stuglo

Members-

Posts

707 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by stuglo

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

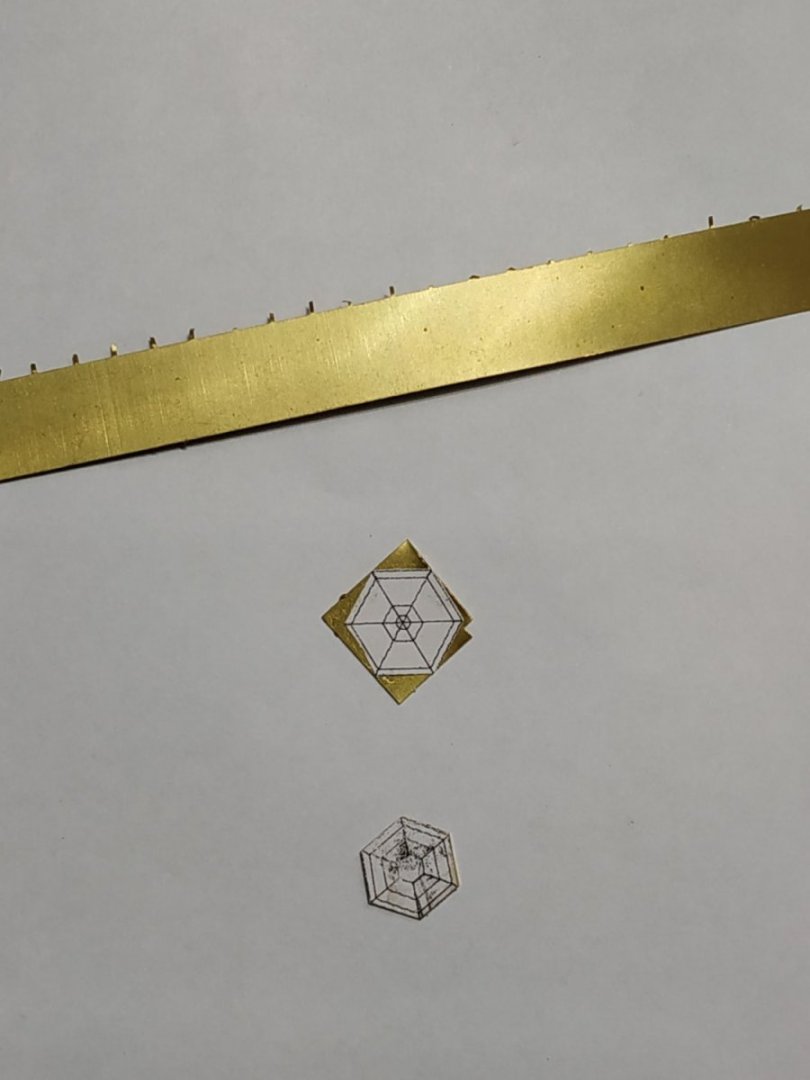

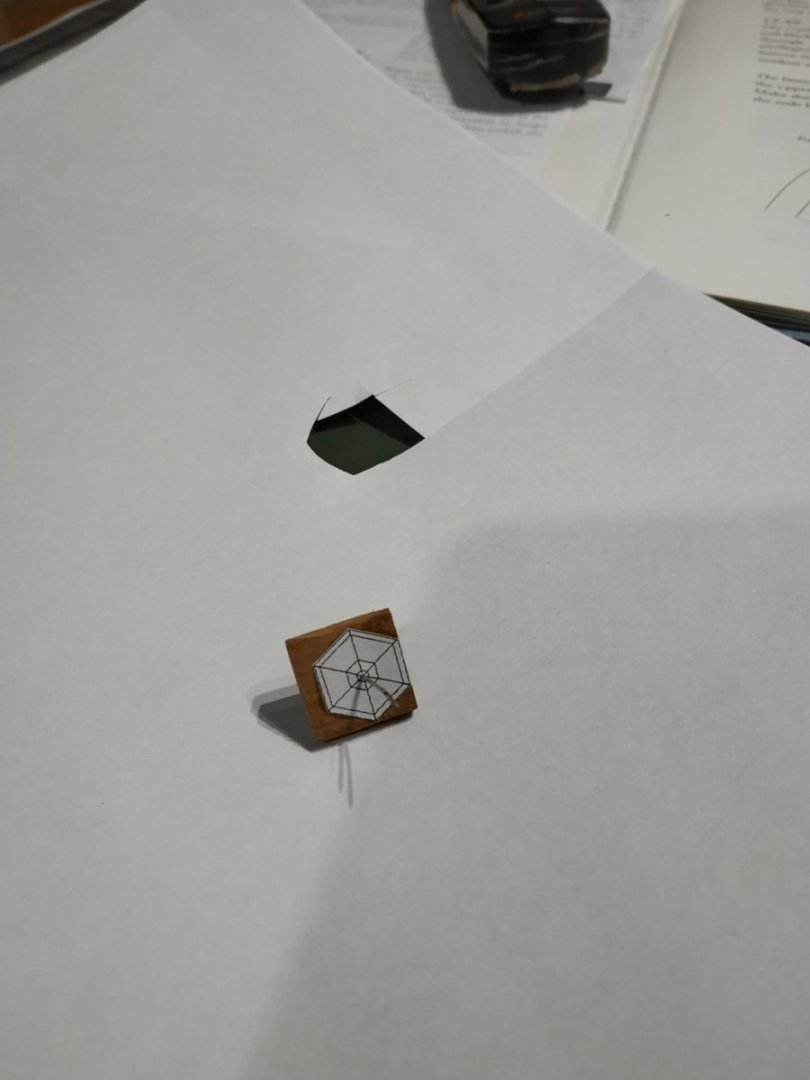

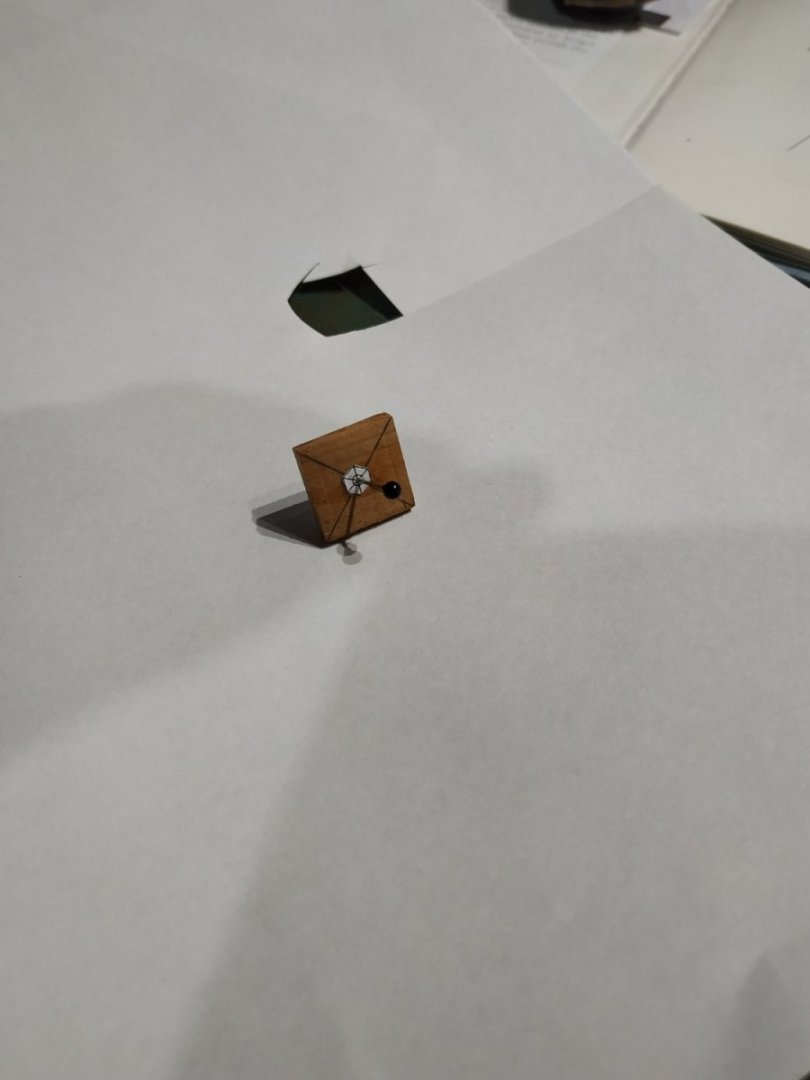

The Stern Lantern At first glance, intimidating, but with the usual TFFM breaking it down into stages, was do-able. The major hurdle- Munions and Door ( a hexagonal construct tapering towards the base)- were bought as part of the photo etched addition. The main difficulty is bending along the grooves between the sections. I spray painted with aerosol as I find it gives a better finish than “blackening” liquids. The inside is supposed to be red but I omitted this detail. Beneath is a thin Lower Rim. A symmetrical hexagon 13.15 mm across. I made it from a 0.18mm thick brass strip using the TFFM pattern.(A frame from etched parts from an old kit. I find cutting to shape difficult, so after roughing it out, use the band sander.) Epoxy to Lamp for rigidity and spray paint black. Roof. Thickness given as 3.18 but the drawing is more like 3.6mm Looking at my plans, I went with this. Used blank 16mm sq. and as instructed, drilled a small (.7) hole at 14.5deg.near the center. Cutting out the largest and smallest part of the patter, made a pinhole in the center, and threaded one above and the other below the blank. ENSURE a side above and below, aligned and sand to the pattern ALLOWING FOR THE “BULGES” as required.(also slanting aftwards). I used a small hand held band sander and it worked easier than I thought possible. Genius of the author of TFFM on display again. The Vent and Vent Top - are shaped from some scrap soft metal alloy, and coloured black. The Lights Cut from 0.26mm plastic sheet. I find though that even the smallest amount of glue gives vapors that cause opacity. ADVICE sought for the future. The Base. Similar technique to the Roof. Blank 11.5x6.5 and 4.25mm thick. Drill at 14.5deg, pin aligned pattern above and below, and sand to shape. Stool and Crank. I simplified these by making a thin rim with my brass strip, and combined the Stool with the part the Stool sits on (? is that bit called a tang). Again, something left over was exactly what I needed. Eyebolts either side of the Roof, and on the Capping Rail, above the Counter timber. Connected by Support Rods - 0.26mm for which I used covered wire, Central hole in Taffarel for the ensemble at the height shown on the plan.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

The Lower Finishing. Made in 2 parts, separated by the Lower Finishing Rail. An Upper Counter, depth 3mm. Rim as molding narrowing sharply from the Lower Stool. (Initially used a scraper from Artesena Latina, but this damaged the upper surface, so just beveled by sanding). Lower Finishing Rail- 0.8mm thick, slightly proud of the lower rim of the Upper Counter. Lower Counter. Took a blank 35x10x8mm. The upper surface from the given patten, slightly smaller than the overlying Rail. The downward narrowing is more acute aft. Inward surface shaped to match ship’s side. The Drop - made separately. This is pierced by a discharge tube from the Head inside the captain’s cabin. Console Brackets. Adapted from the pattern in TFFM- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Upper Finishing. A very varied structure. Often flamboyantly carved, but often simplified on models. After shaping my block to fit on the Upper Stool, I sanded the curves, up/down and athwartship,in a rather arbitrary fashion. The decorative crown (another leftover) and small blacked chain to represent carved vines (rather fancifully).- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

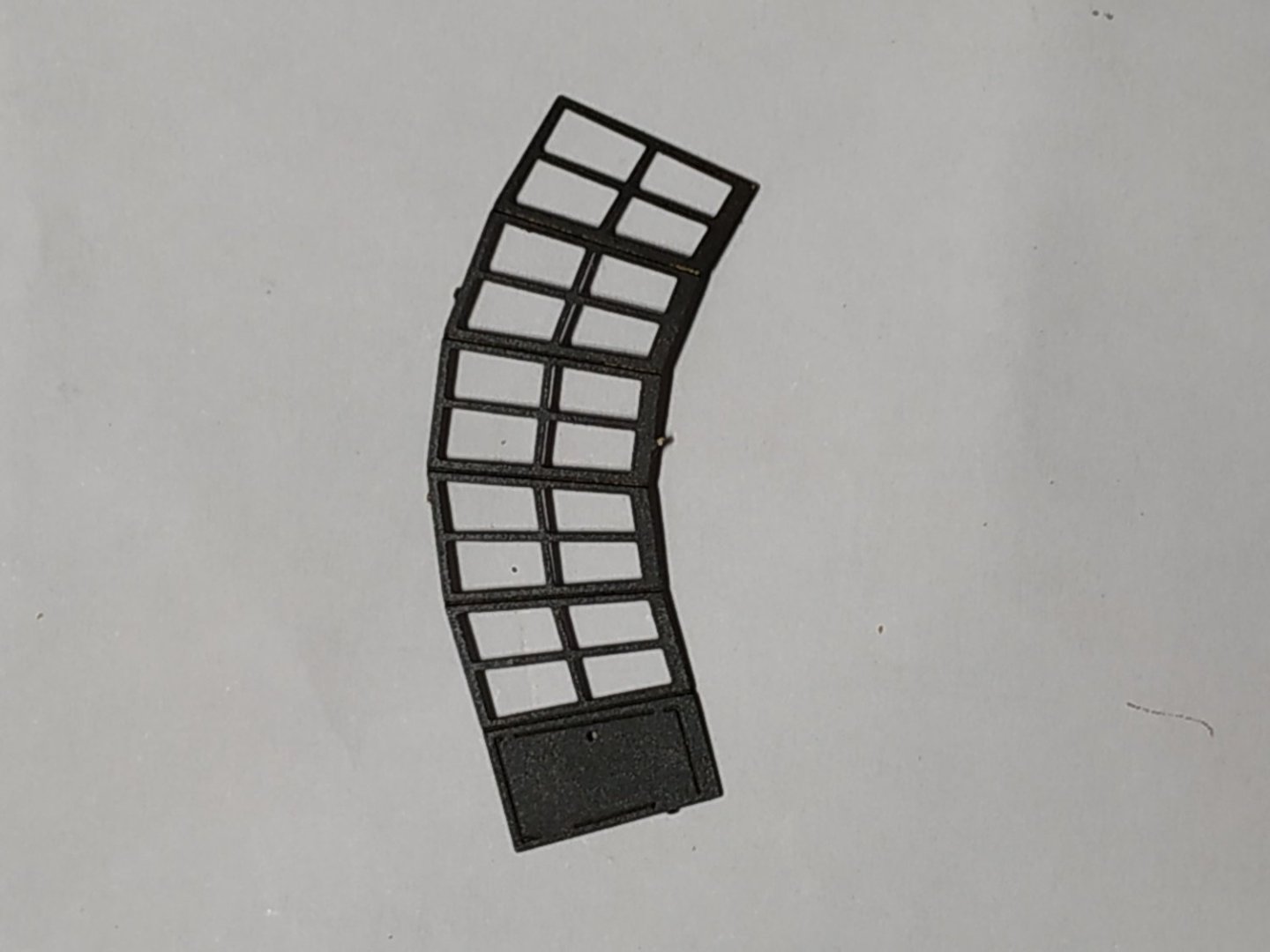

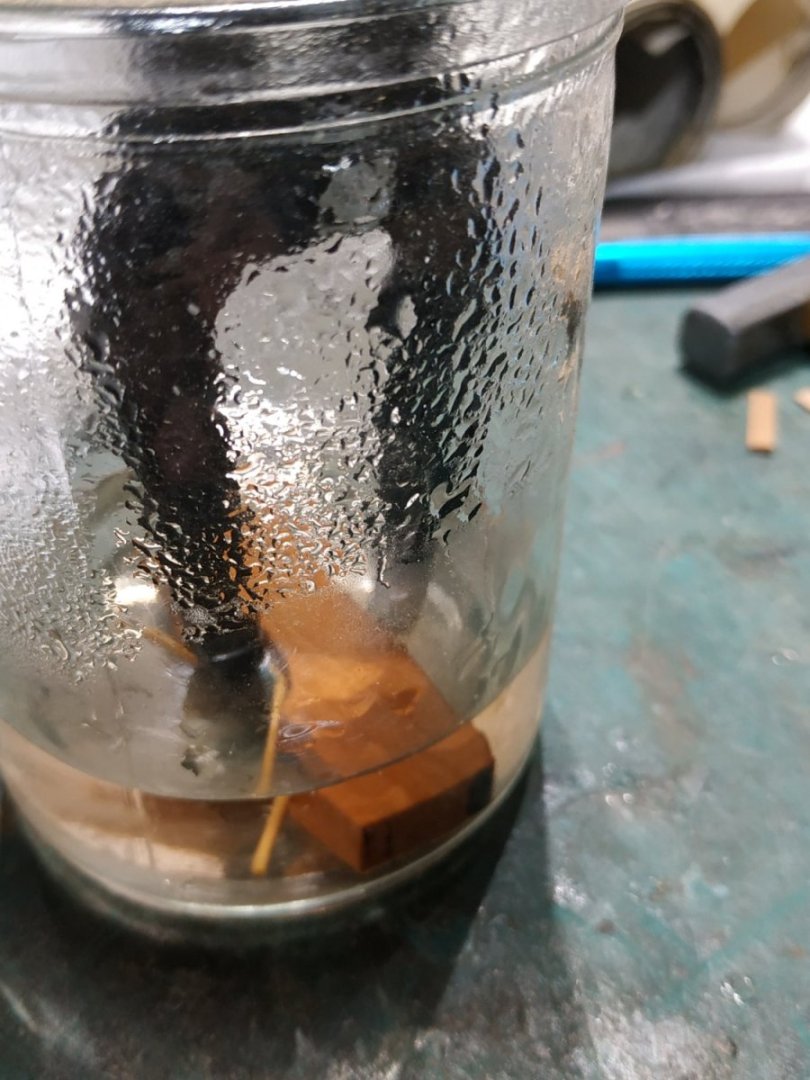

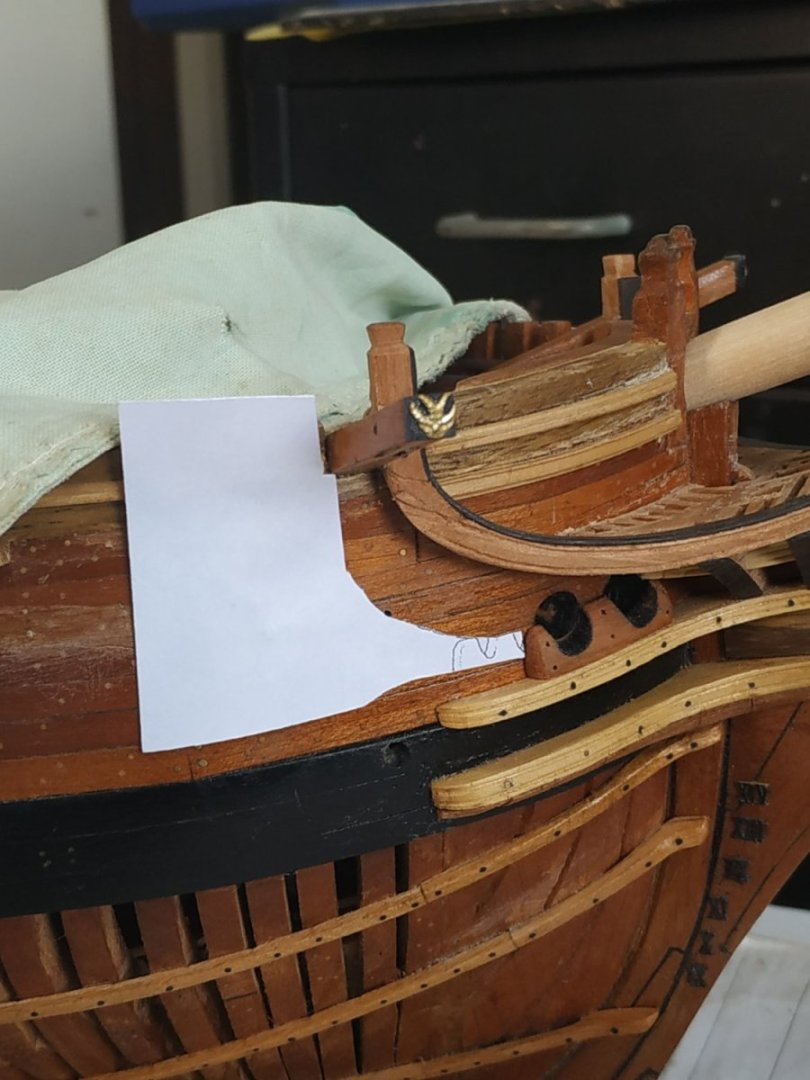

Munions and Lights 4 in parallel. The outermost against the ship’s side and so shaped. Can’t see that dimensions are given, so made 3.60x1.35mm . With a central space , the fore and aft sides appear to differ slightly in width. The frames seem to be set to the back of the munions, but I found this difficult in practice. I had totally forgotten how I made the frame, but was able to refer to my blog of May 15,2022. The main difference was the extension of the frame into the Bell section of the Upper Stool. This I made and fitted separately. While the glue for the Munions was drying, I shaped out a block as the first stage in making the Upper finishing. I usually soak the piece in hot water, before applying an adapted soldering iron against a wooden curve. Because of the peculiar curve, after a quick soak, I clamped the piece to my shaped blank which allowed it to slowly take and hold the shape while still in hot water. It worked nicely. I then fixed this separately. The middle light was made with the plastic shaped as required above the upper rail but unframed, so that the light can be slipped into the upper frame while fitting. The Munions and framing do not appear to be in parallel, but this is an optical illusion. The Pilasters are again leftovers, adapted for the purpose- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

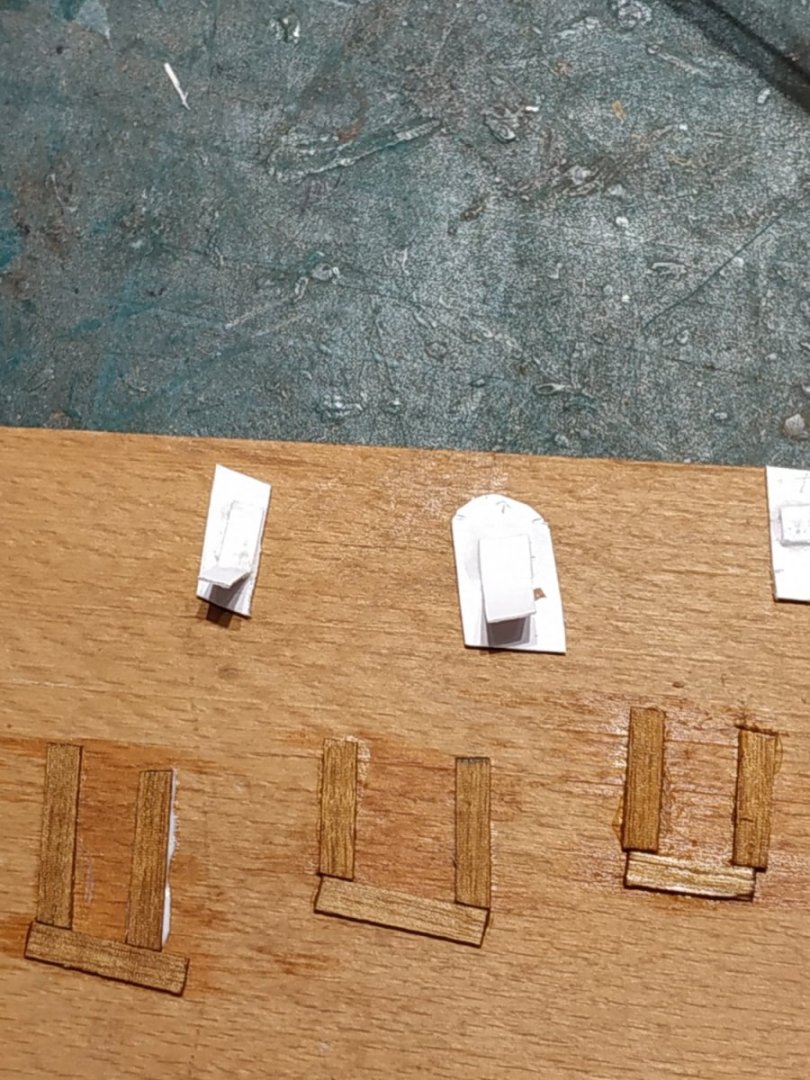

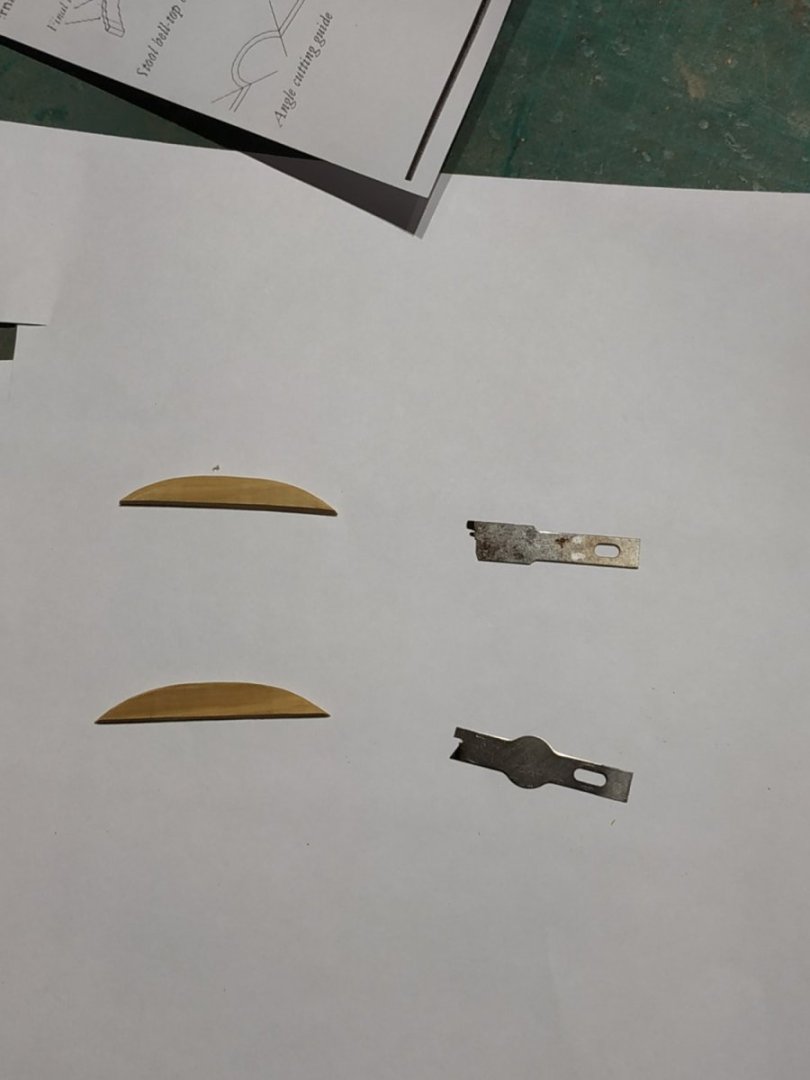

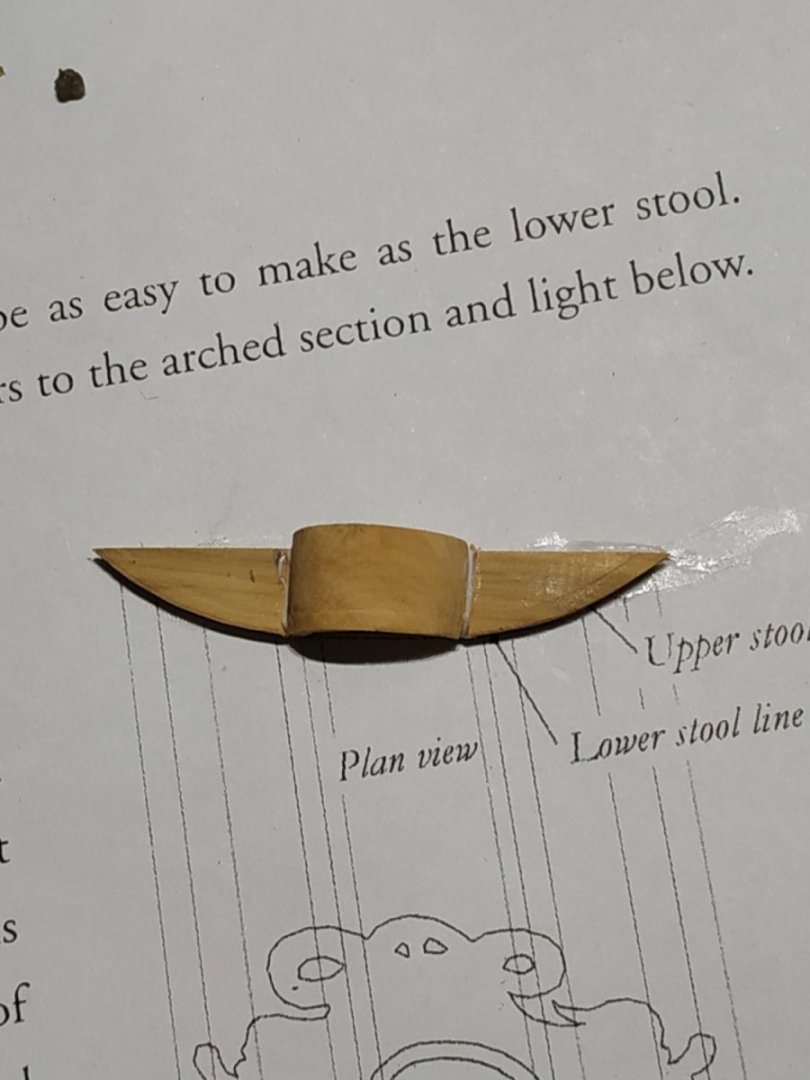

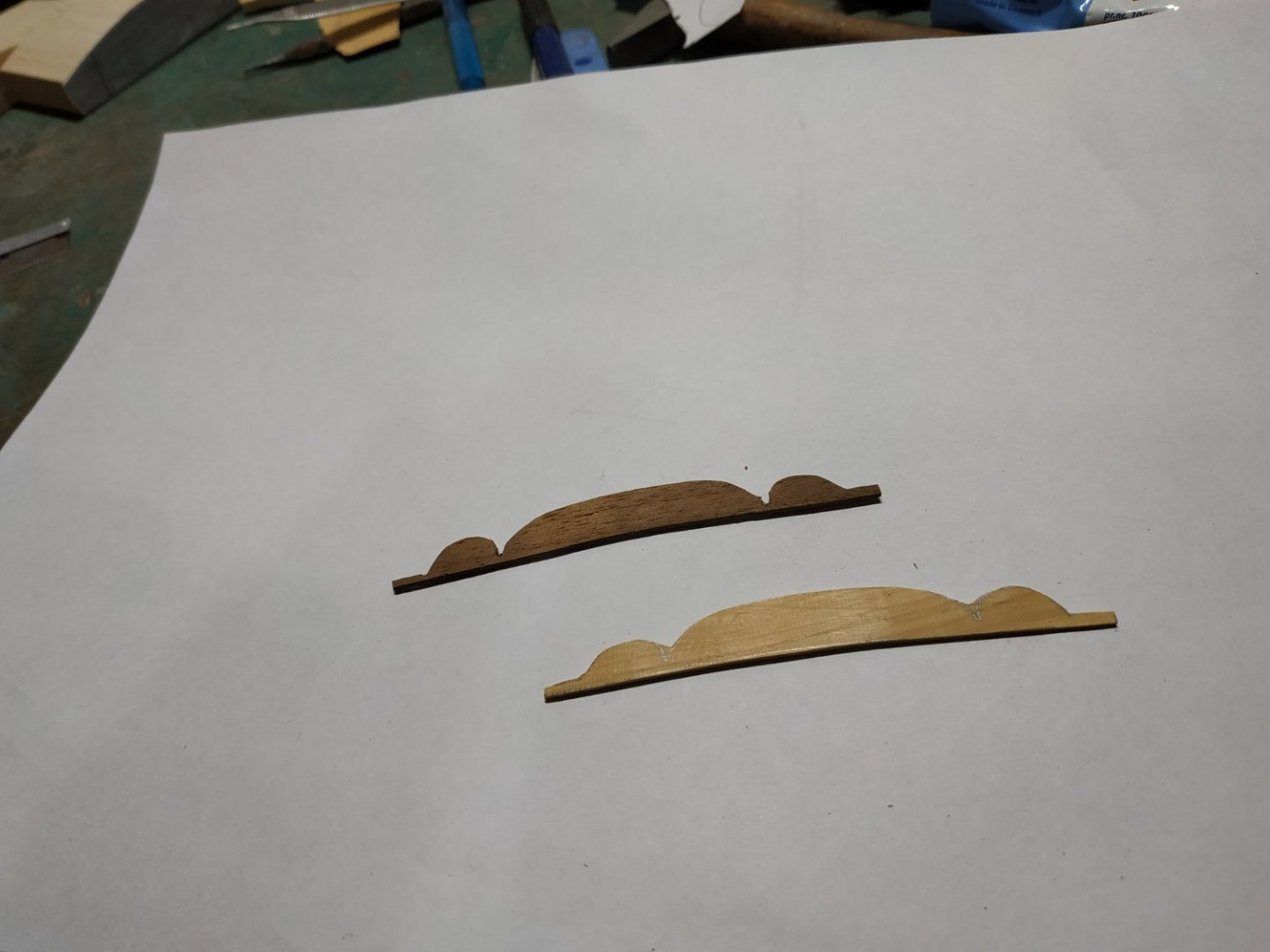

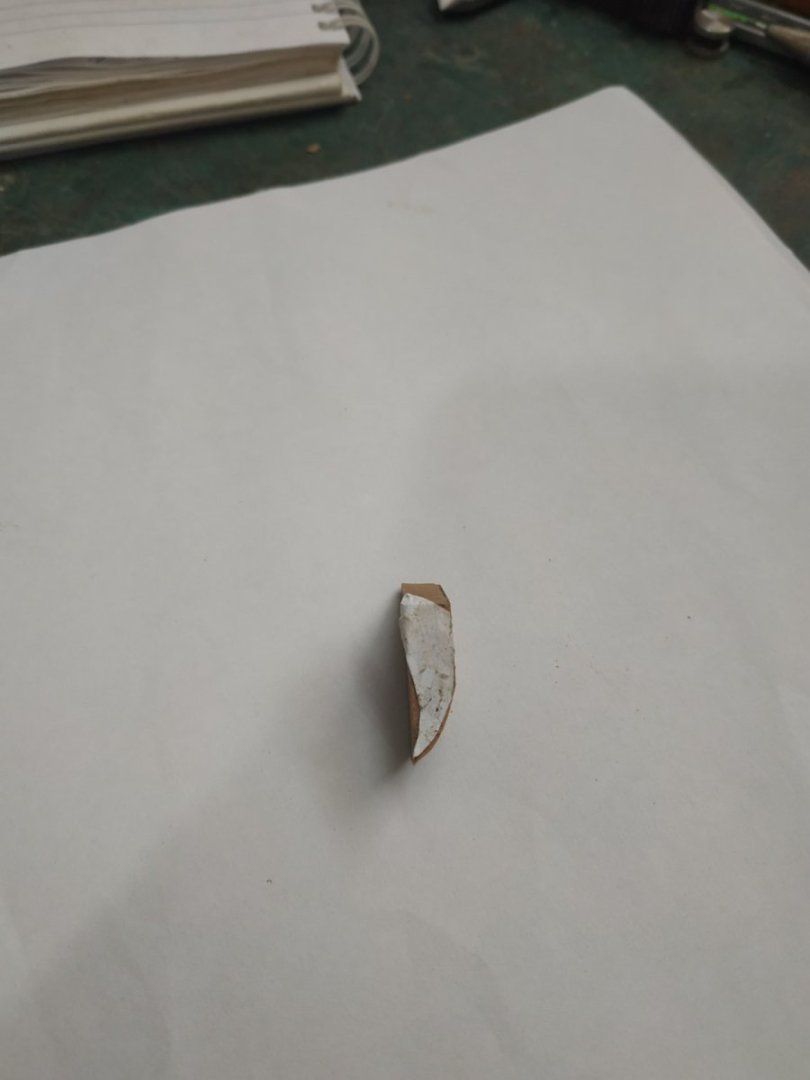

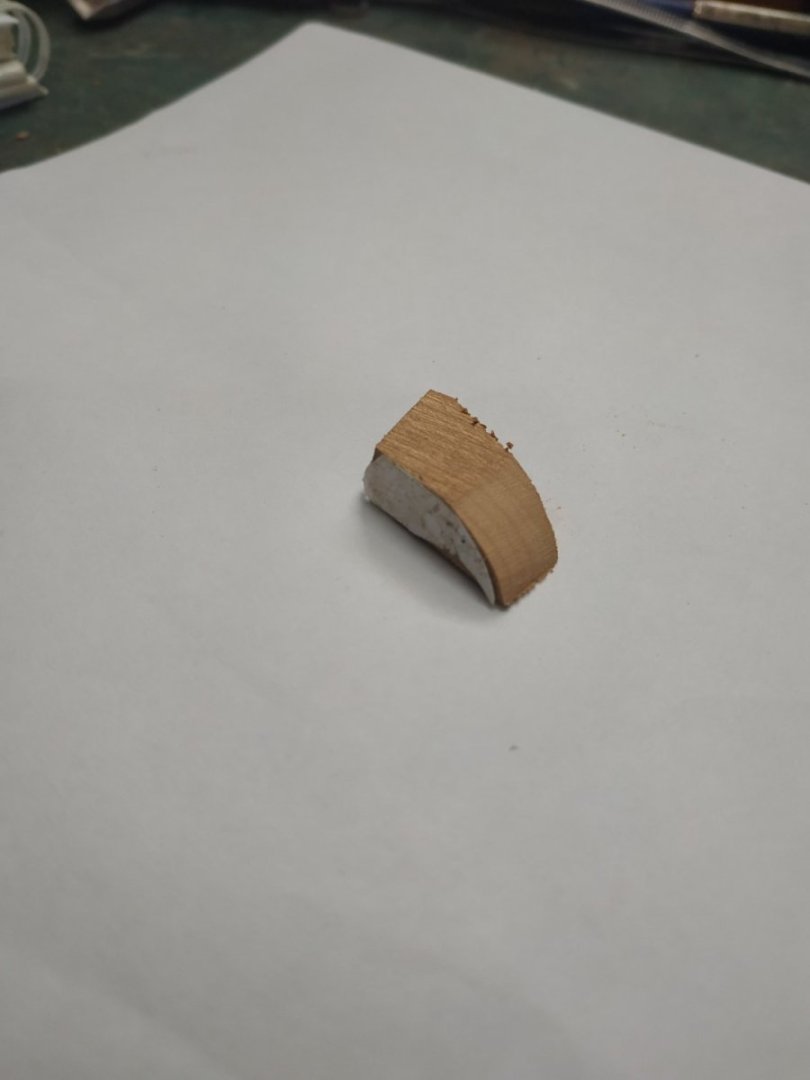

The Quarter Badge Instead of the Gallery in biggerships. Will refer to Atalanta plans for basic outlines, but without the fancy stuff. Apparently, this fitting was very varied. The critical parts are the Upper and Lower Stools. The inboard side is attached to the ships side and follow these rules :They are parallel to each other They project no further out from the ship than the Quarter Pieces Outboard shape is elliptical Athwartship, the upper surface is horizontal Molding on the outer edge (3D shows the difference between Upper and Lower) Upper Stool is slightly smaller. Lower Stool. Check height and slope to plans.(the slope parallels the slope of the Sheer Rail in my plans) My finished width is to be 6.8mm, thickness 2.2mm and length 46 I made the molding off the ship using a scraper scraper, and then reduced width and fitted the inboard surface to the hull with PVA and a couple of drops of cyano to grip while drying.(Pinning seemed a bit dodgy.) Upper Stool Very slightly smaller than the Lower Stool. Made a different molding as this (seemed) to be shown on the 3D The approx, middle ⅓ is replaced by the Bell-top, a sharply arched structure, with the thickness and molding of its “wings”, The shape is described as an “irregular skewed ellipse”. ?Because of the slope, a regular ellipse looks odd. Using the pattern from TFFM and a blank 10x8x9mm milled and filed the shape, including the minimal curving of the outer edge and the 45deg joints. **The corners broke with scraping the molding.** Again using the plans, removed the middle segment and the edges sanded to 45deg so that the Bell-top fitted with the make the appropriate total length for the Upper Stool. After gluing, the molding can be patched up where the corners were reattached. I used boxwood for colour and relative ease of scraping the molding, but on the curve this was difficult. The asymmetrical shape was not the easiest to make. Thankfully, only putting on one side. Note also when gluing the Bell-top to its wings, ensure alignment horizontally, and between their inboard surfaces. When glued, the surplus from the inboard surface of the Bell-top can be removed and the whole beveled to fit to the ship’s side so the upper surface is horizontal. Ensuring the Bell-top sits over the port, the Upper Stool is parallel to the Lower Stool and starts about 3mm aft of it. Glue in position as before. Go away and rest until the glue is firmly set before any more messing !!!.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

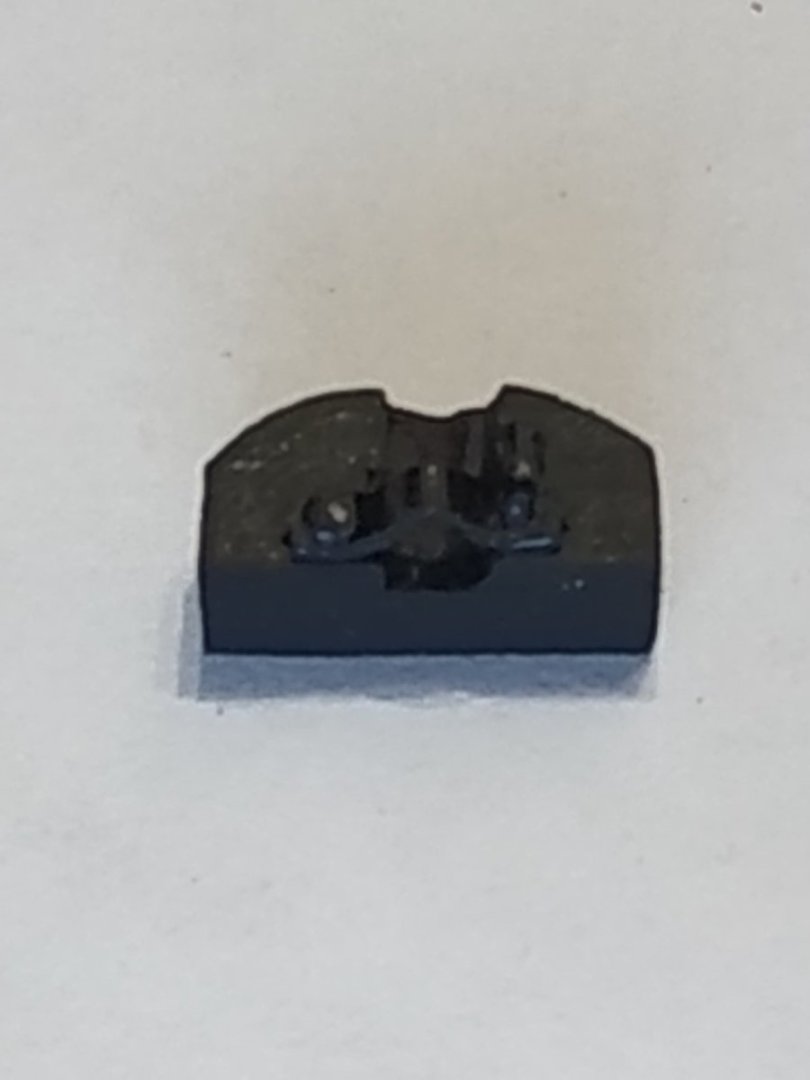

Ensign Staff Capsquare and Step This is shown as a horizontal piece inserted into the Capping Rail, to support the Staff. However, due to the dome-shape of the central area, I followed that shape for the upper surface. The staff has a diameter of 2.4 mm, so a vertical groove was filed out at half this depth. The Capsquare is similar to those on the cannon trucks, so I used one, brass pins, one bent over to represent the bolt. The step is a simple rectangle with a 2.4mm hole, and fixed to the deck.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Lower Quarter Pieces. Continuing downward from the Upper Quarter Piece, it extends to cover the upper Wale strake. Follows the curves of the Stern and the Hull, thinning downwards- more so across the outer face. Molding with shaped scraper. Not satisfied with the first attempt. I didn’t consider the effect of the grain and different wood shade. Remade both the Upper and Lower Quarter Pieces The bird of prey is homage to the build log of Dan Vadas’s HMS Vulture. This helped me over some significant difficulties. A great model ship builder.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

PS. The Munions were spares I ordered from the Agamemnon kit. Perfect fit.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

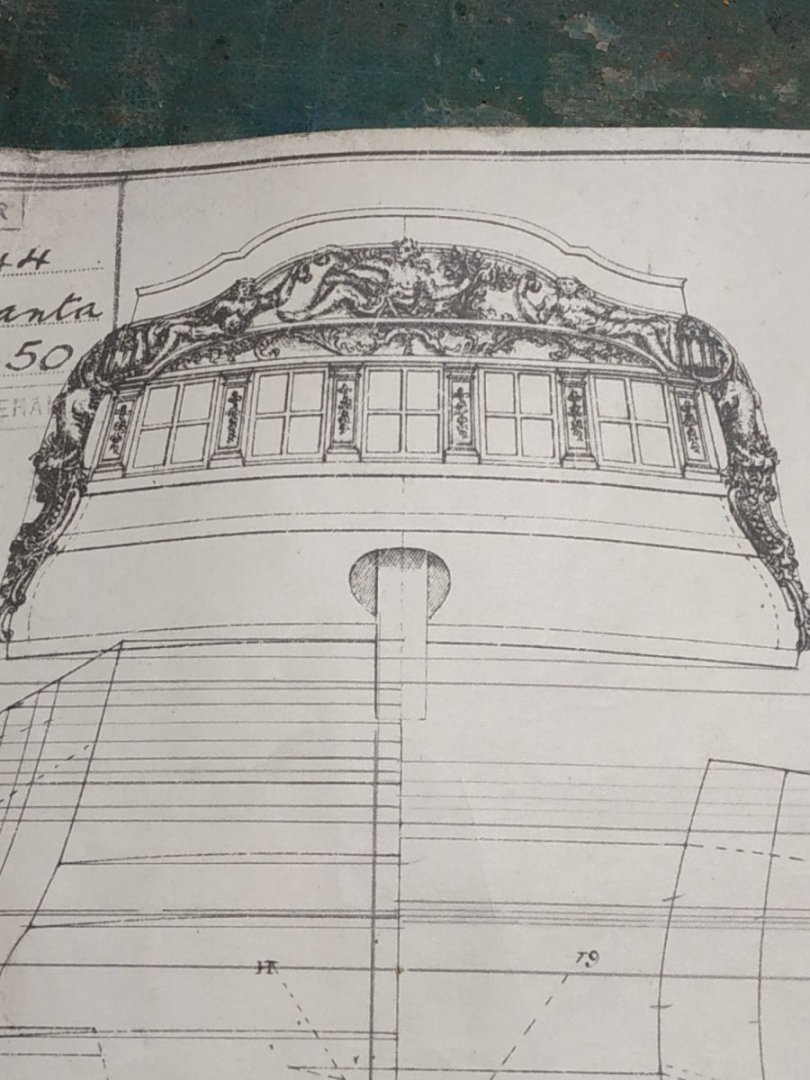

Capping Rail A narrow molding above the Taffarel. 4.5mm wide and only 0.8mm thick. I made it thicker as my first attempt broke and to ease my conscience, thickened it to match the plansheers. I considered various methods - several short sections or bending (? possible in 2 planes without twisting) and decided to make it in 3 pieces, the main from bulwark to bulwark, and shape it from a solid blank, 11x18x15 CMS. Firstly, the curve of the Stern, then roughed-out the shape of the upper Taffarel. Sanding and file to shape, then thin to the decided thickness. The outer parts are easier. Before fitting the middle section, file out a section in the centre where the Ensign Capsquare Base will fit (12.5x1.3mm). (I followed the TFFM pattern for the Taffarel, but there is much variation. Below is the plan of the Atalanta- the form of the Caprail would be relatively easy, but all that carving!!!!!)- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Upper Quarter Piece A piece, outboard and level with the Lights, extending downwards of the Additional Thickness Piece. Width and thickness of said Piece, narrowing downwards to about 5.5mm. My outer surface has a molding rather than some fancy carving- some sources say this was a possibility.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

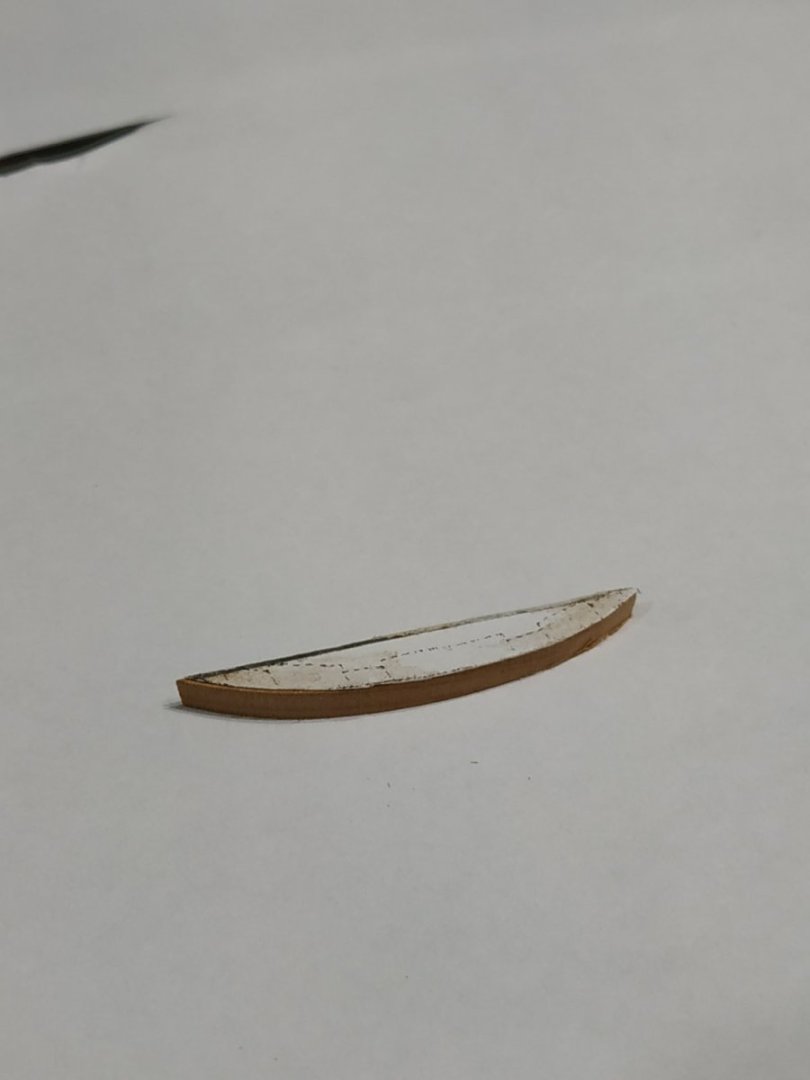

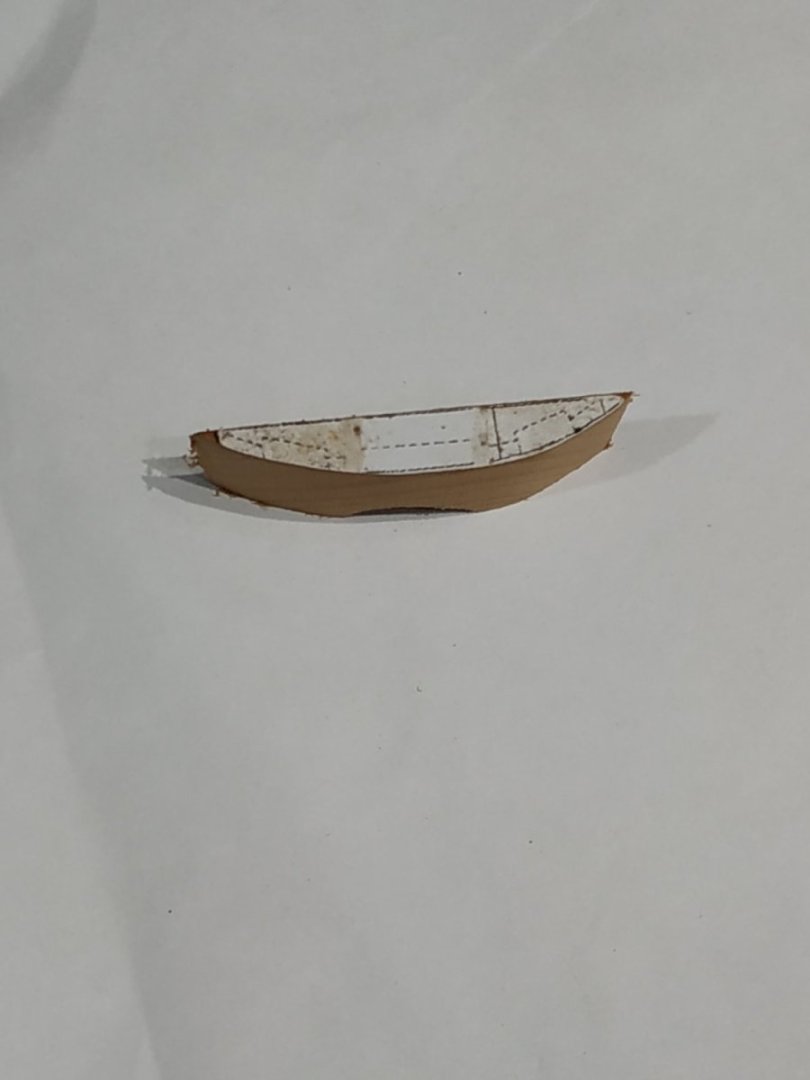

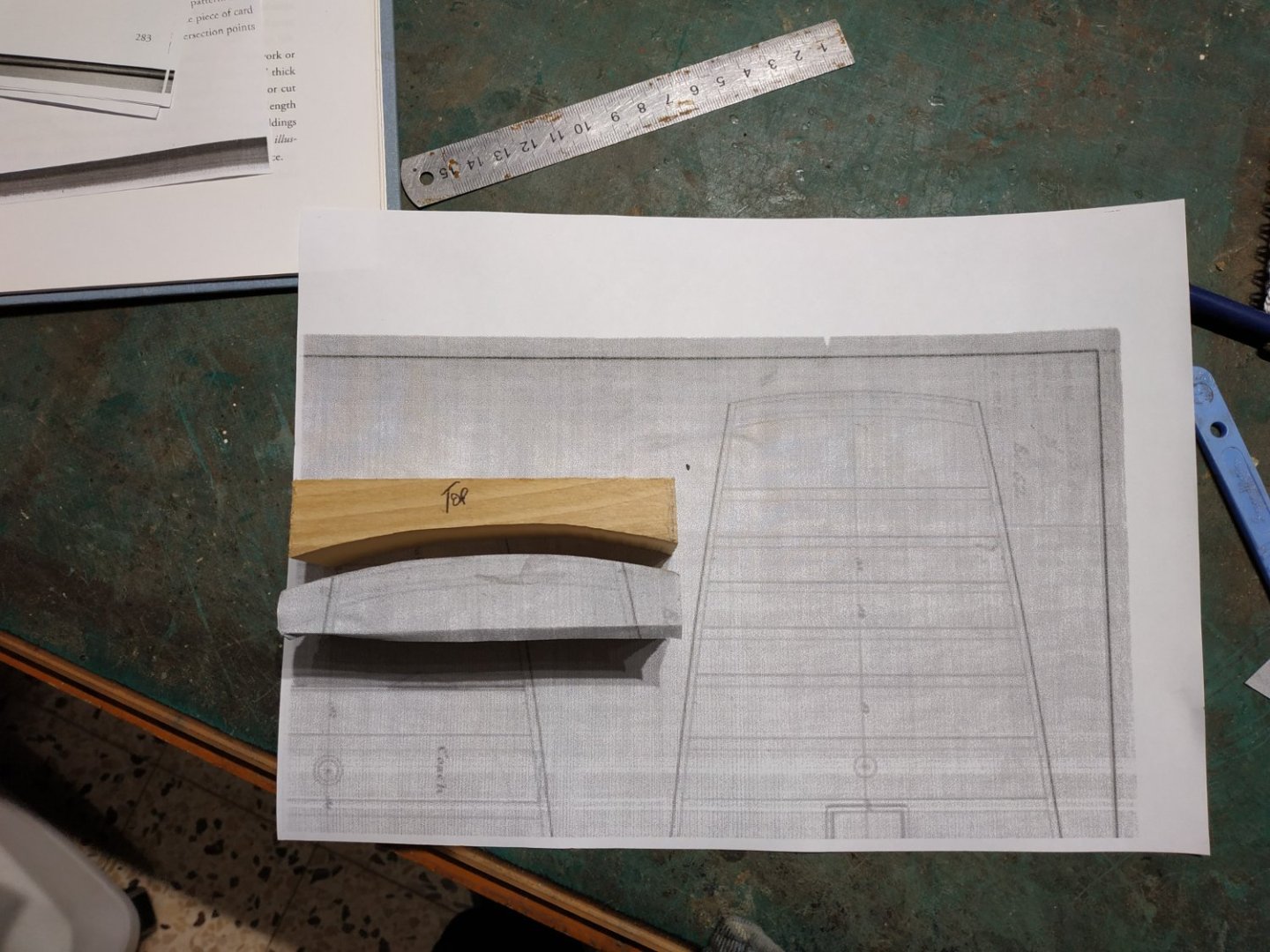

Structures of the Stern. I’m somewhat daunted by this. Its a visible structure that seems complicated to make. As usual, TFFM simplifies this into a number of steps. Taffarel Pattern. Explanation given how to draw this given the ship's plan. However the final result pretty much suited my build, so I used this directly. (I have plans for Atalanta and the Fly -the size and pattern of the Stern are different.) Taffarel Base. In order to shape the curve of the Stern, a jig was made. A spare block of wood is split into 2 halves, using the shape of the curve taken from my Atalanta Quarter Deck Plan. The formed Stern will be clamped between the 2 halves. The Taffarel. TFFM describes a thickness of 3.18 mm below the line of the Coves - 1.06 mm above. Within the Coves, the area is carved out into various decorations. To avoid the carving and thinning I followed the suggestions of Dan Vardas’s blog. Using 3 pieces of different woods, I made each the same thickness of 1.03mm. The outer and middle from the same pattern - just the area of the Coves and Necking.. Some small alteration was necessary to match the Arches of the Coves to the position of the Munions. The shape of the Coves marked and the “rim” roughly hollowed out with the mill. These 2 are glued and clamped in the jig. Using the full pattern, and the inner layer was cut out. (**When offered to the stern I found it fell too short of the Quarter Deck Planksheer-and I had to remake it.**) The outer pair is now glued to the inner layer and pressed within the Base jig to try with the required curve. ( 2 spare bits can be used to even out the sandwich.) When dry, using the convex side of the jig to support the part, the Coves, the Arches and Necking are further shaped with scalpel and chisel. The whole is glued and pinned with treenails to the Countertimbers. Additional Thickness Piece. Forward of the Taffarel extension beyond the Hull, 2.12 mm to match the thickness of the Quarter Pieces.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

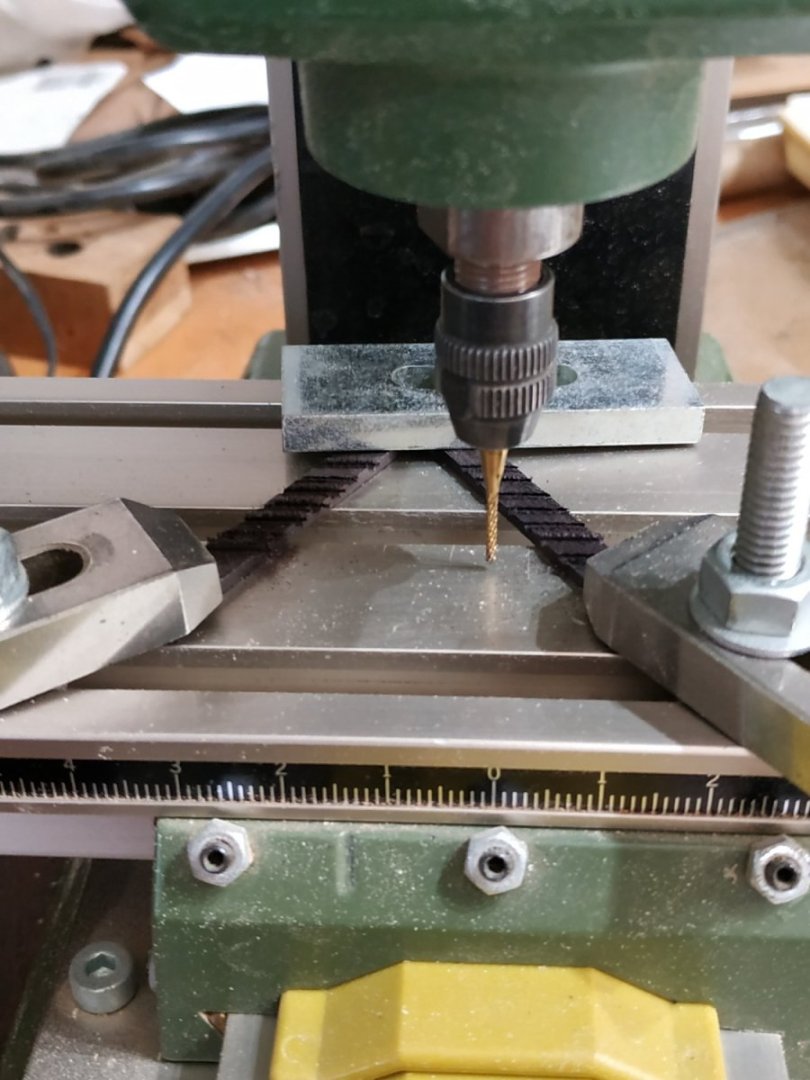

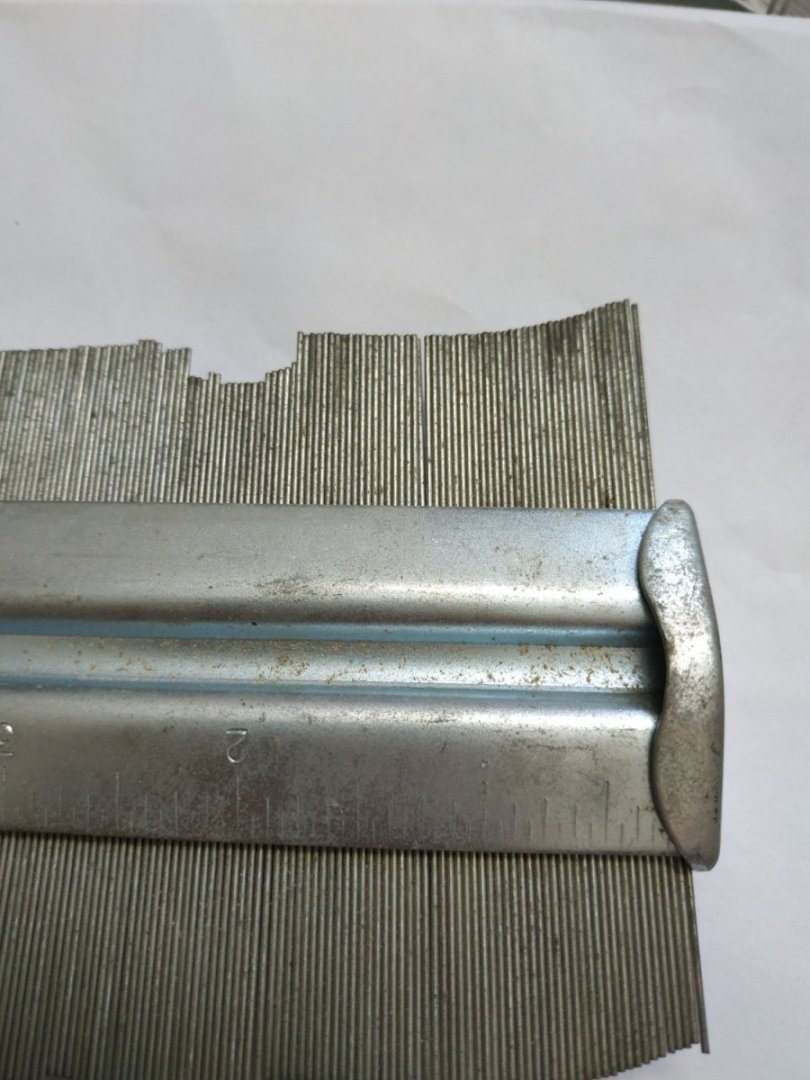

Steps to the Waist. From the Fixed Gangway to the Waist of the ship. Styles 1.33mm thick, steps 0.8mm thick To position the Styles that follow the curve of the Gangway, then are in line on the deck, the upper steps form a curved or “winding” shape. *********************************************************************************************************** Rather than set up the table saw, sledge and jig to groove the styles, I tried my trusty mill. The angle of the styles to the deck was about 60. Geometry 101 gave style/gangway about 30. The 2 sides of the styles must have opposite grooves. I cut a piece of a point of 60 to some thin spare stocks, set it vertically, then clamped the styles either side of this and ran the mill piece horizontally across both. Repeated passes at 6mm intervals, and voila, matching grooves for the styles.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

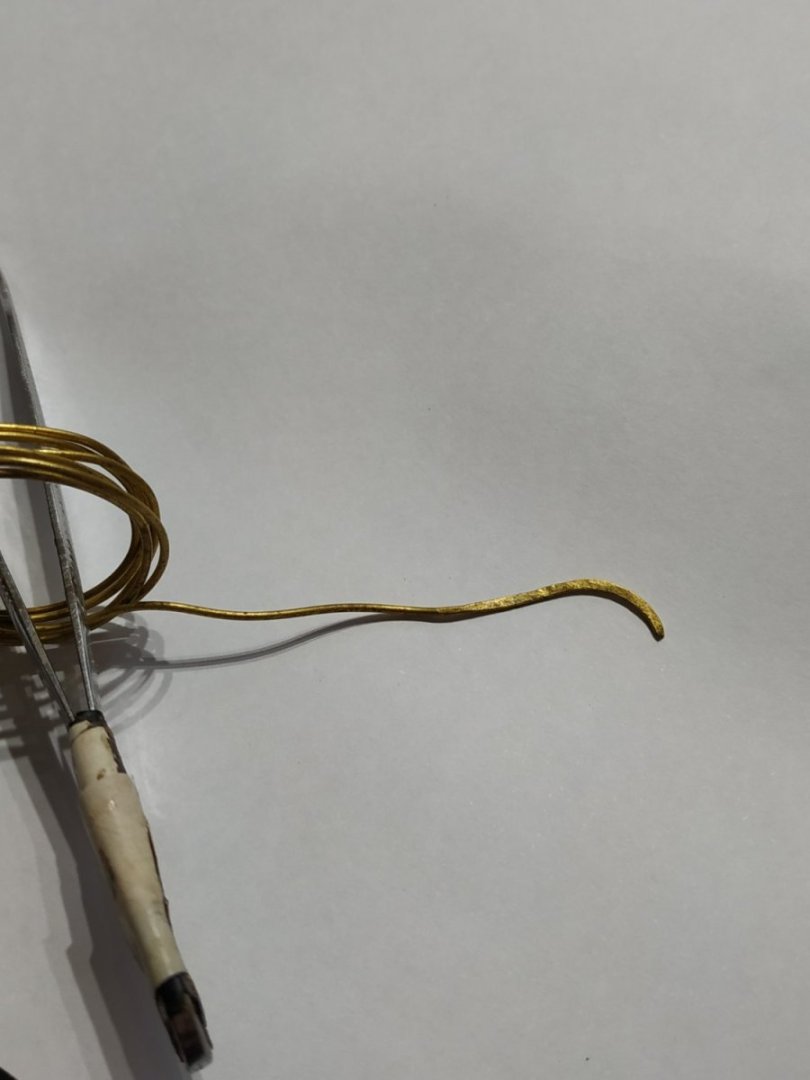

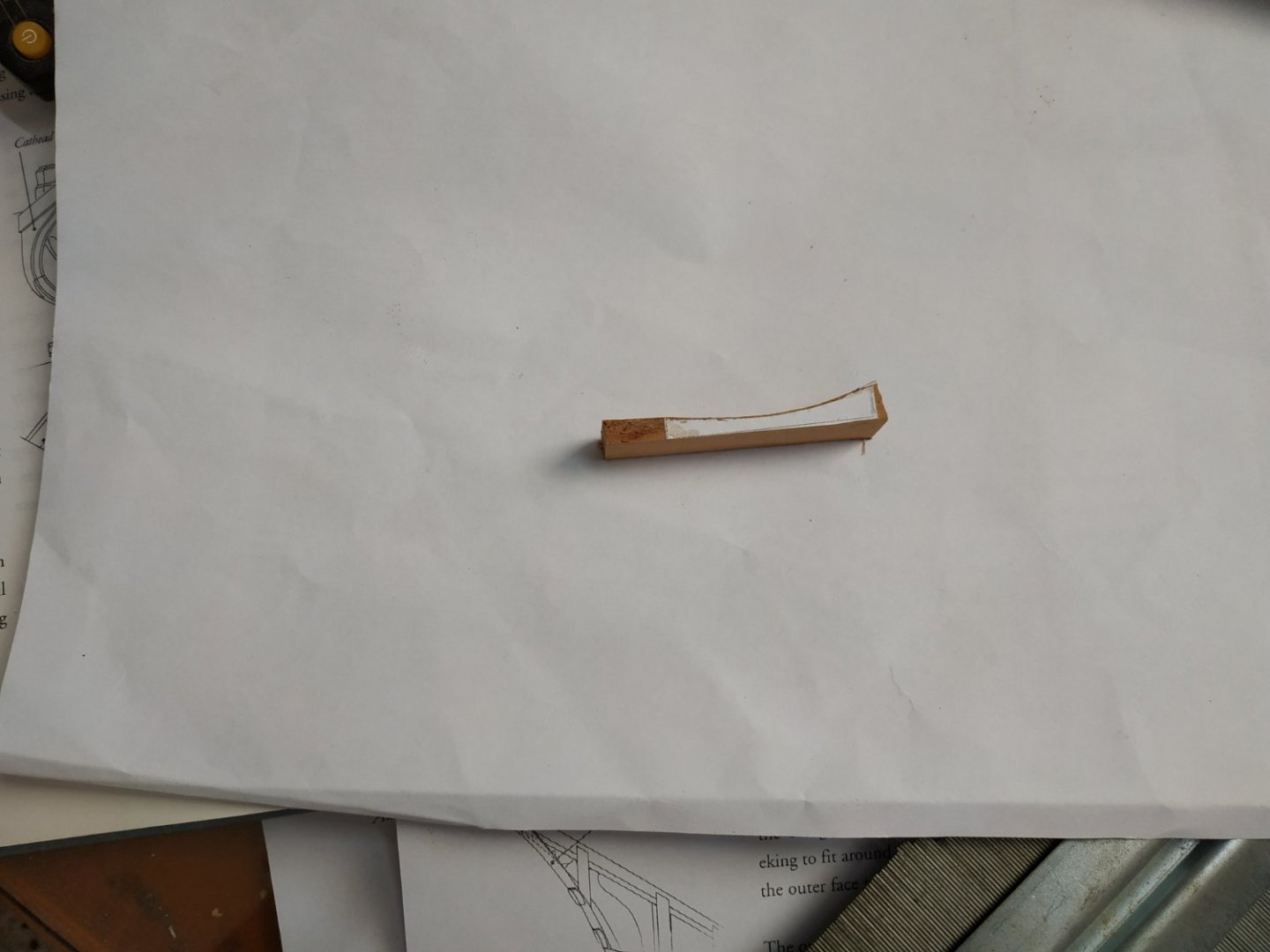

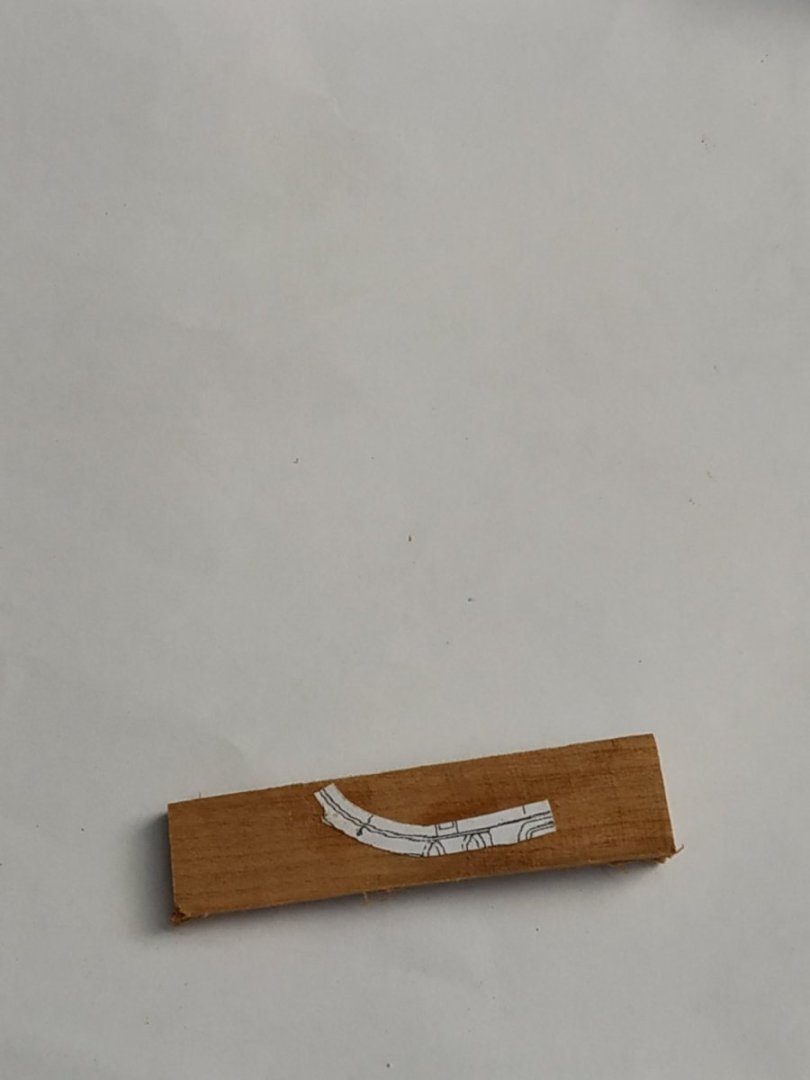

Fixed Gangway Newel Post and Railing The Post: From the corner of the Fixed Gangway, supporting the Rail which runs to the outer Stantion of the Quarterdeck Breastwork. . The Post is 22.3mm high and made from 2.65mm sq. stock. It was a spare left over from a batch previously turned. The Railing: 2.4 x 1.6mm thick. The aft part forms a dog-leg or “crank”, to meet the outer Breastwork Stantion. In section, shaped handrail-like, formed with a scraper. Iron Strap: 1.6x0.53mm. Hammered from 1mm copper wire. As well as the crank, similar to the aft of the Railing, it has an upward curve so the aft end sits on the Breastwork Rail. Used copper blackening solution.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Fore Channel Deadeyes and Chains. Sizes of Deadeyes: 5.3 and 3.71mm Chains . 4 parts: Upper link enclosing deadeye Middle link- os variable length Toe Preventer plate. TFFM explains how to make these. I will use my parts box and purchase more as required. Billboard, Bolster and Lining. These protect the ship’s side from the anchor flukes. Lining - 3 planks 1.33 mm thick, overlying the Wale. The curved side forms a radius centered on the Catshead. Bolster- Rests on the Wale, above the Lining. 41.34x4.24x3.71mm deep Inner surface fays to ship side, and is scored to fit over the Preventer Plates Cross Section is chamfered so the lower edge is flush with the Lining. Billboard- Supported by 2 stanchions, 2.12x2.65mm wide, between the Bolster and underside of the Channel. Planks 1.33 mm thick- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Fish Davit Cleat (Thought I’d make some parts out of order while working on the Planksheer) Above the 1st port. Width 4.77. Length 24.5 with a slot for Davit 8.48. Made as the previous block- pattern and milling. Fixed Block for Main Mast Shown on Atalanta plan. Almost opposite the Mizzen Mast. 19.8x 1.2 high x 5.3 mm with a slot for a sheeve 1mm wide. Timberhead enclosed within the aft section. Fixed Block for Main Brace Similar to Main Sheet Block, but 4x4.24 mm wide- The aft “tail” fitted around the Outer Side Counter Timber. Thinner sheeve (0.53) set at angle. I wedged the piece in the mill vice at the required angle and milled the slot “straight”- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

The Timberheads. 15 per side. Position as per Profile and Framing plans. Size and shape given in TFFM ch.3.30 of vol. 1 4.24 mm wide and 2.65 deep. As before, milled a groove on the angled strip (another strip wedged under one side) on both wider sides, then using the jig, matched the “thin” sides using a file) These are also blackened to match the Planksheer. The Quarterdeck Planksheer was fitted in the same way as the Forecastle Planksheer at this stage to allow the Timberheads to be fitted. On the unfinished port side, blanks are fitted to represent where the extended frames should have been left.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

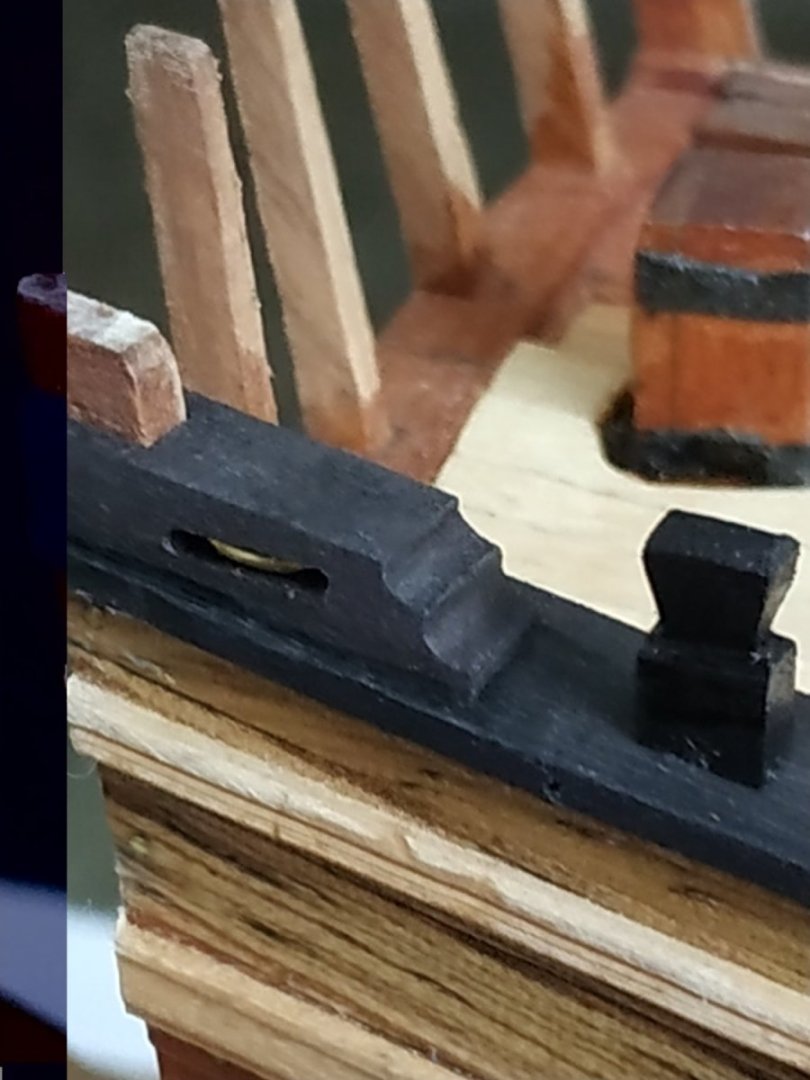

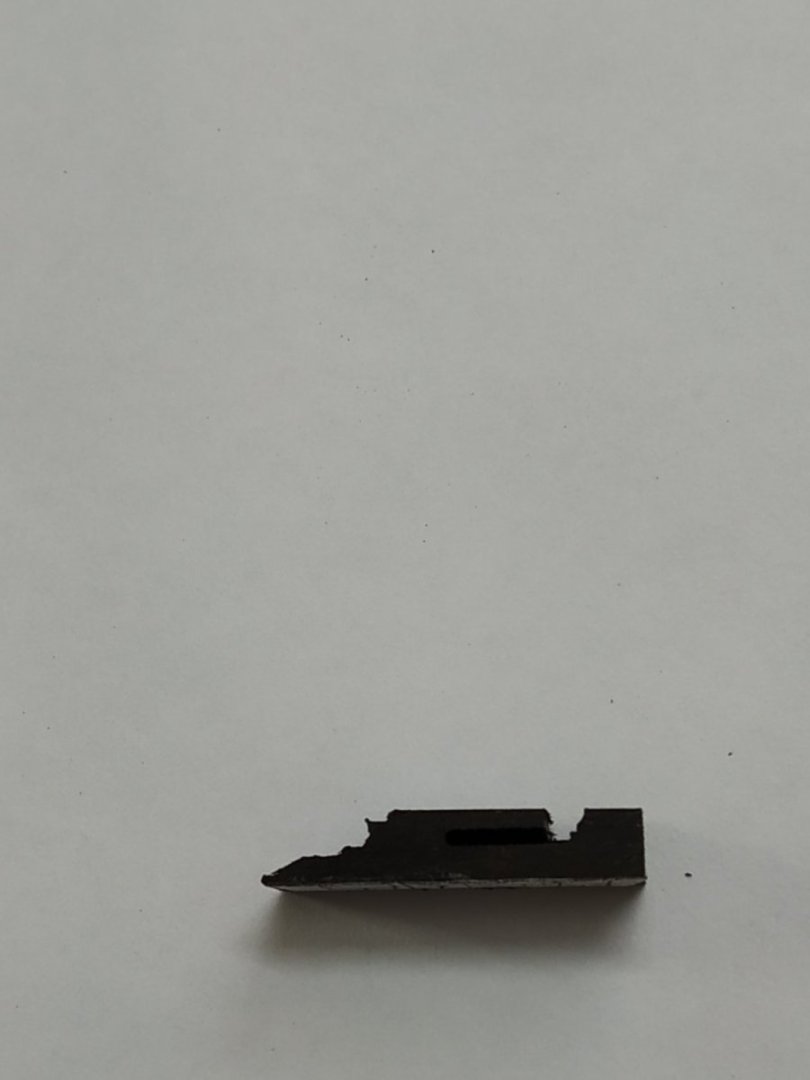

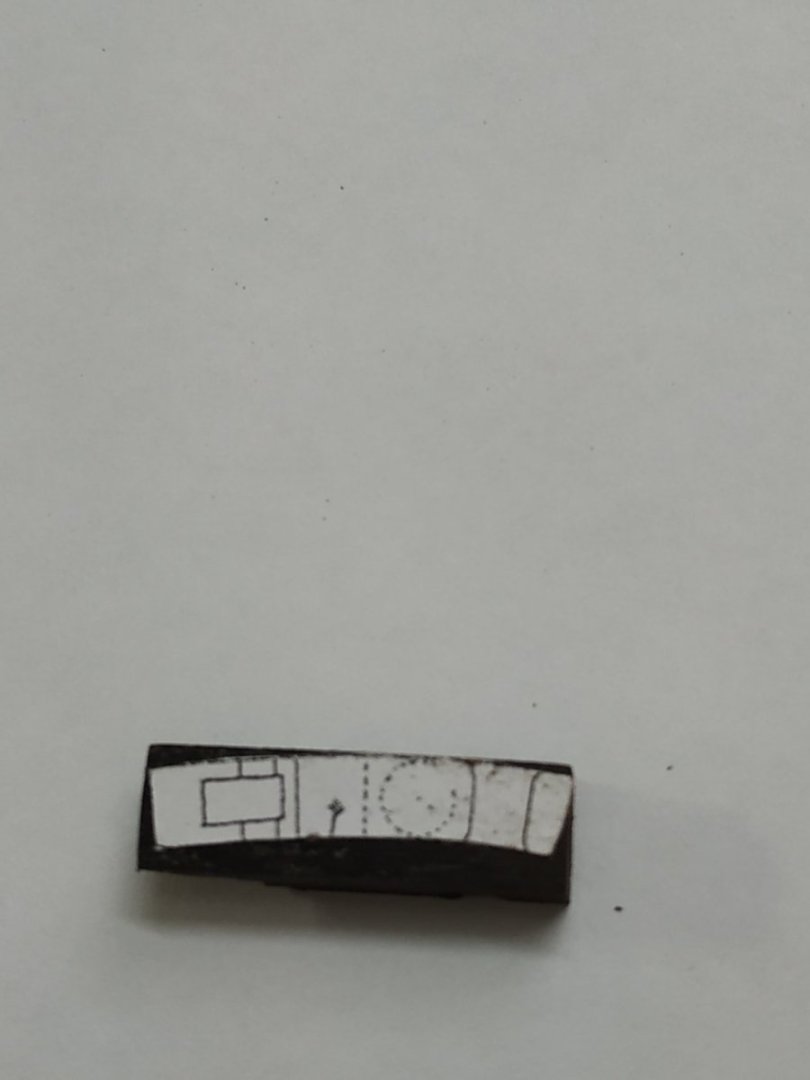

Cat Block for the Falls This is a type called a “snatch” block because it has a slot or “swallow” on 1 side. The “tail” of the block is mortised around a timberhead. It is curved and coloured to match the Planksheer. Size: 4.77 mm wide and 3.71 nn thick. It contains a Sheeve, 4.24x0.75 mm. To allow for the curve, I took a blank 6.5 sq. Using a pattern, roughed out the side profile with the mill. Also used it for the slot and curved entry. *Mistake* - cut the profile curves at right angle to the block. When I later shaped the curve (using another pattern ) to follow the Planksheer curve, realised that the profile should be at rt. angles to the curve. These were redone. The other Timberheads will be fitted onto the Planksheer, and therefore, rather than mortise one into the Block, simply attach one onto it. (allowing for the thickness of the block at this point).- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Planksheer of Forecastle TFFM suggests making it in 2 parallel pieces as the Breast Rails, but as I have not yet made the Timberheads, this isn’t necessary. The Planksheer is 1.33mm thick. It overlaps the combined width of the hull wall. Using a card pattern taken directly from the model. The length is divided by 2 or 3 scarph joints. I found it easier to fit the aftmost section. This covers a Hance. I subdivided the piece- hollowing a square piece to cover the Hance, shaping the outer surface after gluing in place. A short straight piece, before shaping the next curve in a similar fashion. The rest fitted and shaped. As before, the wood didn’t lend itself to shaping a molding, so I simply chamfered it. For the scrolled Terminal, I added a 2mm cylinder-shape. The Planksheer should extend to cover the Bowsprit Cross Chock, but mine is too high - or rather the Bulwark is too low. I decided to leave this as is. (Personal note. I’ve been on holiday and haven’t worked on the boat for a month. Brain and hands feel “rusty”. Do others find this?)- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Seats of Ease Just the forward pair. The Discharge Tube fits in the space of the Gratings of the Head, made for that purpose. The shape is a parallelogram. The walls are 0.53 mm thick. Each face is given as 4.77 across, but I made it “to fit”. The inner wall rests on the Lower Rail-the outer face shorter to allow the outflow. The two other sides of height allow the whole assembly above the Gratings to be 7.95mm. I made them in situ, stucking them separately into the Gratings gap, and sanded the top combined surfaces to be horizontal. The Seats, also 0.53 thick, are 7.42 sq. with a hole 3.71mm diam. The seat shape is also a parallelogram. The False Rail and the parts of the decorative Rails of the Bow previously removed, are now cut to length and replaced.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

The Eking Rail The continuation of the Cathead Support. In my plan,Atalanta, this extends above the center of the Hawse Bolster. (there is no 1st Head Timber) The first job is to fay the inner surface. This is a significant curve. I remembered my pin jig that made it easier. Again an oversize blank, 15x50x10mm. With the Supporter held in place by tape,I then made the scarf joint, marked the lower curve, then the parallel upper edge. Finally the outer edge. I epoxy-ed the joint for strength to allow the final shaping off the model. The plan calls for molding the outer surface, but I was disappointed with my attempts on the cherrywood Main Rail, The 3D and other illustrations show a coloured insert similar to the Covering Boards of the Head Timbers, so I followed suite- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Cathead Supporter A knee supporting the Cathead. TFFM recommends cutting out a paper pattern to follow the AFT curve and stick it (photo glue) in position on the Bow. This is an excellent idea and simplified the repositioning of the piece accurately when frequently offering up and modifying the piece with its complex curves. Although the final width is only 2.9mm, a larger blank is required. I started with 6.5x16x25mm I thought I would detail how I deal with various curves - possibly like others, but it might help a few. The order these curves are made may vary, but again following TFFM this was made easy. Start with the upper angle of the Steeve where it lies under the Cathead- in my case 110 deg. The aft edge of the Supporter is initially vertical before curving forward. I stuck a cutout pattern (reversed) and roughed out the shape. The Inner surface is then fayed to the hull. The forward surface can now be marked to follow the aft, and the piece shaped and thinned with files to slightly more than the required 2.9mm The concave curve of the outerface can be shaped, keeping said face at right angles to the aft face. A scarf joint is made at the lower end where the Eking Rail will be joined.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

"Yes Druxey, my grandfather told me of such a thing, but few living people have actually experienced it😉" I actually was asked this as an immature and naïve boy of 13. My father explained what it meant, but at the time I think the tailor must have been on auto pilot as the question was irrelevant. PS I am not elderly- elderly people are older than me.- 475 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.