woodartist

NRG Member-

Posts

292 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by woodartist

-

San Francisco cable car by kgstakes - FINISHED - OcCre

woodartist replied to kgstakes's topic in Non-ship/categorised builds

Really clean build! -

For those who have built your kits, and considering the time, effort, and expense of building a quality ship, they will not be seduced into buying an inferior kit. Those that do so will notice what could have been and that is a horrible realization. Been there done that, will not repeat the mistake!!

-

I whole agree. I bought 2 pairs and with the second pair I filed the v a little deeper to accept larger pins.

- 48 replies

-

- Lady Isabella

- zulu

-

(and 1 more)

Tagged with:

-

Importing files into Delftship

woodartist replied to woodartist's topic in CAD and 3D Modelling/Drafting Plans with Software

the pdf files really help.Thanks so much, I will figure this out somehow. -

I have never used a cad program before for starts, however I have downloaded the free version of the software, I am trying to import plans. I have the same plans in jpeg, bmp, and tif files. I would like to learn how to use the software but can not find a basic tutorial to get started. I thought that if if loaded in some boat plans that I have that it would be a place to start. But when i try to load the plans into the app it appears that Delftship only recognize fbm or bak files. How can i proceed? Is there a basic tutorial online?

-

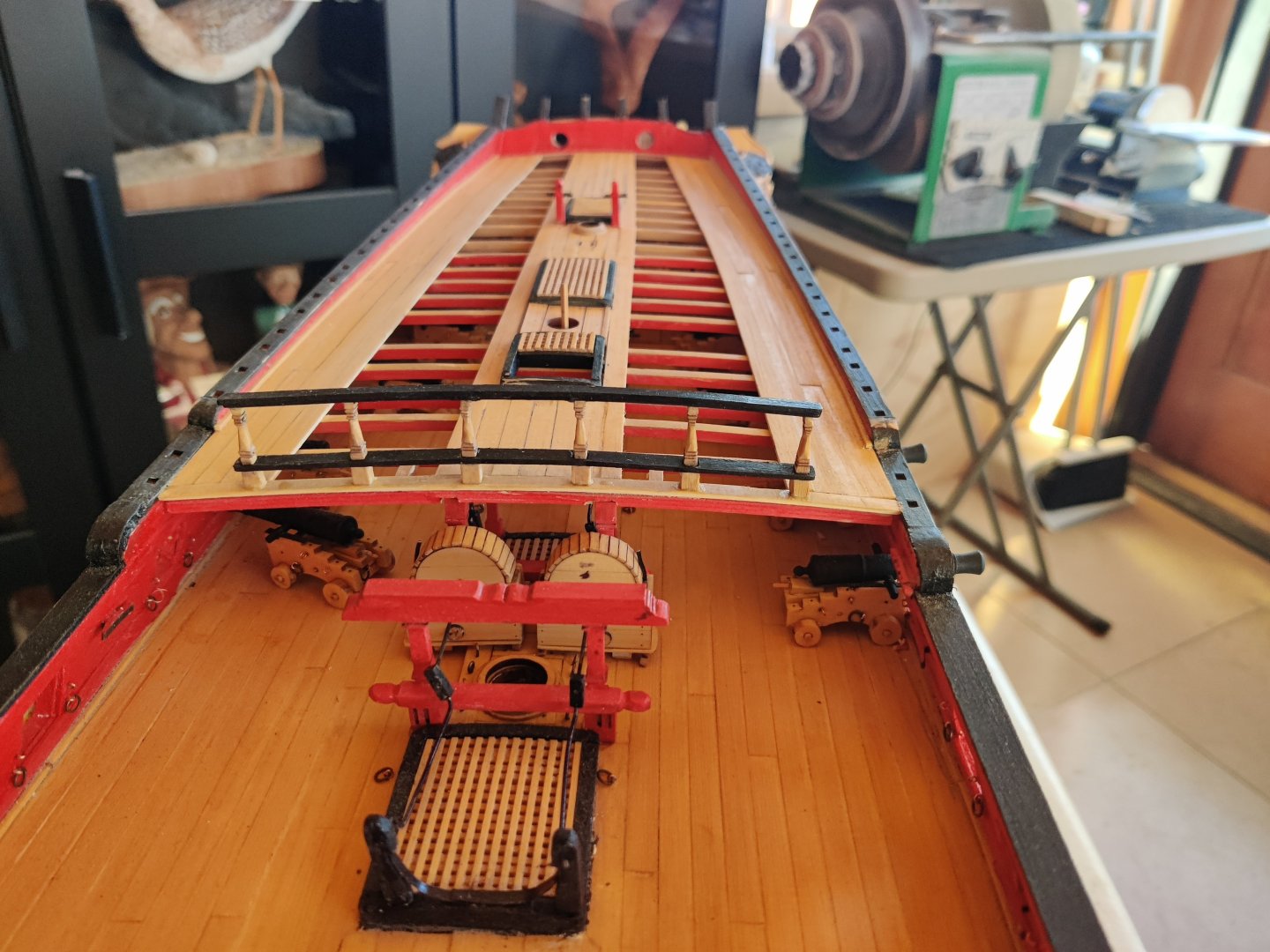

USS Constitution by mtbediz - 1:76

woodartist replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thanks, I am sure you are correct -

USS Constitution by mtbediz - 1:76

woodartist replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I was referring to a post you made on 9/23 #26 that shows a photo of the gun deck hatches. I got the Proxxon mill you recommended and was starting to make hatches with it so I was looking at your early posts when you described the process. -

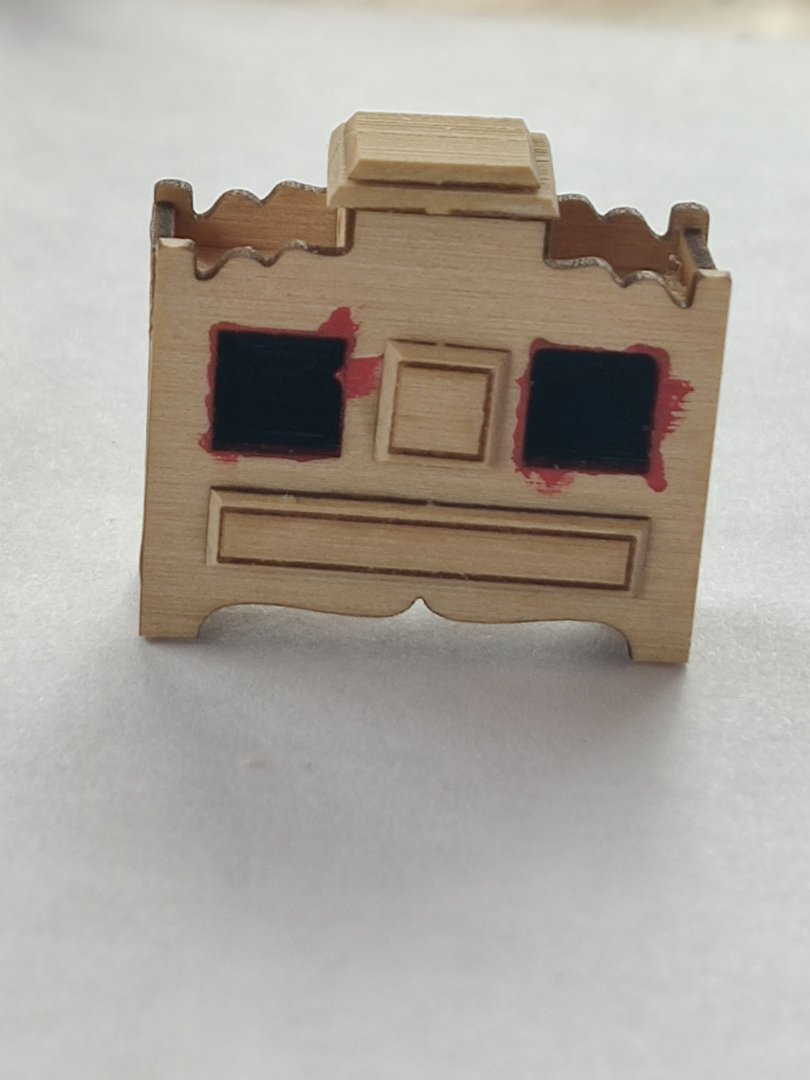

USS Constitution by mtbediz - 1:76

woodartist replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

The grating at the bow in blue is proud of the frame, all the rest are flush with the frame? Is that intentional? -

USS Constitution by mtbediz - 1:76

woodartist replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Fiskars cutters are available from Amazon, they have a cutter that will cut 30 sheet thickness of paper for $60 and one that will cut 12 sheets of paper thickness $22 -

Work area pictures only

woodartist replied to Johnny Mike's topic in Modeling tools and Workshop Equipment

i have a small 10x10 workshop in my back yard. I used to do a lot of wood carving and taught small classes in my shop. Now it is my boatyard. -

thanks I will research further on the machines, software and 3D forum

-

Is anyone using a lazer cutter to make parts? What equipment are you using? What software are you using? Any recommendations?

-

Johnny I had an accident and lost use of my right arm bicep. I can still move my right hand but it is stiff and does not have a lot of flexibility. I use my left hand as my primary hand now because I can not raise my right arm without assistance from my left arm. So I am incredibly slow in moving and each move has to be planned in advance. I use a 3rd and 4th hand a lot, I use reverse tweezers a lot to hold things, I use super glue much less often because it takes awhile to get pieces situated. I use a white glue that can be released with alcohol as well. Mainly it is just realizing that I have limitations and plan accordingly. Can I be as good as those with two good hands, NO, but I can still do quality work and enjoy the process. I do 1/48 scale but no longer try to do 1/64 or higher. I also do admiralty models because rigging is not possible with my limitations. I still have great fun.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.