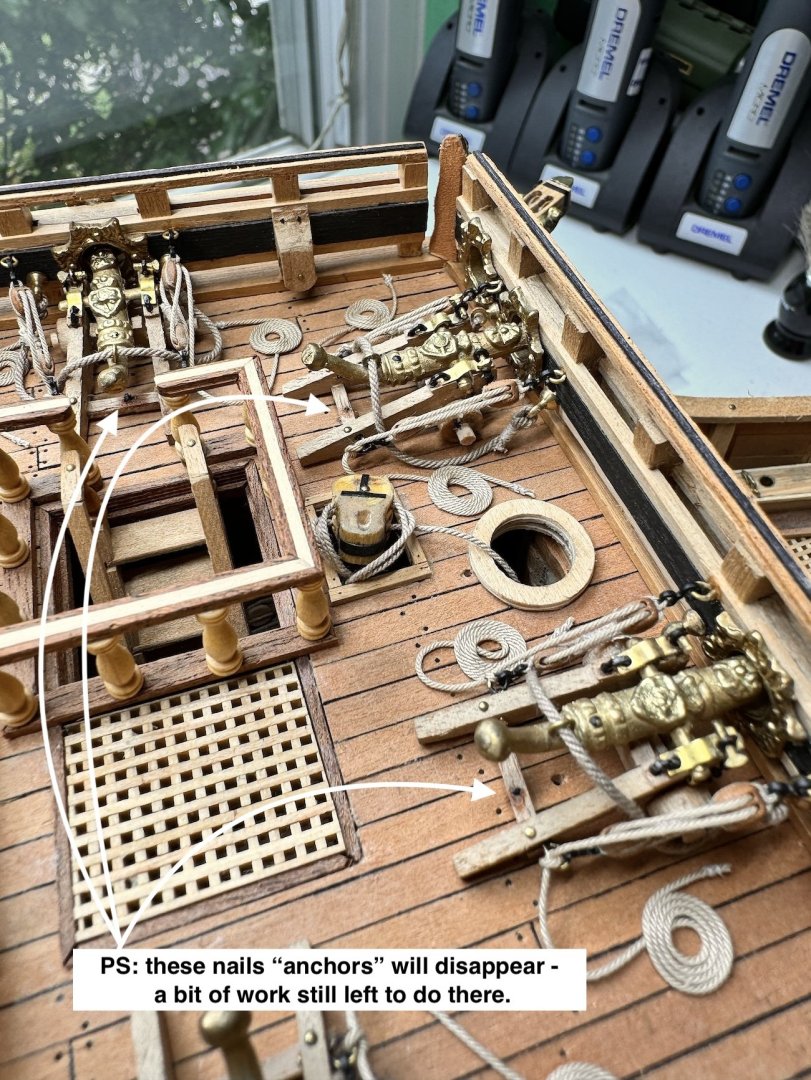

Hi, It’s been a while since I’ve checked-in as well as posting any updates. Been busy with other bits of my life. But, very lately, having found some disposable time I have done further work on this so far “lifelong” build. Some thoughts - 🙂 1) I know hinges should be black along with other bits as well. I chose leaving the hinges brass purely for their looks – given this ship’s hundreds of other bronze parts, and that this project bears very little relationship to any historical accuracy. as I’ve mentioned before……. 2) But, I am regretful that the gun ports (doors) appear a bit too thick. I had overlaid thin strips above some other matching wood strips that I had available, and cut to size. No other (to me available) wood matched the very light outer hull planks that run the lengths of the lower, and upper-gun decks. And I don’t have a wood strip sanding drum. So be it…. Thanks for your continued interest. Regards,

-

Marc, Been away from fro a while - just catching up -- As Gary said just above --- INDEED.... Regards,

- 2,623 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Such beautiful work - builders such as you rise to the occasion of such a complicated build given that 1000s of images of this ship that are available (helpful indeed - but those details are beyond my skill set) that said, errors then could become issues 😬 Not for you - perfect - my skill set will never rise to your great build — Big cheers to you 😊 We all have our comfort levels. Your work in this log has been SO appreciated - enjoyed following 👍 PS: when I was working I had a few days layover KLHR that - of course - put me on a train to Portsmouth - and Mary Rose before the museum was rebuilt to its current great rebuild.. Cheers MJD

- 527 replies

-

- caldercraft

- victory

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.