stuglo

Members-

Posts

707 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by stuglo

-

Grip with a strip of folded sand paper (rough side towards wood)

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

British Pathe film: Model Boat Building, 1956.

stuglo replied to uss frolick's topic in Nautical/Naval History

Just skill and not a Proxxon in site -

I'm visiting Berlin in 2 weeks time. I would welcome suggestions for tool/ model shops to visit and anywhere to purchase wood. I will be in the area of Museum Island, but the wife is accommodating.

-

I personally can't and avoid painting models. If I could approach the skill of Kevin, I might change my mind.

- 1,129 replies

-

From time to time you show some new tools that you acquired when visiting NYC. As some of my family will be visiting there next month, could you suggest some useful stores to explore so that I can choose my presents. Thanks.

- 1,129 replies

-

You've reawakened my interest in this tool. What would you suggest as the basic burrs and accessories based on your experience ?

- 1,129 replies

-

Welcome. We have a local Israeli model boat building club. We would be most happy for you to join us. The next meeting is this Friday. Looking forward to hearing from you.

-

"am working on the handrails. It's all done with 0.2 mm black monofilament line," Was it easy to fit the CONTAINMENT rails after handrails, or better to do these first? Your build is an excellent one. My painting with spray cans was OK for the hull but excessive for the deck fittings. Probably my inexperience and lack of patience.

-

I also remade it. Some much of this kit is brilliant, that I wonder if some of the simple stuff (mainly wood) was designed by someone else!

-

In fairness, I must update these comments, because as I proceed with the build, the PE and plastic parts are really compensating for the initial frustration. The amount of work and expertise that must have gone into the planning details is phenomenal. The issue with the wood should be easily rectified; then the kit will be perfect.

-

I'm spending more time correcting the wooden parts than I would have if I made them from scratch. The design is really good, the the fun in the project drains away with the frustration and annoyance. The old kits I built were far less inaccurate. ? Imperfect or inappropriate use of modern technology + lack of consideration for the purchaser/builder?

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

No lining, just a block on the side of the hull not planked. Main problem is angle for drilling. An angled blank for direction and a big prayer.- 475 replies

-

I see you have fixed the 1st planking before the decks. Is this in the plans because mine says to complete the planking after the decks are fitted? Your way seems easier and better.

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Thank you.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

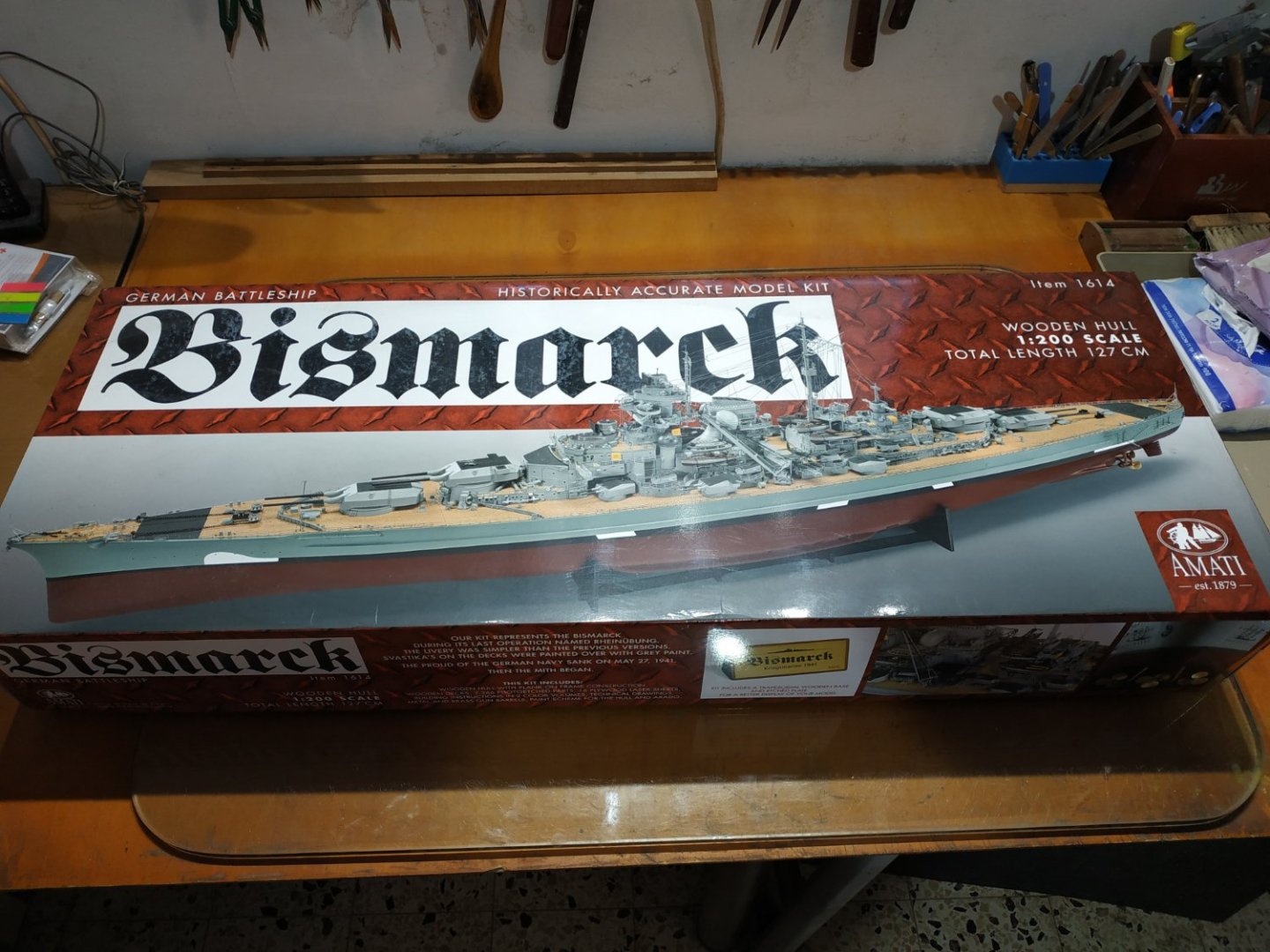

Finishing my Swan Class Sloop Mast Wedges, stubs for the masting, and a figure head. I purchased the Lion figure (boxwood?) online from PRC. Required some adaptation for fitting. Not one of the class as listed, but I read somewhere that a generic lion figure was sometimes used even when the ship’s name was something else. Well, 30 months, about 3000 hours, 500+ postings. What a voyage of discovery. There were times, particularly at the beginning, that I wondered if I’d even depart the harbour. Of course, without the practicum TFFM books , Dan Vardas blogs and Kevin’s Videos, I would have been sunk many times. Thank you all. Thanks to the Bosun (wife) for tolerating my taking a spare bedroom (and sometimes a second one), disappearing for hours, making noise in the early hours of the morning, and turning a blind eye to the expense of the new tools that I acquired. My grandchildren, perhaps hoping to inherit the ship, are even more attentive than usual. Like a good book that you regret when finishing, so is this project. I have more on the shelf, but will return to a Swan, perhaps with reduced innards, but fully planked and rigged. I have volume 4 TFFM and enough cherrywood stock. And now for something completely different (Monty Python)---- The BISMARK - Amarti kit.- 475 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.