-

Posts

986 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by EricWilliamMarshall

-

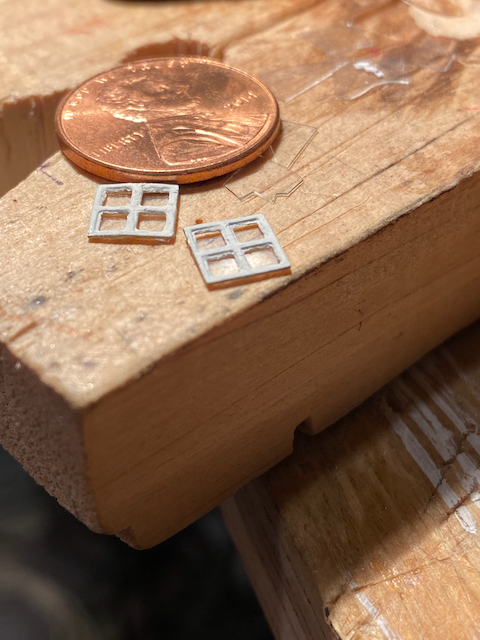

This kit has brass etched windows. I didn't like the look of thses 'solid' windows (which most folks paint blue) so I drilled out the solid part and then tried to file the edges. I don't have files small enough to work those surfaces. Larger ones mangled and bent the brass. I then spent way too much time trying to cut glass of the windows. It turns out that a regular glass cutter works best. I used glass slide slips/covers as my glass source. The first cut would go well (after a bit of initial practice). The second cut is always very difficult. Very taxing of what little patience I have. I'm not sure if I would recommend this path for everyone but it isn't an expensive detour but merely tricky detour.

-

Cheers to solid foundations! I wish you peace and while nothing is perfect, I hope your work on the Tennessee provides a slight respite.

-

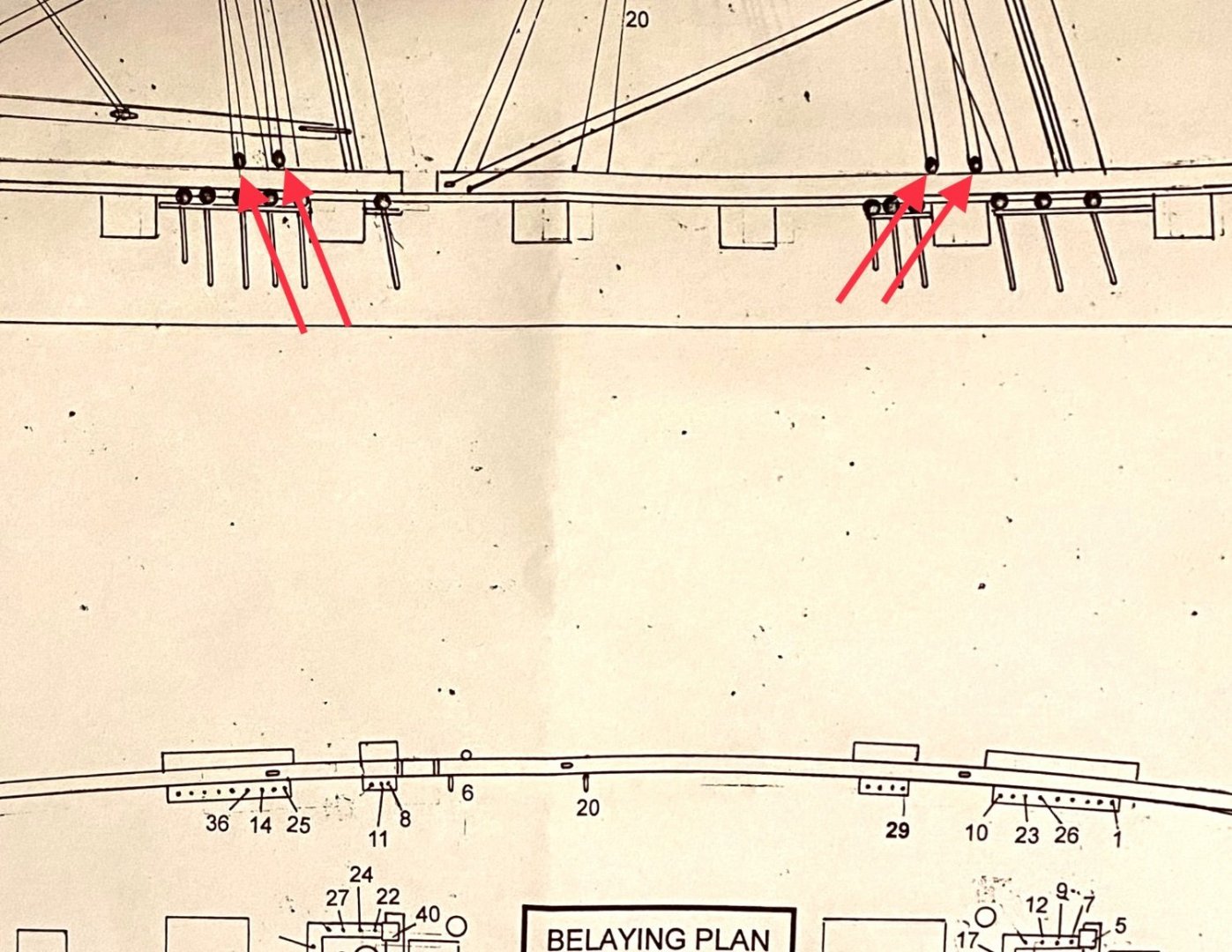

A bit of tail chasing as I tried to decode the instructions and redo some work. I foolishly spent an afternoon trying to look up brace holes (main and fore) in my little library to no avail. I will also note that the overhead view of the ship doesn’t show eight “blocks on the cap rail caps” but the side view implies eight, so I went with eight. Little by little.

-

I would like to tip the hat to @Chuck Passaro at Syren Ship Model Company again for the quality of his products as well as his speed!! I ordered Monday evening (5:55 pm) and I have the blocks in my hands as of 1pm on Thursday! Thanks again!! The blocks that come with the kit are beautiful but made of metal. They are heavy and I'm tad worried about the tension needed to keep the lines looking 'natural' (yes, a load word if ever there was one). Since I had issues with my number of previous builds, I thought it prudent to check my options before commiting all in.

-

No worries - this is a hobby not a job! Thanks for the update!

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

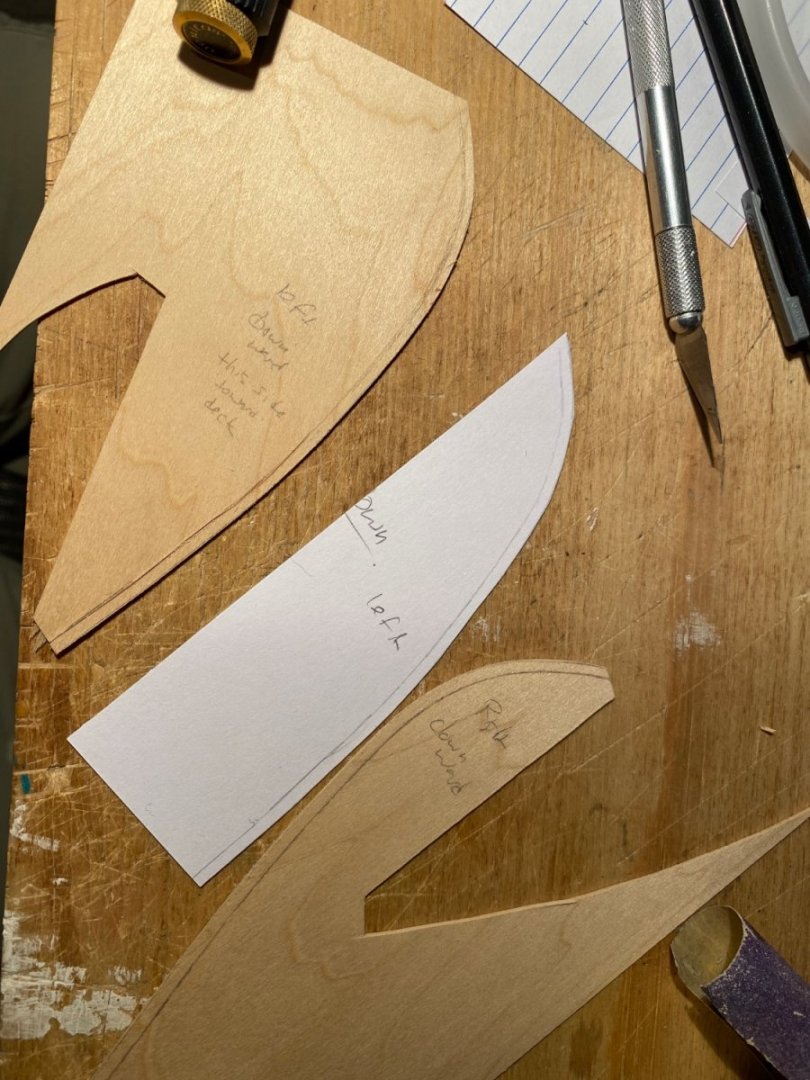

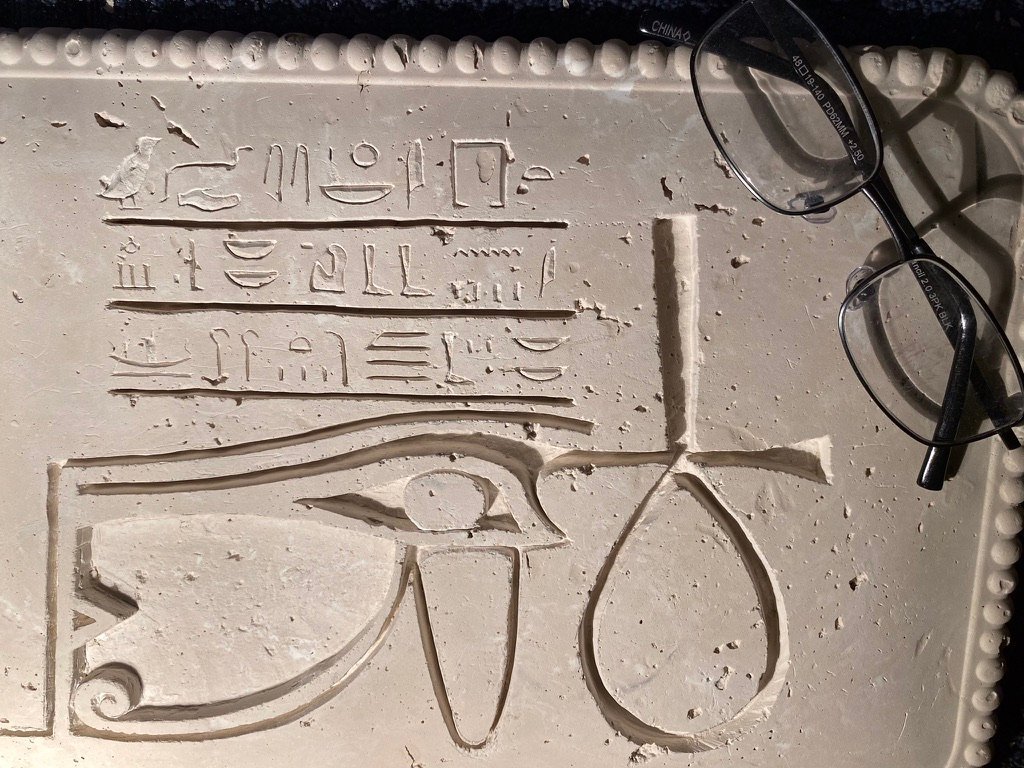

I believe I used 1/32 x 3/16. It doesn't run as long as the others. I found that I'm not picky regarding the brand of glue, but I found that thicker 'gap-filling' glue works best for me. I use a pin mounted in a pin vise to apply it from a drop or two on some plastic recycling (yogurt lids in my case). No complaints! I'm happy with the techniques and the overall look of the model. In hindsight, I wish the planking was cleaning and the carvings thinner, but nothing to lose sleep over.

- 123 replies

-

- Model Shipways

- Pinnace

-

(and 1 more)

Tagged with:

-

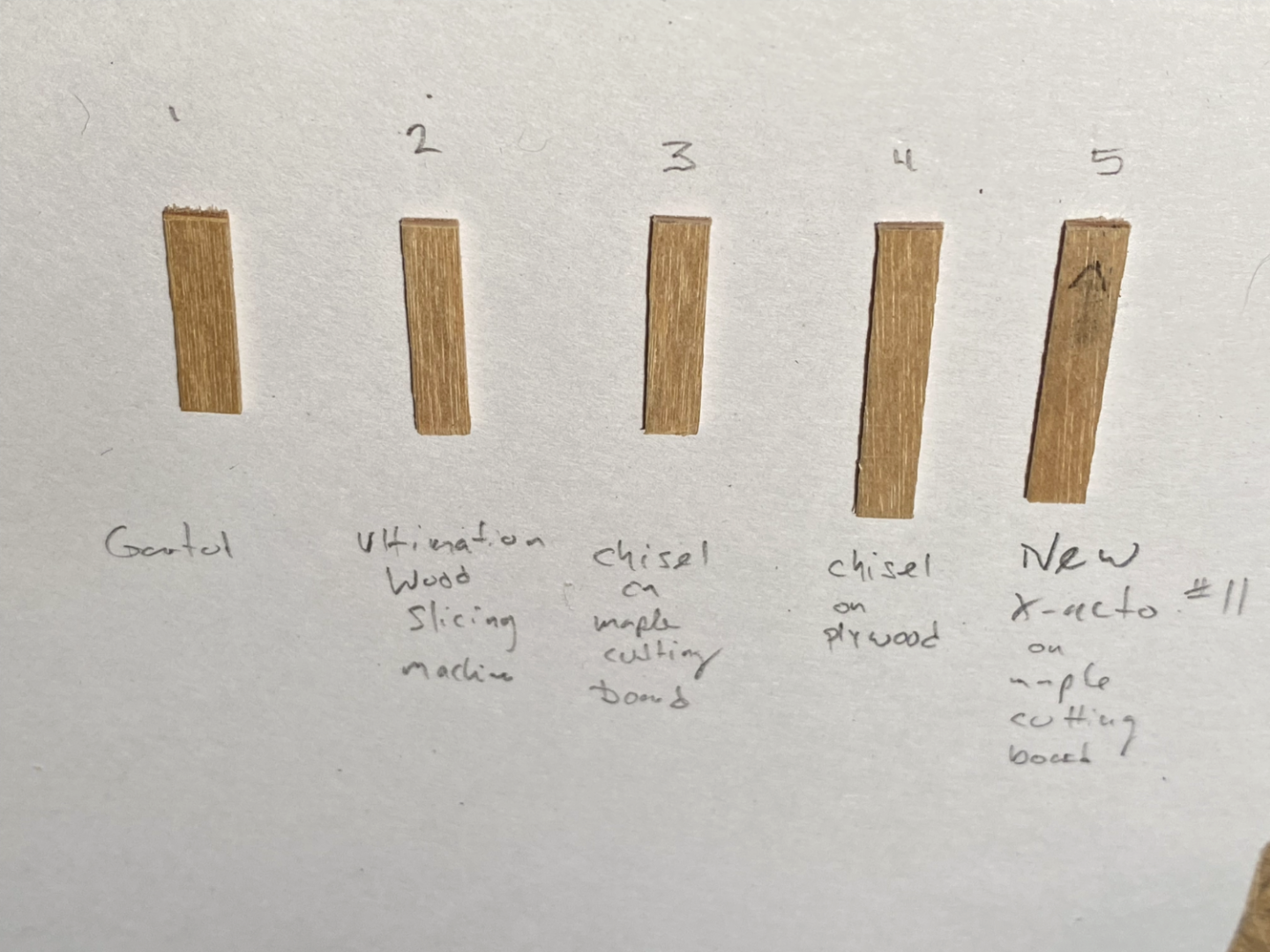

Unfair tool comparisons! I compared the cutting of the Slicer to ye olde #11 x-acto blade, a sharp 3/4” wood chisel and a much cheaper tool, Gartol miter shears. I found the Slicer to cut better than the x-acto and the Gartol. The wood chisel was just as clean as the slicer (and I hadn’t bothered to strop nor sharpen the chisel before the comparison). So if you are comfy the care and feeding of wood chisels, there is not much to be gained by the Slicer. However, if money is no issue, the Slicer is fast, easy to use and rugged. And, perhaps, your repeat cutting depth gauge will work.

-

I now have a newly acquired tool - the Ultimation Slicer which came to me via the latest Northeast Ship Model Conference raffle. Pros: Solid platform, which can be mounted. Cuts cleanly! Plenty of leverage. Plentry of visibility. Blade doesn’t make contact with metal but instead with self-healing cutting matt material. Blade beveled on only one side Adjustable fence for full range of cuts Detailed etched protractor for making cuts of exact angles. Fence tightens firmly in place. Cons: The adjustable stop for repeat cuts did not work. That is to say, it was slightly mis-machined and the guide could not travel with in a couple inches of the blade. This tarnished the idea of this being the “ultimate” chopping tool. I did my tests with that assembly removed. The etched surface is in a low-contrast color, making it hard to see sometimes. It would be nice if the protractor was 270 degrees (or more) instead of only 180. I keep finding myself looking for a degree and staring a bare metal before look to the other side. It would also allow one to clamp exactly to angle you wish. Very slight play between the base and the fence. Not a deal-breaker, perhaps not even noticeable to most folks. No way to quickly and exactly find common angles like 90, 60, 45, etc. Again not a deal breaker, but many similar tools boast quick-set ways to select such angles. Two knobs to tighten the fence, instead of one. It is priced at $175 (US Dollars).

-

Thank you for the kind words. (And nice to see at the convention although we didn't chat much!) And for everyone's likes!! As for the plating, I still see the errors, glitches, etc. but for my first attempt at copper, it looks better than it ought to. I have to say copper is a wonderful material to work with (at least in this context).

-

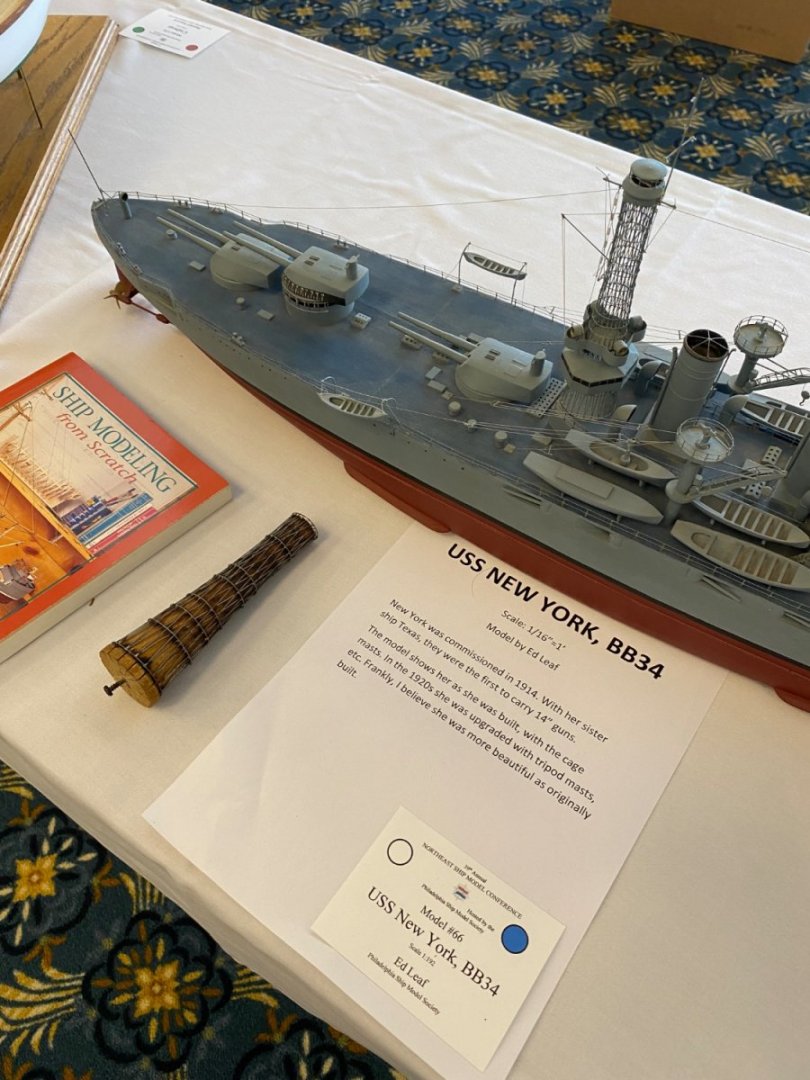

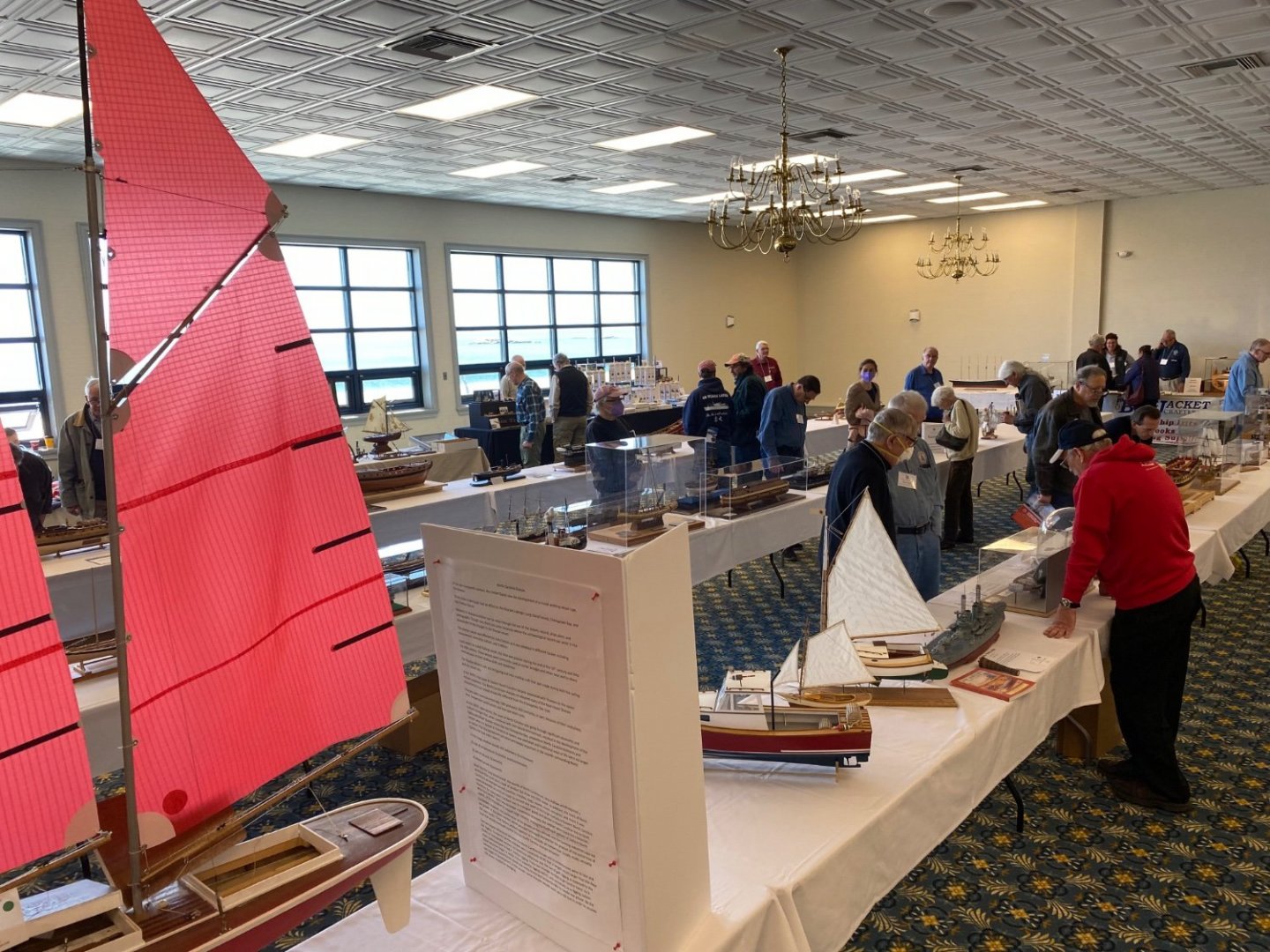

I squeezed in as much as I could to my visit to the conference. I hit Mystic Seaport, Battleship Row, H.P. Lovercraft’s grave and the USCGC Eagle. Sail Master Melissa Polson presented at this year’s conference and is seen here shipside answering questions. Here are some action shots of Dan Pariser aka @shipmodel and Rich Lane (https://richardlaneart.com/) teaching the finer points of rigging and applying copper leaf respectively.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.fc5d633a7b34428fcf19419a73d56d55.jpeg)