-

Posts

7,324 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Mirabell61

-

-

Congrats Richard,

it has been a pleasure to see this wonderfull build rise from keellaying to slip into her element down the slipway,

may she have always a handwide water under the keel

Nils

-

Ron - thanks for getting back to me. The last few sheet plans are getting harder ..... Have some good rigging reference books which have helped but not on this occasion

Thought when buying the 1.3 thread it would be good but it turned out to be double the thickness to the 1.0 - so don't know what is going on there....

Thought when buying the 1.3 thread it would be good but it turned out to be double the thickness to the 1.0 - so don't know what is going on there....Did you sort another stand for you Supply? Looking forward to your next build. Doug

Nils ( Mirabell61) - thanks for looking in and your nice words. Was wondering what are you building ?

Just posted this when saw Frank 's reply so edited my reply - Hello Frank - the rope in a separate bag was for the anchor and yes have tried Cornwall and one other but they all deal with the same suppliers. What did you use on your Supply? Anyway how are you - well I hope....

Regards

Doug

Ron - thanks for getting back to me. The last few sheet plans are getting harder ..... Have some good rigging reference books which have helped but not on this occasion

Thought when buying the 1.3 thread it would be good but it turned out to be double the thickness to the 1.0 - so don't know what is going on there....

Thought when buying the 1.3 thread it would be good but it turned out to be double the thickness to the 1.0 - so don't know what is going on there....Did you sort another stand for you Supply? Looking forward to your next build. Doug

Nils ( Mirabell61) - thanks for looking in and your nice words. Was wondering what are you building ?

Just posted this when saw Frank 's reply so edited my reply - Hello Frank - the rope in a separate bag was for the anchor and yes have tried Cornwall and one other but they all deal with the same suppliers. What did you use on your Supply? Anyway how are you - well I hope....

Regards

Doug

Hi Doug,

If you wish, have a look into my (mirabell61) build-log for "HMS Pegasus" swan class...

cheers,

Nils

-

Hi Michael,

your rigging and all the Fitting out and the choise of materials and their dimensions provide the confedence that this cutter could be magnified to actual size and sailed in a good breeze with filled red gaff sails and humming stays.....

Beautifull build Michael I like it

Nils

-

beautifull neat and tidy work Doug,

I like the ship and rigging in the way you do it

Nils

-

Kimberley,

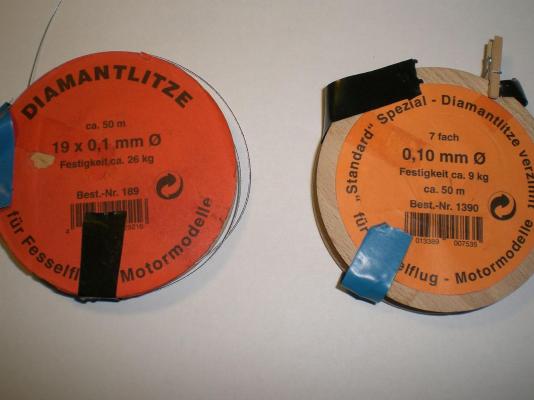

the cord Comes in 50m lenth on wooden spools in either 0,3mm thickness or 0,5mm thickness. I found These at Ebay, but probably you can find them when Google-ing up "Diamantlitze", or on enclosed Web link

http://www.rc-toy.de/1390+-+Graupner+Diamantlitze.htm

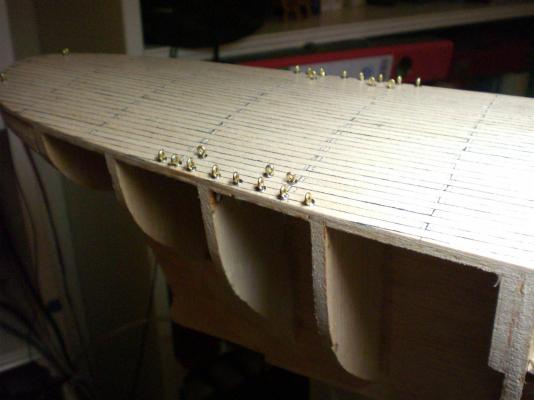

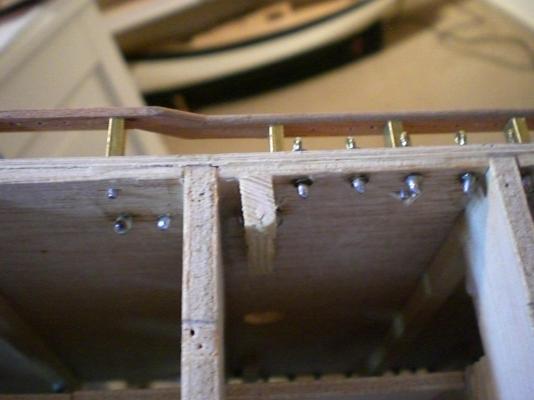

The pics enclosed Show you what I meant relating to fastening Point above resp. underneath decks.

I remember that the plastic model hulls usually come in two halves, glued together with the decks carefully fitted in place before, unfortunately not allowing Access to the deck underneath afterwards. If you require a sturdy stresstaking basepoint you shall have to treat your deck before it is permanently glued in.

One pic Shows (still without ratlines) the spanners in the upper shroud cores (the smallest spanners I know of in brass are

fitted with M1 left and righthand thread and spanned by the common sleeve on the two spindles.

all this probably will not be of much help when rigging smaller plastic models, but I asume in case of someone rigging up a Clipper or other tallship in plastic could be considered in order to avoid slacking loose lines

Nils

-

Hi Kimberley

as far as the plastic kits sails are concerned I have no experience at all. It can help to reinforce the plastic masts with wire inlay in case they come in semi halves from the mold.

For larger scale Wood built ships I use thin galvanized multisoul wire cord you may know from in circle flying wire controlled model aircraft. This is very flexible, has a high yeald strength and is easy to solder. When using this on shrouds, stays, backstays etc... in combination with spanner Fittings you can Play bassguitar on the strings. It is necessary though to povide durable and well placed Counter bases beneath the main decks. Unfortunately I have no Surplus sail in the Moment to send to you, but I`m sure that other fellow MSW builders may be able to help out here.

Nils

-

Aah you`re quite right B.E.

the state of my Pegasus always Looks at me when I step into my modeling Office and I turn the spotlights on

The coppering is already getting dark and dull and I asume I need a kick to boost the next sequences in build.

Funny, in the past it could often happen that I become "pregnant in mind" with a new build idea/desire and I caught myself in grooving in on something interesting, but that did not happen here yet.

So I`m quite confident that it shall go on soon

Cheers

Nils

-

admirable model B.E. !

also nicely presented sea surface structure, model colours, sails, and the Little figures all around that bring life into the ship.

Is the glass/acrylic protection case self made ? it Looks great

Nils

- tasmanian and Blue Ensign

-

2

2

-

excellant good neat work Bob

I`ll watch the "Essex" on her way...

Nils

-

Impressive work with the full functional Tackling Michael

combinations brass / Wood, two colour rigging, etc, I can feel with the fun you have, as you admit yourself by doing the Fitting out, shall be staying tuned for the next Pics

Nils

-

Hi Danny

I just love that model of yours, all the high skill work is presented by non hiding the fabulous wood juctions and fitting out work from beginning on...

Nils

-

Beautifull work Karl,

its like looking into a 18th century real ship after being Fitted out at the shipyard

Nils

- avsjerome2003, Jeronimo, Bindy and 1 other

-

4

4

-

-

Hello Heinz

I liked to hear that my method of sailmaking was of help for your intended Cutty Sark sailmaking. Trust the stainless steel wire reinforced bolt rope Feature is understood an no Problem.

It is correct, that it is a bit difficult to Transfer the requirements for the sew-work to a good sewer Person who is not generally involved in the model rigging. This is really the reason why I started to do Trials on the sewing machine by myself.

The method proved allright for both complete sail sets on Gorch Fock II and Pamir

At the end of page 1 (of this post) there is a leaf in JPG formate with scetches of the sewing sequences. Please let me know of what sequence your sewer shall require Special advice for.

Feel free to ask I shall be happy to help.

Further Details can be exchanged via email addresses (mine is : nils.langemann@t-online.de) or by Personal Mail (PM) on this forum

Regards,

Nils

-

very nicely built whaleboat Buck

reminds me of Mobby Dick film Scenes in the whaleboats.....

Nils

-

very impressive build Tony

it`s a real delight to study your build log from begin to the current state, a masters work !

Nils

-

Hi Remco

thanks for your remarks in your post #265 and for sharing all your build-log from begin to date, it`s real eyecandy to study in all Details

Nils

-

Allan

a lovely nice and clean built boat you Show us, thanks for sharing. Frames and beams arranged as it should be with These classic boats, a Little pitty that These wooden Features are not visible any more afterwards

Nils

-

Hi Giampiero

thanks for sharing your fabulous Model, very neat and accurate work, from the state it is already presenting, it shall certainly grow to a spectacular Piece of model art

Nils

-

Thanks for your birthday greetings Anja,

Nils

-

beautifull work Sparrow !

Your R. Caroline Looks superb

Nils

-

Beautifull work Karl

I love those Tacklings of the guns, the staircases, the great cabin interior,the very skilled workmanship and, and......

Thanks for for sharing this eyecandy provided with your Build, its such a pleasure to watch. Also your Pictures are of amazing Quality and good choise of objects (like under deck views) to be presented.

Nils

-

Hi Chis

congratulations, a stunning example of shipbuilding art by a master of this trade....

Nils

-

lovely work Toni

would like to see more of the interior Fittings....

Nils

Licorne by mtaylor - 3/16" scale - POF - TERMINATED LOG

in - Build logs for subjects built 1751 - 1800

Posted

Beautifull model Mark,

Ilike the lines of that ship and your acurate, neat work in achieving this build so far...

Nils