woodartist

NRG Member-

Posts

292 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by woodartist

-

I would love to start on this when you are ready. It looks awesome. Have you considered fully planking one side of the hull?

-

I too am a big fan of West Coast Lumber Schooners. I frequently visit the Port Gamble Museum, which houses the memorabilia from the Pope and Talbot lumber operations. There are numerous photos of the ships that sailed from their lumber mills on the Olympic peninsula and sent lumber to San Francisco.

-

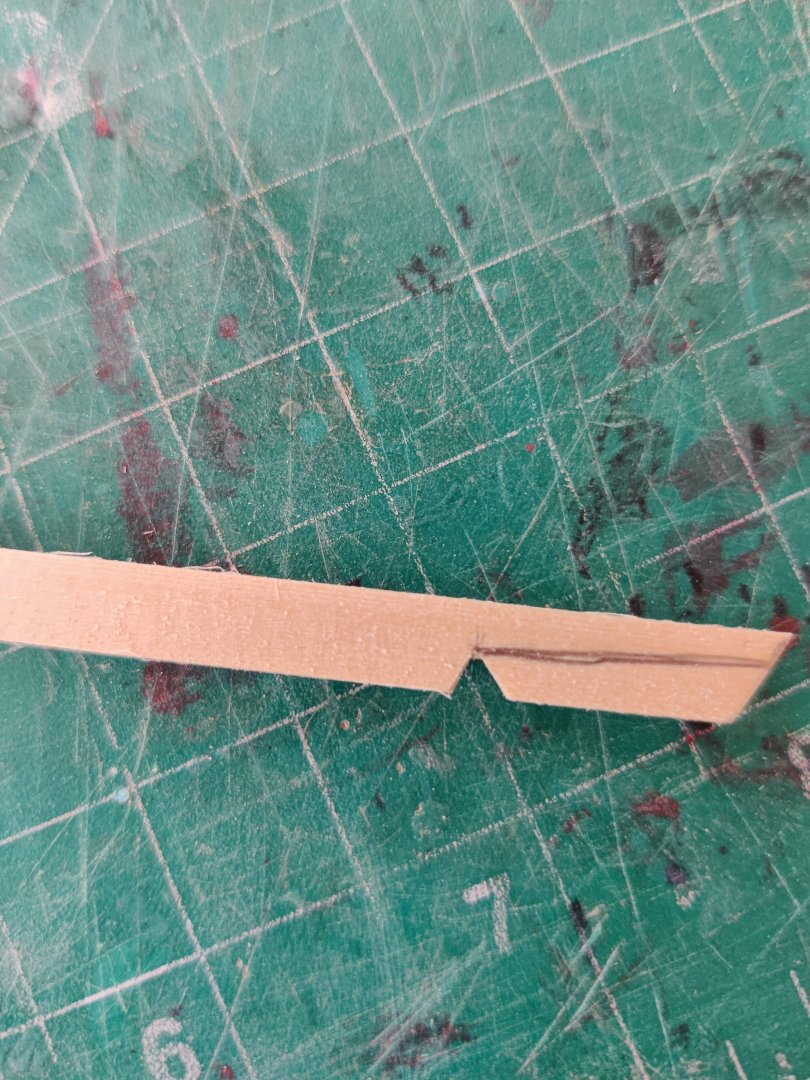

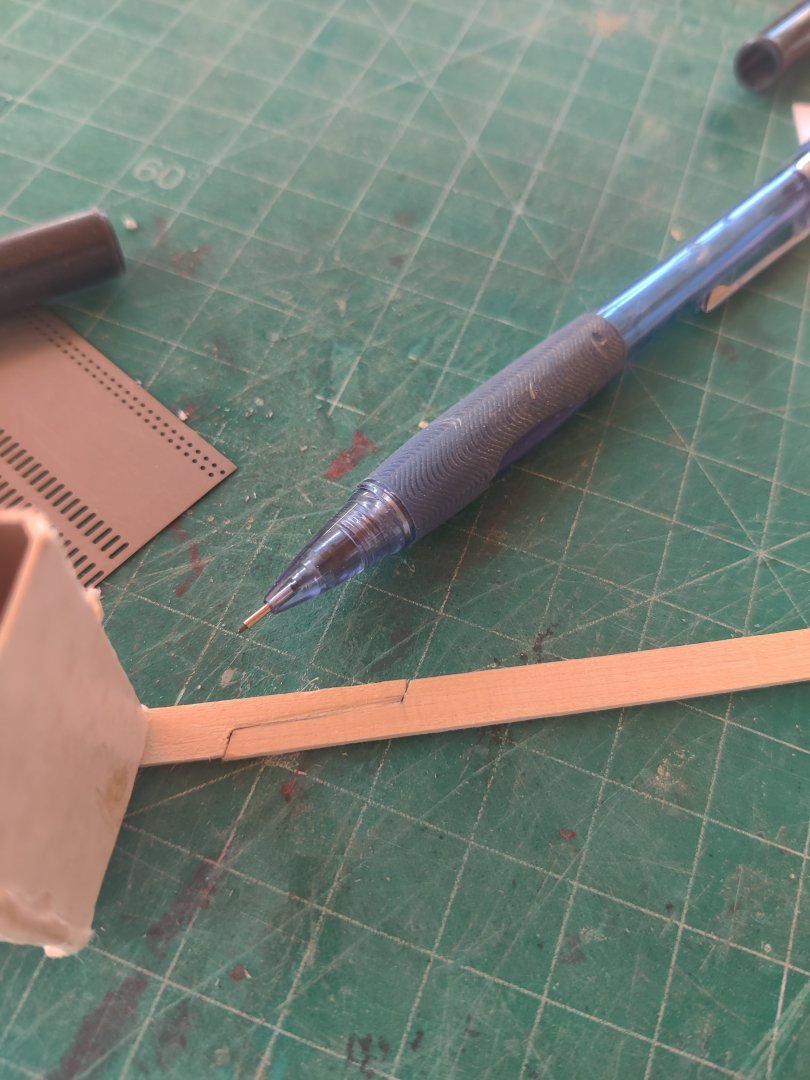

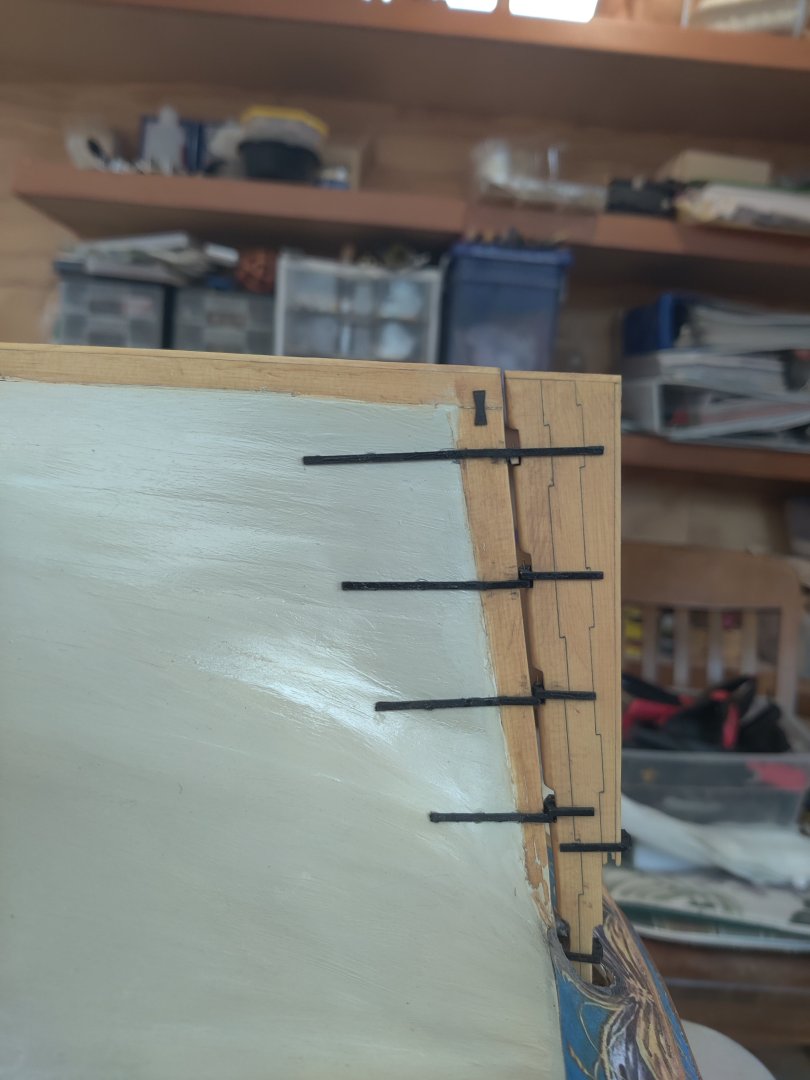

I finished on side of the forecastle cap rail. It was not without its problems, all self inflicted. I was not exact in fairing the bow. The curve at the bow was slightly different. I did not see that until I tried to place the cap rail on. The laser cut piece did not fit the curve. To cure that I had to cut the rail in two places to match the curve. It is not perfect but I did the best I could. The opposite side will be much easier because it matches the curve of the laser cut pieces. Thank goodness.

-

HMS Victory by ECK - OcCre - 1/87

woodartist replied to ECK's topic in - Kit build logs for subjects built from 1751 - 1800

Great idea to use the tape to reduce splitting -

I can not tell from the picture if there is a rabbit on the bow and stern where the planks meet the keel.

-

What do the color changes on the strips signify? Why do the lines on the strips run in different directions?

-

I learned more about planking from Der Alte Rentner log on planking than i did any place else.

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

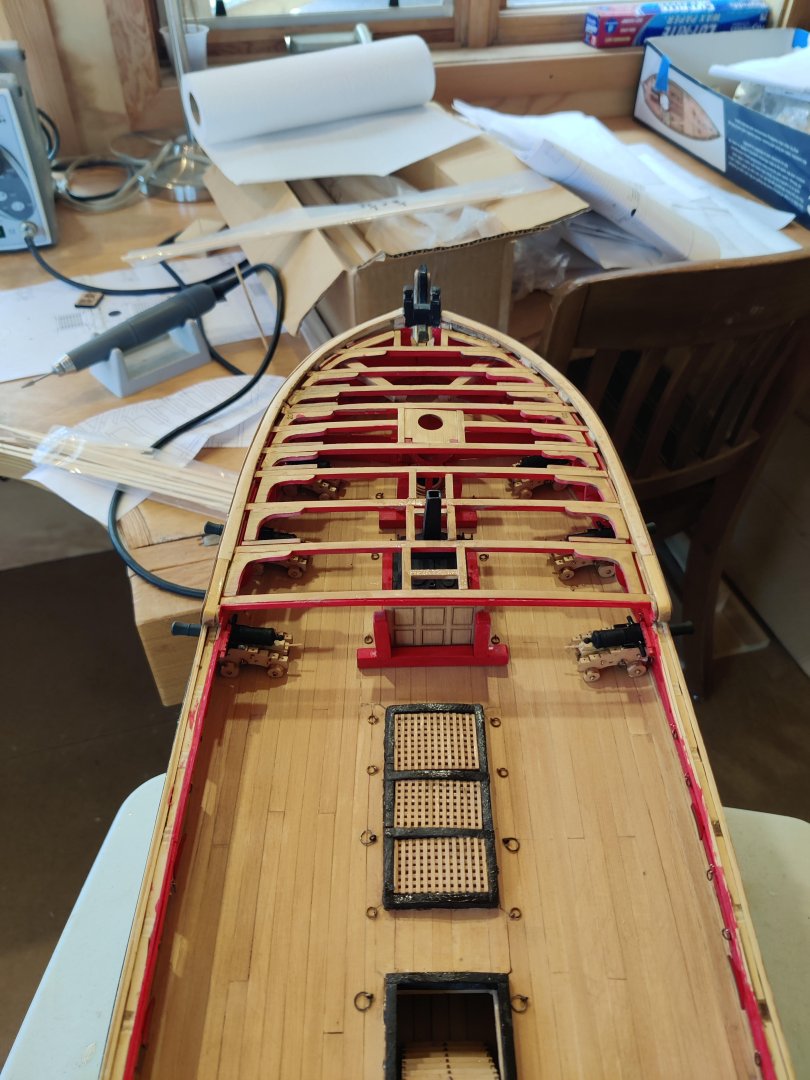

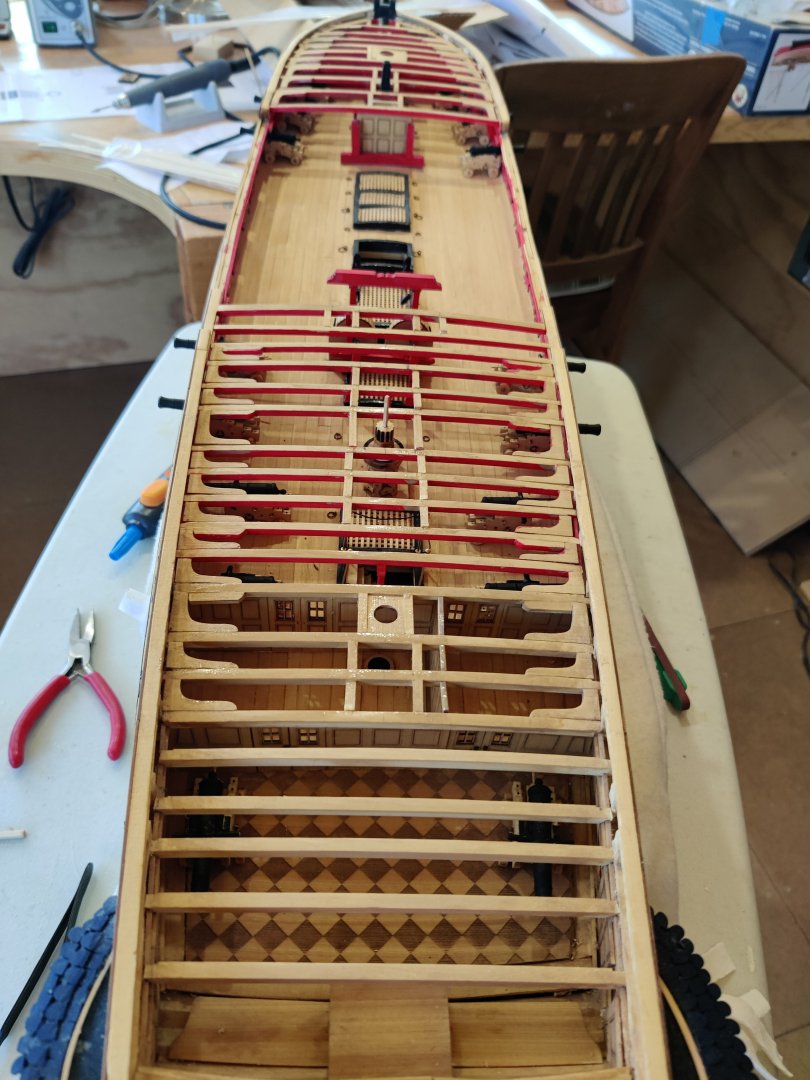

USS Constitution by mtbediz - 1:76

woodartist replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

beautiful, love to see your work -

i was going to order more parts, anytime in the next 10 days is ok. I have deck planking to complete

-

Thanks, This has been a very rewarding journey. There are some really awesome examples and it is hard not to compare ones work to those, nonethe less completing each task and chapter is so exhilarating that it motivates you to face the next challenge with a smile. Your guidance and others makes it all possible.

-

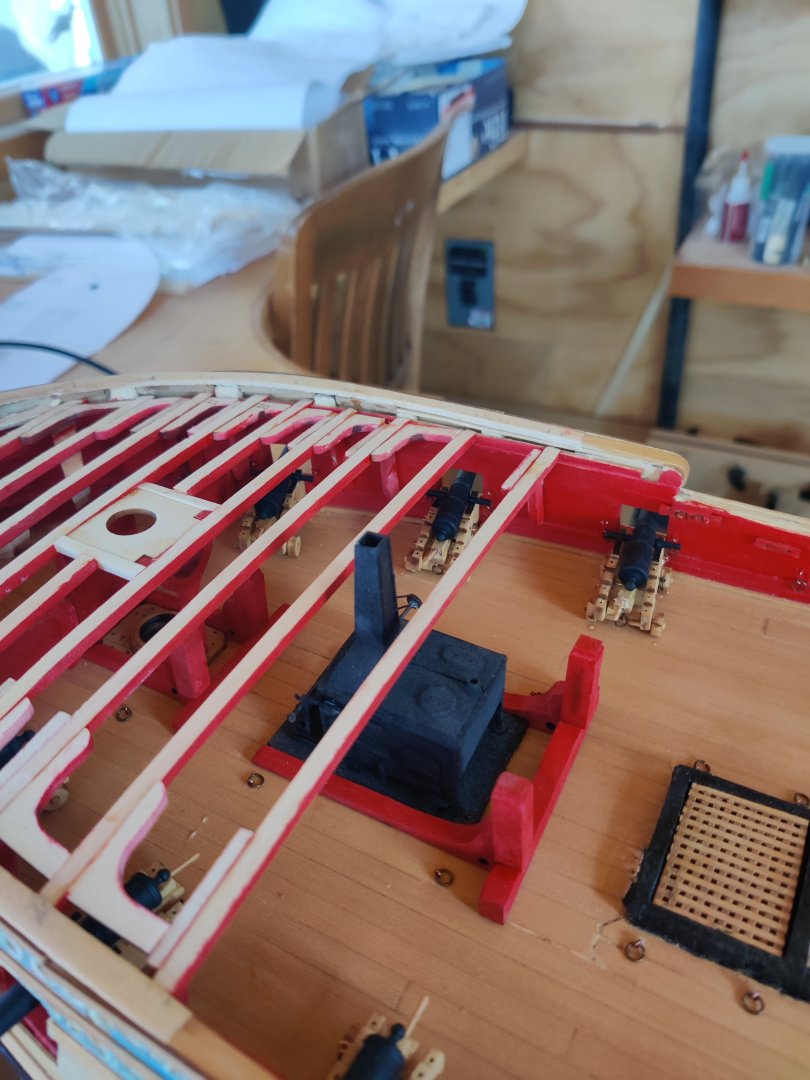

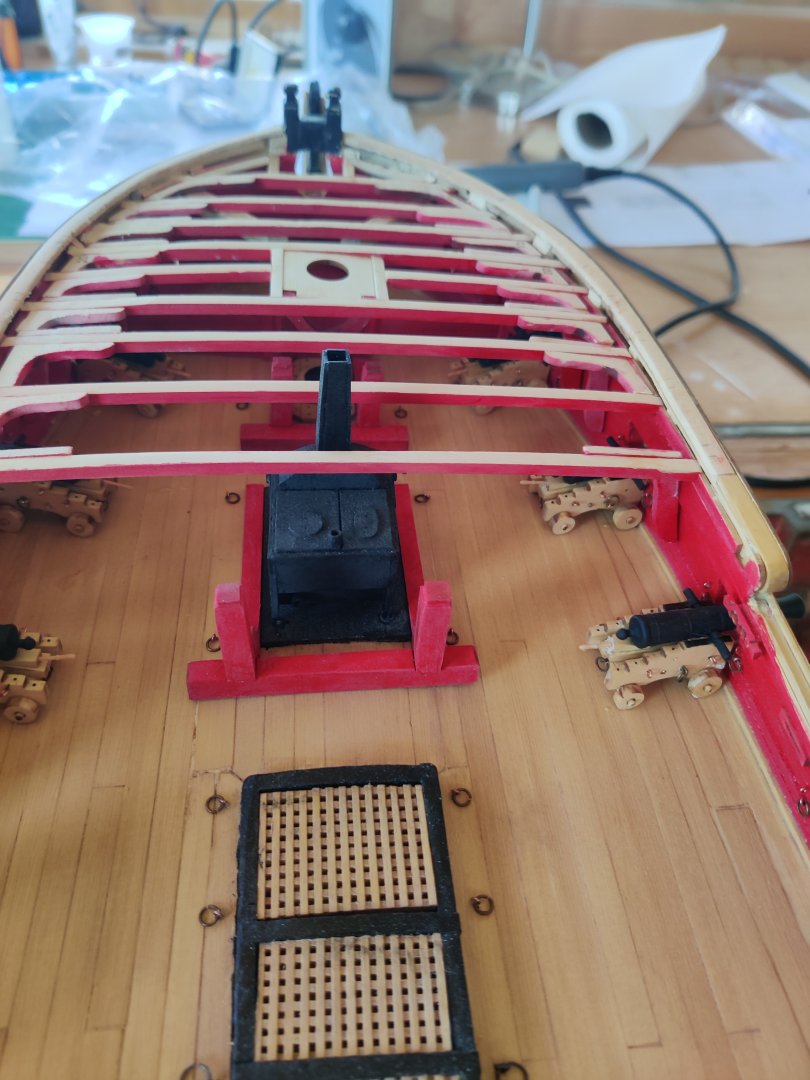

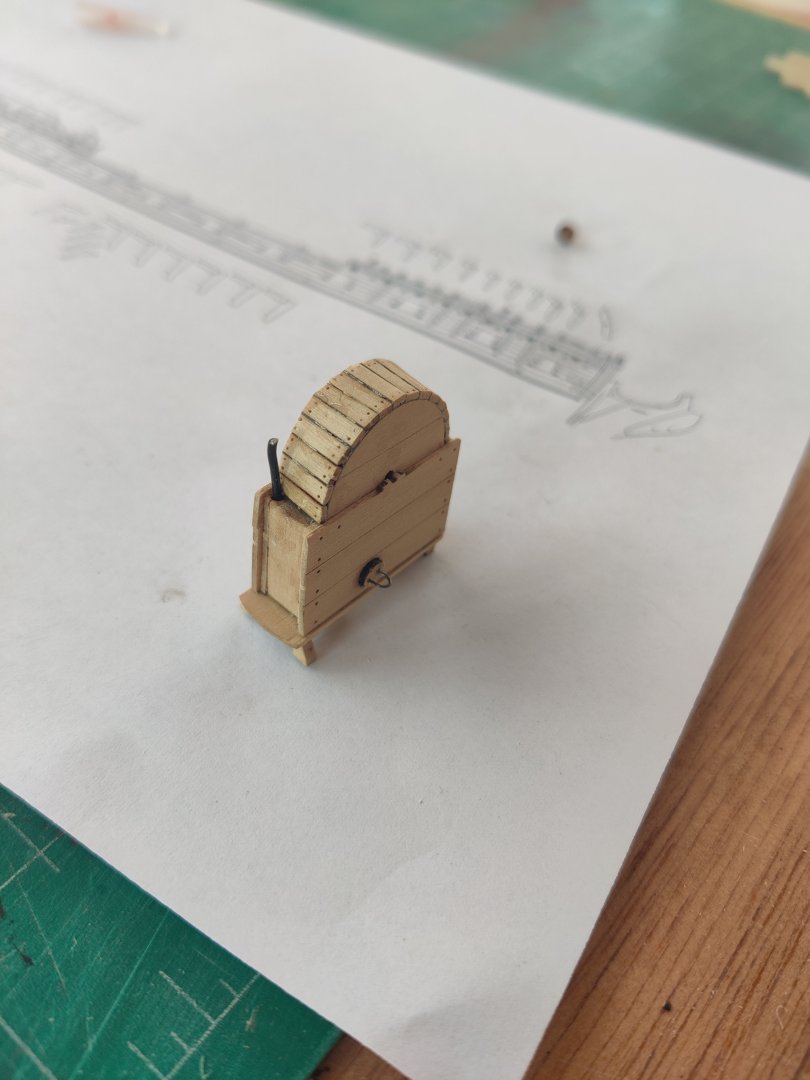

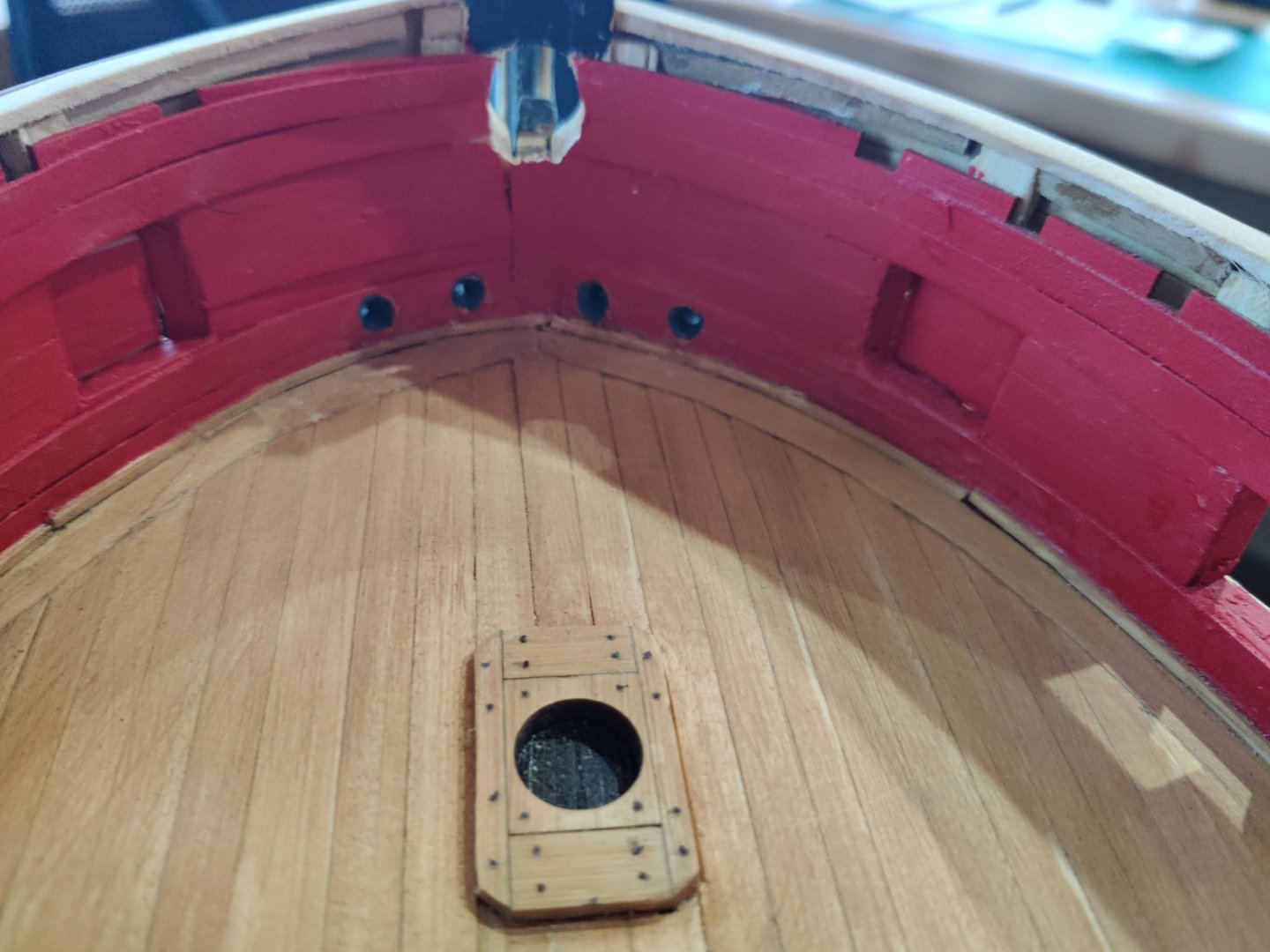

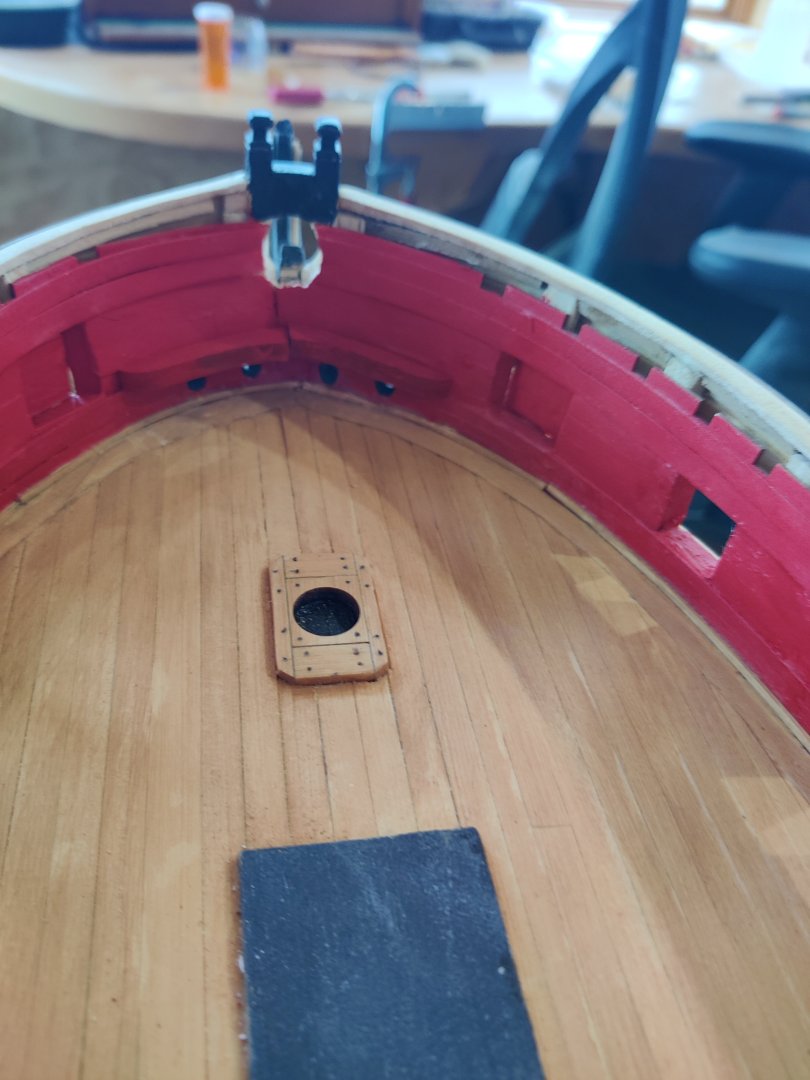

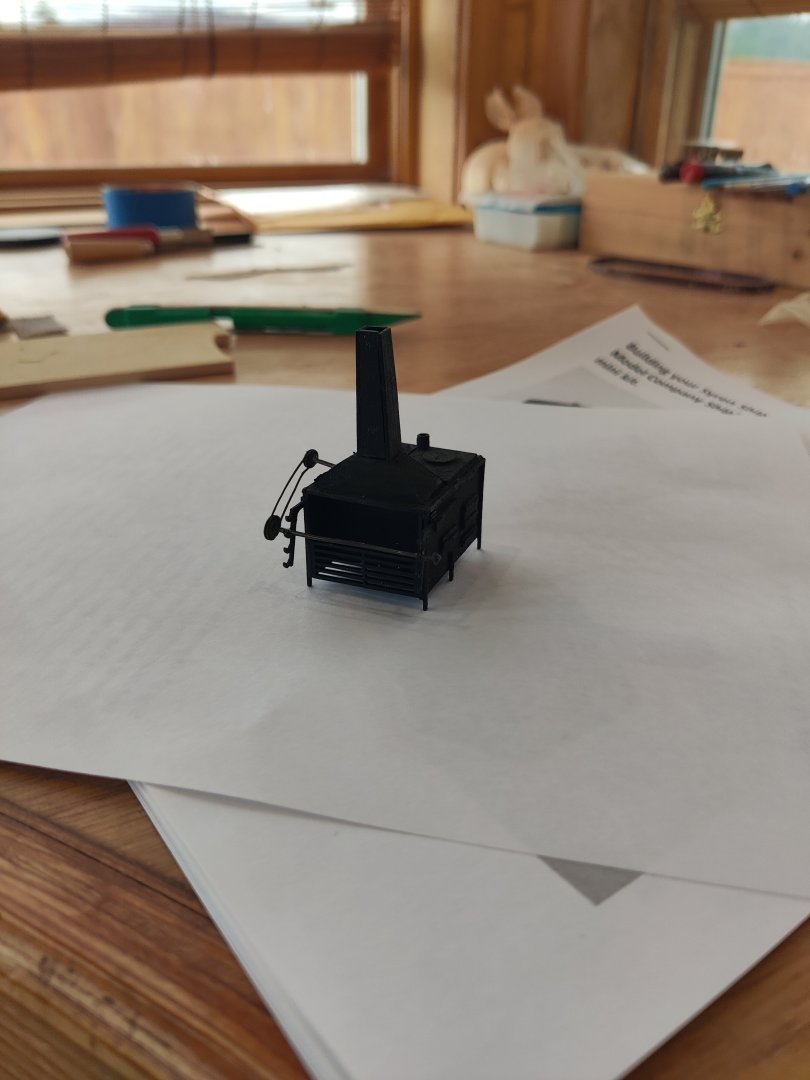

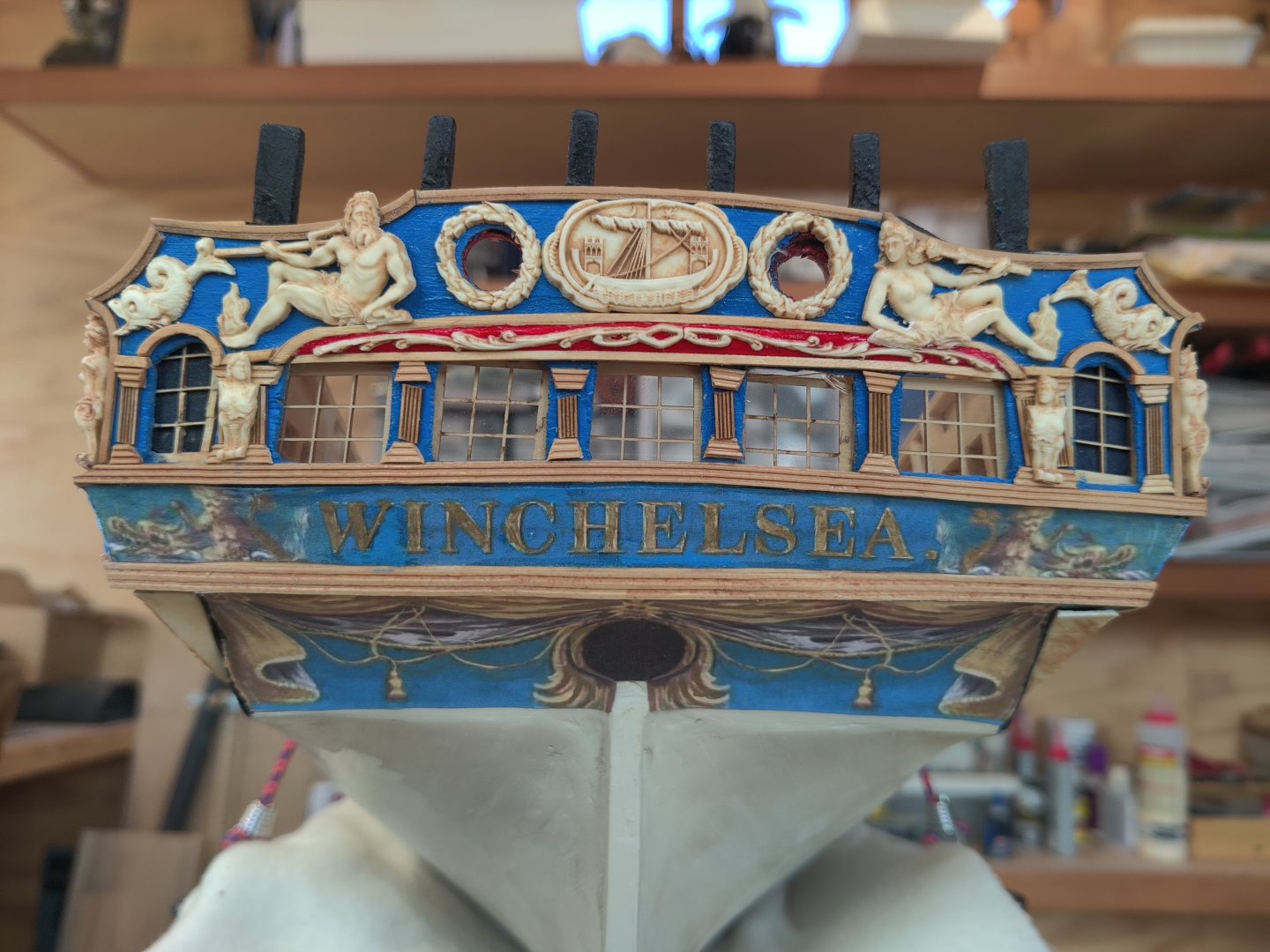

It has been 6 months since I last posted but I have been diligently working. However, Chapter three took me a very long time. It is very detailed work and trying to do it with just one hand created a lot of challenges and i ad repeated do overs in the process. The final product is not without flaws but it the best I could muster. I simply do not have the capability to be as precise as the masters that exist on this site. Nonetheless, I really enjoy the challenge.

-

USS Constitution by mtbediz - 1:76

woodartist replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I absolutely love the precision of all that you do

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.