-

Posts

310 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gabek

-

I don't have any familiarity with Linux versions - but the print dialogue in Adobe Acrobat has color management tools in the Advanced Print settings. Check the advanced tools in the software you're using to print PDFs to see if they have an equivalent. Hope this helps, Gabe

-

Great work, Bob! I seriously don't think the actual Duchess had as much adventure as yours! Looking great. Clear skies and sharp tools! - Gabe

- 207 replies

-

- vanguard models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

Gorgeous work, Michael! And you have my brain humming about making a mini rope walk. Great idea! Clear skies and sharp tools, Gabe

- 61 replies

-

- Agamemnon

- Ardent-class

-

(and 2 more)

Tagged with:

-

Hello Alistair, What brought you to our fair (and frigid) province?! And you only got -15C? Come at the end of January/early February and we can give you -35! 🥶 Stay cool, Gabe

- 258 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

You're nailing it, Bro! (Well, actually you're gluing it...but you know what I mean!🤣) - Gabe

- 258 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

Great looking, Bob! This will look spectacular when you're done. Clear skies and sharp tools, Gabe

- 258 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

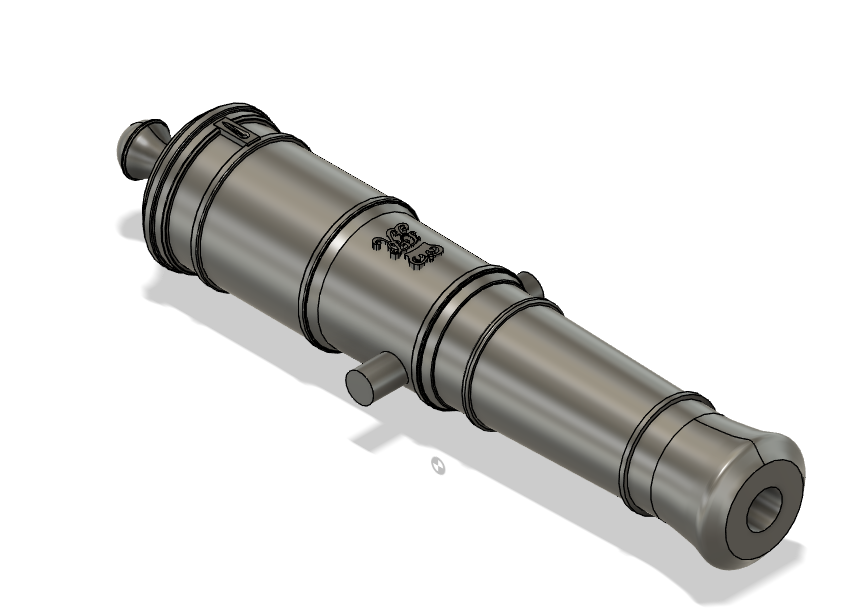

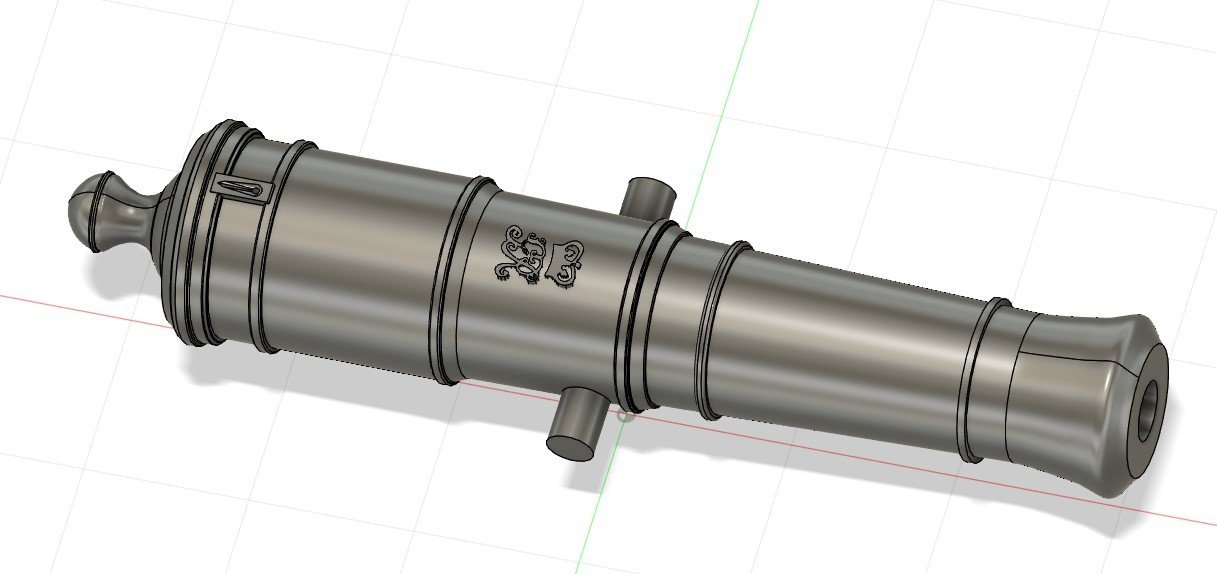

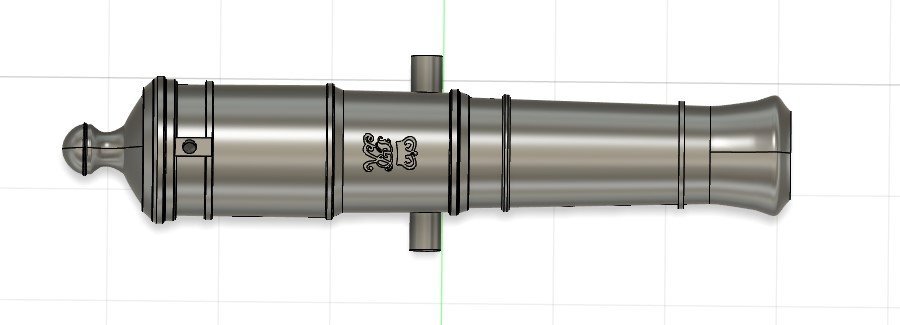

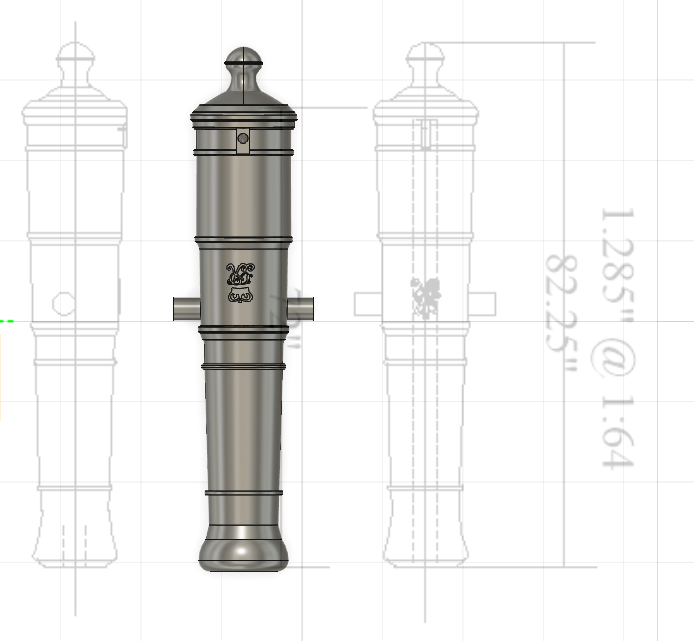

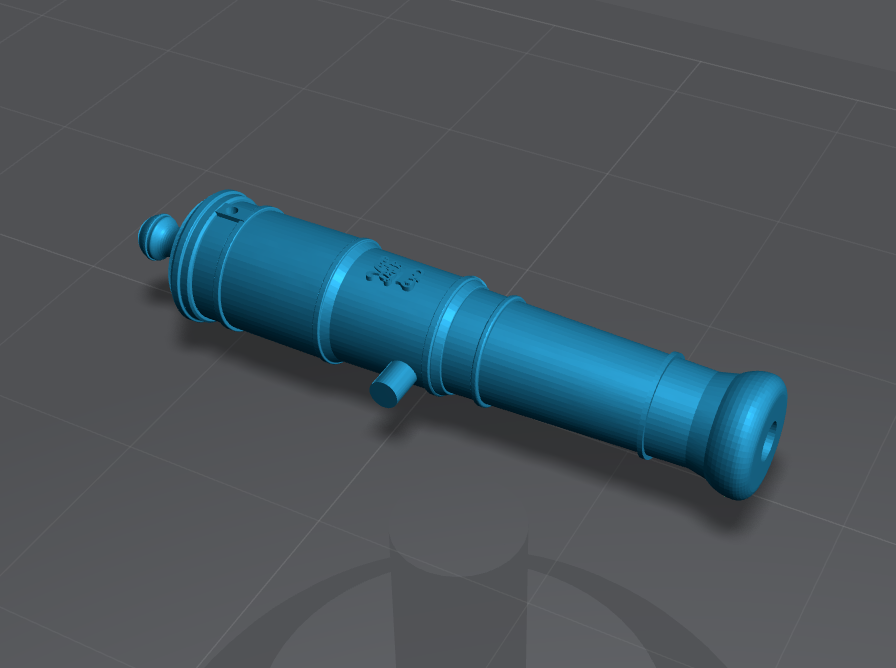

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

Final (?) product. 1:64 6-pounder Royal Navy Cannon - George III era I printed these at 0.03mm resolution in Anycubic ABS+. If anyone wants the .cbddlp file created for these prints (with supports) just send me a message. If anyone chooses to print these out I would appreciate a photo! I hope this helps, Gabe 6-pounder cannon_.stl -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

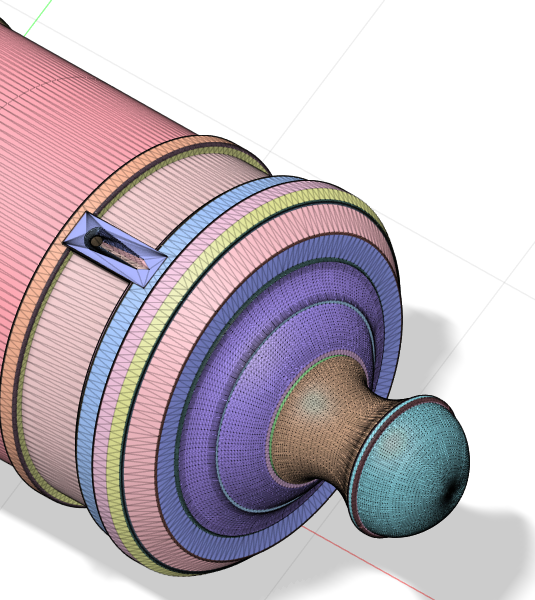

Hello everyone, In response to people who have warned that there might be a split in the .stl where I created the complicated curved bodies I checked the meshes in Fusion 360 and I do believe that they are stitched correctly: Thanks for your input, folks. I will be posting the .stl for this file shortly. Clear skies and sharp tools! - Gabe -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

Thanks, Phil. I do use Chitubox on occasion so I'll make a point of checking for these errors. Regards, Gabe -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

Thanks! I had spotted that earlier and they were placed on the end like you recommend on this version. Regards, Gabe -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

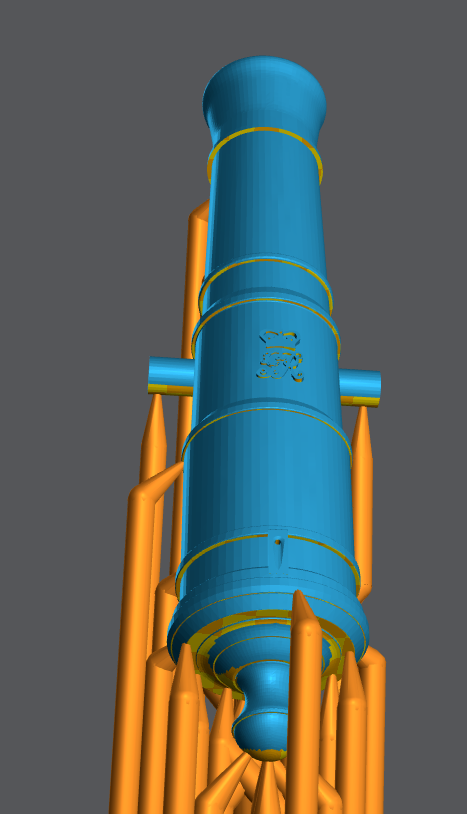

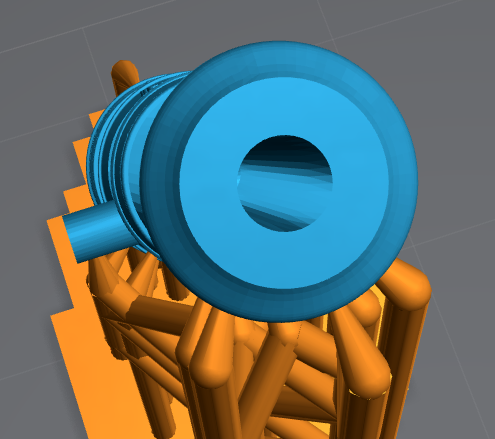

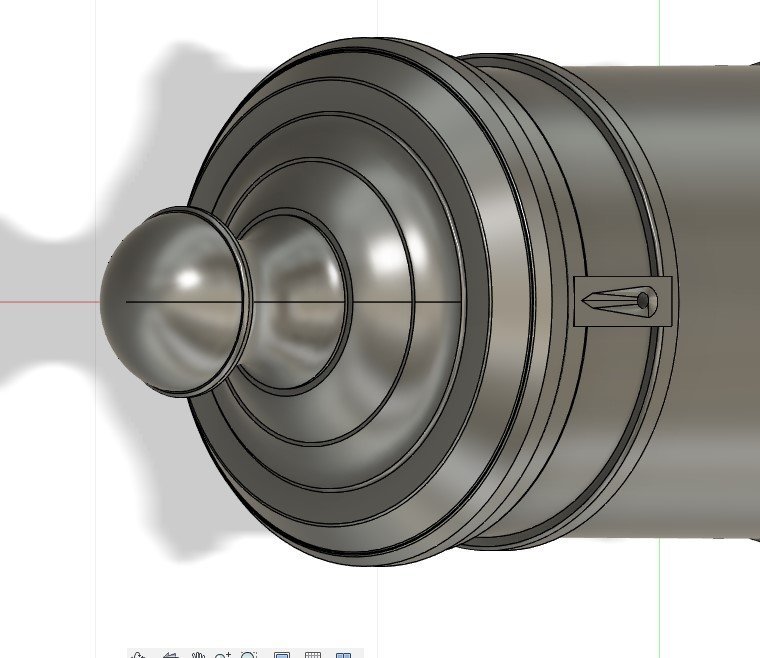

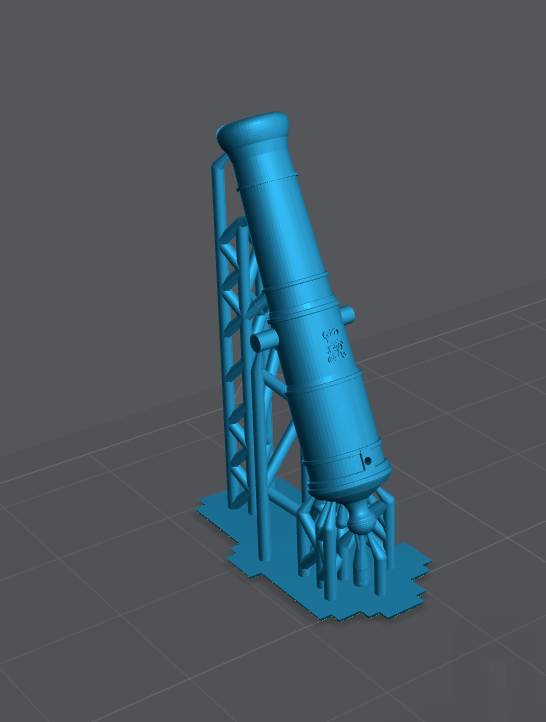

I'm sorry, Lieste - I don't quite follow you. The lines on the cascabel and the muzzle appear to be artefacts of the drawing (Fusion 360), not seams in the model. I'm printing in resin at 0.03mm resolution and have yet to see the line and there isn't any kind of infill. In the slicer (Lychee), here's what the model looks like: -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

LOL! I'll go 20 cannons for 10lbs, Bob! -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

Hello folks, Based on suggetions from @thibaultron and @allanyed, I've made some more modifications to the 6-pounder. Namely, I added the trough, reshaped the cascabel, and adjusted the breech rings. Here are a couple of screen shots. Once people are good with these latest changes I'll post the .stl and .cbddlp files for everyone to use. When I feel up to it I'll make a gunlock for this cannon. Regards, Gabe -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

I actually just guessed at the vent diameter because the drawing I referred to in AotS Diana only showed the barrel with the gunlock. If you have diagram with the trough I can easily add it. To be honest, I knew that this detail would be almost invisible at 1:64 so I didn't fret too much. - Gabe -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

Thanks for posting this, Ron! -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

Thanks, Gary And they're on my list! Stay tuned. Regards, Gabe -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

In answer to @Lieste 's rebuke of my first attempt at a cannon barrel, I have corrected the muzzle to what I hope is a more acceptable shape. I admit that I had incorrectly shaped the muzle. The lines you see in the muzzle would not be printed - they are simply artefact lines from revolving the complex shape of the muzzle. You see the same lines on the pommelion. These would not be printed as you see them. Please let me know if these are acceptable. Attached to this is the .stl file for you to download. I will post a ready-to-print, supported model once people are satisfied that I have a correct cannon barrel. Kind regards, Gabe 6-pounder cannon - amended muzzle.stl -

6-pounder, Royal Navy cannon barrel - George III era

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

I based this model on diagrams that were supplied to me, which I quite obviously didn't even follow all that faithfully. Yes, I can see the hideous mistakes, particularly at the muzzle. My apologies for sharing something so inadequate. I won't bore you with some of the mitigating circumstances that contributed to this failure. Thank you for your corrections. Please disregard my work. -

Thanks, Andrew! I'm pretty sure that my grandson be immersed in models…whether he likes them or not! 🤣. That and fishing! 🎣🤣

-

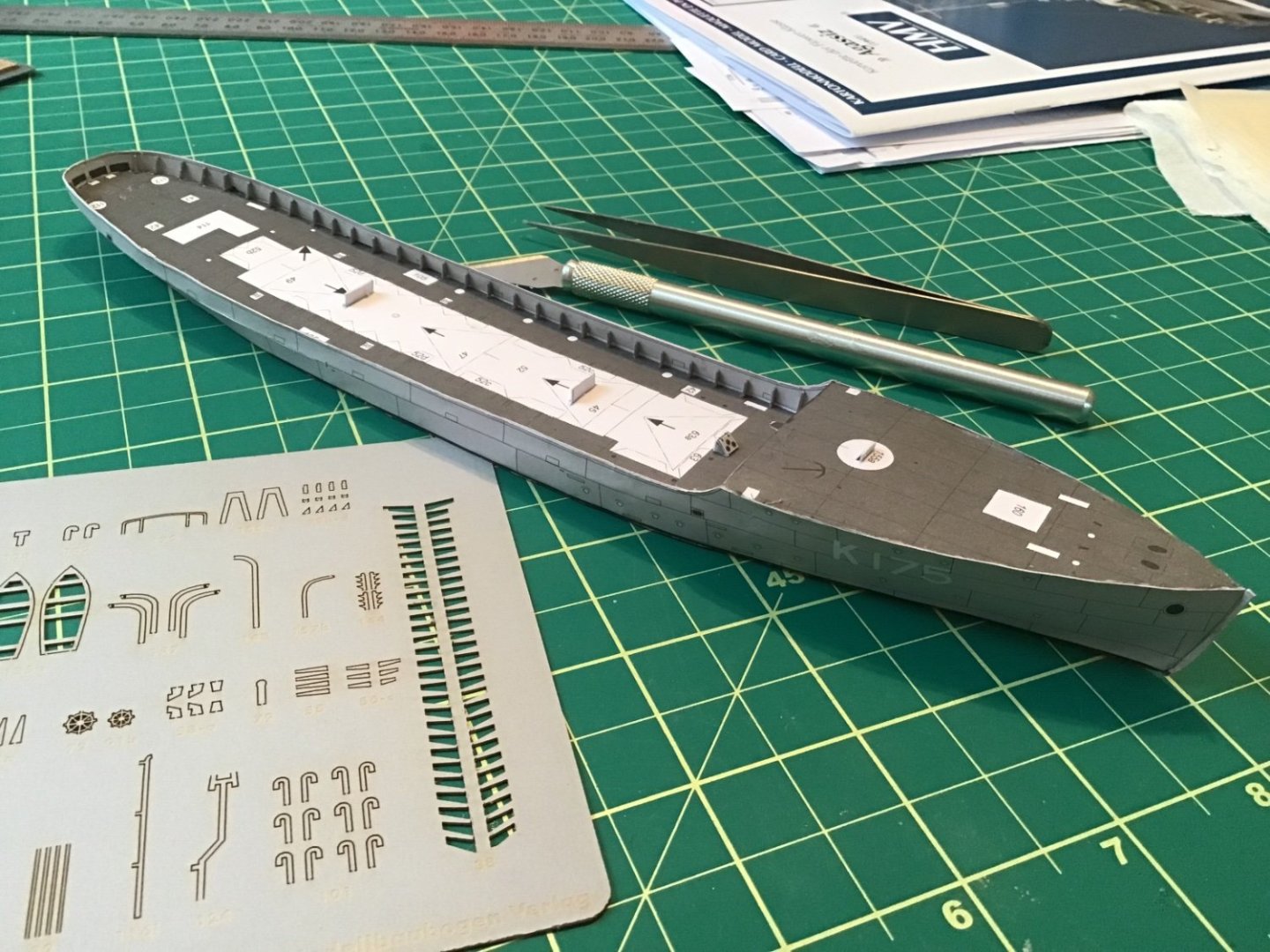

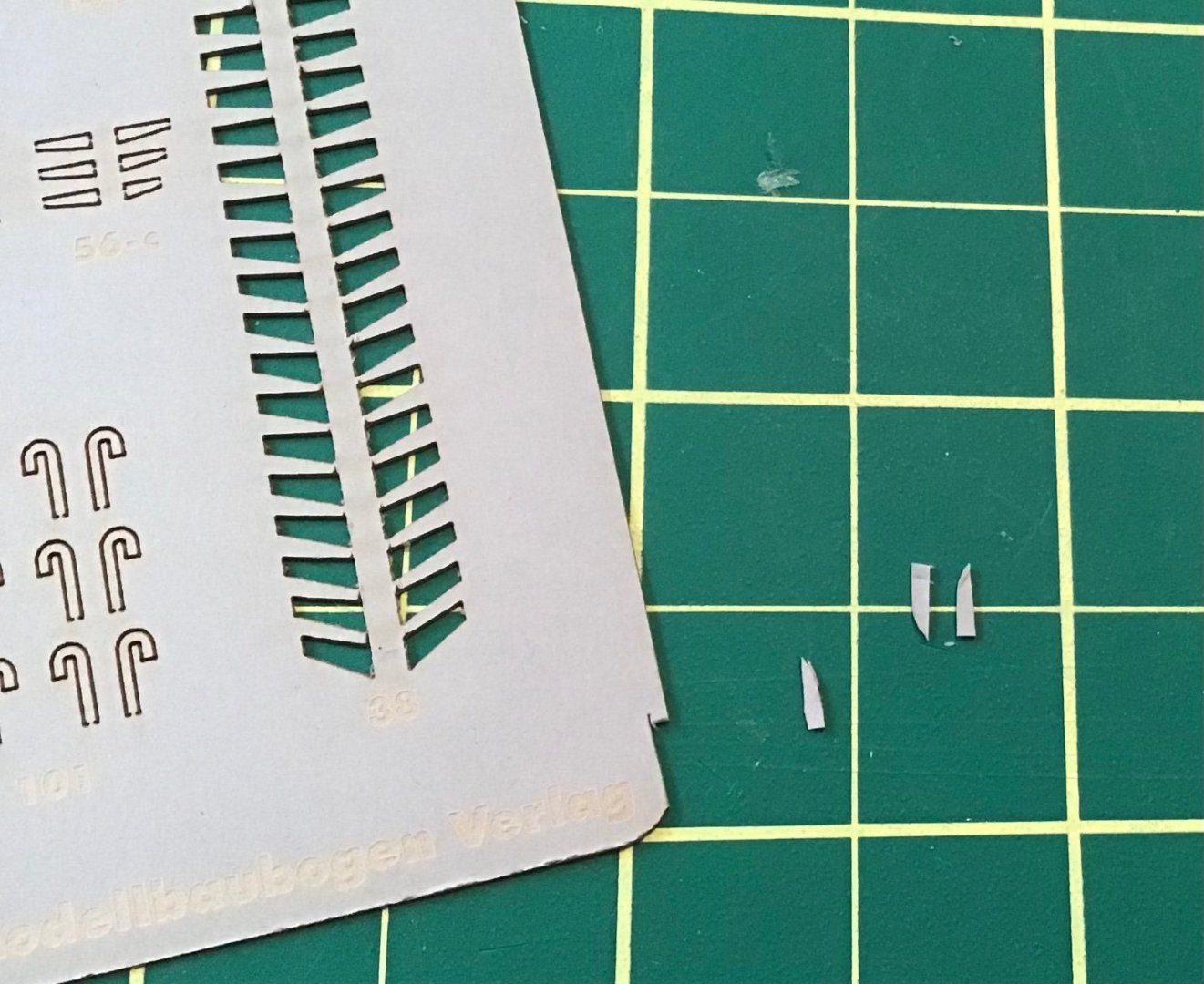

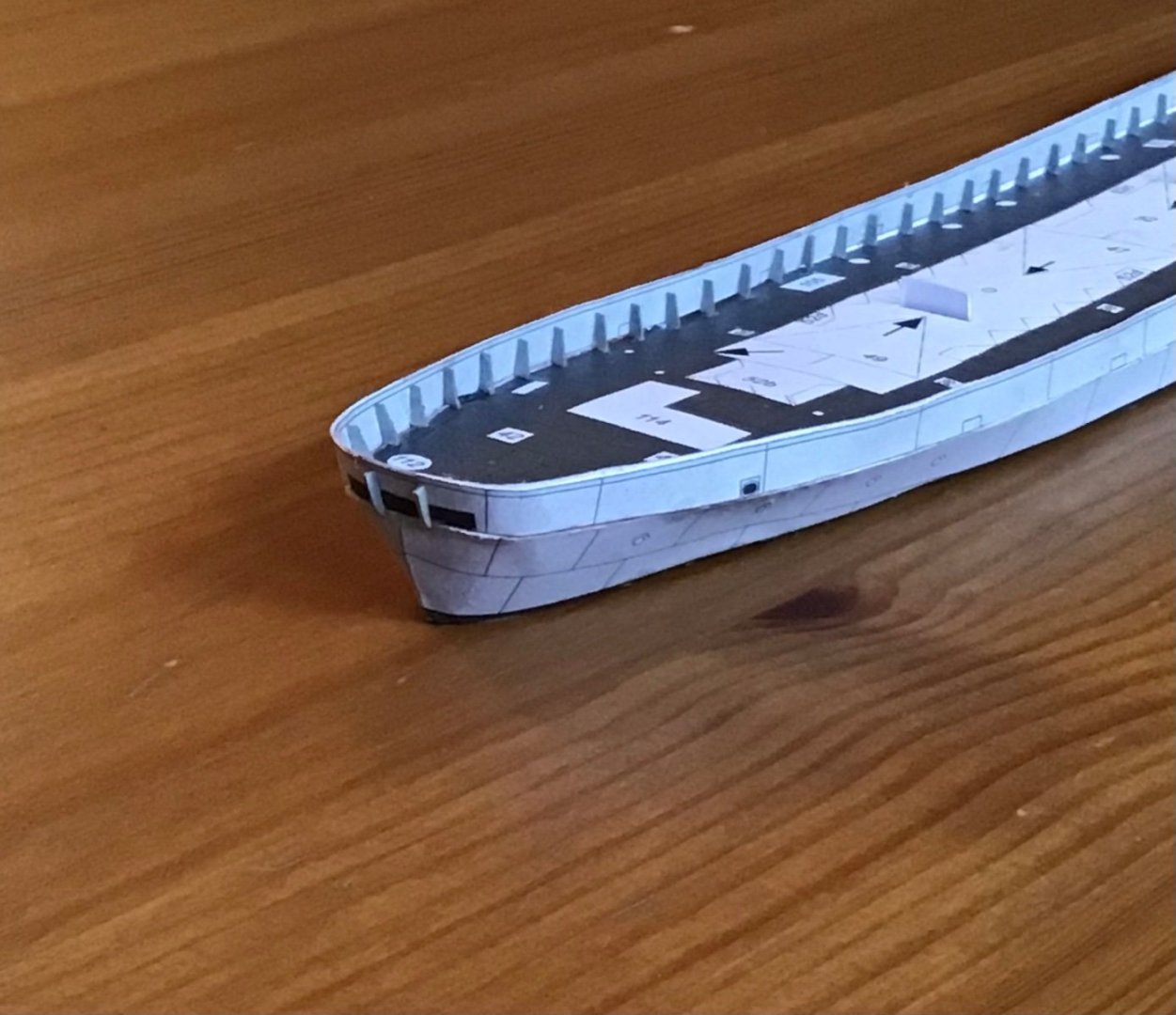

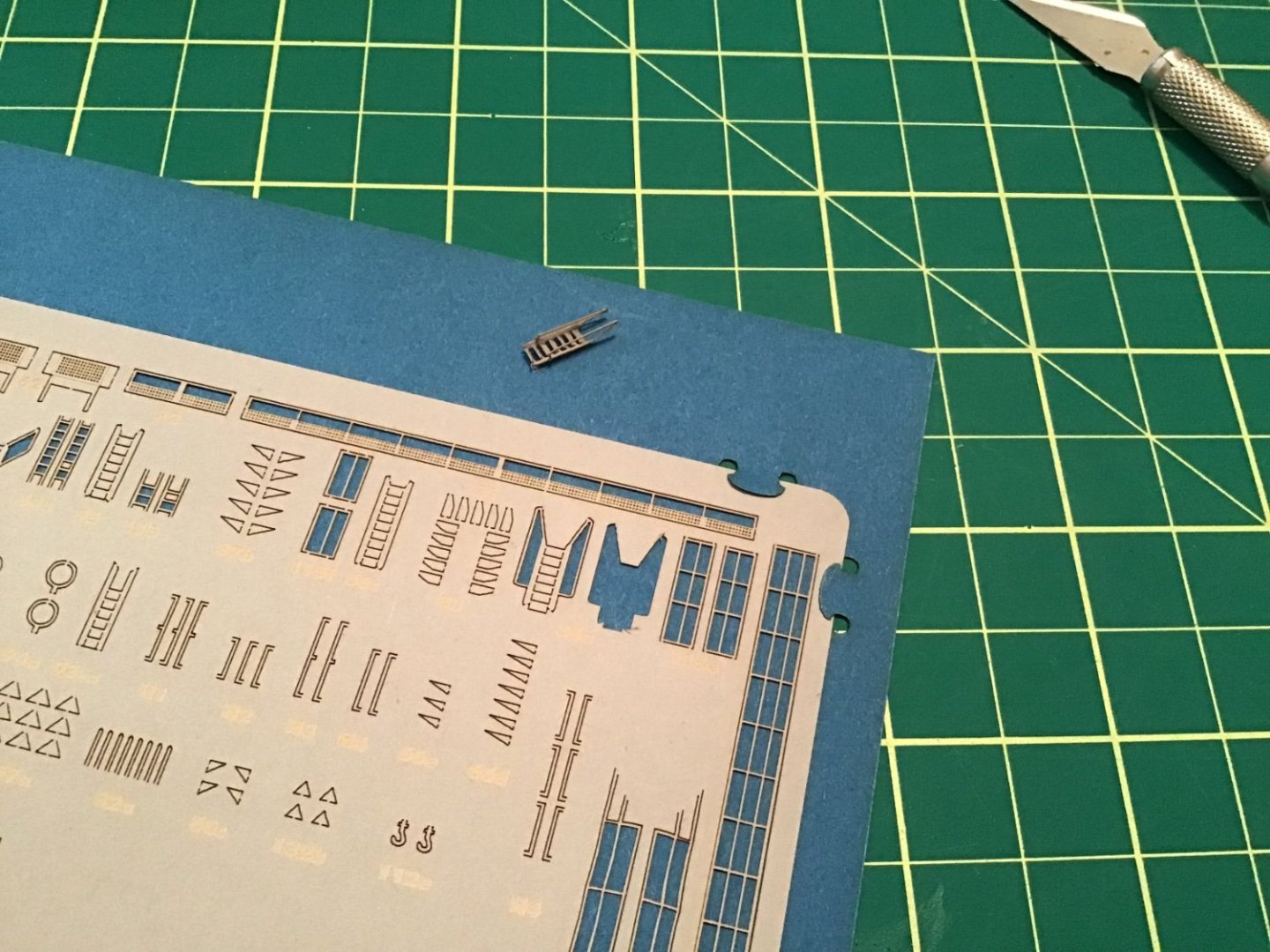

Fourth trip to the cottage Wanting to be close to home for the birth of our grandson and the subsequent visit from my sister and mother have happily kept us away from the cottage. By the way, here's our little admiral, Duncan: (and because of the modeller in me I have already researched and located plans of the Royal Navy Admiral Adam Duncan's flagship at Camperdown, HMS Venerable, and purchased the Trumpeter model of the modern day HMS Duncan…) On to the HMCS Agassiz/Wetaskawin… We only stayed at the cottage long enough to mow the grass (and much taller month-old poplar trees) and a few chores so in the lulls I managed to attach the bulwark stays(?). This is when I the laser cut kit that I purchased paid for itself…again! I almost think it is a necessity to get the kit if you want to build this model. These tiny parts were painful enough to install without having to worry about cutting them out accurately, etc. The thicker card stock of the laser kit made these pieces nicely stiff and resistant to the somewhat ham-fisted manoeuvrings I put them through. Their thickness also helped in squaring them to the bulwarks. Outboard of the transom were two flanges similar to the bulwark stays that likely support the depth charge chutes. In real life these are likely thinner than the bulwark supports so they weren't included in the laser cut kit…but I thought it would be advantageous to make them thicker. So, I sliced off a couple of these from the edges of the laser cut card. (OMG! Getting in close sure shows off my crummy workmanship!) I had time to glue in the stem… And that's how she sits until our next visit… Clear skies and sharp tools! - Gabe

-

Hello modellers, My friend and fellow Manitoban, @Knocklouder , asked if I could print up some 6-pounder cannons for his HMS Pegasis (Amati, 1:64). I based the following design of the 6-pounderm found in Anatomy of the Ship: The 24-Gun Frigate Pandora. I did not include a gunlock in this design - just a simple touch hole. The emblem on the cannon is George III but I think it could pass for the very similar George II - particularly at smaller scales. This file was created in 1:64, but can be scaled up or down as needed. Attached are the .STL and the .cbddlp files for anyone who wants to print it off themselves. The .cbddlp is pre-supported. I used Anycubic ABS+ on an Elegoo Mars printer and had very good results - I can supply the print parameters on request. Hope this helps, Gabe 6-pounder cannon.cbddlp 6-pounder cannon.stl

-

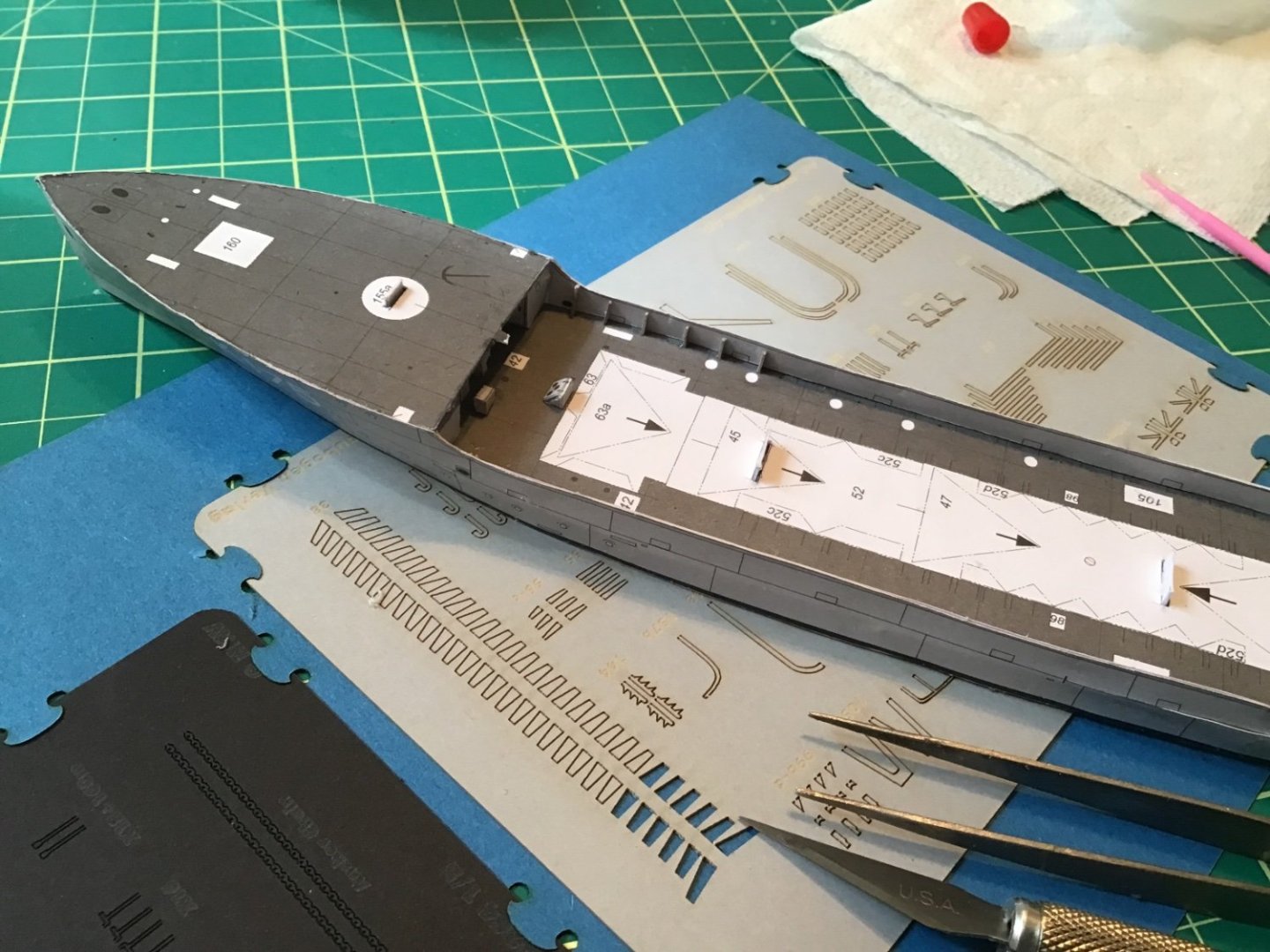

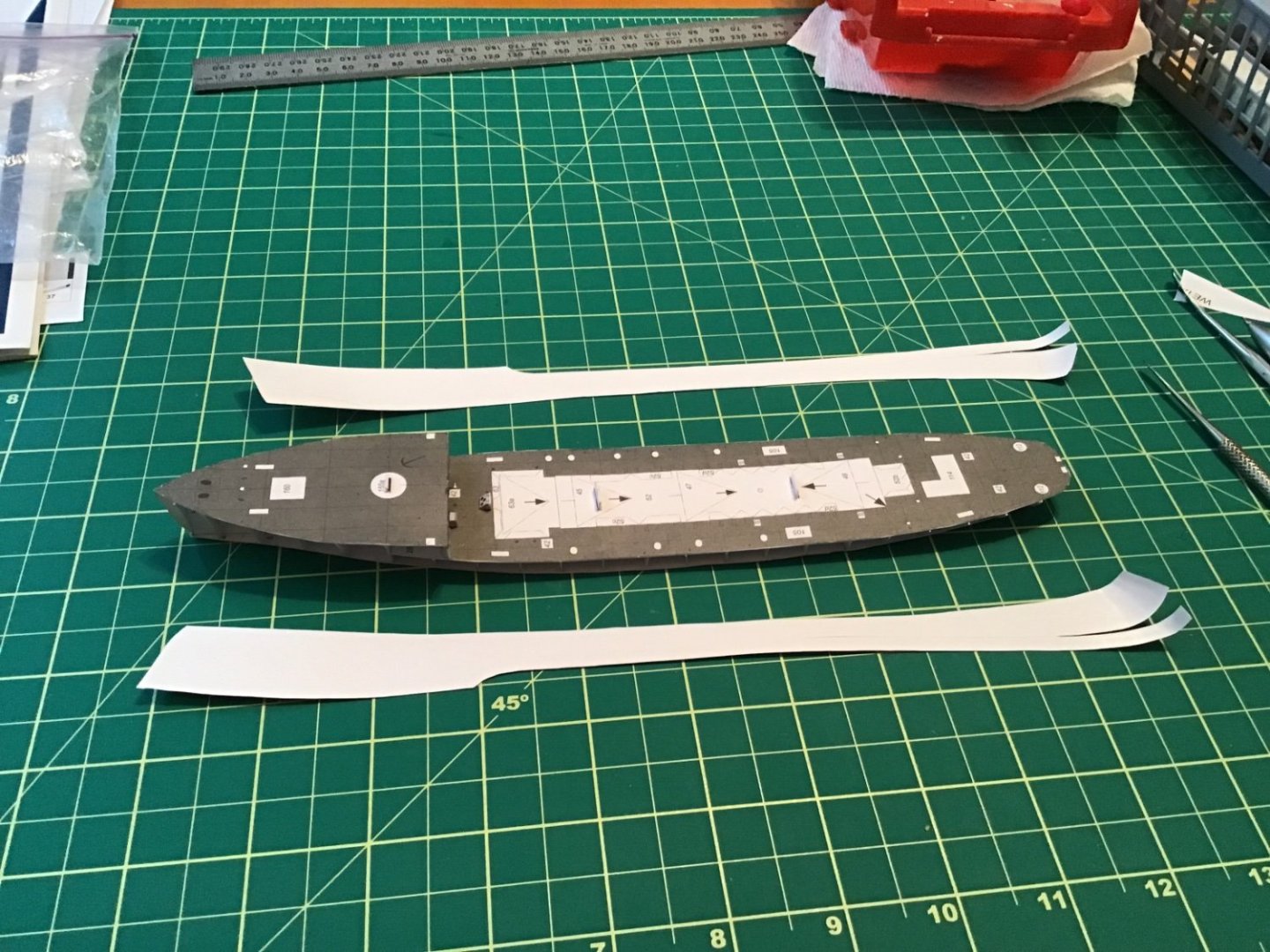

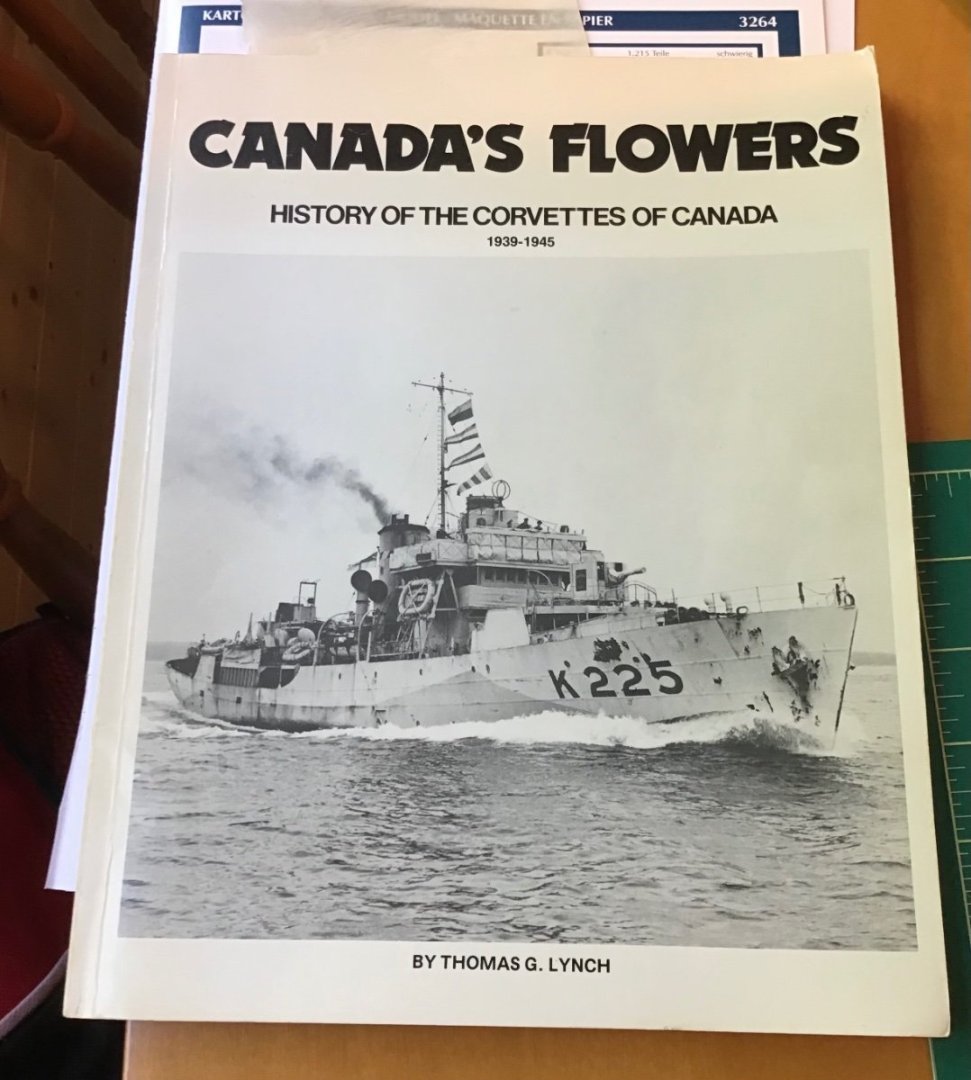

Third trip to the cottage Tiny steps… The next pieces, according to the plans, were the ladders to the forecastle. These would be the first pieces from the laser cut set to be used. I am very impressed with this set as it is well labelled and has an index and diagrams of all the sheets to help you search. After carefully fussing for over an hour with the first tiny ladder, attempting to bend those blasted minuscule treads into place I was not in the mood to bend the second one right away. Nonetheless, I carefully glued the first into place and as I saw those delicate rails sticking up above the forecastle I knew they would certainly be crushed as I continued with the rest of the model. I carefully took it off before the glue dried and stored it in a pill bottle for now. Big steps… At this point I had a choice of which of the four ships I wanted to build so I read over one of my reference books on flower-class corvettes that I had brought up to the cottage. I have purchased several books on these ships because I will be building the Revell 1:144 HMCS Snowberry kit in the near future - my first plastic model in 50 years. HMCS Wetaskawin was mentioned as having sunk a u-boat early in the Battle of the Atlantic, so I went with that ship for this model and cut out the lower hull and gunwale pieces. Clay modelling tools were used again to create curves to match the deck shape. Over two days I alternately glued hull sections. First the lower hull, one side at a time. To thicken the gunwales and provide printed details on the inboard view, the model requires an inner gunwale be glued to align with the outer section. And then I made the stupid mistake of trimming off some lower hull that was sticking slightly above deck on the port side before gluing down the gunwales. This has left a little gap that I may have to address.🤬Fortunately, there are three more gunwales that I have to try and patch/fix the issue. I should mention that I debated at length about cutting out the scuppers. I regret my decision not to. I think the model would have looked better and now that I completed these steps it will be too difficult to do a good job of cutting them out. And this is how the model sits until next visit: Clear skies and sharp tools! - Gabe

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.