woodartist

-

Posts

286 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by woodartist

-

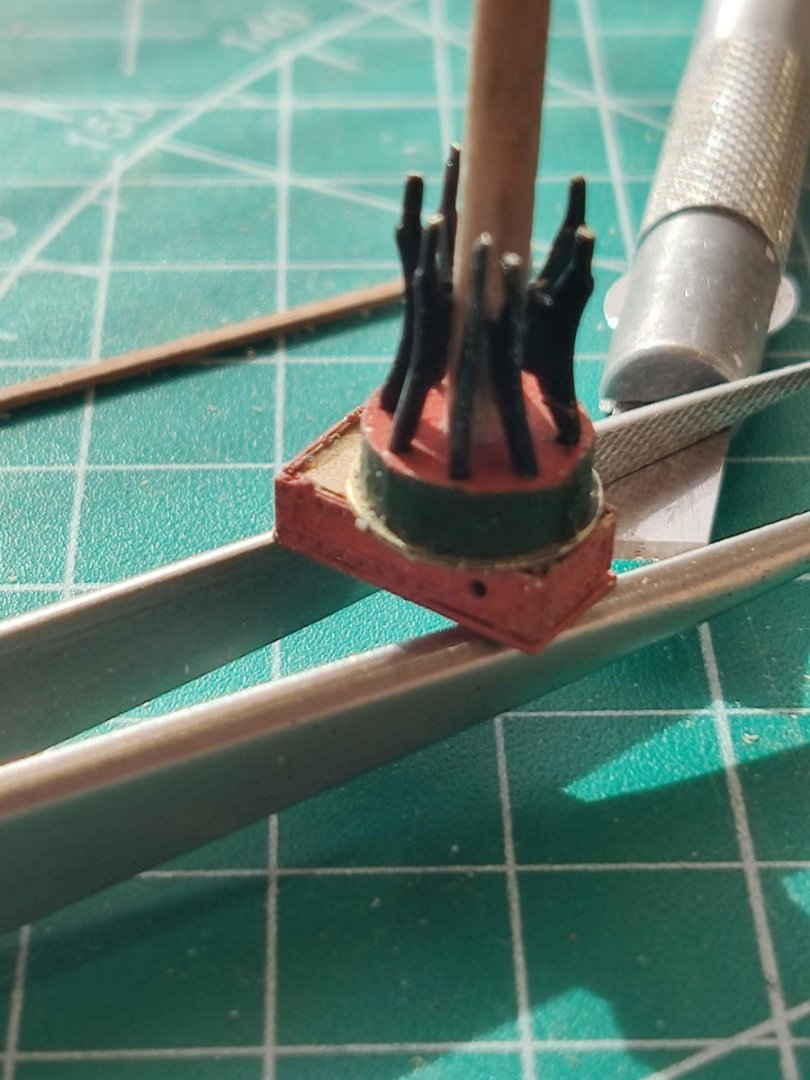

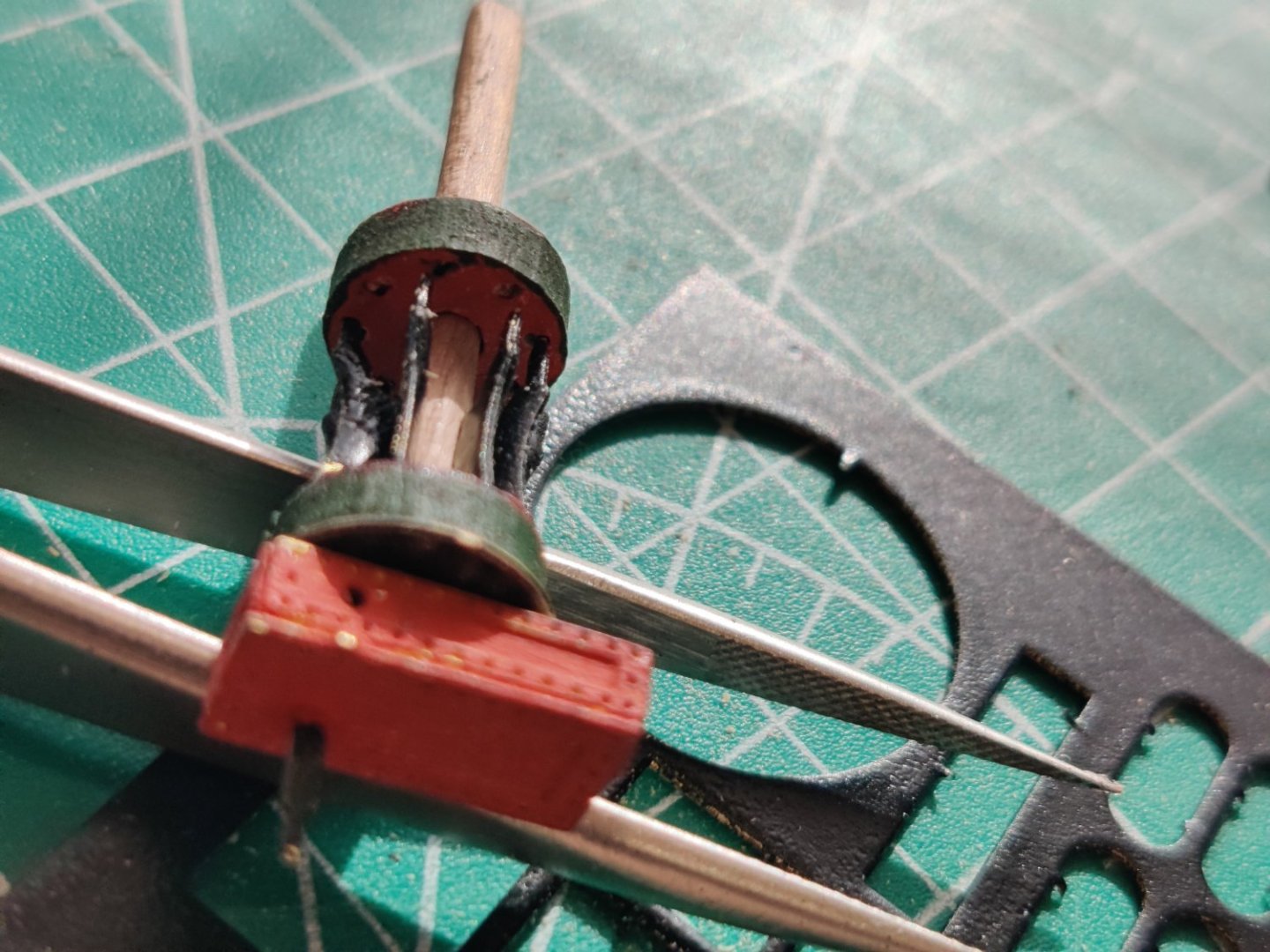

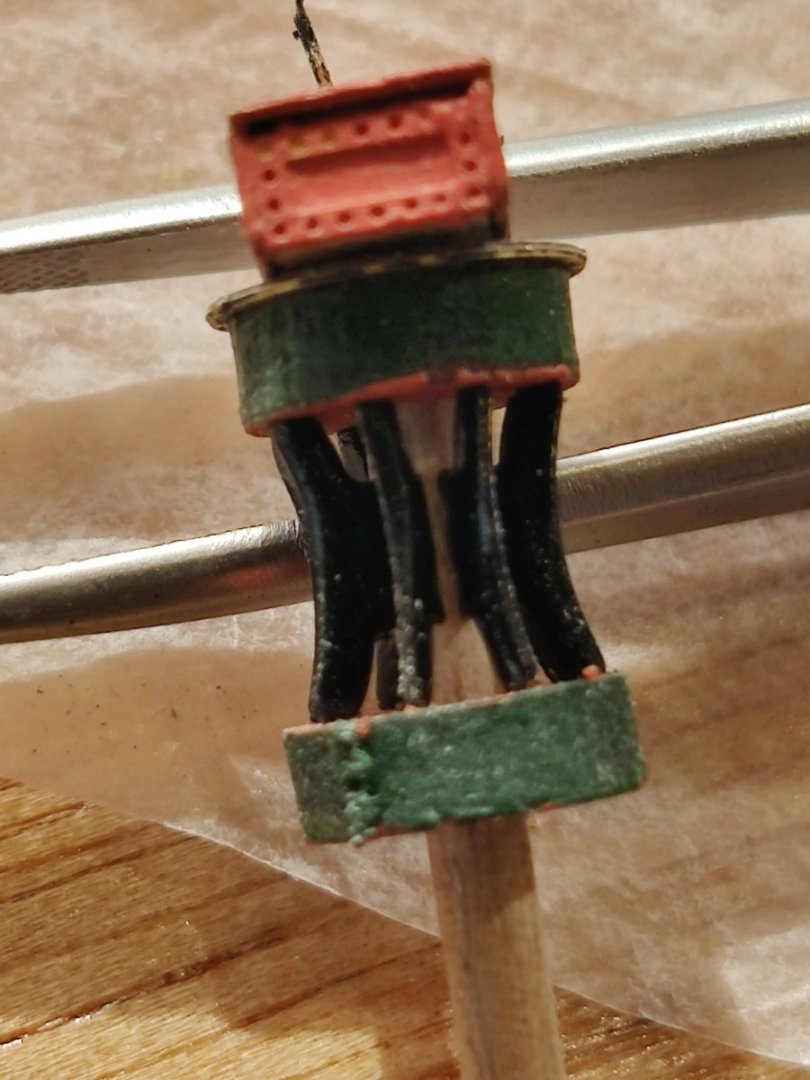

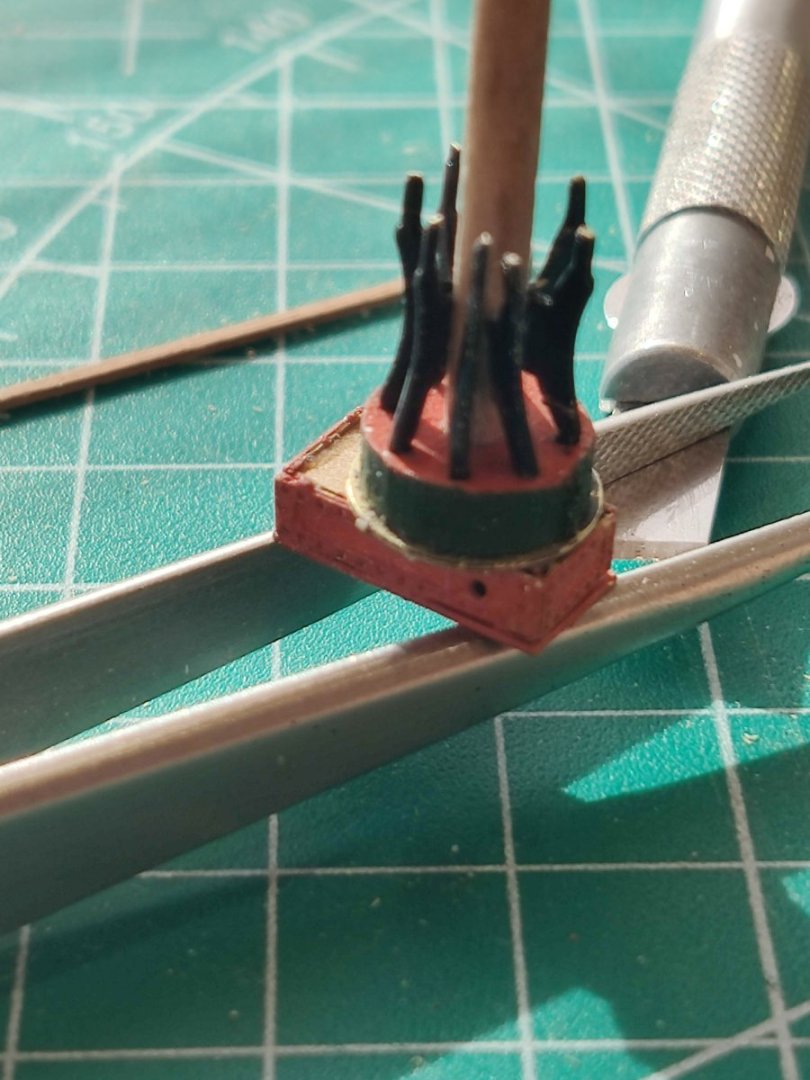

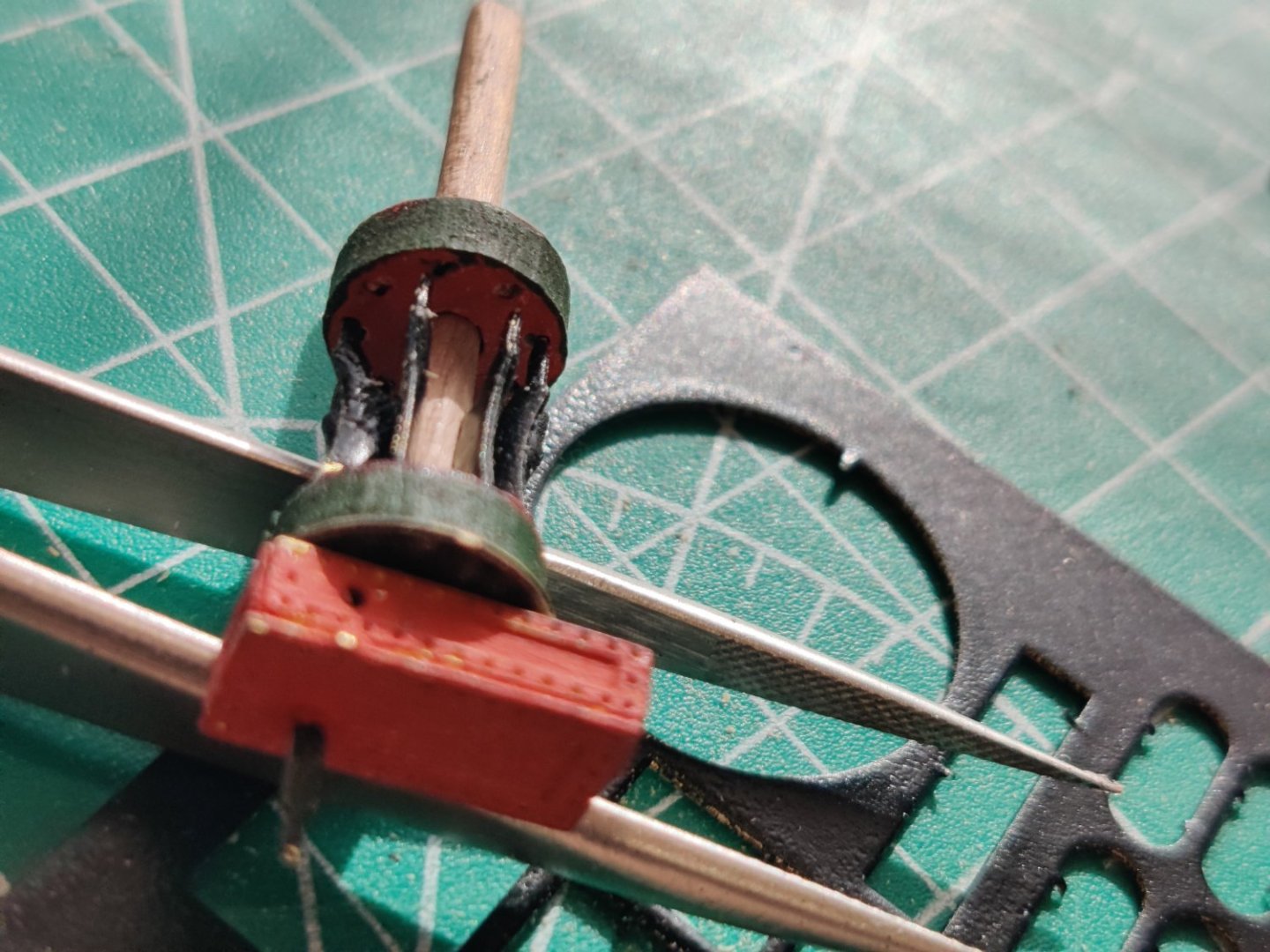

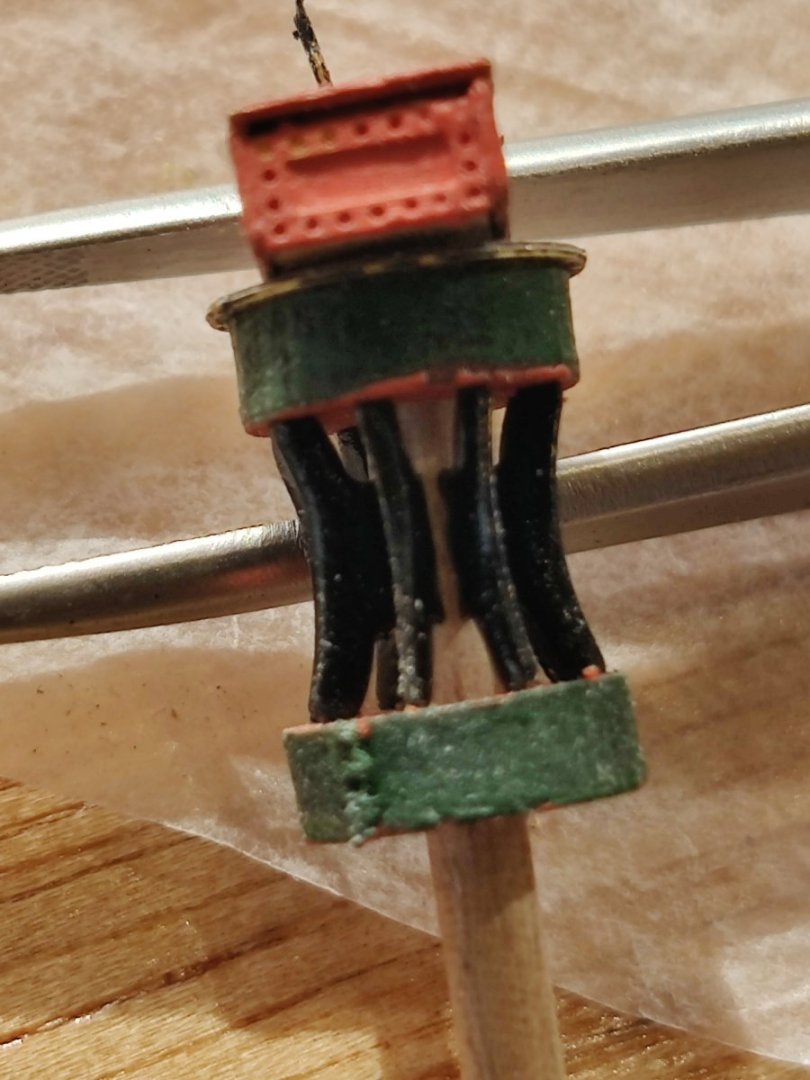

Working on the steam powered winch, it is wise to paint the component pieces before starting assembly, and just do touch up painting after assembly. Be sure to sand the dowel before cutting it to the 40mm length, it is much easier to sand then cut to length. Add the brass components that are not to be painted until after the assembly, including the post which is inserted into the orange top piece. It is helpful to have the winch sit flat when inserting the 8 center pieces that are painted black. You will also likely need to re-drill the eight holes for the center pieces after painting.

-

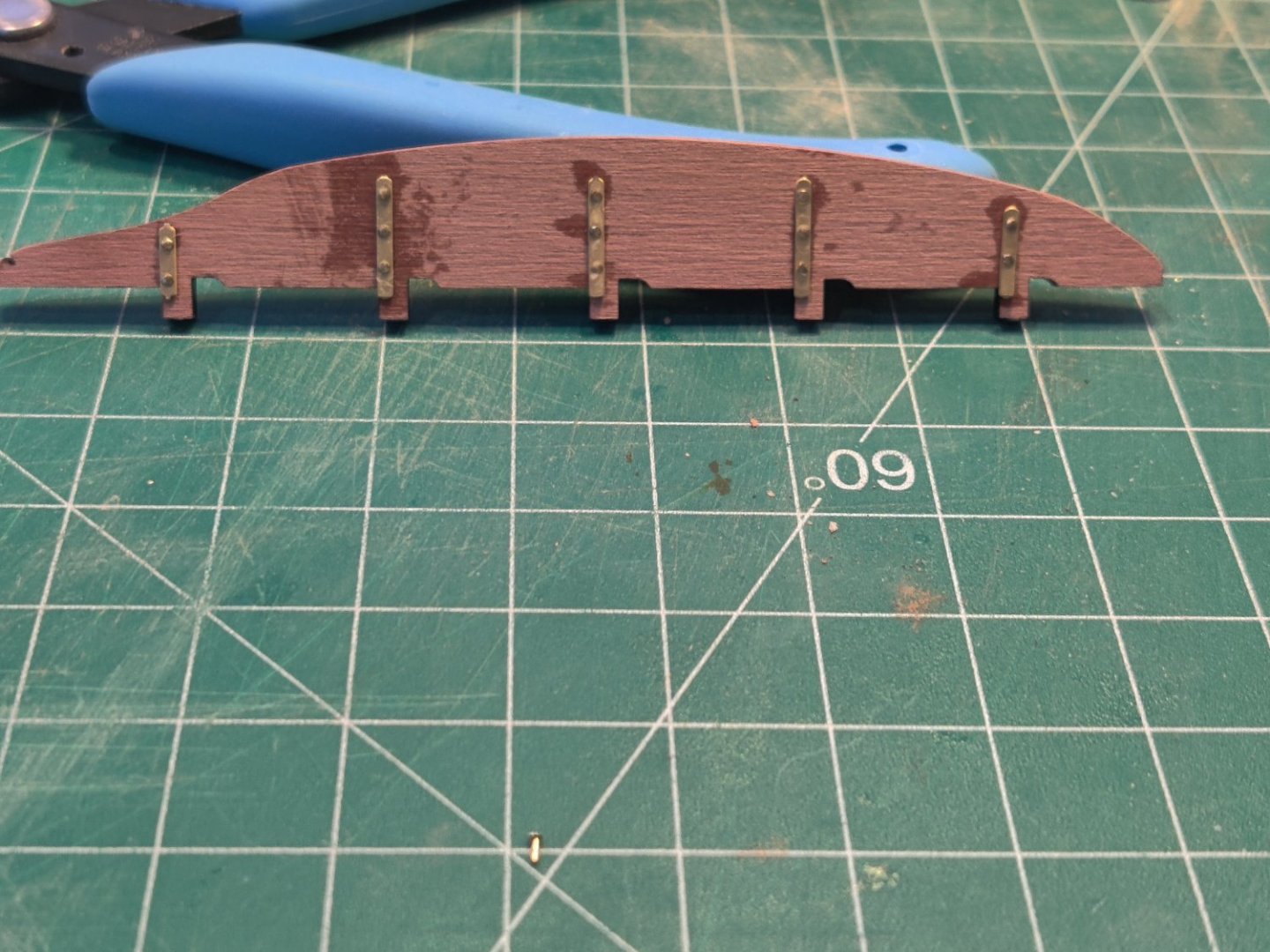

Some tips for novice builders on Lady Isabelle that I learned the hard way: 1.The brass plate that goes on the bow, if you are going to paint it black, wait until it is installed with glue to

paint, drilling the holes for the pins and the hammering of the pins ruins the paint, also the pins are too long at the top of the bow, you need to cut about 1/8" off the pins and it will fine. 2. Go thru all the instructions and identify which brass parts will need to be painted black. It is much easier to spray paint them when they are still connected to the brass plate card. Remove those brass parts that you do not want painted black while they are attached to the brass card before you paint the remainder of the parts. 3.Put the string thru the back of the stern steering box before you assemble the box. 4. Before you paint the bow, put pins in the three holes that will hold the little brass plate. the holes are so small that they disappear when painted. Also if you have sanded the bow the pins may be too long and will stick out the other side and will nee to be trimmed. 5. Before you start putting the 50+ rib pieces on, cover the two large openings on the main deck. I dropped one off the tweezers and it fell into the space and became attached somewhere on the inner hull so I had to make one from the edge of the wood pair card piece. I am sure that there will be more tips I learn the hard way before I am finished.

-

Thanks for the suggestion on using Gorilla Super Glue Gel. I got some and it is so much easier to use, using the squeeze handles give a measured amount of gel.

-

-

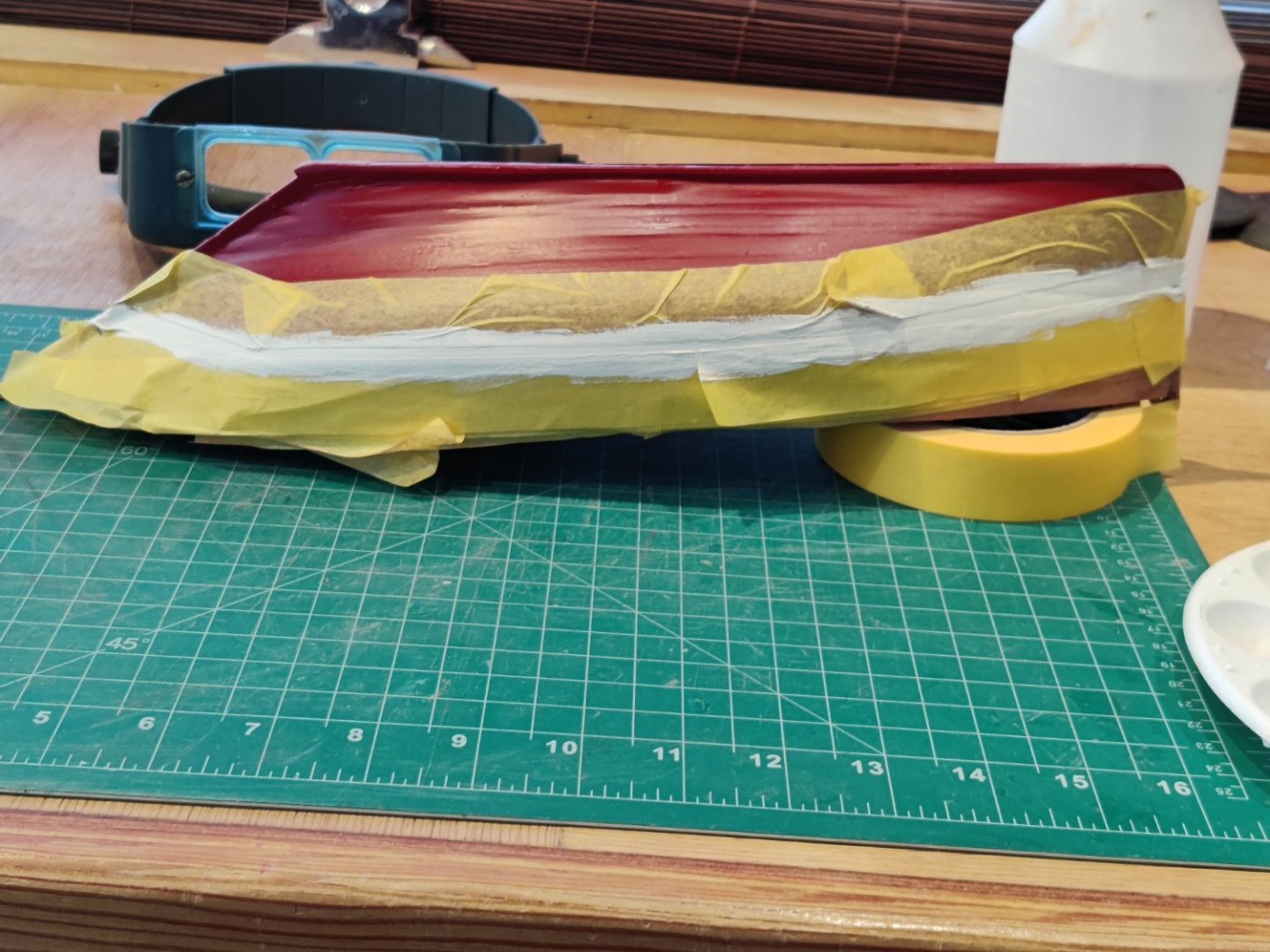

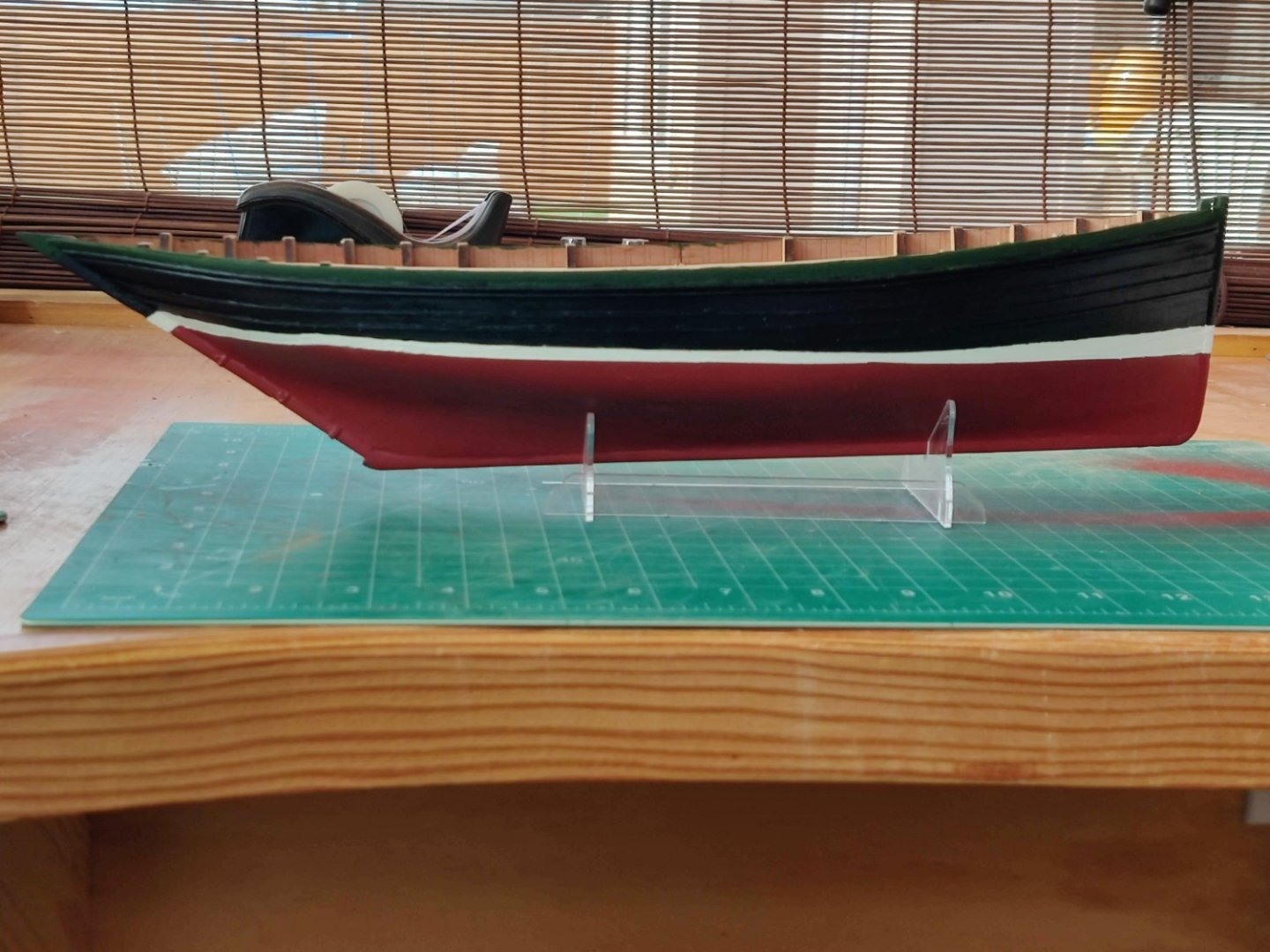

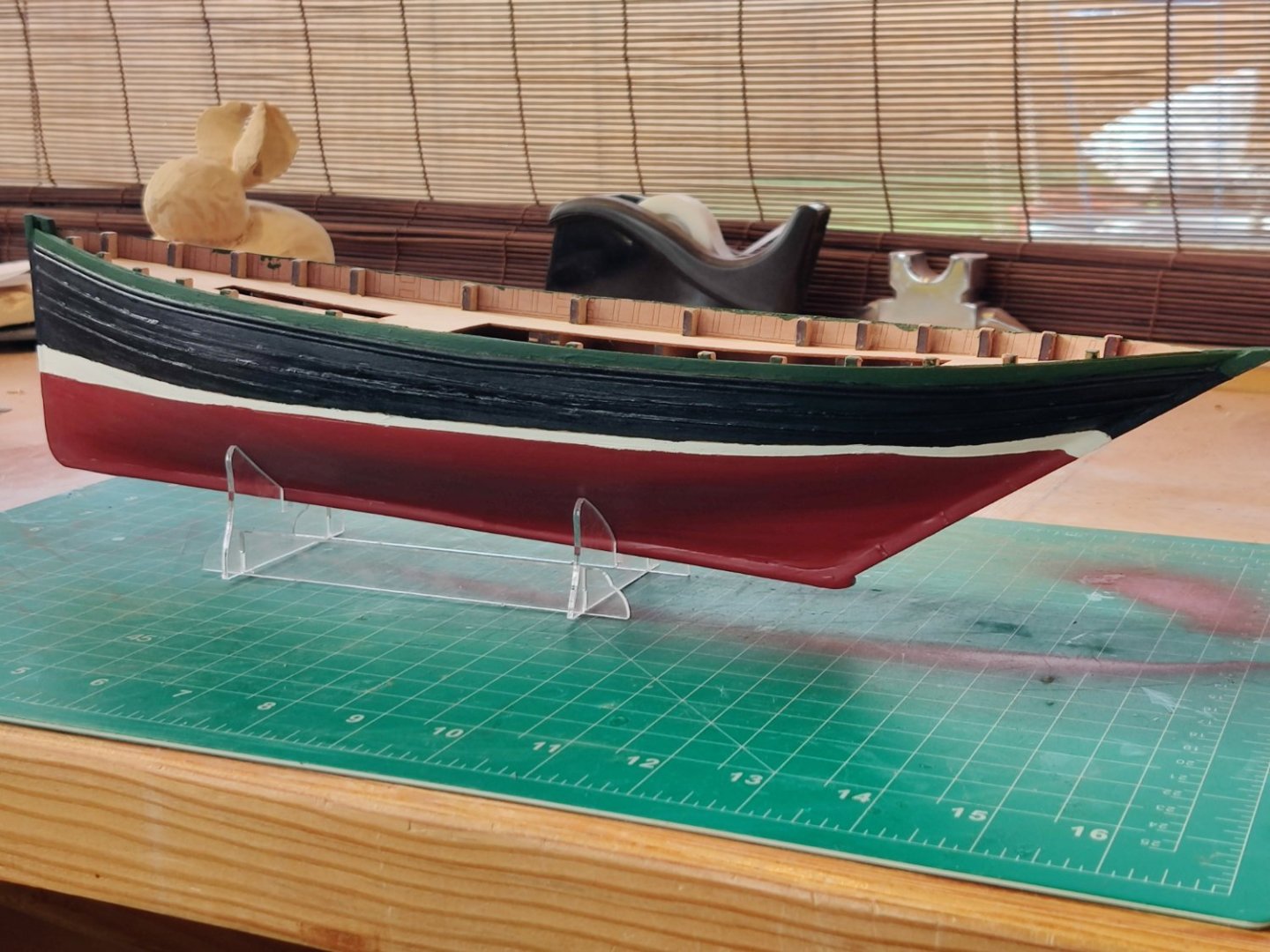

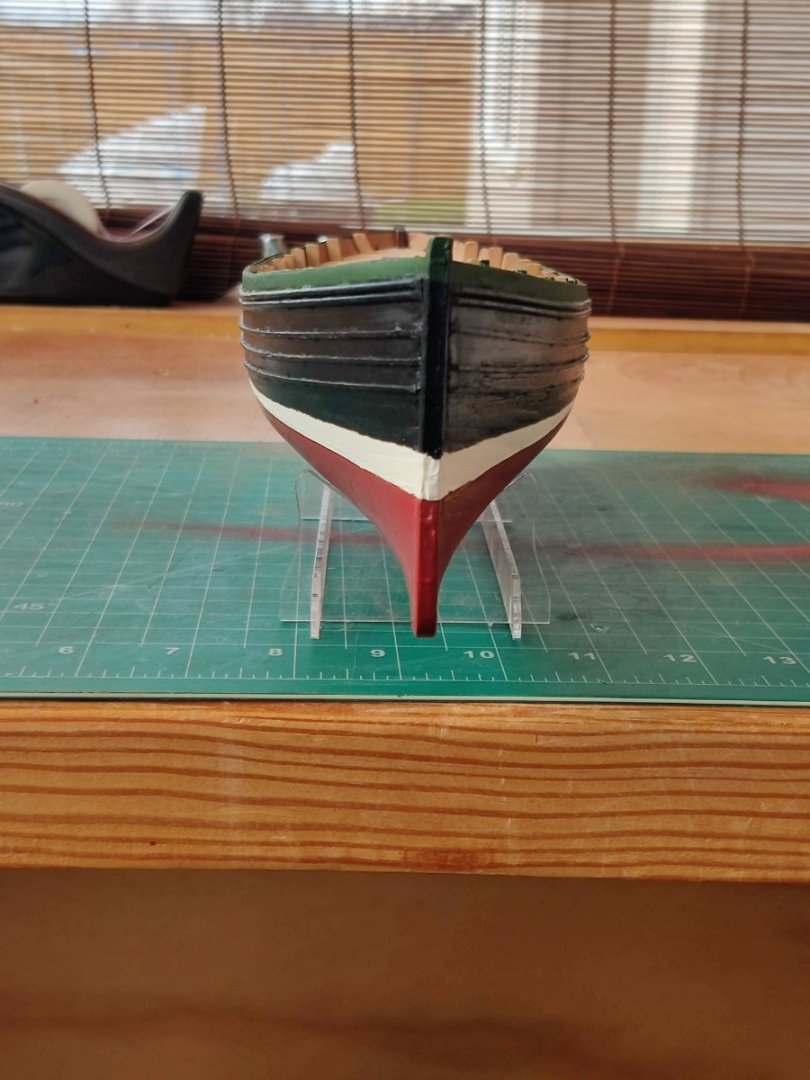

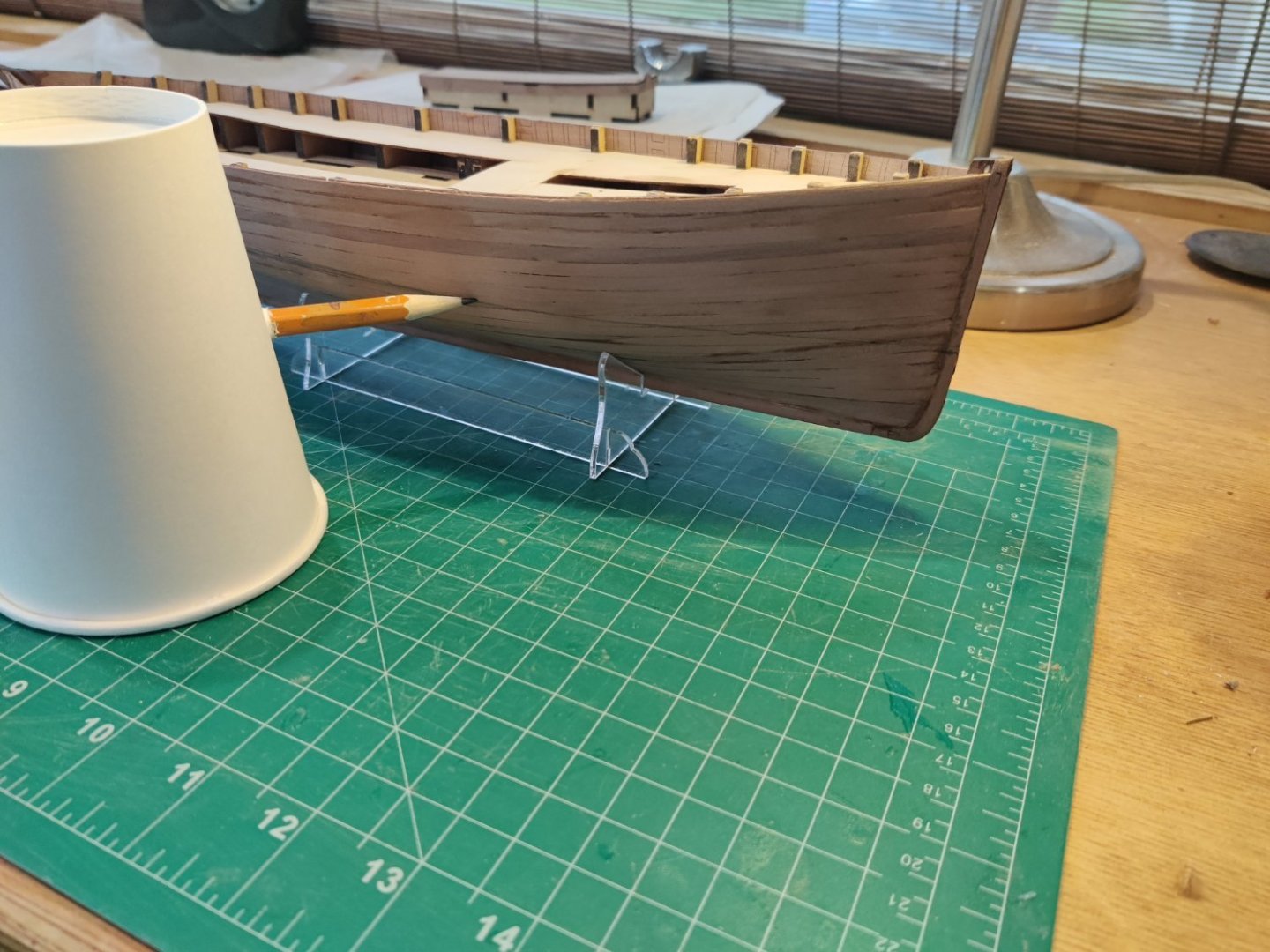

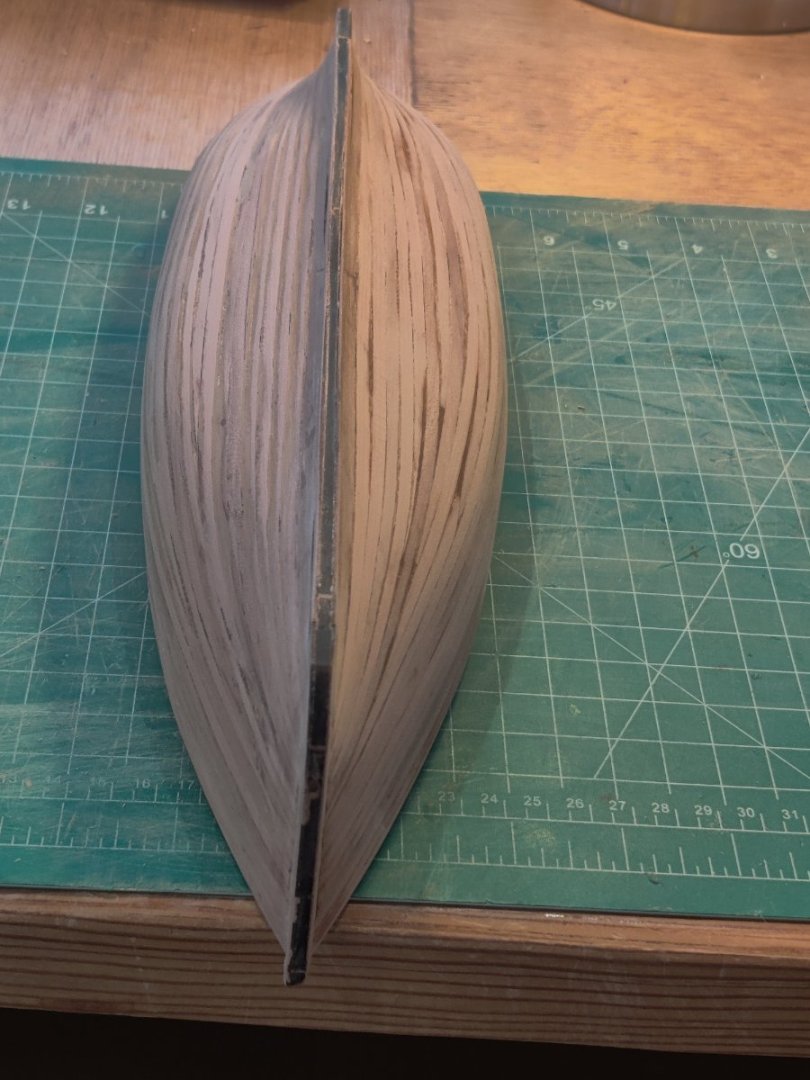

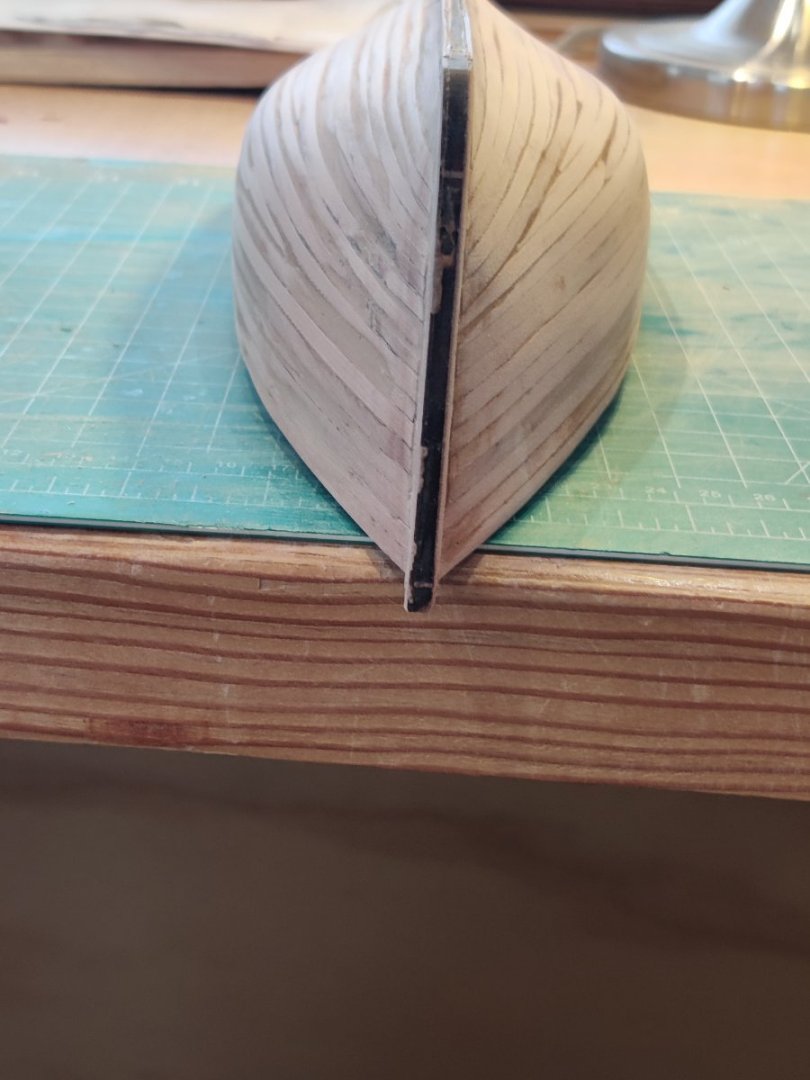

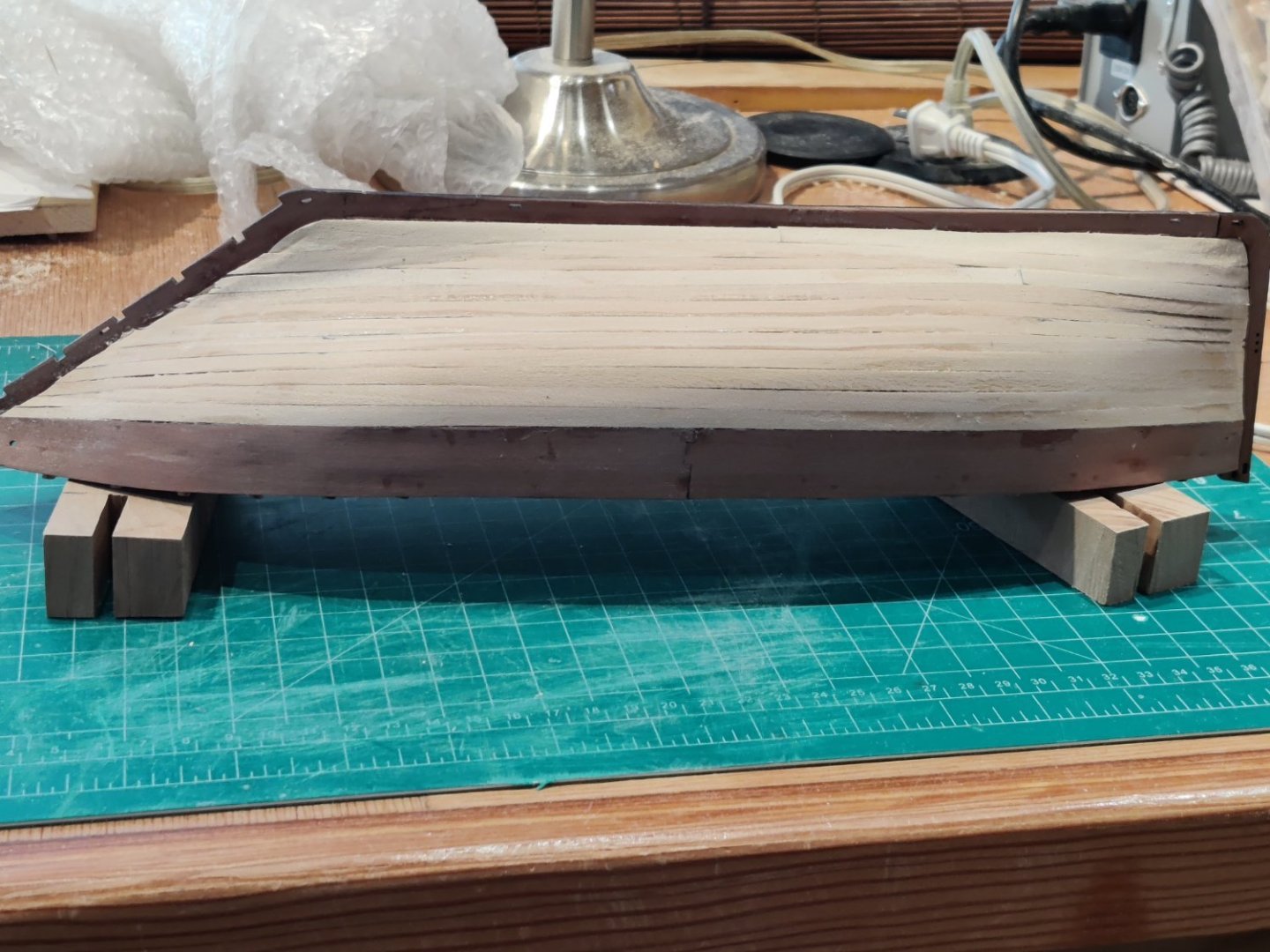

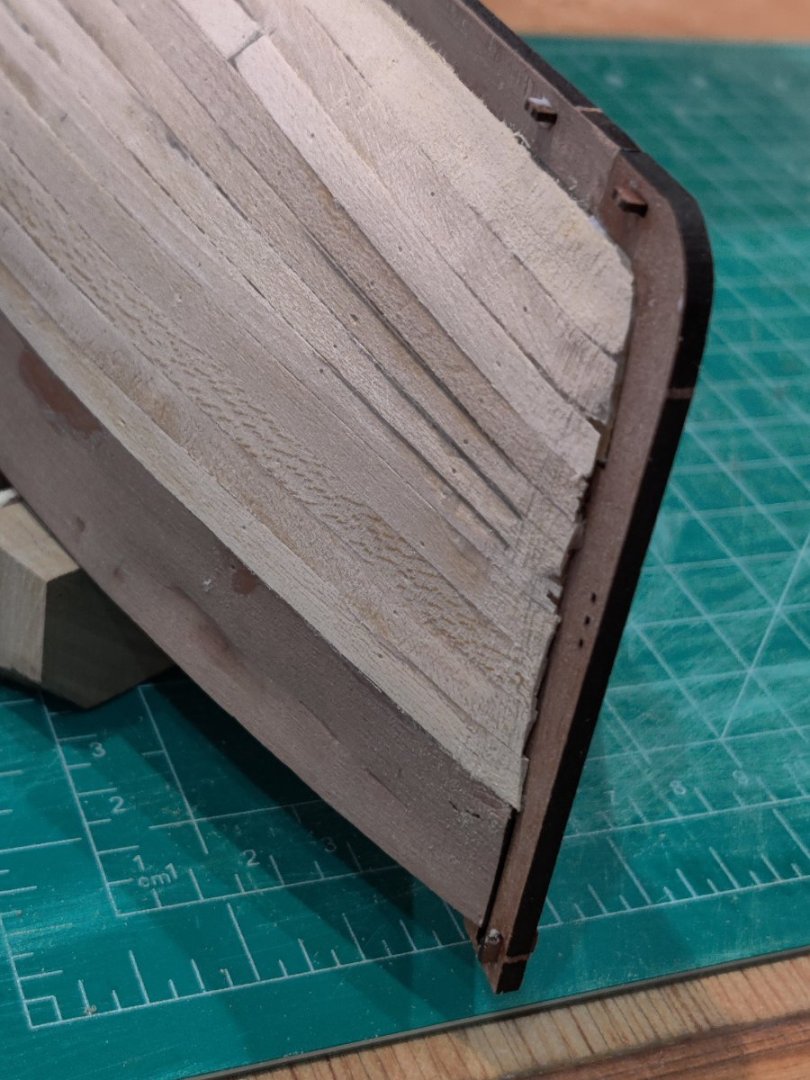

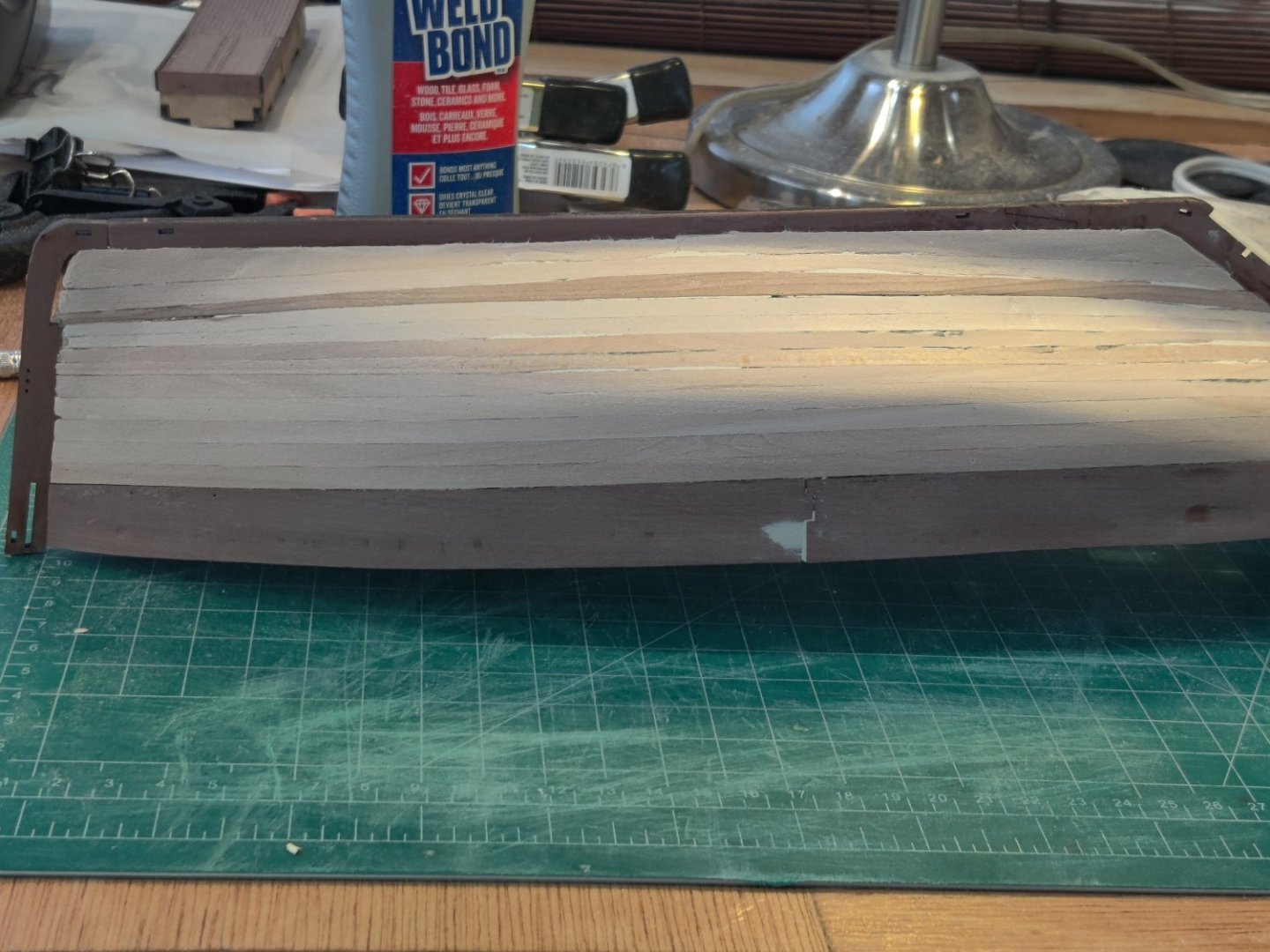

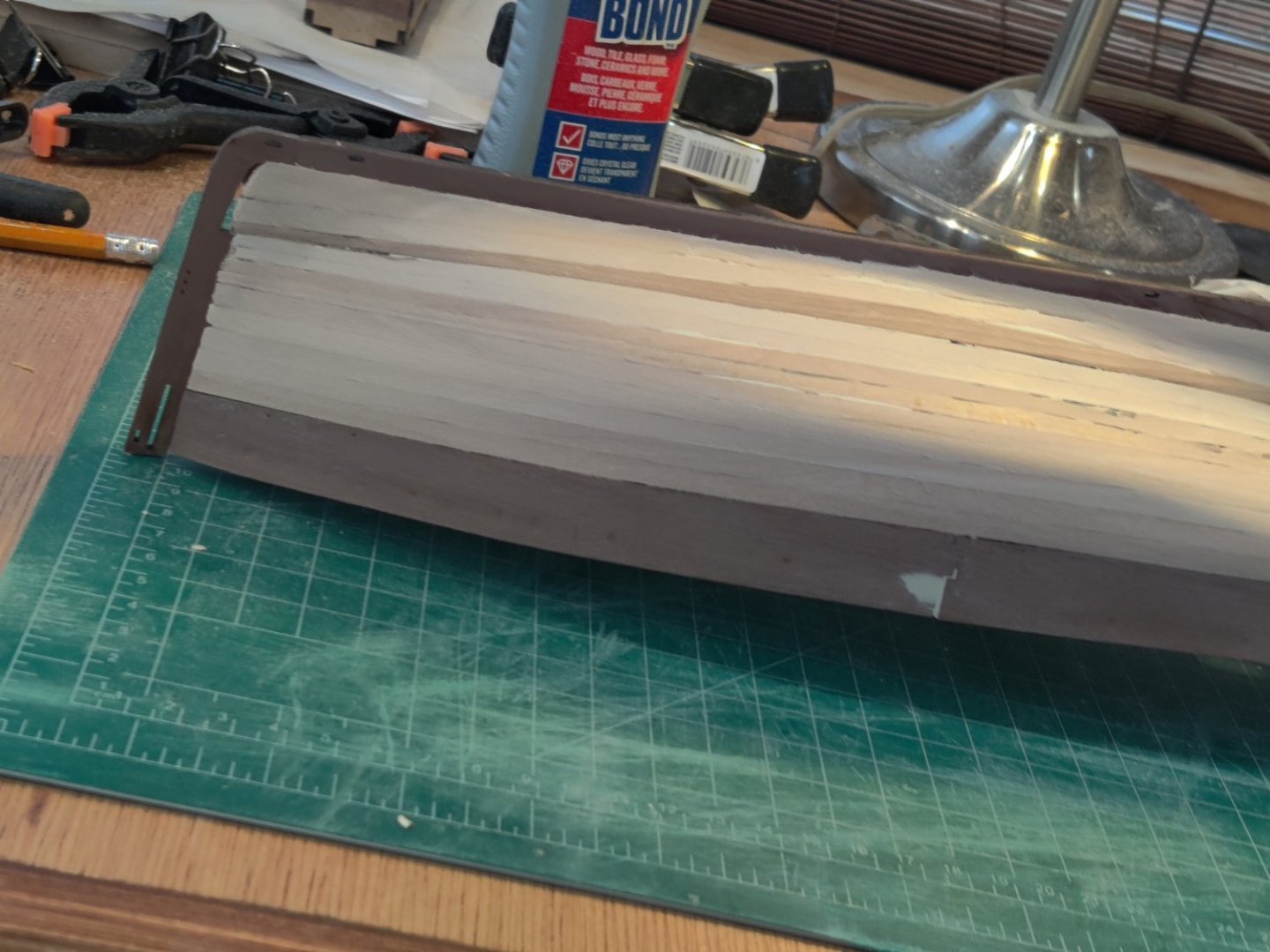

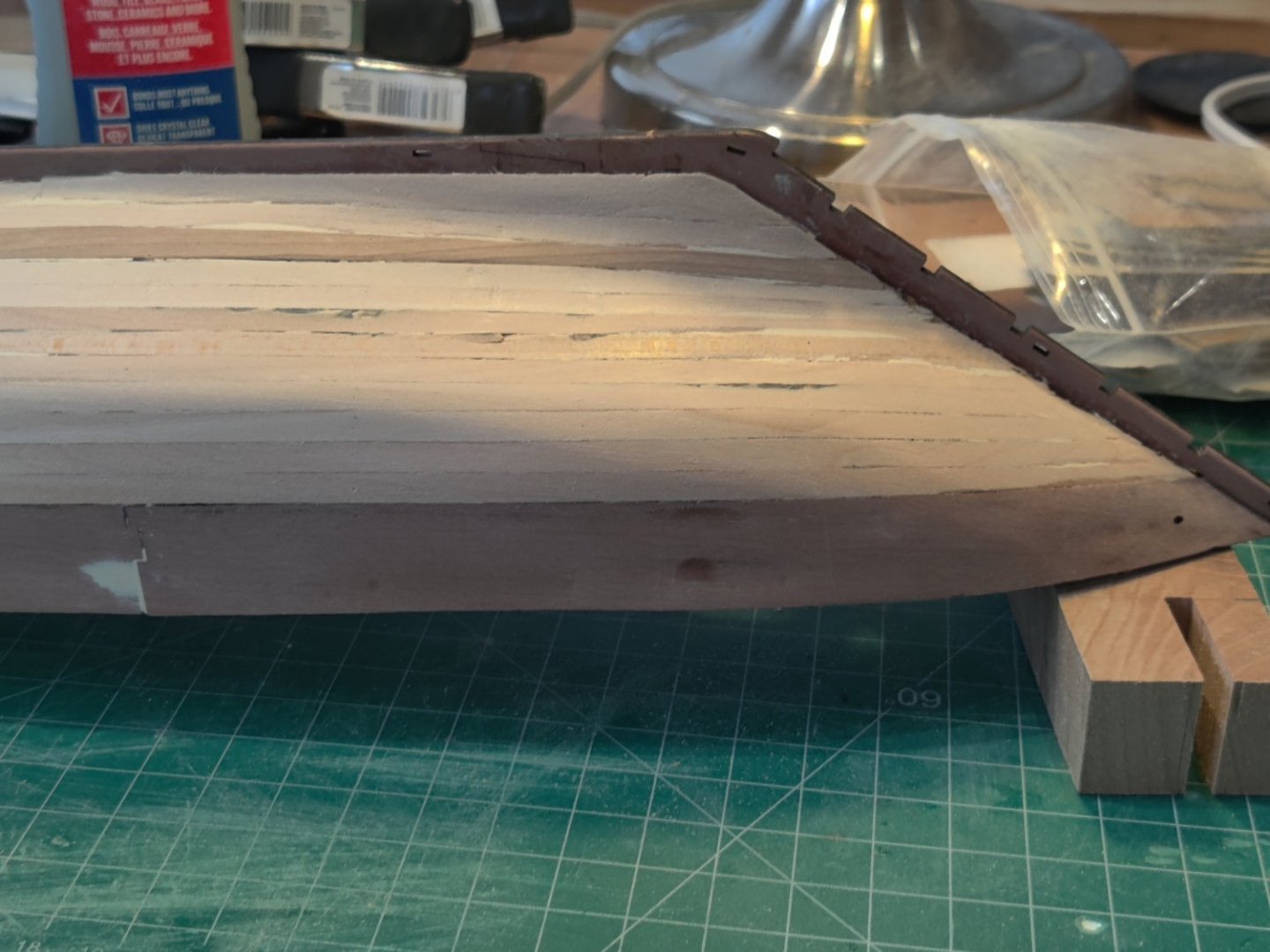

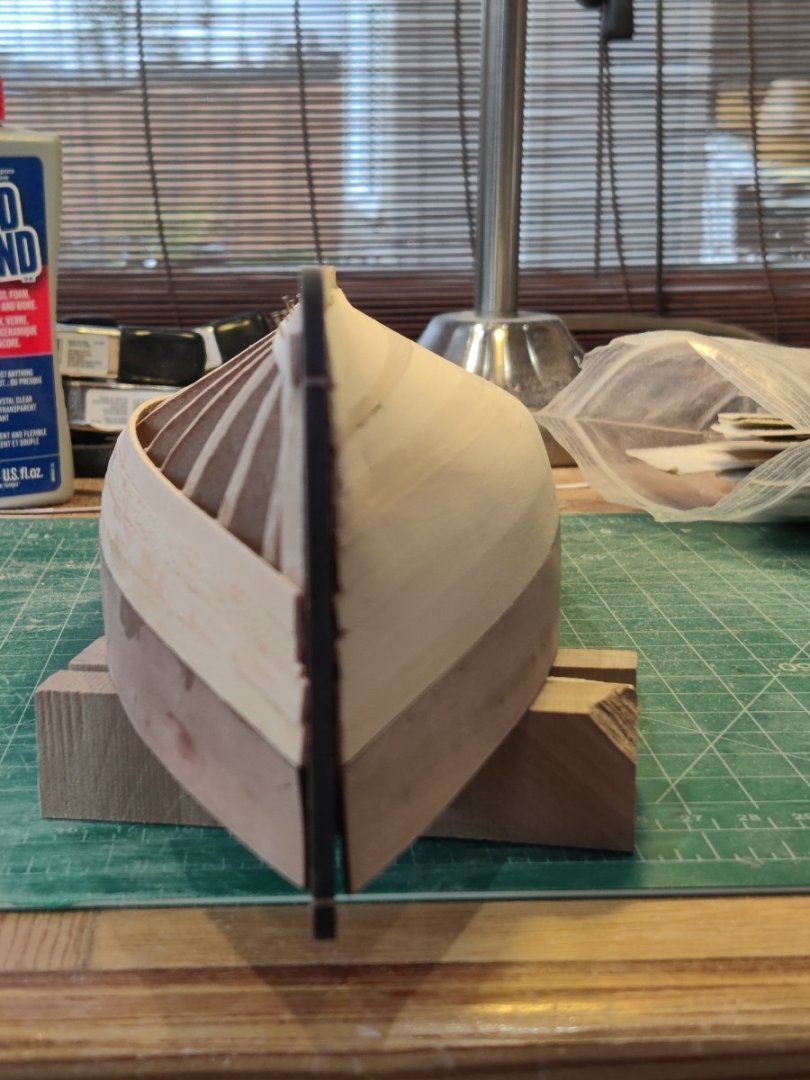

The one side of Zulu now has the first layer of planking completed and I spent the last few hours getting it sanded. I put some wood filler in the gaps before sanding. when you look at the pictures below from the side it looks like there is a swale. However, when you view from either end you do not get that impression. I think it is the color change in the wood that created that impression, not sure. It feels really smooth if touched so I am a little conflicted. Thoughts or suggestions are appreciated.