woodartist

-

Posts

286 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by woodartist

-

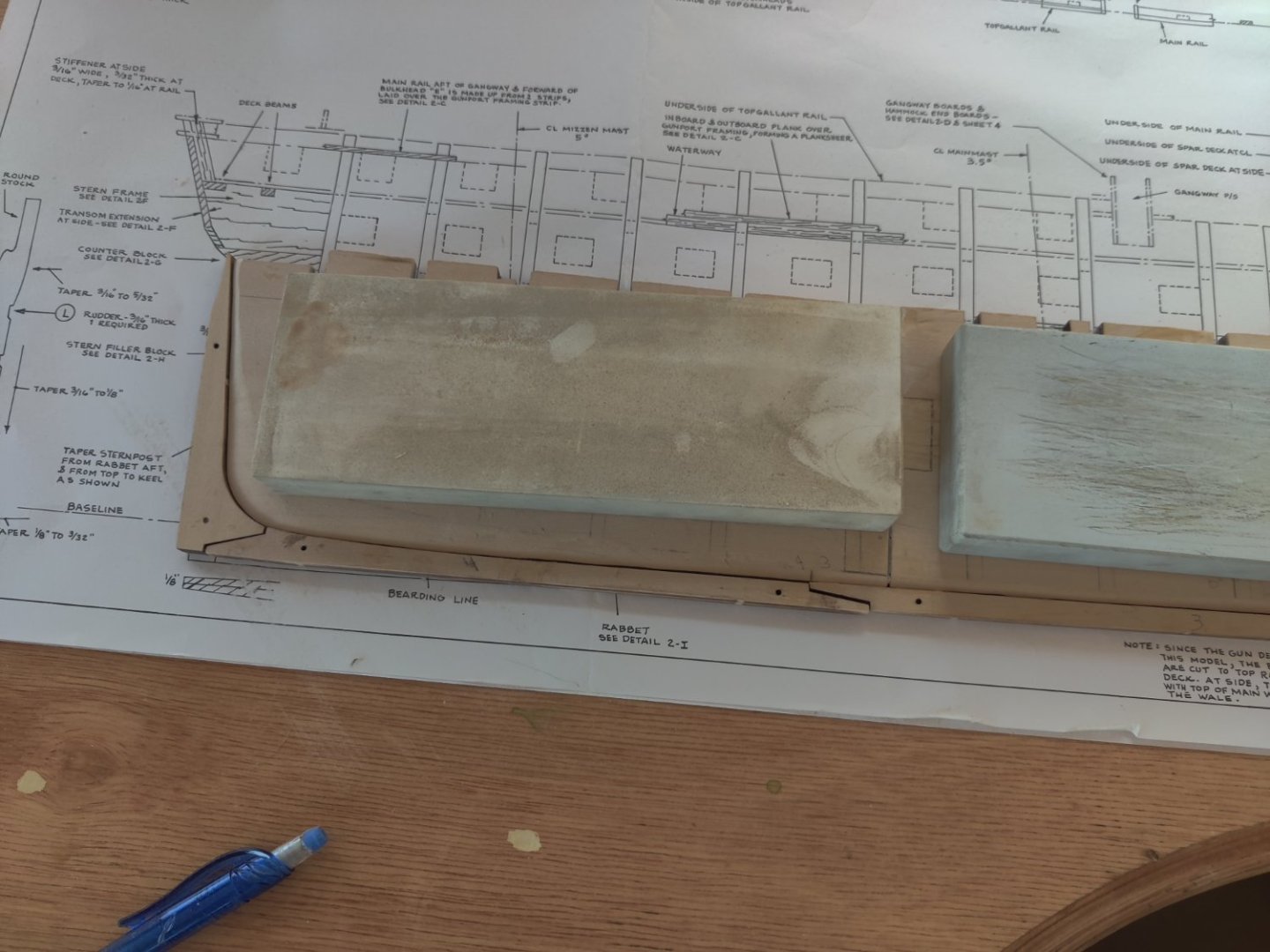

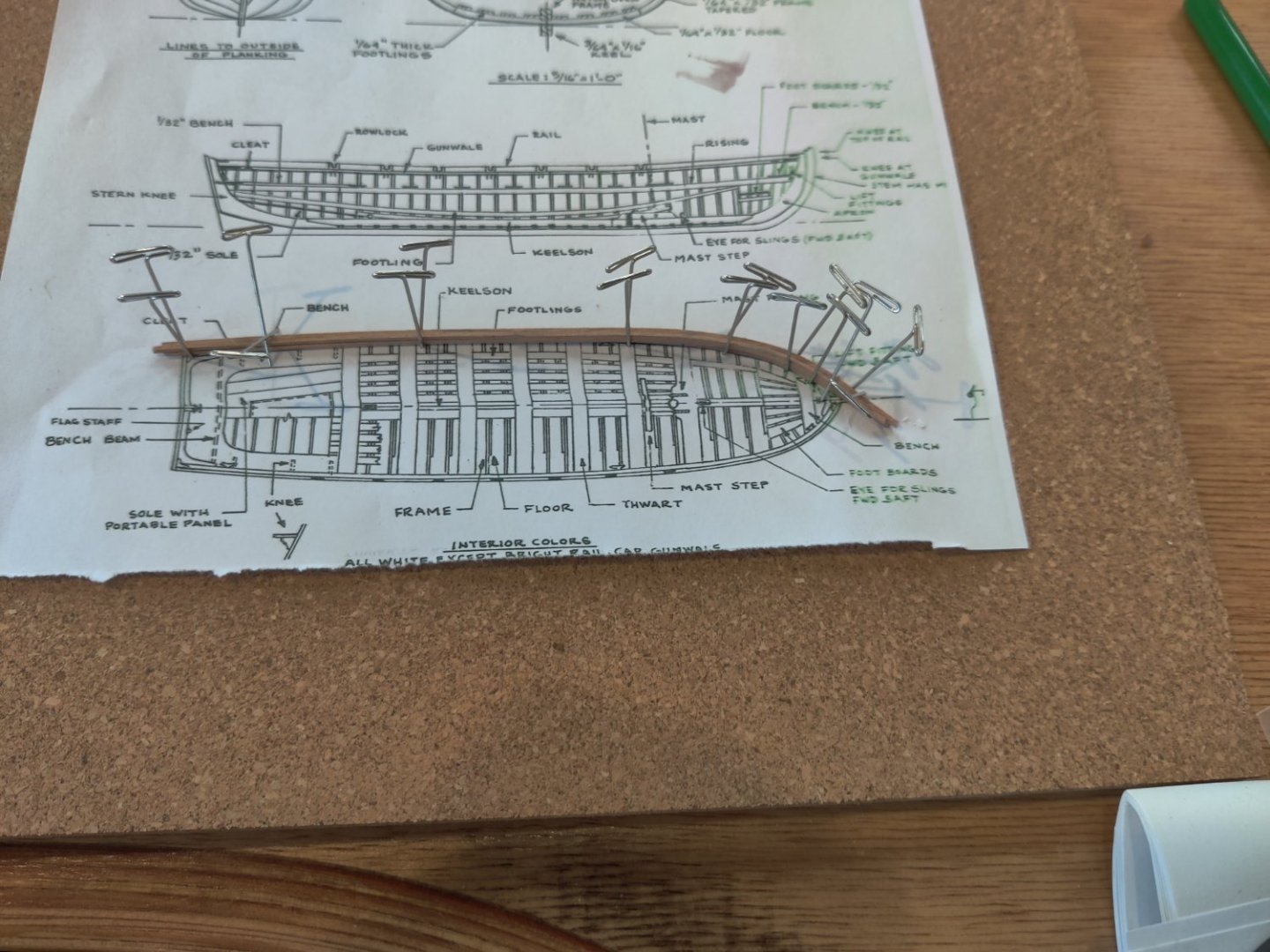

Before I make a fatal mistake, I need to better understand the relationship between the Bearding line and the rabbit. Am I correct that the Bearding line is the merge point between the Keel and the lowest plank on the hull? Is the goal to reduce the thickness of the keel at the bearding line by the thickness of a plank so that the last plank's bottom edge is flush with the keel?

Is the rabbit the rounding of the bottom edge of the keel, so that there are no sharp edges? To do that would you find and mark the bottom center line and then gently round each side of the keel to the center line?

Also, I am still concerned about the difference between bulkhead from the pattern plans as referenced in my last post.

-

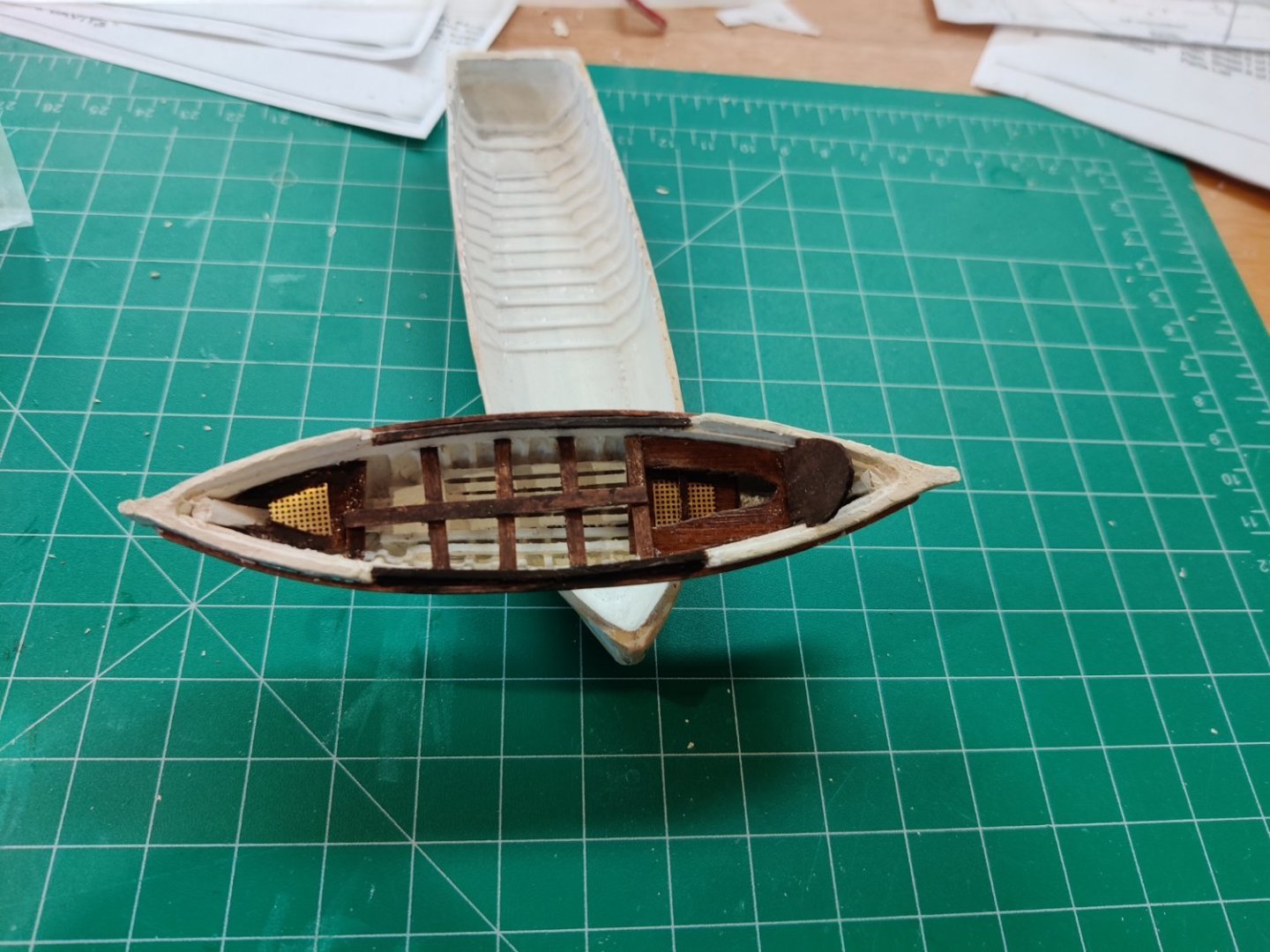

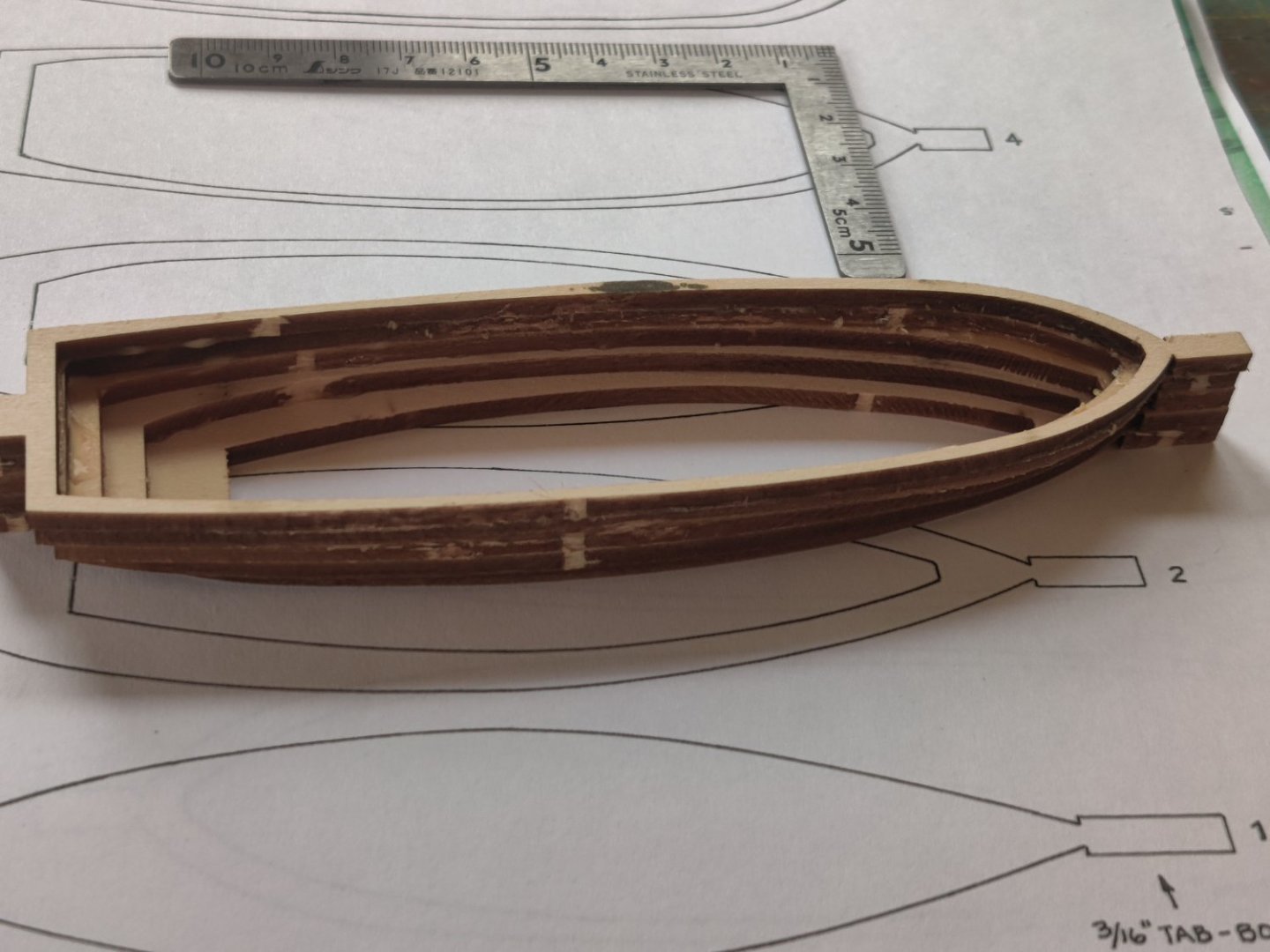

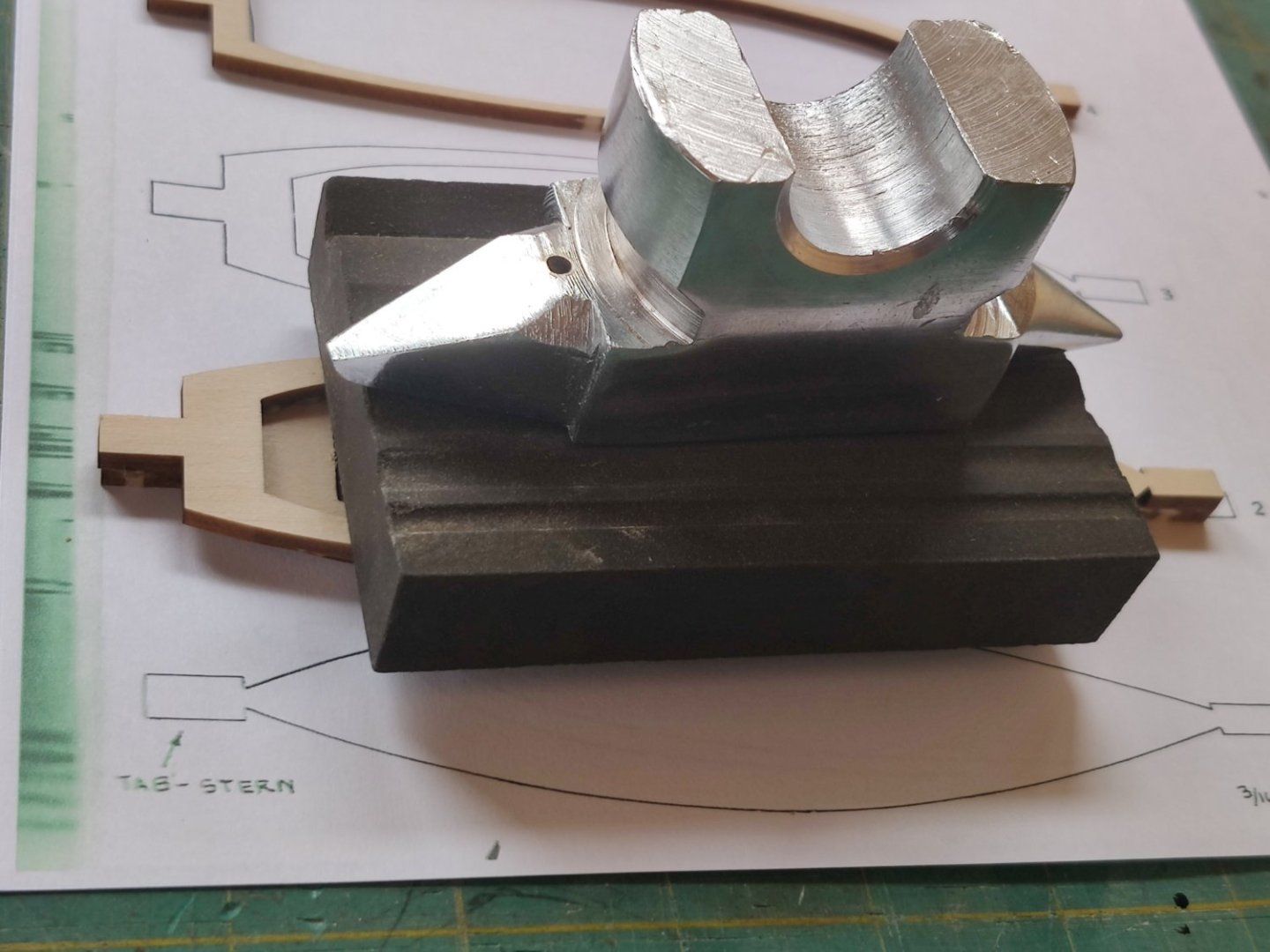

A picture is worth a thousand words:

The line of the inboard plank corner is also called the "back rabbet" line.

Here's a fairly decent tutorial on cutting rabbets: Cutting a Rabbet Line - The Suburban Ship Modeler

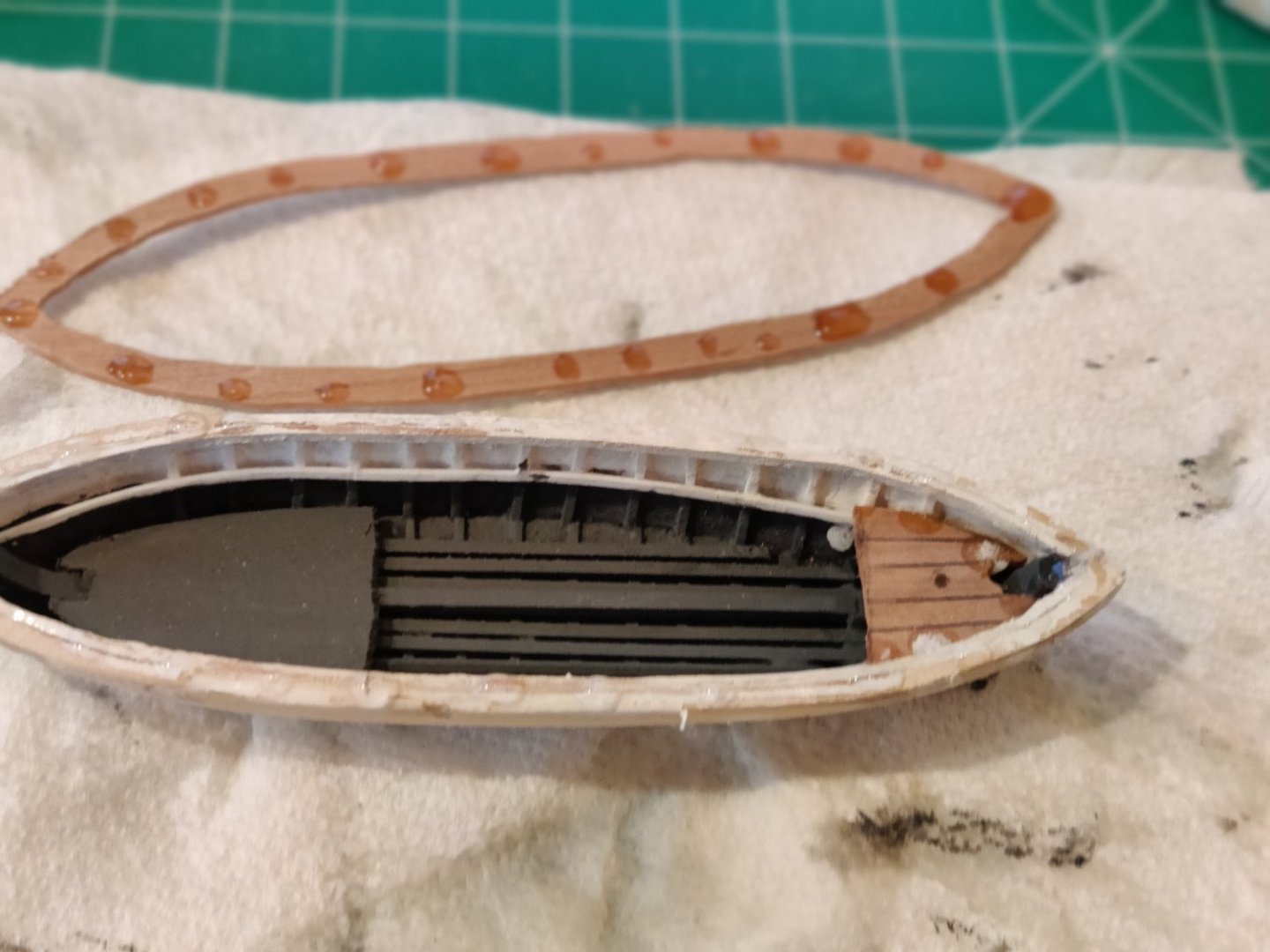

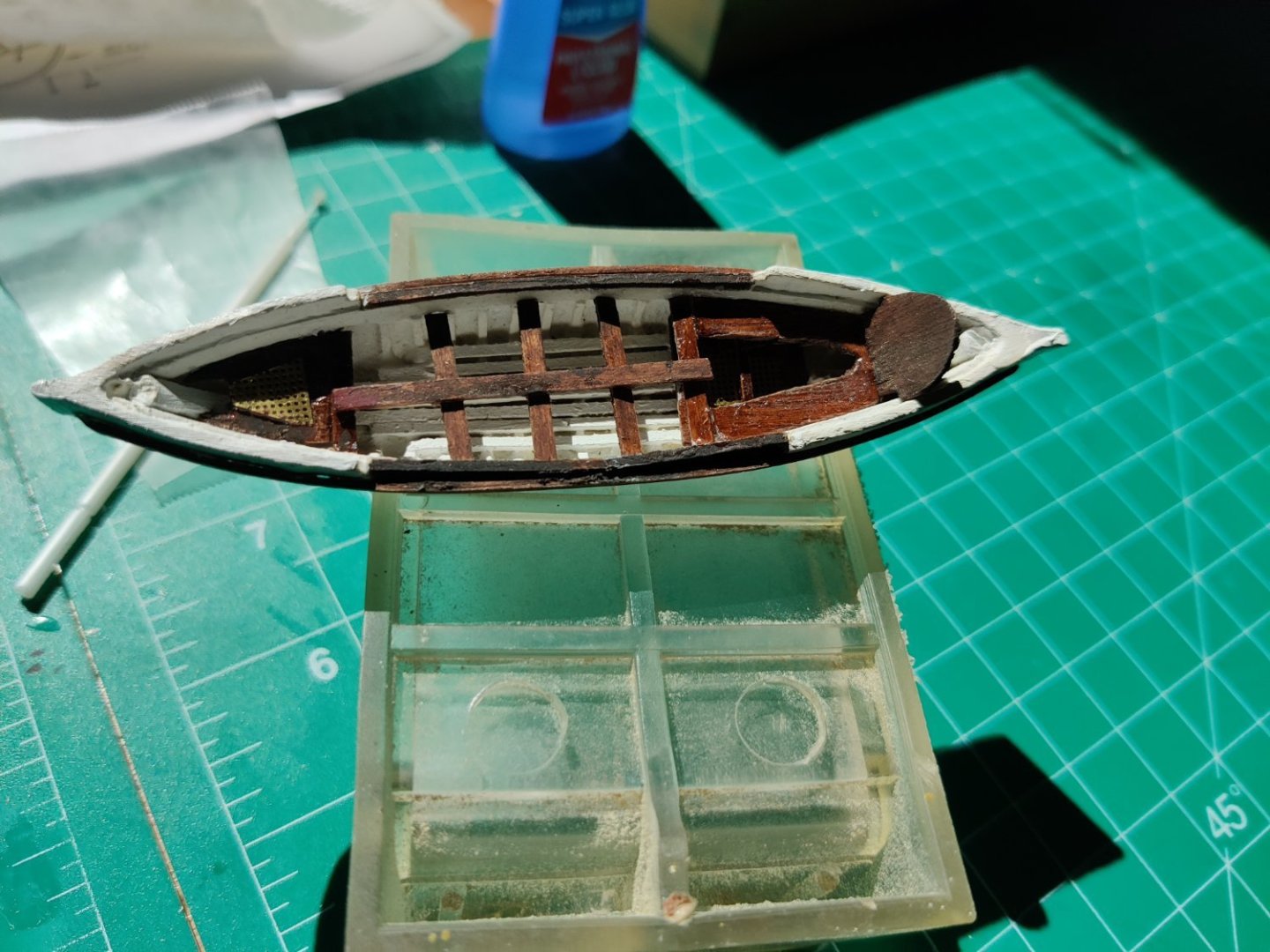

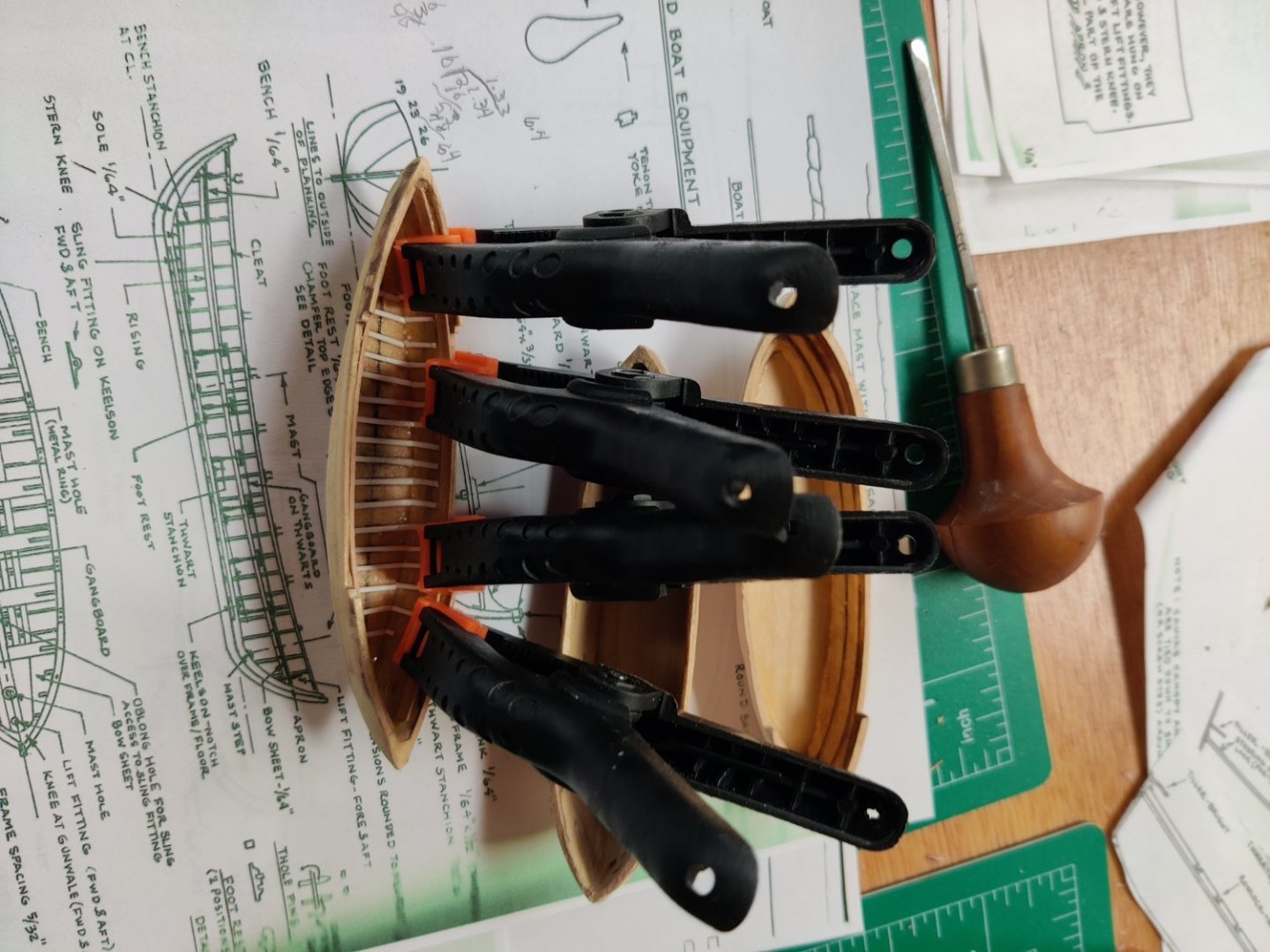

The shape of a backbone rabbet is a rolling bevel, created by the use of a "fit stick" the thickness of the planking stock. The above article explains its use. Basically, it's an exercise in cutting notches at each frame end and then connecting them all in a graceful curve.

-

-

-

Is the build log for your original Winnie, available? I think I saw portions of it and it was built with boxwood, but now I can not find it. I wanted to compare it with the current build log on the Group Project to see what may be different.

Thanks

-

Thanks for the primer!! I will need to digest it with several readings. There is a lot of content. The glossary was a big help, iI would have bee lost without it.

-

Chuck

I signed up/paid to get plans for Winnie. Considering building the Winnie. Read a lot of the build logs. Confused by the scale postings on build logs. Some list 1/4 others list 1:48. Are these the same build or is there truly 2 different scales? Without completely reading every page of build logs have there been any issues with the cherry? I read one log where the builder started in cherry but later started over again in boxwood. Thanks