DaveBaxt

Members-

Posts

1,324 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DaveBaxt

-

Cheers Allan I have based my sizes of shrouds on the main mast to be 1mm and on the others I have 0.75 mm. This is the closest I have to what I worked out from Lees book. I was working on the same for the rat lines 0.1 mm . It is either that or 0.25mm which I think the knots will too big. Perhaps on my next model, I will go down the route of making my own rope to get nearer to scale. I have bought some rope in for the Stays .Perhaps I should have bought some for the shrouds too. However buying it although a very good rope it is quite expensive as I am quite wastful. Haha. I would like to thank everyone for partaking in this thread. Best regards Dave

-

I am just wondering is this is really the way ratlines and how they are attached. I came across a modeller who sugests using a needle. So my question is this. Is using a clove hitch on the ratline done for convenience due to being an awful lot of them ? Thank you Best regards Dave

-

Sorry if I am hyjacking this thread a bit but whilst on the subject I have been considering using Superphalatic glue on my future keel . https://www.hobbies.co.uk/deluxe-materials-super-phatic-glue Insread of the usual PVA. Rather than adding pva to individual pieces and waiting for the glue to dry . Build the model up in a frame which together with a false deck keeps everything lined and square, then add the glue later. I know this is used by other modellers but used on MDF but unsure if there is enough penetration on plywood? Seems to work quite well on smaller projects. Thank you and sorry again for going off track a bit. Best regards Dave

-

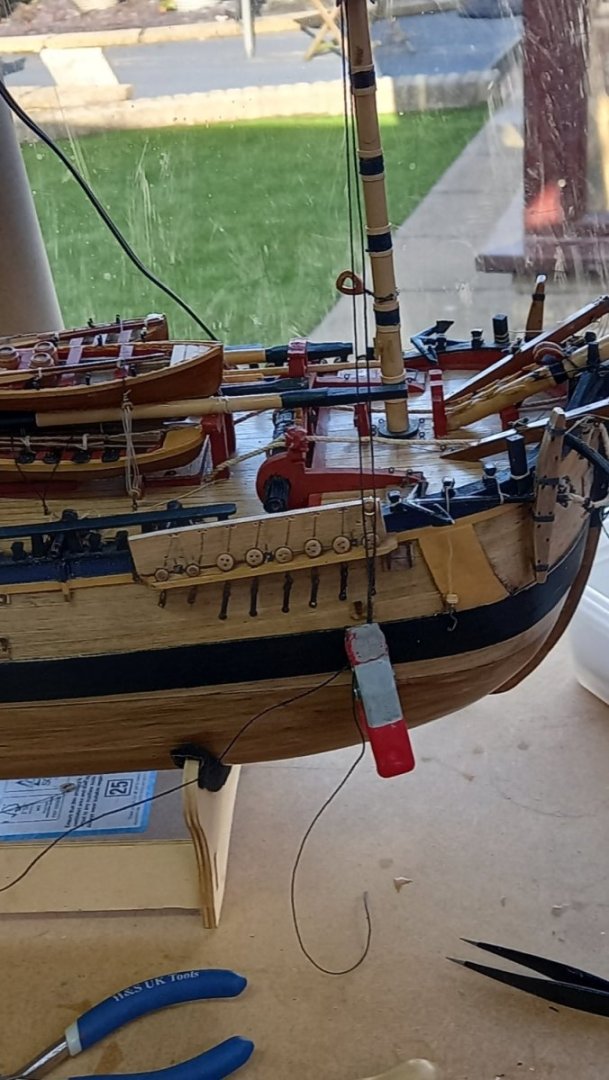

Thank you again jason for Clarifying regards the Steps. During my time finishing off the rigging on my Endeavour build it id my intension to read your Diana Log together with DaveEN and Dunnock log from start to finish before actually making any headway witn the Diana in the hope that I will make a few correct disicions rather than regret any major mistakes. I still have a lot of stuff to do on the Endeavour , so it will be some time before I can really get started.

-

Forming a rabbet

DaveBaxt replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

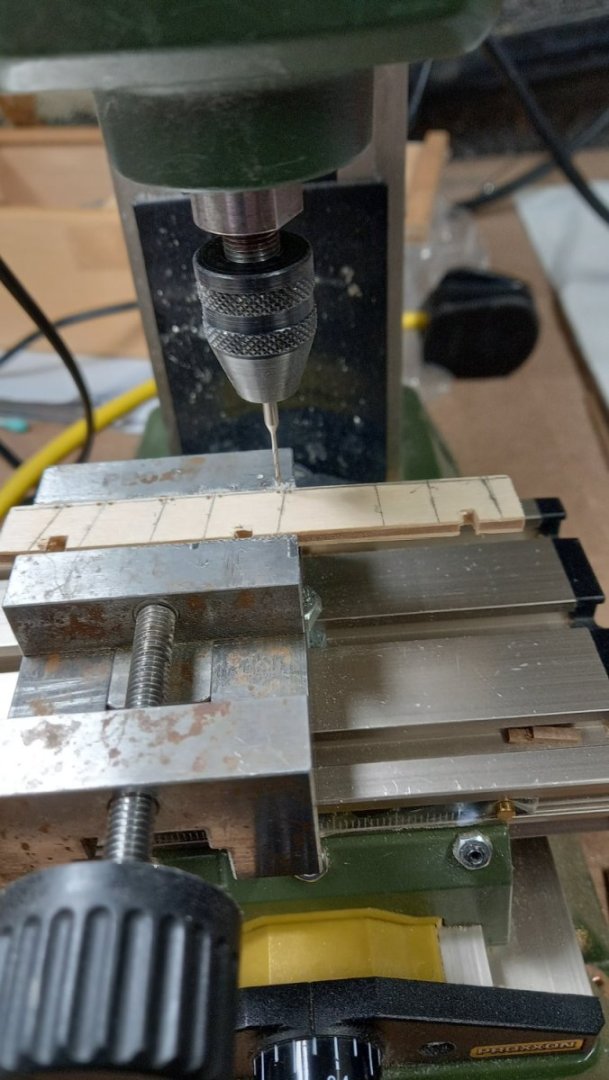

Thank you once again Mark and good to hear from you again. I have thought about using my milling machine for the straight bit of the rabbet . I have been trying to do source a set of chisels to do the job which is in my price bracket. I did come across a set of 3 Veritas chisels https://www.hobbies.co.uk/veritas-3-piece-miniature-chisel-set but are way too big. I will do a search and see if they do any more as I do like there planes and sharpeners. I have sourced a couple from axminister which I was looking into and might try a couple of these.https://www.axminstertools.com/kirschen-micro-chisel-skew-chisel-no-2-1-5mm-600057 Best regards dave -

David I also came to the same size main mast of 11.1mm and I also get the same for the Bowsprit. It might be worth us checking these sizes against some other reference such as james Lees. The sizes supplied by caldercraft are the same dowels supplied for the Endeavour which is only half the size of the Diana model. I am hoping I can source some square boxwood at 11mm . Timberline only do 10 mm and 13 mm but I have heard that if you give them a call they will ablige. I think Syren models also supply 11 mm but the imperial equivelent. As ever you have created some amazing details. I also like the look of the slipways for supporting the models. Great ideas.

-

Welcome aboard Jason . I am sure your help will be invaluble .Sorry I missed this post and I thank you for itemising each problem so hopefully a will not miss anything out.Mmay I ask, when you say adjust the formost frame did you mean adding building up the pieces to maintain the strength as you did on your Diana log rather than move the gunport. I am now planning on replacing both stem and stern and creating a rabbet for the first row of planking.I was not aware of a problem with where the steps are located so will take a closer look. Thank you again Jason for your help. It is very much appreciated.

-

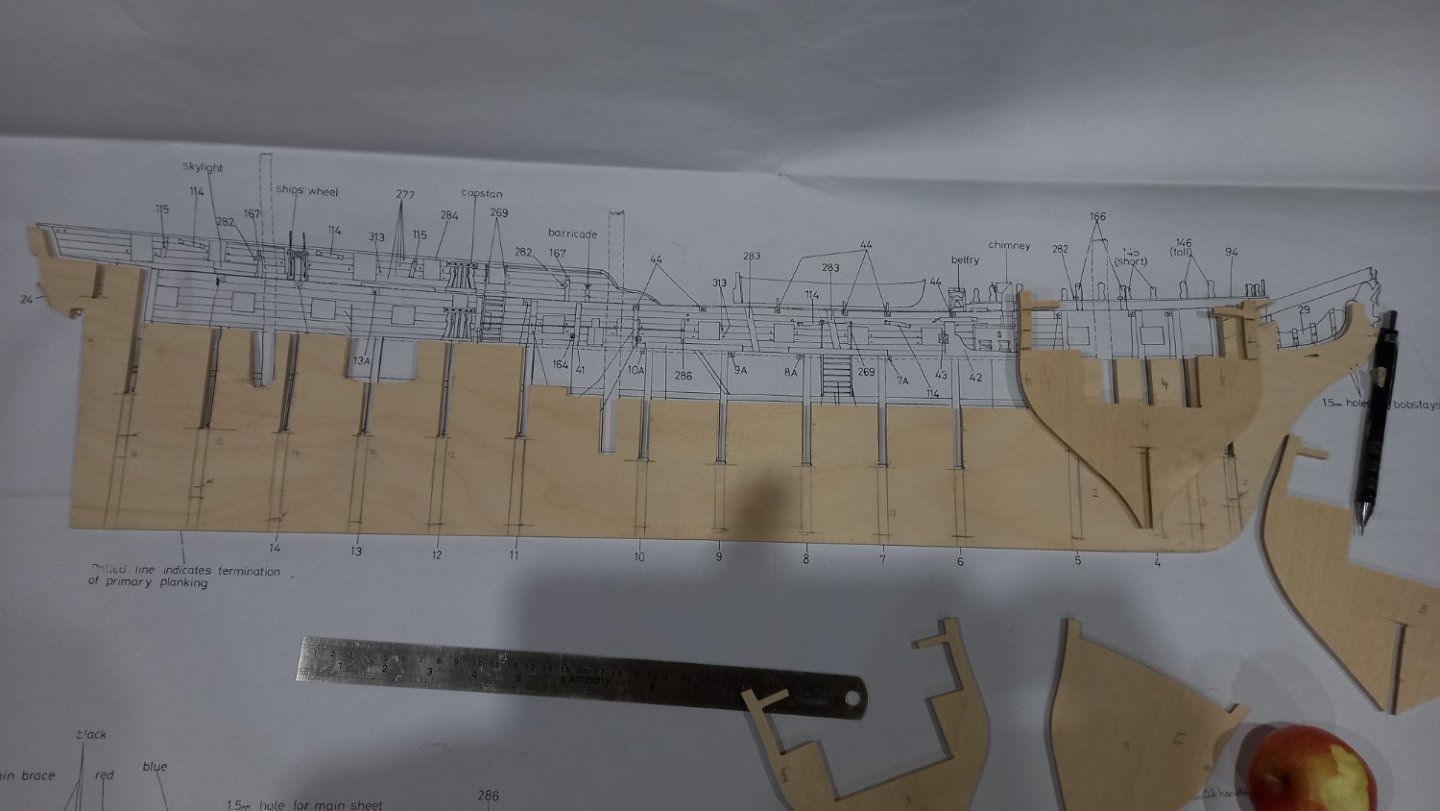

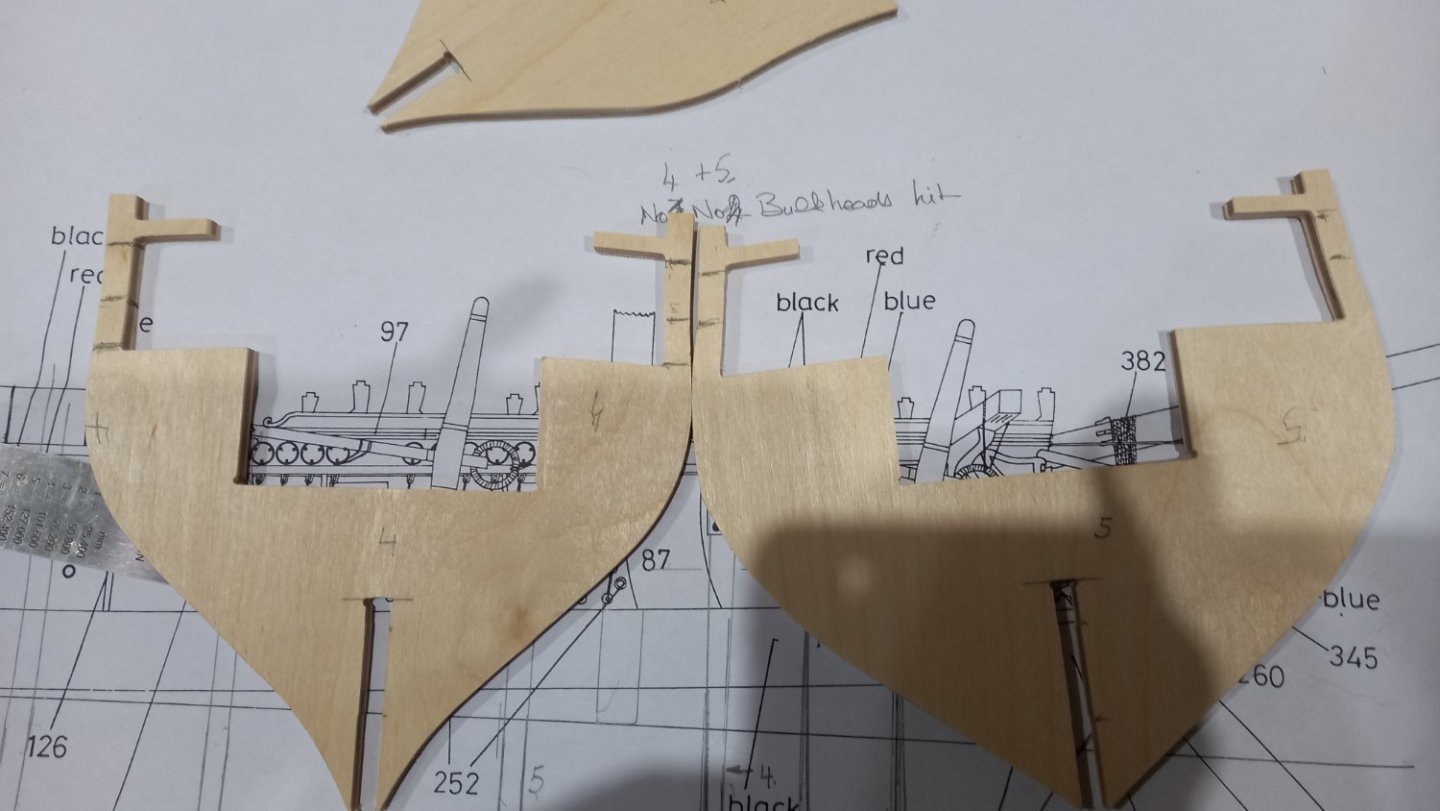

I have had a closer look at the Caldercraft drawings and think sheet one is to be used as a template for securing the position of the gunports but could be wrong. The sizes of the drawings coincide with the length of the false keel, however the slots for the bulheads are slightly out the further aft you go but only by 1mm. The only gunports which fall foul of the bulkheads can be seen as No 4 and No 5 bulkheads when using the caldercraft drawings. I have marked the sections of material on the bulkheads which will need to be removed after planking. After two layers of planking are glued in place, hopefully I can get in there and remove these sections. I am not sure if I need to glue any material acting as supports , perhaps this would make it more difficult to break off. when needed Also I have been looking at the positions of the channels and apart from the fore channel being slightly forward related to their mast the other two seem correct. However I also need to check if the shrouds miss the top gunports. I have not checked any of the gun port positions againt AOTS Diana as perhaps this will only complicate matters. I hope I am not wrong. At the end of the day I just want the model to look good and her fittings historically accurate as best as possible. I would of course like to get the sizes of the masts and rigging as accurate as possible.

-

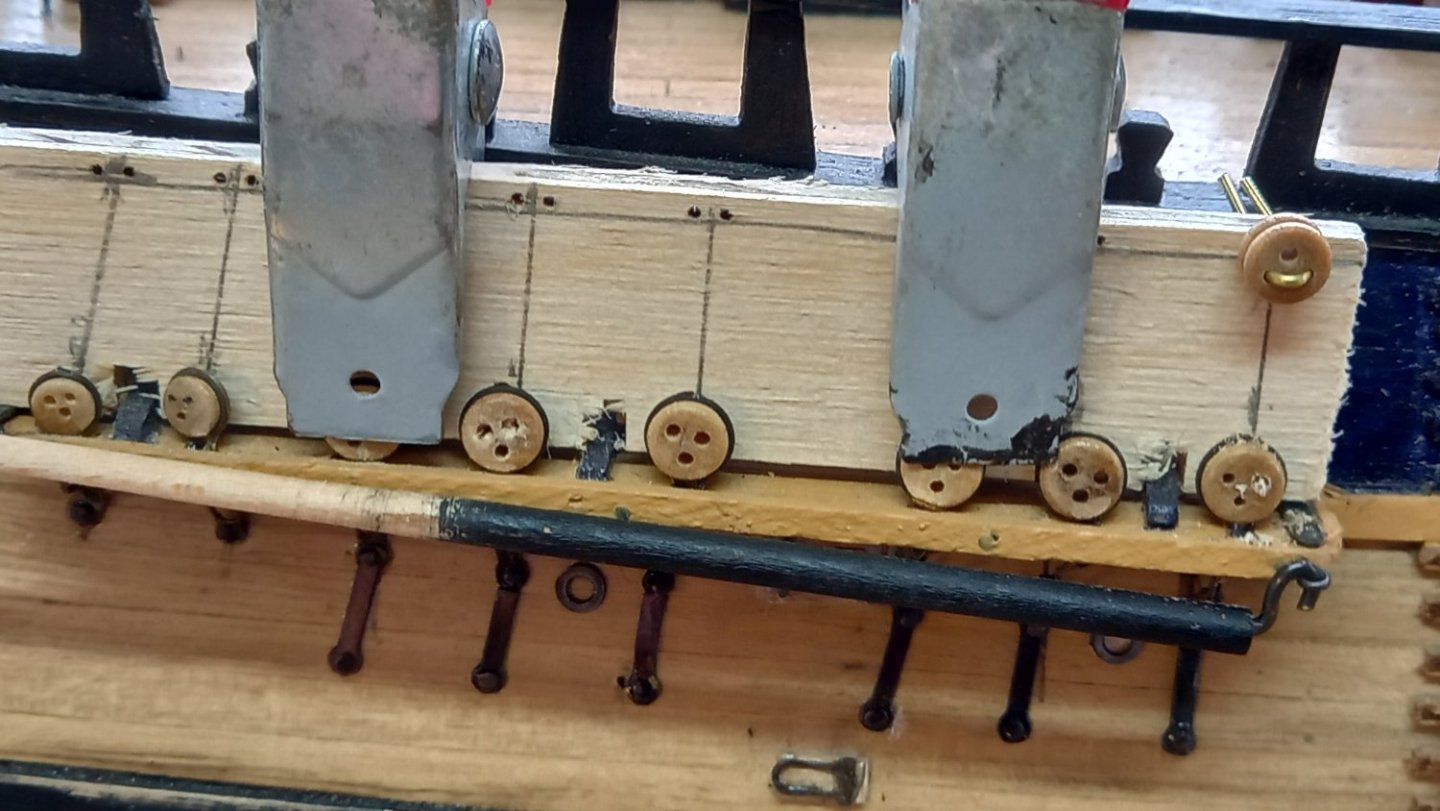

Moving on to the Fore lower mast shrouds using 0.75mm black thread . I made a jig for each shroud port and stbd as I found this method kept the upper dead eyes a the same hieght rather than the traditional brass wire which did not work to well on my last model. There are signs of one or two lower dead eye securing wire come loose and have always found this a problem of the upper chain plates. I will have to try something better on my next ship.

-

Forming a rabbet

DaveBaxt replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

Thank you once again Gregory for your help and patience. I have had a look at your Constitution and can see how you have added a strip to create a rabbet and this another ecellent solution and I could go down this route if needed but would possibly need to remove some material from the false keel first. By the way tyour Constitution looks a first class model and is a credit to you. Best regards dave -

Forming a rabbet

DaveBaxt replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

I think this would be the cheapest solution ( I already have a Dremmel)for me and definately worth consideration. Using the wooden ply sheet what the keel came attached to for a guide would be a great help too. As this could be the only attempt at doing a rabbet and not sure I want invest too much in buying expensive tools is definately something I would like to attempt on scrap wood to see what results I could produce. Thank you again for your help. Dave -

Forming a rabbet

DaveBaxt replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

I would just like to thank all who have answered my call as I now have a better understanding of how rabbets are formed and what is required. Also thank you for the recomendations regarding equipment needed and how to make these as the jeweller type chisels gouges etc are probably out of my price bracket . Thank you also for any great links posted too, as they are a great source of reference. Again it amazes me how much help and patience is at hand on this forum and I am forever grateful. Best regards Dave -

Forming a rabbet

DaveBaxt replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

Thank you Jaager for your recommendations annd will take a look. -

Forming a rabbet

DaveBaxt replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

Yes it is all one piece, however as many have done before ,I am considering replacing both the stem and stern section with boxwood. Some modellers have added material to the bottom of the straight section of the keel but as Alan has metioned whether or not this required. -

Welcome aboard David. I am really happy you and DavidEN and not forgetting Andrew are following on with my attempt at the HMS Diana. Its a case of working out the best approach of moving the bulkhead out of the way or part of it rather than moving the gun port and when is the best time to do this. I think Beef Wellington had a good idea by adding pieces of plywood onto the bulkhead so that when gun port is cut out then the bulkhead can be cut away too. without loosing any strength in the planking, although I worry about loosing the profile of the hull if I do this. I would like to get this done sooner if I can, that is before the planking is started but unsure if I can. Perhaps Beef Wellington spots this log and would be kind enough to add any comments as anyone else would be welcome.

-

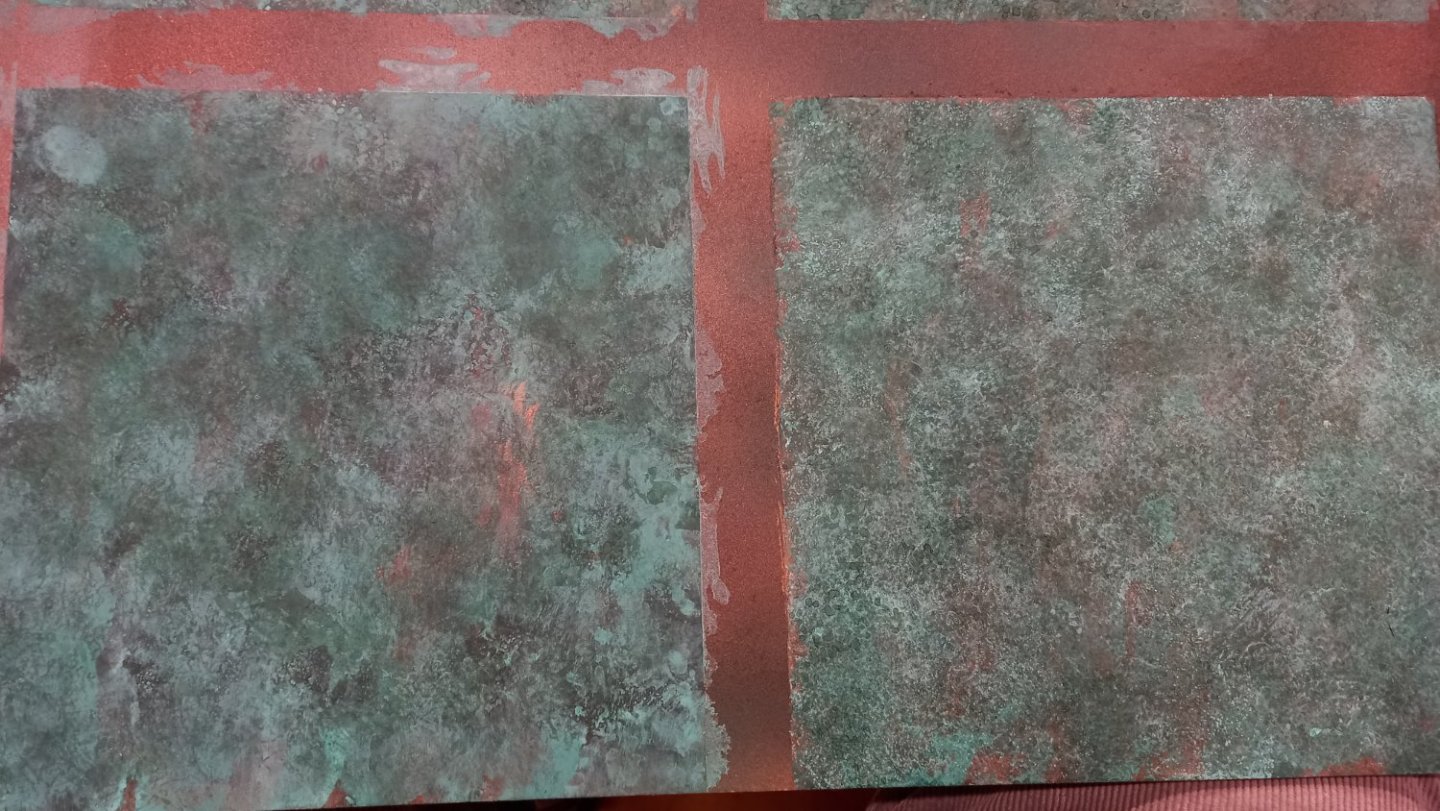

I am not sure if I am coppering but will probably do another layer of planking using walnut. According to the instructions the second layer of walnut is 1 mm thick so the two layers are a total of 2.5mm. The clearance under the bulkheads is 6mm so that would give me a depth of 3.5mm so perhaps this is what David is referring to but unsure. It is my intention to paint the bottom of the ship with copper and vedigris and attempt to create something similar to this rather than using the tiles which have out of scale nail heads on them.

-

Forming a rabbet

DaveBaxt replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

Wow! what a fantastic collection and probbably worth a small fortune. I will send the guy an email but probably beyond what I have in my wallet but interested all the same . I have just emailed Mihail and he would gladly make me a set but unfortunately the transfer of funds to /from Russia at present are not allowed .Thank you once again Allan. -

Forming a rabbet

DaveBaxt replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

Sounds good. Look forward to your pics and any explanation would be appreciated. Best regards dave -

Forming a rabbet

DaveBaxt replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

The idea of using a guide sounds like a good one to me . What make of route are you using? -

Forming a rabbet

DaveBaxt replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

This sounds like it could be more difficult than first thought but still willing to give it a go. My first two bulids have been smaller models and I have not attempted a Rebbet but the ships were smaller and perhaps my thinking was ' they did not need them' Although I think I would prefer to use a machine if I am honest, however its probably about time I git myself a decent set of chisels so I will be looking for recomendations and hopefully I can get them here in the uk. So what kind of chisels do i need other than very small probably the thickness of the first planking 1.5mm ? Do I need a gouge or flat,curved or butt. As these are quite expensive, I want to make sure I get the correct ones. Once again I would like to thank you for your quick response and guidance. Best regards Dave -

Thank you Andrew and David for your kind words of support. I think I am going to need a lot of it on this one. Regards changing the position of the bulkhead to accomodate the gun port. I am wondering if it would be best to fit new bulkheads either side of the gun port or can I do what Beef Wellington has done and just add some material at the side to support the planks . This is definately going to take some figurering out. As it is quite some time since there have been any completed Diana's, I don,t suppose they have changed the design slightly or is that just wishfull thinking ha ha . I have yet to check the gun port templates before I start with any glueing.

-

What is the prefered way of doing this, Miniture chisel set------- ( Is there one small enough 1.5mm) I would need to buy one of these. Dremel.----- I have one at hand but would need to buy a plunge router for this which is quite cheap but unsure if it would be steady enough. https://www.amazon.co.uk/Dremel-Attachment-Precision-Drilling-Trimming/dp/B0009EQ5QA/ref=asc_df_B0009EQ5QA/?tag=googshopuk-21&linkCode=df0&hvadid=309785472429&hvpos=&hvnetw=g&hvrand=1171505061803571346&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=1007202&hvtargid=pla-406644565655&psc=1&th=1&psc=1 I am the proud owner of a Proxxon bench saw and milling machine, Both could be used to form the straight edge but not around the bow. I would lean more towards the Proxxon milling machine if I were to go down this route. . I could of course try and use a Dremel free hand without any guidance but think my hand is not too steady ( age related) Any other ideas out there would be appreciated. Best regards Dave

-

A bit late to the party here but some great ideas here which hopefully I can replicate on my Endeavor build as |I move onto the shrouds

- 11 replies

-

- block seizing serving

- serv-o-matic

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.