-

Posts

142 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

California

-

Interests

rc helis and planes, miniature model painting, model boats golf, sports, guitar, board games

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Coyote_6 reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

Coyote_6 reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

-

GrandpaPhil reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

GrandpaPhil reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

-

GrandpaPhil reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

GrandpaPhil reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

-

Elijah reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

Elijah reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

-

WalrusGuy reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

WalrusGuy reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

-

ccoyle reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

ccoyle reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

-

Rowboat reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

Rowboat reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

-

Matt D reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

Matt D reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

-

SIDEWAYS SAM reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

SIDEWAYS SAM reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

-

Gregory reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

Gregory reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

-

Final pics. Edit: Oops, I forgot to thank everyone on the site for their input and help. Could not have done this good of a job without the members and their support. Thank you everyone

- 195 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

SIDEWAYS SAM reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

SIDEWAYS SAM reacted to a post in a topic:

Enterprise 1799 by Rowboat - FINISHED - Constructo - Scale 1:51

-

I hope to be done soon. Then I'll post the final pics. Started this in Oct. 2019, so approximately 1 1/2yrs to complete.🥂 Bought this kit on Ebay thinking I got a steal of a deal, lol, ended up costing me,. Learned a tremendous amount about wooden model ship building. It's kind of funny that some of the things I was so worried about in the build turn out to be no big deal. Most of the deck is covered so any flaws are hardly noticeable, unless you're a model ship builder. The rudder and planking underneath the stern, will hardly show any flaws. That damn Stem, I broke 4 or 5 times, looks just fine now. The planking, though not laid correctly, looks fine on the ship. One last post coming ....

- 195 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

Today was a great day, I got the last sail attached to the ship👏. Still need to tidy up some rigging and clean up the deck as well as put up the netting but the sails are up. I'm just going to post a bunch of pictures, no notes.

- 195 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

@mikiek thanks for taking the time to load all these pics. I did buy this kit probably 8 or more years ago on eBay. I just opened it a little over a year ago, when I started the build. As my build log attests this is a Frankenstein kit🥴. Only with members help have I been able to get this far.👍 Just a few more sails to go. Thanks

- 195 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

Rowboat reacted to a post in a topic:

Enterprise 1799 by mikiek - FINISHED - Constructo - 1:51

Rowboat reacted to a post in a topic:

Enterprise 1799 by mikiek - FINISHED - Constructo - 1:51

-

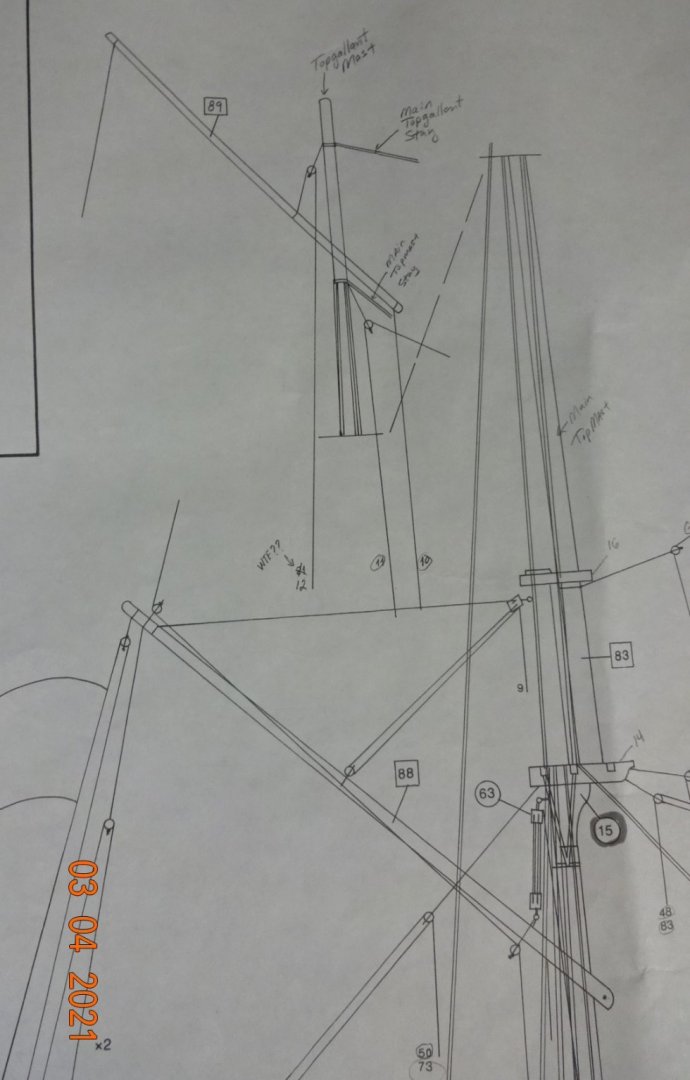

Any idea what this symbol in the pic is below. I'm working on the jib rigging and cannot figure out what this is. Disregard any handwritten notes. Any help is appreciated., thanks

- 195 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

Here's some pics of the schematic for my Enterprise 1799 In this pic the yard numbered 89 is the one I added the rigging lines to at the ends. Clearly this image shows a line coming off the right and left side of the yard. @mikiek This is a close of the top section. A closeup of the lower section

- 195 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

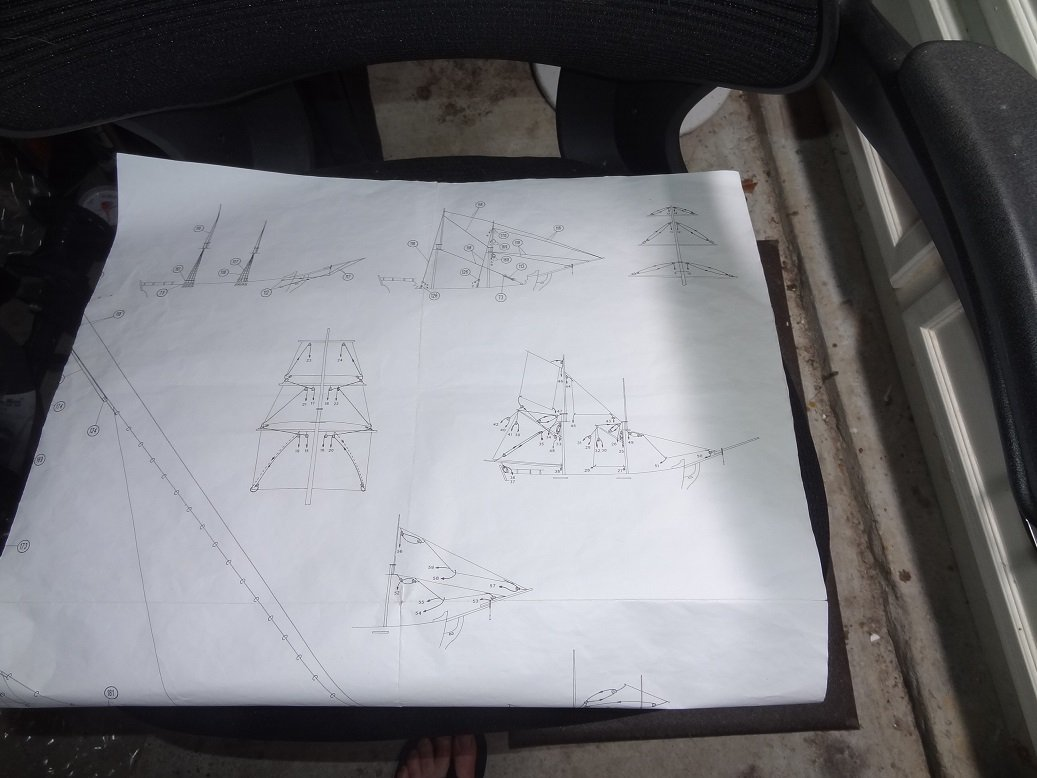

Reading through your build log one more time I found this picture of the running rigging. Your schematic of the rigging lines is much more detailed than mine. I have one picture of the main mast with the 3 yards on them. Then some rigging lines coming off the yards, that's it 🥵. No wonder I am having such a hard time with rigging 🤢. I even see in the image below there are details for the 3 jig sails, I have none. Luckily, I have help from you guys.

- 136 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

Current state of the build. This time I labeled the lines, much better. Next step is to start tying off all those lines........

- 195 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

Why did know one warn me of the rat's nest coming up in rigging the foremast sails. holy crap! Lots of work verifying which line goes where and where to tie it off at. Countless times grabbing the wrong line and trying to make it work (that's on me of course, lol, the whole thing is on me). Anyway here's some progress. A close up view. A closer up view... A closer closer view

- 195 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

Thanks for the input Mike I have not been happy with the rigging on the top main mast Gaff sail. After studying the schematics for far to long I decided to go with what I was seeing. Now you may ask yourself, "WTH is he talking about? He was supposed to do that from the start. 🤔". You see, I like doing things wrong the first time, I guess I learn more that way. 🤥 Actually the problem is I tried using the manual and "looking at other members rigging". Which just confused me more. The schematic shows the top main mast gallient yard with a rigging line coming off the starboard side (actually tied to the yard) then running through the block at the end of the bottom gaff yard, then following the bottom gaff yard towards the mast where it goes through another block and then down towards the deck, finally being tied off. The top gaff sail seems only to be tied to the bottom gaff yard. Well, I hope everyone is thoroughly confused🤔. Here's some pics. This image shows the rigging now tied off to the starboard side top gaff yard, as well as showing the 2 blocks the rigging runs through. This picture shows the port side rigging tied off to the top yard gaff. This image shows the top gaff sail tied off to the bottom gaff yard. Originally I had tied the rigging to the sail. This image shows the rigging line supporting the sail. I can't make it anymore confusing than that, 😅. Right or wrong, I now like the way the sail hangs and can be adjusted.

- 195 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

I think I have it figured out. Once I tied both lines to the same corner of the sails ( two on the left and two on the right) I played around with the rigging. Checking how loosening and tightening worked. The line coming from the top gallient yard and tying off at the left corner is used to pull that corner up and towards the mast. The line coming from the top foremast yard and tying off at that same corner is used to pull the sail back into place. Looking at schematics didn't really point this out, at least to my newbie eyes. Once I committed to tying off both rigging lines to the same corner I was able to figure it out. Things are rolling along now. I have 7 sails mounted, 4 of them are completely rigged. I still have 3 sails to sew, mount and rig. I can start to see the light at the end of the tunnel on this build.

- 195 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

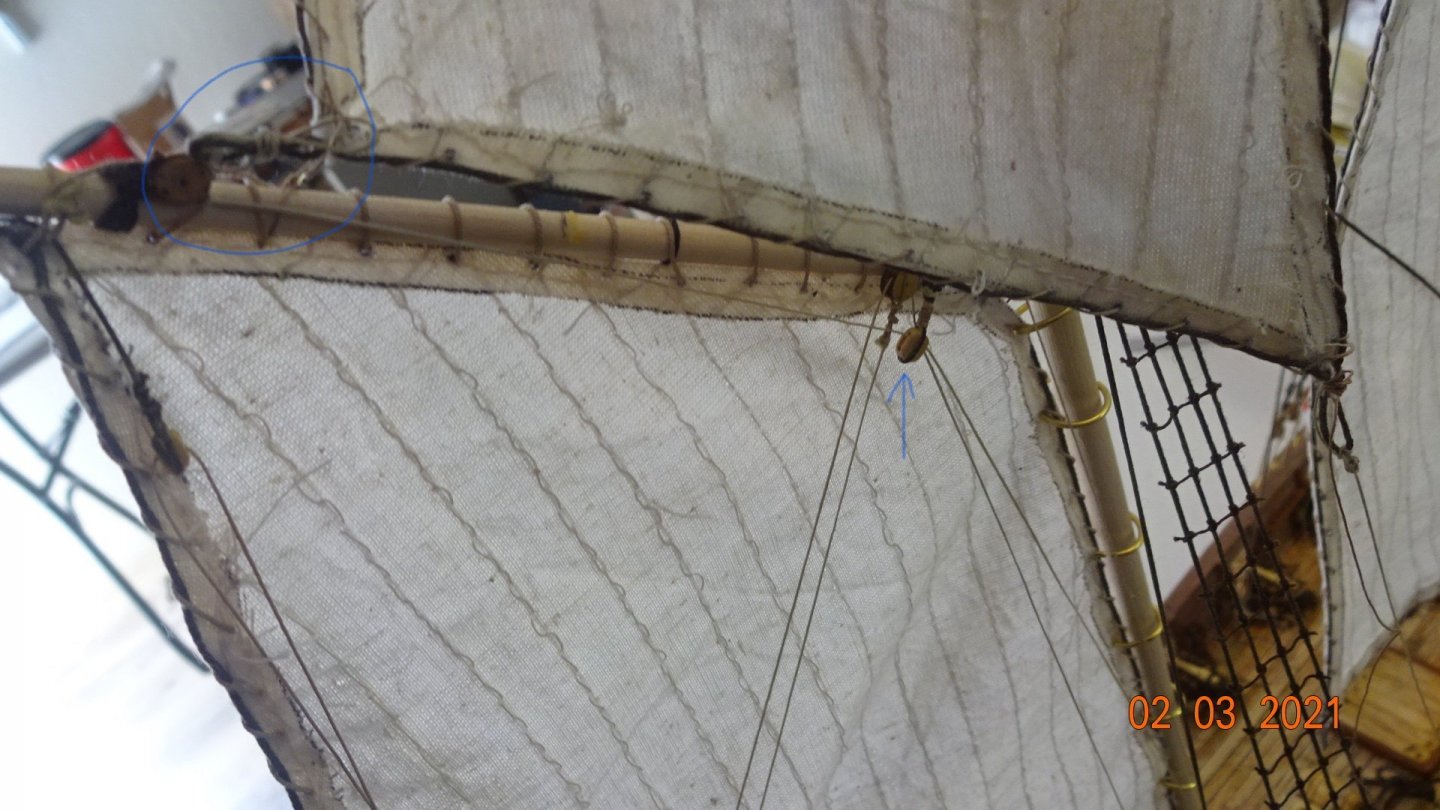

Thanks again Mike. I have been able to determine the rigging lines from the top gallient foremast however I am having concerns on the block rigging for the clue and tack lines ( the bottom corner lines at the loop). It looks like the 2 rigging lines on each side tie off to the 1 corner loop on each side. In the picture the red arrows point to the 2 different rigging lines. The blue circle is where I tie both lines off. Does this look correct?

- 195 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

@mikiek Thanks for the input. So it seems like I have it setup correctly although the block on the main mast should be higher. Thanks on the verification of how the sail ".... doesn't sit very well ...". I'll have to turn the fan on an see how it works now😁

- 195 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

Back again after fixing my issue with the bending of the sail to the main mast. Not to much to say, so just post pics of the work. Only the sails attached to the main mast are complete and tied off. Not sure if I tied off the main mast top sail correctly or not. I have one rigging line that runs up from a main mast belaying pin , passes through two blocks and ties off on corner of the top sail. That was my best guess of where that rigging tied off. The other side of the sail has the running line tied to a loop on the corner of the sail and is tied directly to a belaying pin on the starboard side of the ship. This is how I understood the directions. But I'm not sure if I did this right as the sail angle seems odd. If anyone can validate this I would appreciate it. Next I added the gaff boom to the foremast. This time corrected all the mistakes of my first attempt on the main mast so things went smoother. The rings I had previously put on the mast made attaching the sail easier since I had pre-punched the holes. Here is the current state of the ship. That's about it for now. Still have 5 sails to wrap , maybe that's a good thing "only 5 sails to wrap" .

- 195 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

Some things that I did to sew the sails. 1. Well, actually I didn't the wife did, at least the main part 2. I did draw in pencil lines every 10mm to be the stitch lines. 3. Also, marked holes every 10mm for the thread to wrap the rope (Not sure if they should be closer, maybe 5mm) 4. Pierced the holes with a sharp punch (using a regular needle was to tough to pull through) 5. Pierced holes for the rings that would attach from the masts (for those sails that needed it) 6. Used a special needle with a larger eye opening to sew with 7. I found that when measuring how much line I would need for a sail I used this technique For each side, except the side that attaches to the yard, I used 3X that length. Ex: If right side is 100mm then I measured 300m, if left is 75mm I used 225mm, if the bottom was 90mm I used 270mm. The total length was enough to complete the wrapping of the rope and attach the sail to the yard. I probably could have used 2X on the longest side and it would still work 8. Wet the line and hung with a weight on it, to get the twisting out ( recommended by a member) 9. Pulled the line through beeswax 10.When hand sewing pull slowly and keep the thread away from itself. Pulling builds up friction and if the line gets to close to itself, it will attach to itself and start twisting. Lastly, be patient.

- 195 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.