DaveBaxt

Members-

Posts

1,324 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DaveBaxt

-

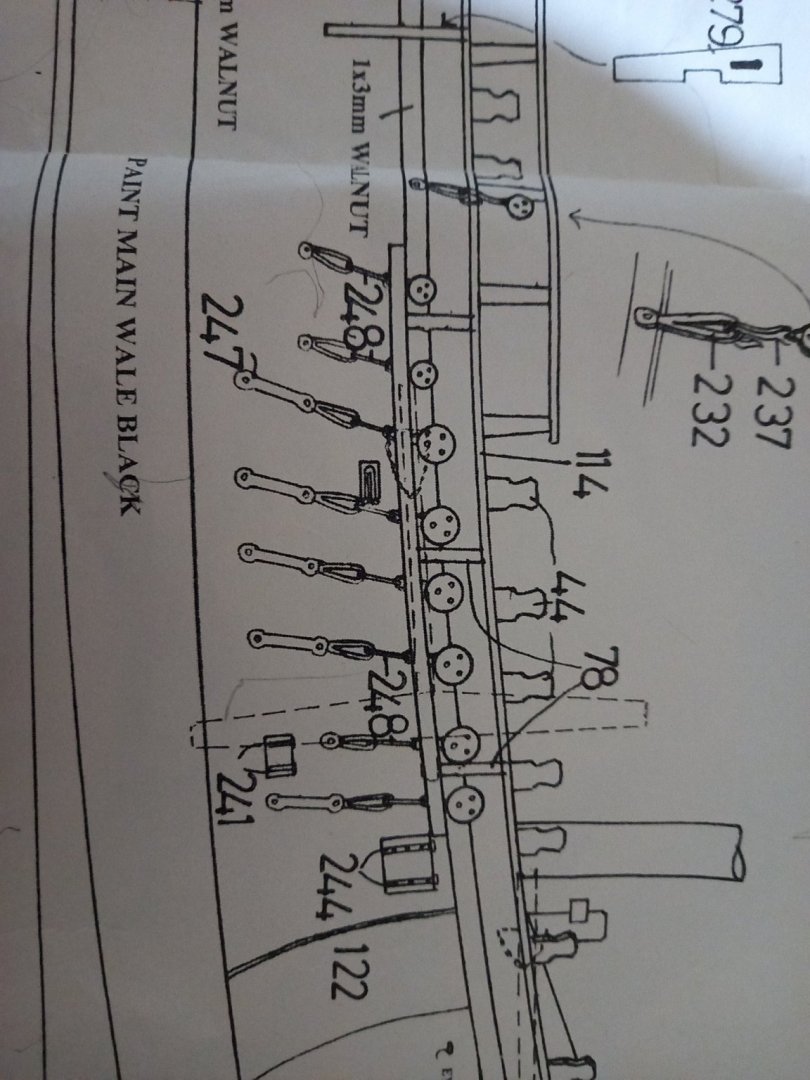

Thanks guys. and just for a bit more back ground here is one of the photos that I have of the replica. I suppose if the position of the Channels could change, Is there any models of the Endeavour out there which have the Channels under the wale? Just wonder where Caldercraft got there information from. Thanks you Allenyed for the link to the photo which also has the channel in line with the wale.. I also wonder what position other model makers of the Endeavour have their Channels. I thought I would also add a photo of the drawing I have form Caldercraft. F Am I correct in thinking that if I place the Channels where indicated there would be a reduced chance that the shrouds would clear the cap rail . Also does anyone actually fit the channels onto the wale itself and pin right through into the hull ? ( As stated inthe book Historic ship models by Wolfain Monfield. In my last modal The Bounty and my first .I cut the wale away then fitted the channel onto the hull. What is the correct procedure? Sorry for more questions. I have since looked at a number of photos of this vessel including the replica and paintings other than the model made by Caldercraft there is only one that I could find from the Australian Maritime muesem ( sorry I could not copy and paste this for some reason) so it would appear that both could be correct. If I did however fit this under the wale and cut the wale to fit the brackets ,I think this would be very strong. Best regards Dave

-

I am currently building the HMb Endeavour by Caldercraft and according to the drawings the Channels are attached to the Hull directly under the upper wale or as they call itupper side rail. However when looking at a the replica of the Endeavour you can see from photographs that the channel is in line with the wale and not underneath. I have looked at one or two blogs of this and can only see they are the same as the replica and even look like they might be attached to the rail/wale and not the hull but doubt this as it would not be strong enough. Unfortunately I do not own the AOTS book of the Endeavour to check this out .Although this has probably no bearing on which is correct my last ship The Bounty by Amati also had the Channels in line with one of the wales/upper side rail. Hopefully someone can help me with this. Best regards Dave

-

Thank you David and I appreciate the reply. Good luck with build and I look forward to your progress

- 310 replies

-

- Diana

- Caldercraft

-

(and 1 more)

Tagged with:

-

Ah! rhat Ah! that was the question I was asking myself ( but as usual I didn't know the answer) So \if I decided to go down the air brush route for painting I would need another compressor or can you raise the pressure enough to work for both? I have just received my crock pot and Sparex for pickling so for the time being I will be using this for removing any unwanted residues, but always nice to lean about more alternatives. Thank you once again for your input. Best regards Dave

-

Starting to look like an awsome model and appreciate the work gone into such a huge model. Well done so far and I look forward to your progress. I am currently building the Endeavour by Caldercraft and after purchacing the book AOTS Diana I have been considering this for my next model but as yet have not attempted a ship with copper tiles or so many gun ports. Good luck with your future progress. Best Regards Dave

- 310 replies

-

- Diana

- Caldercraft

-

(and 1 more)

Tagged with:

-

Unfortunately I do not own an air brush as yet .( Only modelling for a couple of years) but do have a couple of spray cans including primer. I am still currently building up my tool store but hope to one day step up and get one. The Air eraser also sounds interesting and will do a search for them and see if there available in the UK. Once again I would just like to thank every one for their help on this subject. Best regards Dave.

-

I am now considering the stern facia . Although the instructions say fit this before fitting the second planking I purposely left this until after the second planking as I thought it would be easier to trim the second planking at the stern before fitting the stern facia. Also it would be easier to clamp the 1.5x1.5 mm strips of walnut to the stern facia before fitting to the hull I also sometimes wonder if it would be better to fit the wales at this stage, but on this case will follow the instructions and fit the stern facia before the wales. I will take another look at the other Endeavour builds and see what the other guys did. Any thoughts on this would be appreciated. I am also considering leaving the inner bulwark planking until I have fitted the deck planks as I intend to fit waterways and think any inperfections of the waterway outer edge will be hidden. I am not 100% sure if this is the correct way to do this but think it will be the easier as I did make an accurate template of the deck, only a tracing of the deck after the first planking was done. Hope this makes sense. Best regards Dave

-

Completed second planking and started the sanding process. I need to fill some gaps with glue and found it was better to water the glue down so it would run into the gaps. The photos are of completed hull with coarse sand paper. next up will be using medium and fine grade sand paper before sand and sealer followed by super fine sand paper.

-

I appreciate that soldering is another subject matter but I am assuming using Sparex before soldering helps to clean up the brass so the solder takes better. AS you have already mentioned it also helps to remove any oxides after using a torch. Am I correct in thinking that the blackening will not take to the solder? As I am going to try and do some soldering on my current build and listening to your good self I have decided to go down the Sparex route and have purchaced the equivilent here in the uk ( link provided on this thread) I have also purchaced a 1.8 ltr crockpot which will hopefully be suffiecient for my needs. For the record what is the percentage of mix of this stuff to water and how long does it take to pickle before soldering and blackening? Best regards Dave

-

Workshop Vacuum cleaners

DaveBaxt replied to DaveBaxt's topic in Modeling tools and Workshop Equipment

Sounds like you have a state of the art workshop. Unfortunately I am currently living in two sheds which are purpose built for modelling. One is currently for the power tools, the other for everything else. Fortunately the one for everything else is insulated. Best regards Dave -

Workshop Vacuum cleaners

DaveBaxt replied to DaveBaxt's topic in Modeling tools and Workshop Equipment

I would once again like to thank everyone who has contributed to this thread. I have eventually gone with the Fein model herehttps://www.axminstertools.com/fein-dustex-25l-wet-and-dry-extractor-230v-506260 By the time I bought the tools and a couple of extra bags it is about as much as I can spend. No doubt there will be something out there that is better. There are some terrific choices when one starts to look into it, so asking on here has been a great eye opener. Thank you all! -

Workshop Vacuum cleaners

DaveBaxt replied to DaveBaxt's topic in Modeling tools and Workshop Equipment

Thanks for your input.They do look very slick. So another to possibly to consider? I am now leaning towards either Festool or fein as both are stocked at my local Axminister store and would like a closer look. Best regards Dave -

Workshop Vacuum cleaners

DaveBaxt replied to DaveBaxt's topic in Modeling tools and Workshop Equipment

I have been looking at the Festool also but think they are bit too pricey for me having spent a fortune already on a number of Proxxon power tools. Once again thanks for your help and I hope you get what you need as noise in the work place is not something I would like. I see there is an Axminster tool store about 30 miniutes from me so think I will take a look aswell. Best regards Dave -

Workshop Vacuum cleaners

DaveBaxt replied to DaveBaxt's topic in Modeling tools and Workshop Equipment

All very good points and have to admit the household vac I am using at the moment is way to noisy, especially as it sits under my work bench so noise is very important for me and is possibly the deal breaker for me. Once again I thank you for a timely intervention. Best regards Dave -

Workshop Vacuum cleaners

DaveBaxt replied to DaveBaxt's topic in Modeling tools and Workshop Equipment

Sounding better by the minute . Thank you for your quick response and think I will take a punt with this on e as I really like the price. Haha -

Workshop Vacuum cleaners

DaveBaxt replied to DaveBaxt's topic in Modeling tools and Workshop Equipment

Thanks for that and I will take a look at them and see if there any stockests in the UK. Just found this Fein cleaner, which looks really good and discription. Double the price of the Henry but like the idea of the large capacity and high specs. I will have a look at what reviews there is? I can find Best regards Dave -

Workshop Vacuum cleaners

DaveBaxt replied to DaveBaxt's topic in Modeling tools and Workshop Equipment

Thanks for the link but would liek some feed back on that particular item. I will look into the Little Henry which I believe are very common here in uk and if its doing a good job for you, I will definately look into that. I came across this version which I am happy with the price. https://www.equip4work.co.uk/numatic-nrv200-commercial-dry-vacuum-cleaner.html?gclid=CjwKCAjw-ZCKBhBkEiwAM4qfF3D8QBznbSTZruqCY4lhvqQjJ7Dp_ymd5o5P8O_64qLOsL8jlNCLjxoC_wEQAvD_BwE .There are however cheaper models but not sure of the power. Perhaps you could be a bit more specific in what model you are running. Does it reqire changing the bag every time it is cleaned or can you just clean them? Best regards Dave -

I have recently purchased a number of Proxxon tools including the FET saw. I am now looking at vacume cleaner which I can connect to the FET asw ( continously) and also use it for other areas in the workshop. I live in the uk so must be 230v ac with preferably a 3 pin plug. I have been looking at the Proxxon wet and dry vacume cleaner which has the correct attachment for the FET saw, however I have had difficulty sourcing this in the uk. Ebay sell them but ends up taking about 3 weeks from Italy. Just wondering what other alternatives there are in the uk, or where I can get the Proxxon vacuum cleaner here in the UK Best regards Dave

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.