-

Posts

92 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by travis

-

-

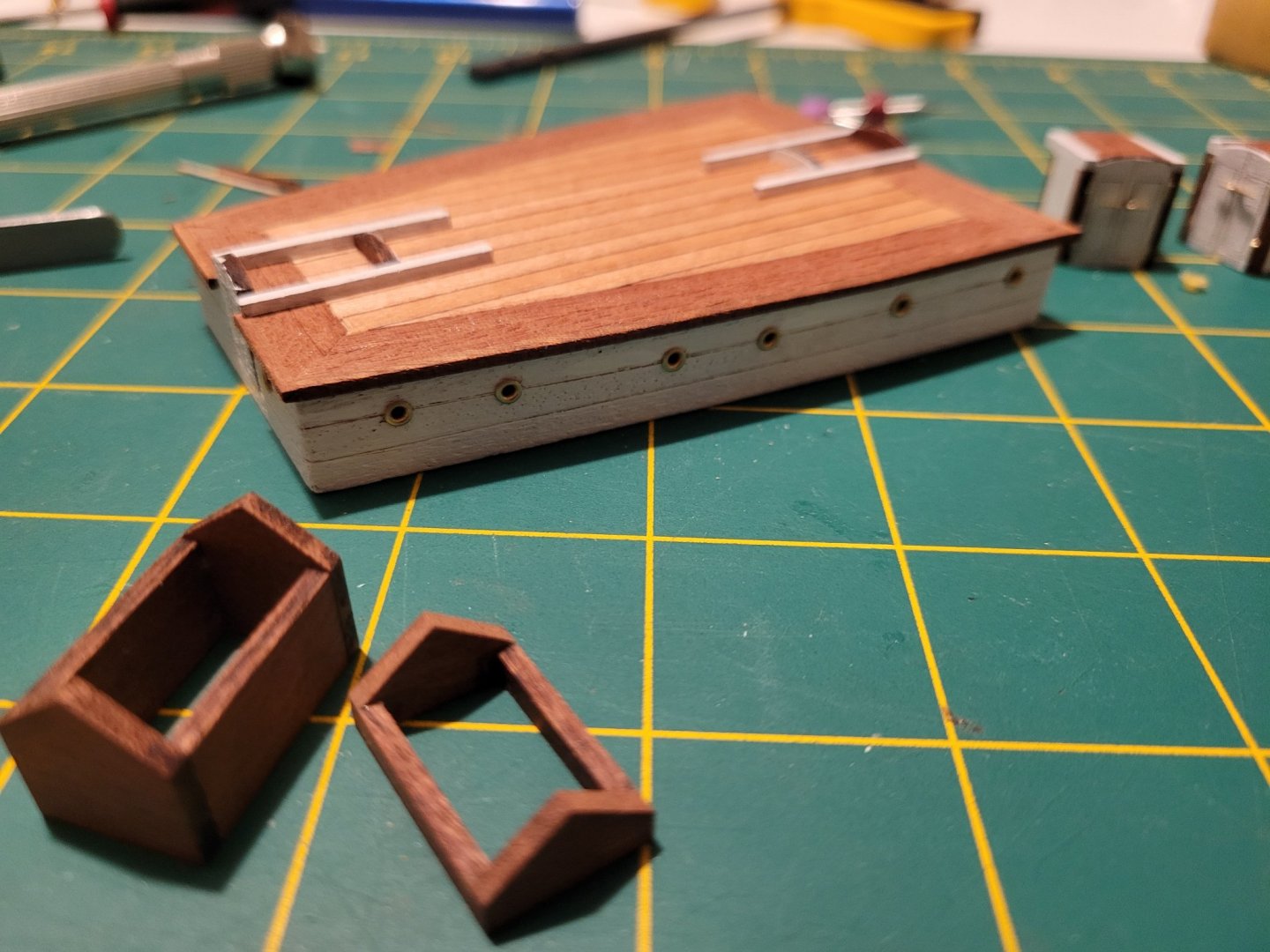

Working on the bowsprit and deck works. Screws are just dry fot for now. Looking for a good paint to make them brass. Struggling with getting started on the bowsprit shaping. The instructions call for an overall length that seems short compared to pics. Trying to figure out how to estimate proper length. There also seem to be some errors on the deckworks. The main cabin area shows two entries but the bluenose ii only has one. Too late to adjust that. They also have the actual barrels on the main deck, not the cabin deck. The skylight is also on the main deck, not the smaller galley deck (which doesn't have a doorway access). Looks like AL decided to cut some corners on these. Maybe just kept designs from their original bluenose or another kit? Adjusting where I can as I go.

- ObviousNewbie, BobG and Ryland Craze

-

3

3

-

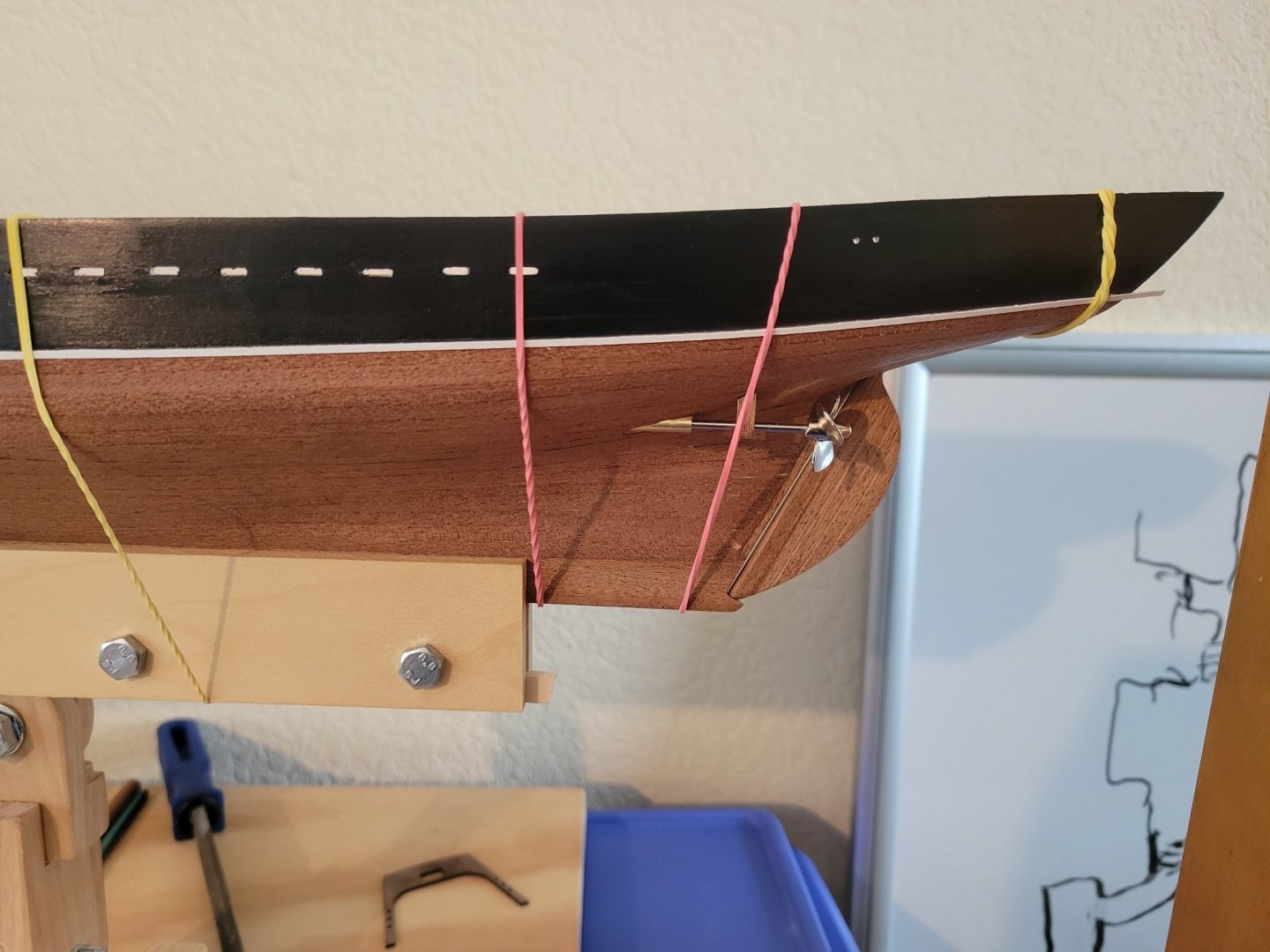

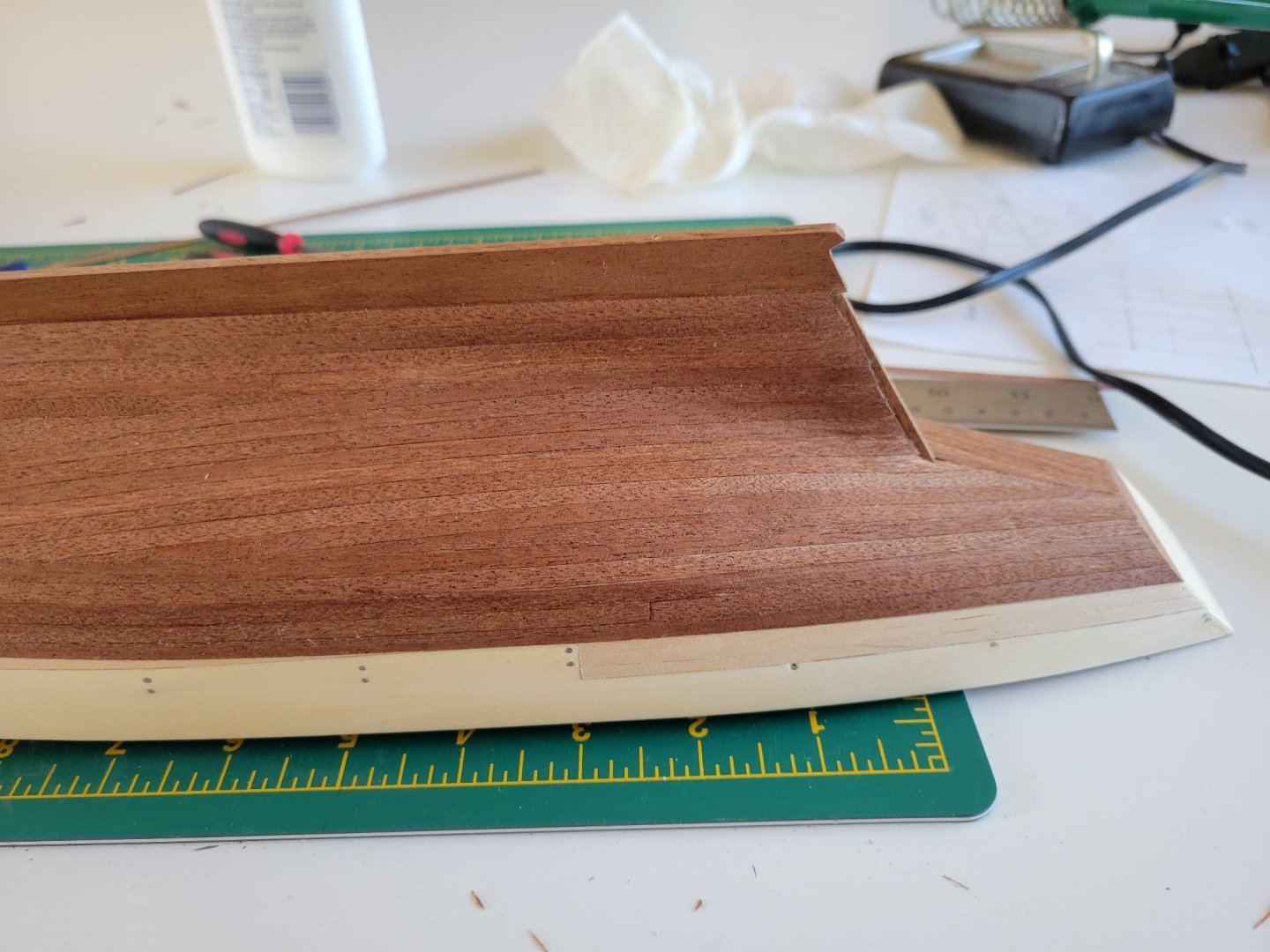

Decided to swap the approach to the white stripe at the waterline. Instead of the 1.5x1.5 sapely, I trimmed down extra deck planks, primed and painted them, and then attached. Makes it look more like a really good job masking and painting but actually easier. My waterline isn't exactly correct (especially at the stern) but I'm not going to worry about correcting that. Looks good enough for me!

- BobG, hof00 and TrunkMonkey

-

3

3

-

Thanks for the comments Bob and Josh. Just going slow and steady.

-

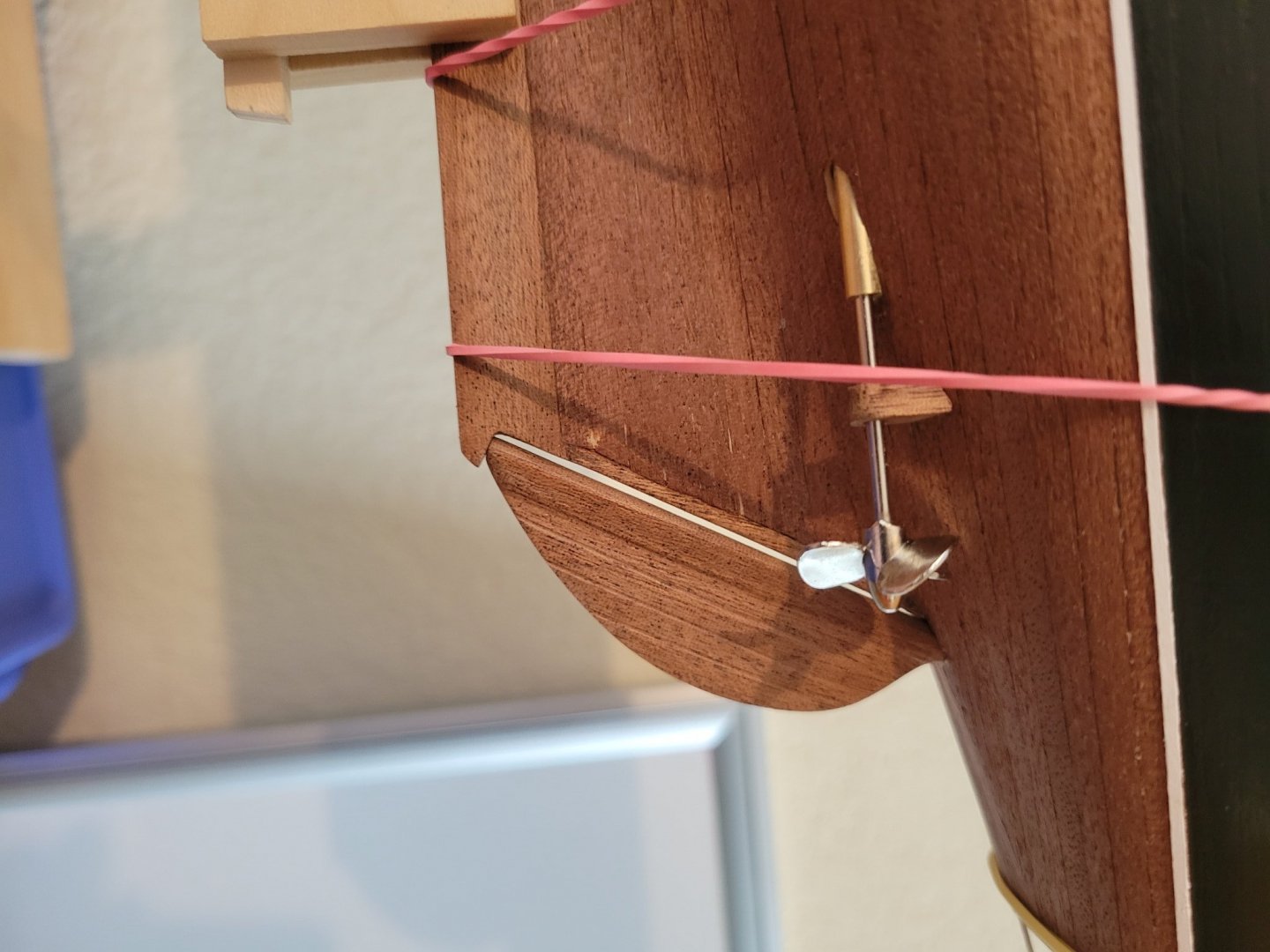

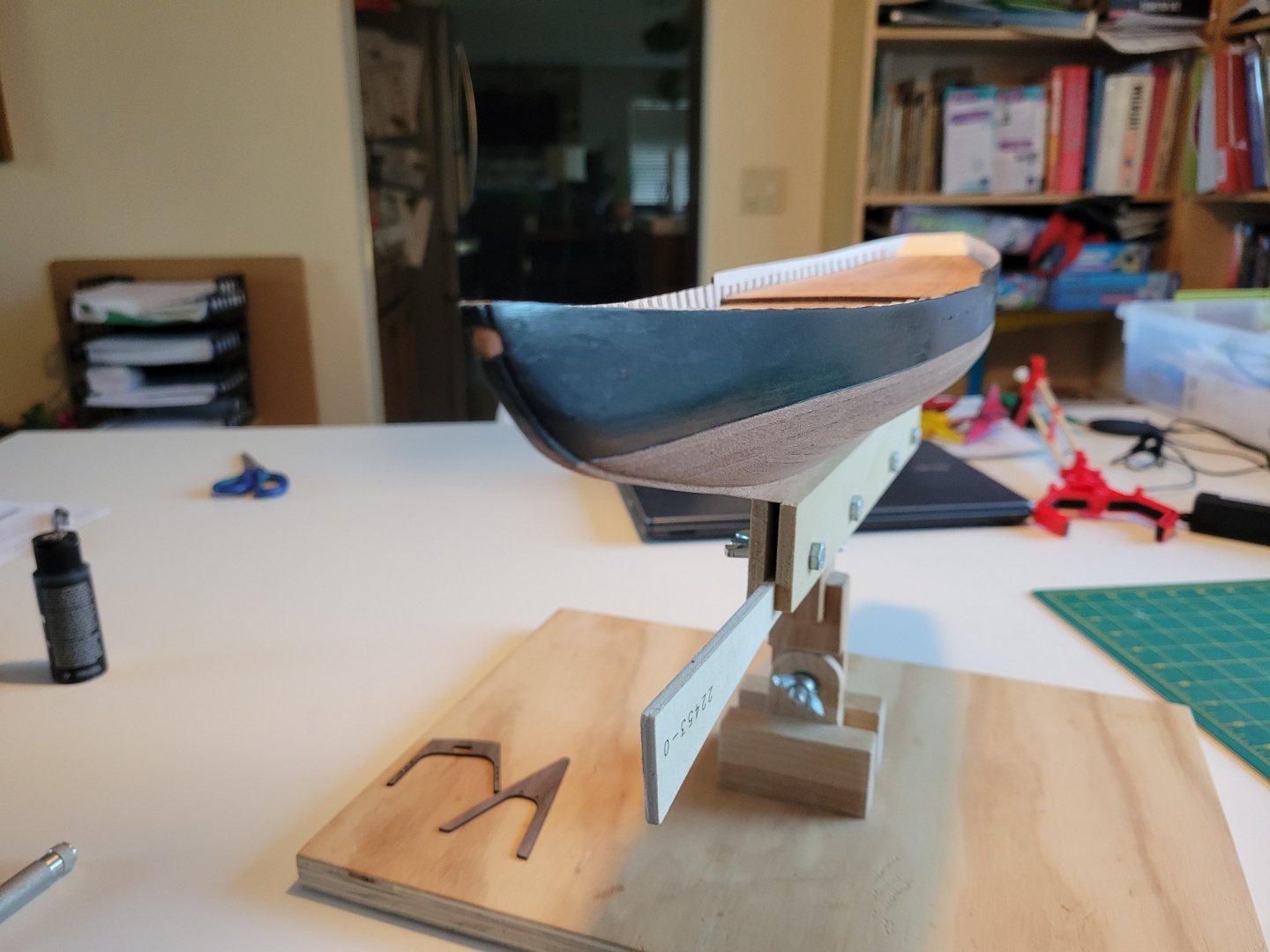

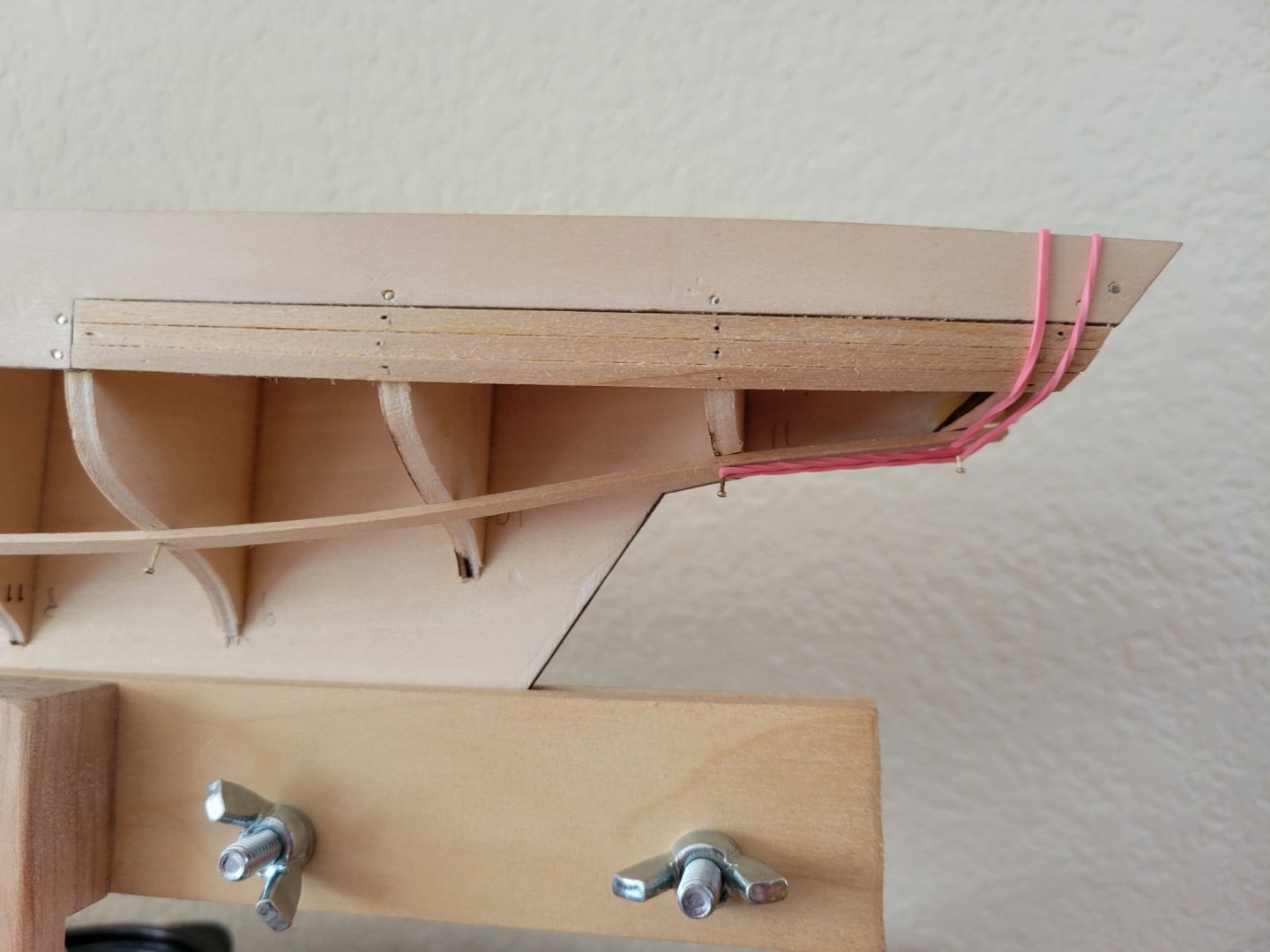

She's cleaning up well. Bulwark are drying. My process here was 1 coat of gesso (nice thin "primer"), filer where needed, gesso again, final filler, gesso, then two coats black. All with sanding between. Drilled and set the shaft pipe for the screws. Trimmed rudder to fit. Next is fully shaping the rudder and bowsprit deck assembly.

- hof00, BobG and ObviousNewbie

-

3

3

-

Tried the "sawdust mixed with elmers" after rough sanding the hull to make filler. Came out a little darker than I had hoped so hopefully it will blend better after I put the final finish. Got the filler piece at the bow that holds the bulwark better now. Time the mask and paint the bulwark exterior.

- hof00, BobG, GrandpaPhil and 1 other

-

4

4

-

Stantions placed, suppers cut. I think sand and paint bulwark is next. But first I need to deal with bowsprite. The bulwark has come loose from the keel at the bow where I need to drill for the bowsprite. I original tried wood glue and then a little ca in the inside after clamping just to get a little extra hold. Didn't work. So little wood to wood contact here. U think I will create a small wedge to sit behind the keel post and flush with the top of the bulwark where it will be under the rail piece and monkey rail when I eventually add those. At least it will give something I can glue to and pin (I think the model shipways version does something similar). I'll send pics when I figure it out.

- BobG, bhermann, GrandpaPhil and 2 others

-

5

5

-

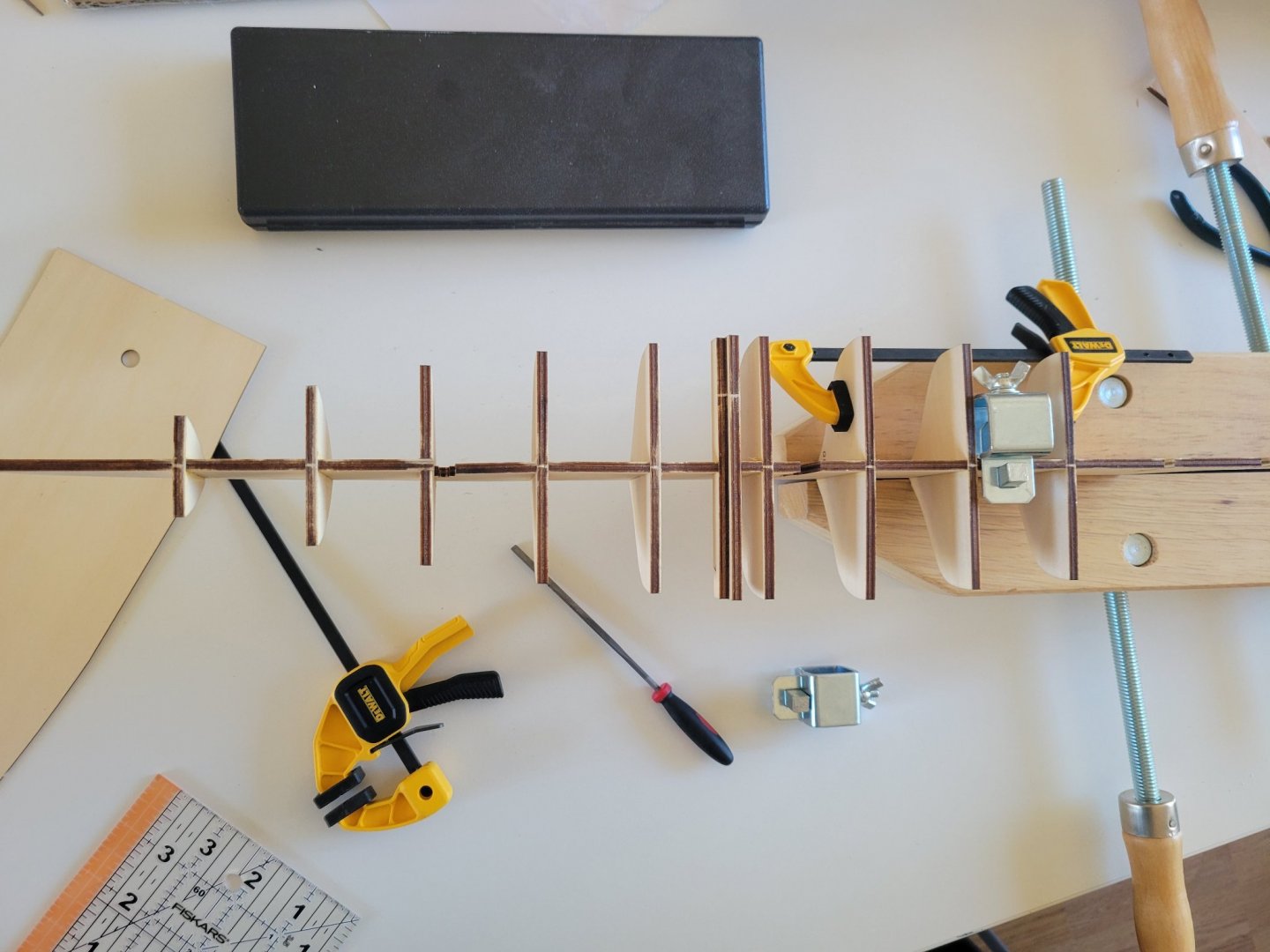

Second plank is on. Time for finish sanding on the hull. The wood burner on lowered heat work quite well to set the planks without clamps or mess. Working on the bulkhead stantions as well. Set the keel as I was planking. I followed on other by drilling a couple spots in the two primary/larger keel pieces so can insert a brass rod through the keel and into the false keel for extra strength. Feels ready for the keel clamp.

-

On 9/6/2021 at 7:00 PM, BobG said:

Very nice work, Travis, looks great!

Thanks Bob. I do find this process a bit cathartic, even if slow.

-

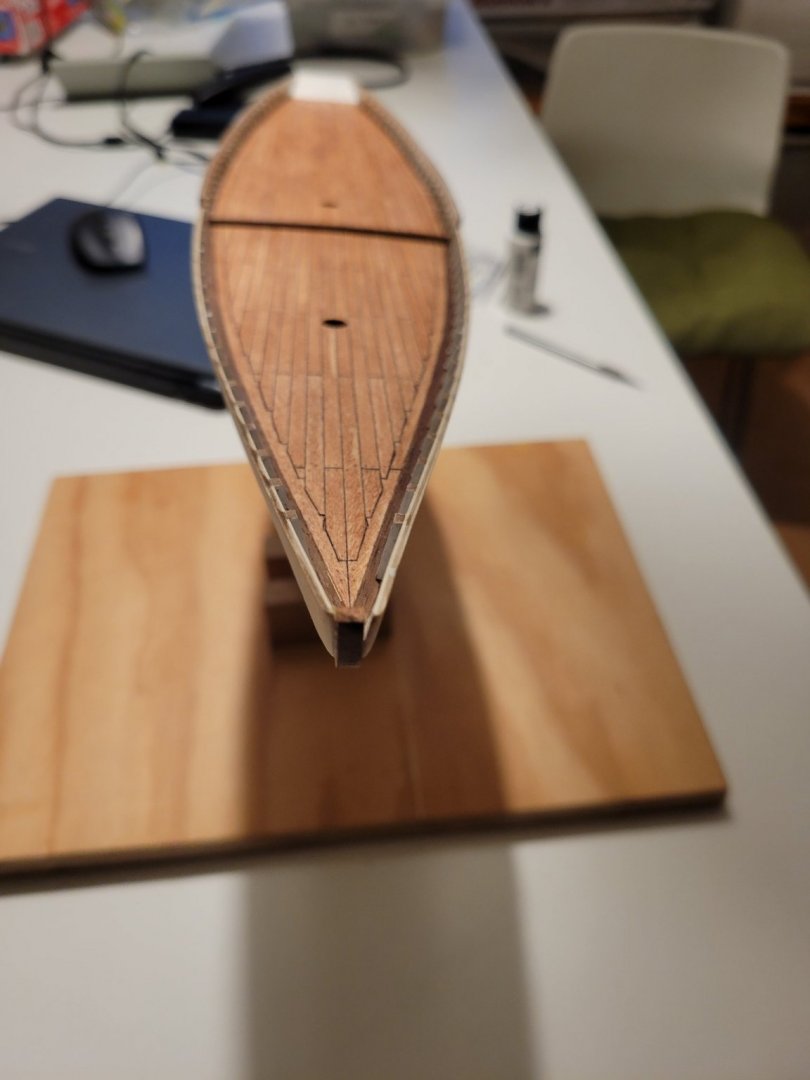

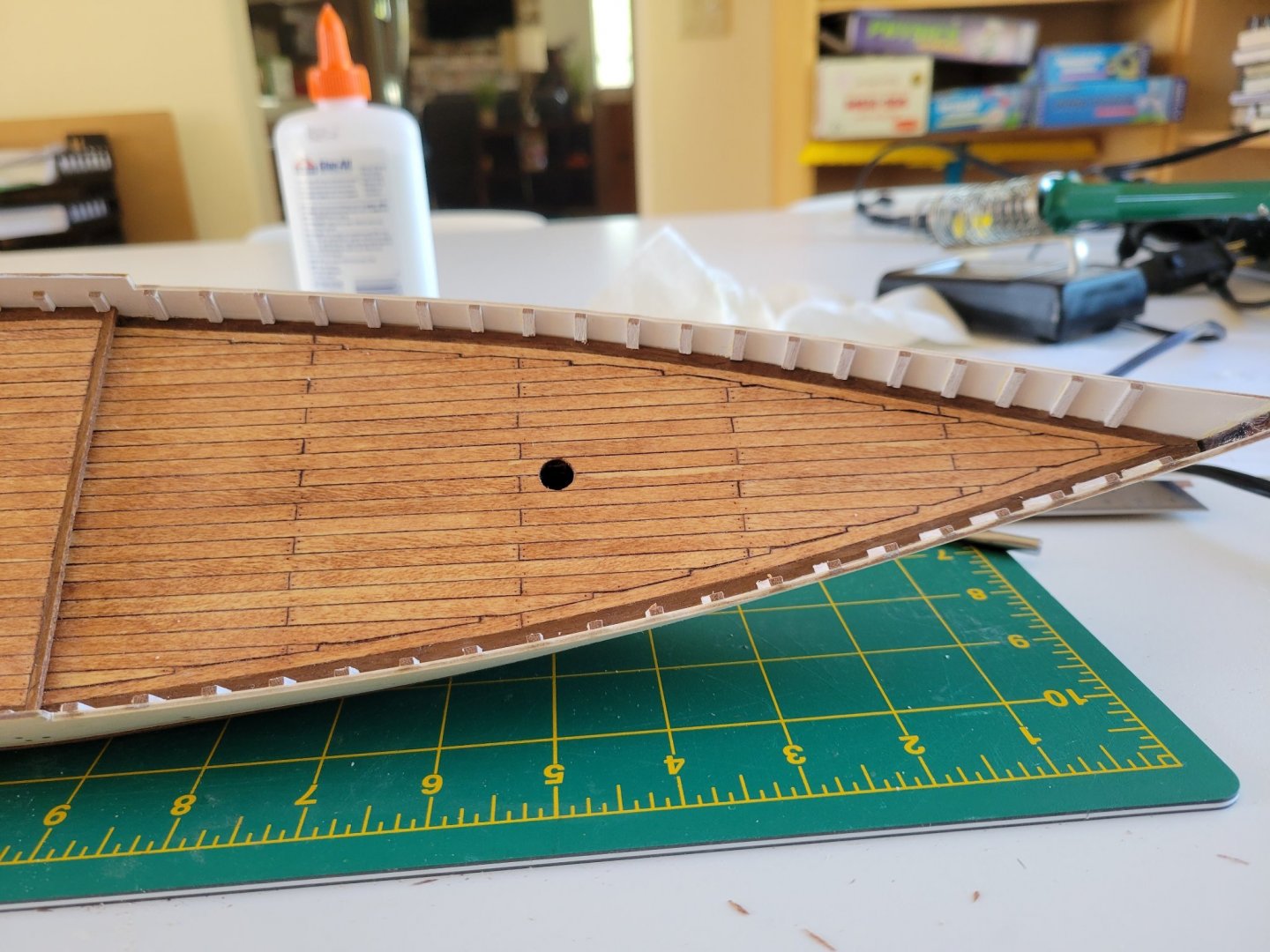

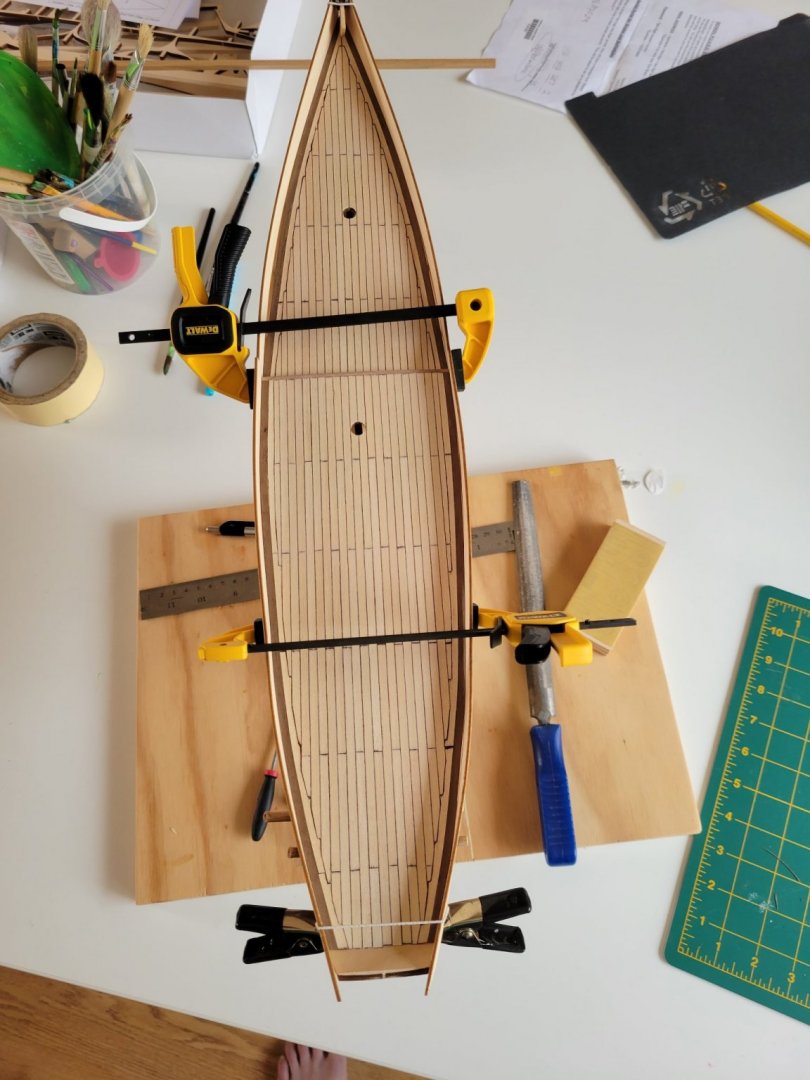

Getting back to the log. Finally finished planking. Almost good enough to single plank but I like the walnut look so going double. Lots of sanding/shaping on first plank layer. Decide I am going to place the keel before the second layer (or at least lay as I go. I like the look of the second plank layer slightly overlapping the keel. Gives a more finished look without the gaps. I also took an idea from someone elses log and am heat setting the second layer as I lay each plank. Don't need to buy anything special though. Just an old wood burner with a shading tip and then an extention cord with a pigtail/dimmer to reduce the wood burner to just enough heat without burning. It's working real well to get the last little bend/curve at the bow.

- bhermann, hof00, ObviousNewbie and 1 other

-

4

4

-

-

On 8/12/2021 at 6:06 PM, BobG said:

Your Bluenose is looking great, Travis! I've always thought she is a gorgeous, sailing ship with her beautiful, sleek lines. My wife and I got to sail on her in Lunenberg, Nova Scotia, 2 years ago. We had a wonderful time and the ship is maintained in pristine condition. By the way, I live in Sacramento. I look forward to following your build.

Thanks Bob. Nice to see another local on here (I'm just up north in Loomis/Rocklin). I'd love to find some time to spend on one of these classics, so far most of my experience has been the "gunmetal gray" of the navy.

By the way, have you found any local model clubs yet (I've only seen the rc groups up here)?

-

-

2 hours ago, hof00 said:

Nice Deck Sir!!

(Love the "Joggles.")

Cheers....HOF.

Thanks. Last kit I sped through the deck. Tried to take a little more time on this one.

-

-

-

Time to start thinking about paint. Don't have an airbrush anymore so trying to decide whether I should attempt brush paint or maybe something like the small Tamiya spray cans.

-

-

Brown sharpie along the edge of each piece. The Sharpe doesn't devolve when I put the finsh on and get the look that is crisp but not too crisp. Then anytime the I fubar and cut a cap a little large, I use the same marker on the plywood underneath before gluing and it blends pretty well. Hides my goofs!

-

- hof00, ObviousNewbie and Hsae

-

3

3

-

-

Keep going. Set the deck plate on fore and aft and furing the stations. As with most, this kit is off on stantions 10 and 11 and it creates a dip. Many people seem to try building up with shims. I found it a lot easier to just putty the dip because I could carefully sand the right curvature into the cured putty and it will have a solid surface to glue to. I've also setup my jig for the water ways once the walnut fries to shape it should lay well on the deck. I think I am going to overhangs the deck edge just a tiny bit to avoid a gap between the bulwark and the waterway. Well see how that works. Easier to sand down the edge than fill a gap.

- hof00 and Baltic_submariner

-

2

2

-

-

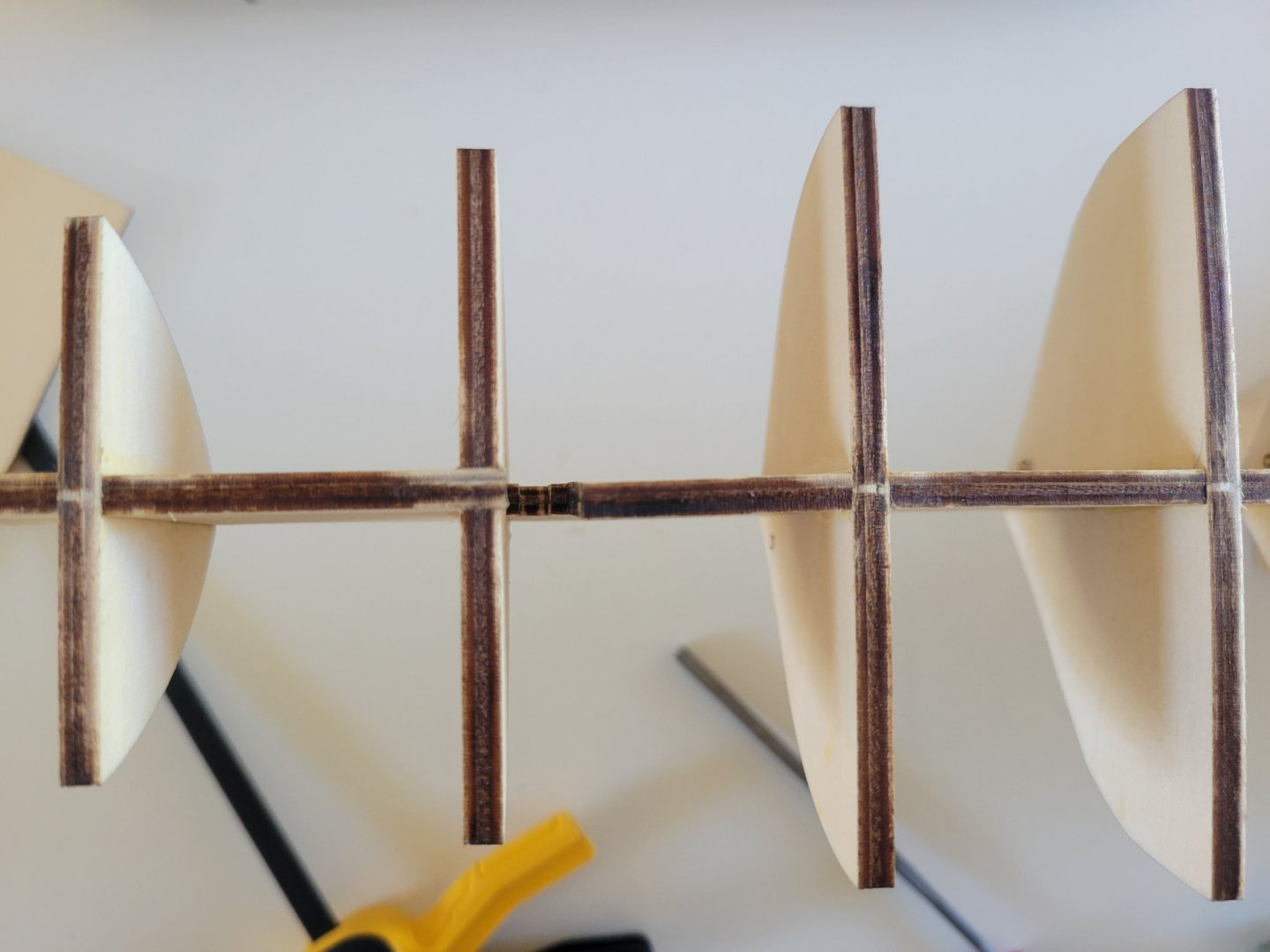

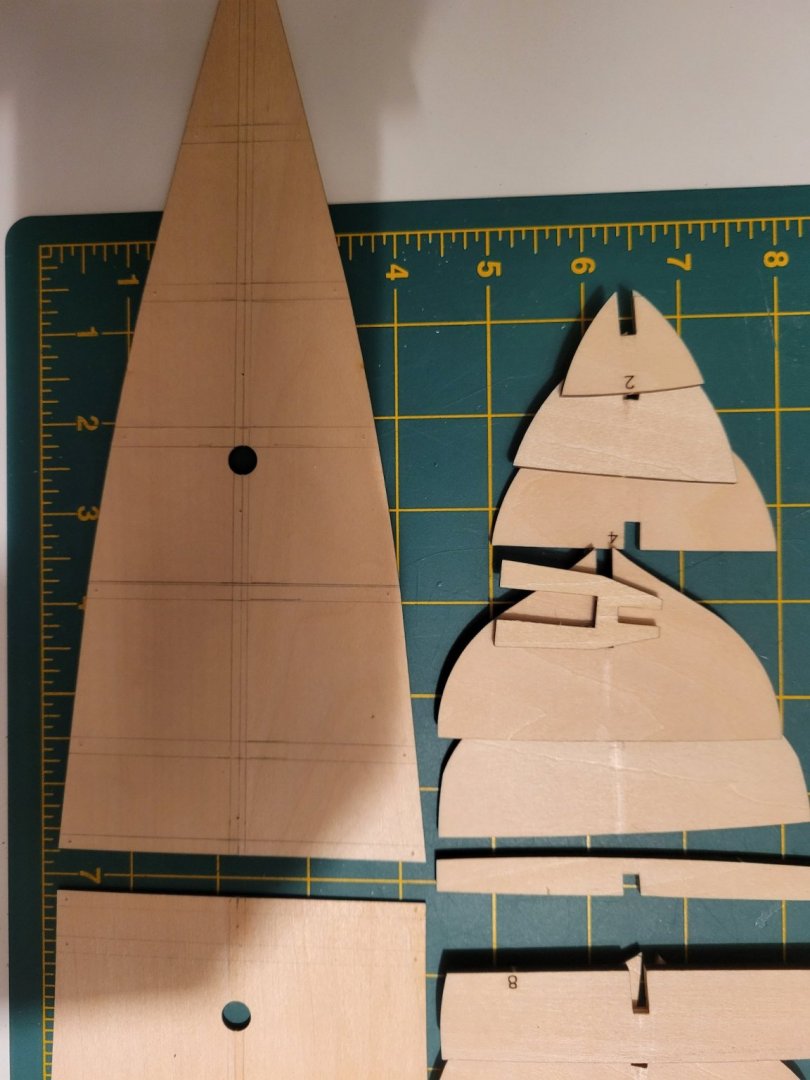

On my last build, I eyeballed my bulkheads. Went together pretty well by I did have some slight twist on a few bulkheads and the deck didn't end up exactly centered. Everything worked out just fine on that build but this time I'm going to see how it goes being extra detailed. I carefully measured the bulkheads and the ran a centerline on the deck pieces and lined out each bulkhead one the deck. Then drilled a couple centered pilot holes so that I can try to set the decks/bulkheads exact when I glue. May not show well in the picks but we'll see how this goes and whether the extra attention makes a difference.

-

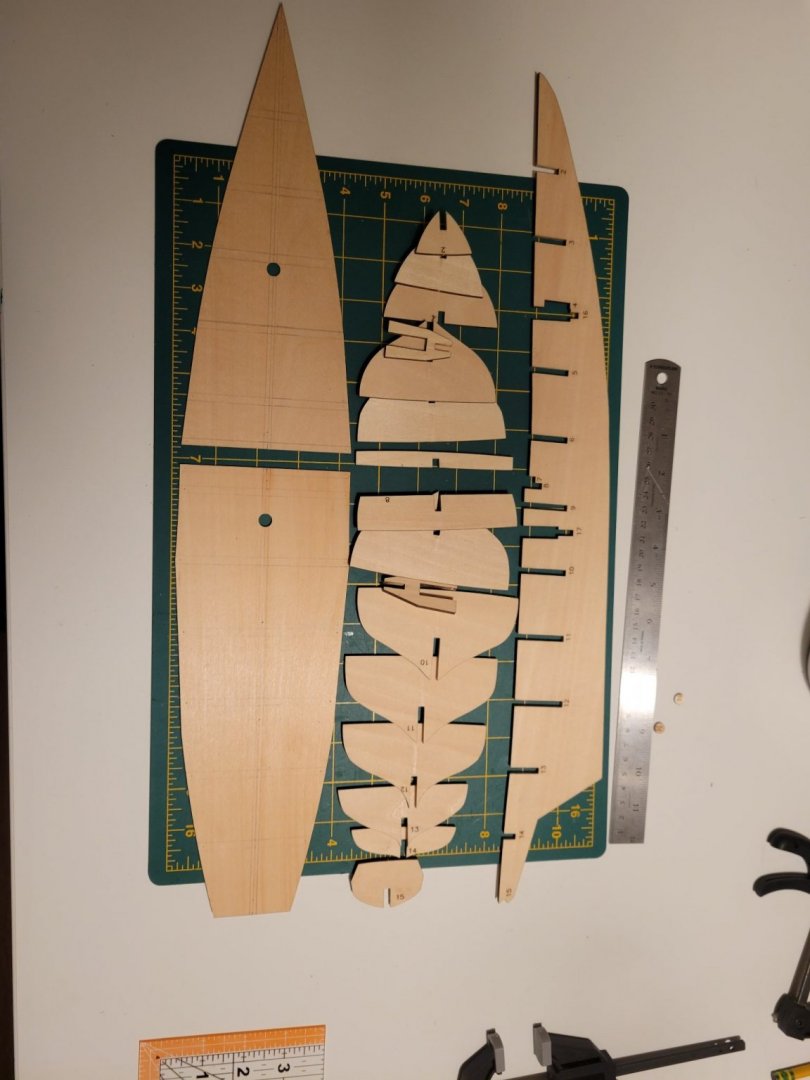

Starting build number 2. Staying with Artesania for this one but a bit more complex than the virginia schooner I started this journey on. Would like to do something like the Ocre Terror but this is my next step in that direction.

Unboxed and everything looks good so far (oldest laptop in the house was the only one left with a cd drive which makes this interesting with no printed instructions but I put everything on onedrive to make it more accessible. If anyone is doing this same, I'd be happy to share the files.) Laying out the false keel and bulkheads. As mentioned by others the AL laser cuts are a bit tight so a little filling is needed but I'd rather have that than sloppy loose! I also found a slight bow in the false keel and a bit more warpage between two bulkheads. Soaked it in water for 20 min and sandwiched it between two mdf boards with pipe clamps. With this west coast heat wave, a half day in the clamps took the warpage right out of it. Flater than flat now!

Bluenose II by Travis - Artesania Latina - 1:75

in - Kit build logs for subjects built from 1901 - Present Day

Posted

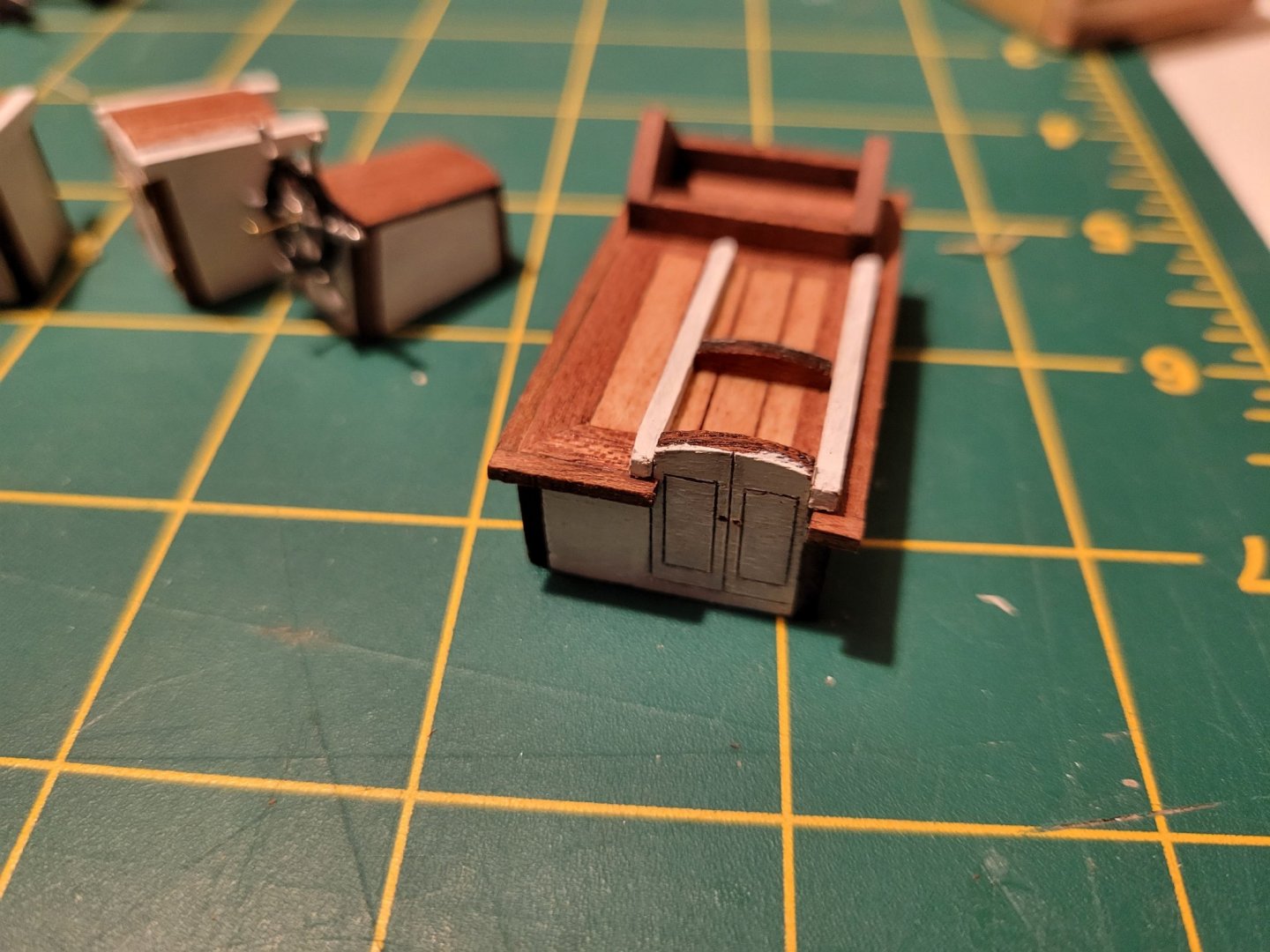

Deckworks update. Working on the windlass. Haven't glued the axel yet as I'm thinking of adding a section between the right drum and the windlass housing to be a drum for the chain haul (to be more accurate?) In photos, looks like it's two drums, housing, main drum, housing, final drum. AL left out the double drum setup on the port side

Skylights ate built and painted. Both cabins are read for finish. At the helm, I added a short tub behind the helm so it would stand off the steering gear cabinet a bit.

I have two challenges now. First, the poop deck from AL is a poor fit. Try to decide if I should modify or rebuild from scratch.

I also made my first big goof. When I started building the skylight panels, I grabbed the wrong wood. Grabbed some walnut of similar size instead of the sapely. Oops. Fortunately, I plan on painting the rails anyways so I can use any wood as long as it's the right size.