Freebird

Members-

Posts

334 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Freebird

-

Awesome Tom! Best Regards …. Rick

- 200 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Excellent! Very nicely executed! Question - where did the longboat come from? Best Regards …. Rick

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hello Tom! I just found your Morgan build, and after having seen it in person I’m even more amazed at your skills! Hope you and your family have an wonderful and blessed Thanksgiving! Best Regards …. Rick

- 200 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Very nice and congrats! I felt the same, never thought I’d get to the finish line. Best Regards …. Rick

- 217 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Kit review 1:25 Drakkar ‘Oseberg’ - Ships of Pavel Nikitin

Freebird replied to James H's topic in REVIEWS: Model kits

In case anyone is interested, Olha Batchvarov has started building one of these, look her up on YouTube. There’s a lot of prep work in the frames and such, but looks like a good build. Her kit has the short planks and she made her own replacement parts. I’ve ordered a kit and should be here next Thursday. R -

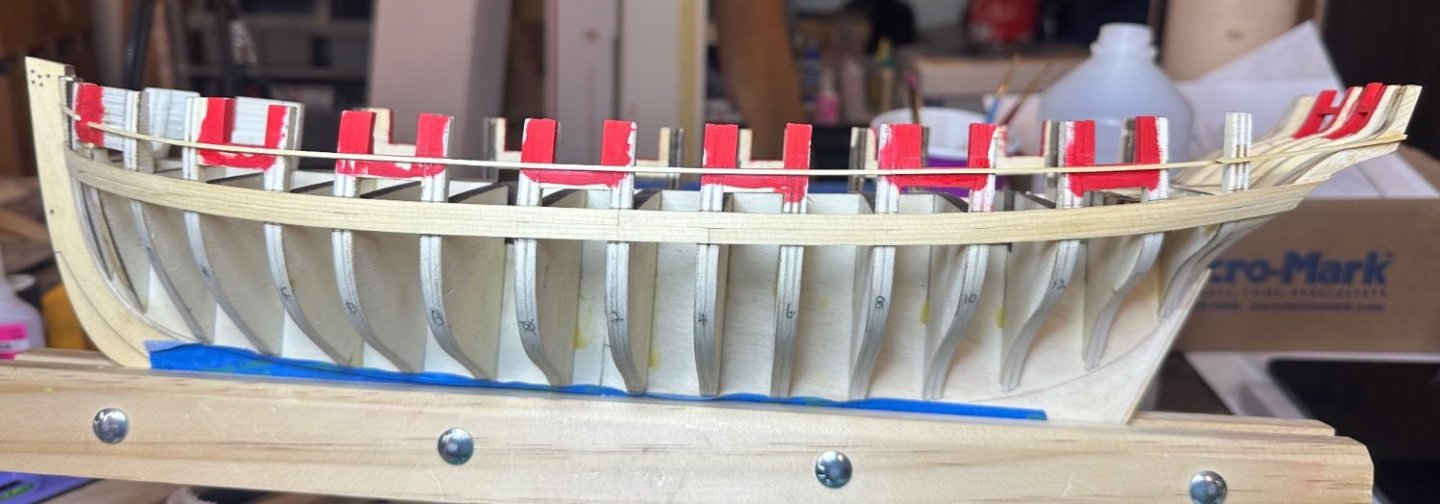

Have completed the port strakes from the wales to the molding. Certainly not perfect, but better. I can really see how fairing and having all of your planks the same thickness is a requirement. I’ve done a light sanding and can see mostly dips where the planks are a little thinner, it really stands out and makes a huge difference. Good thing I like to sand. 😏 Best Regards …. Rick

-

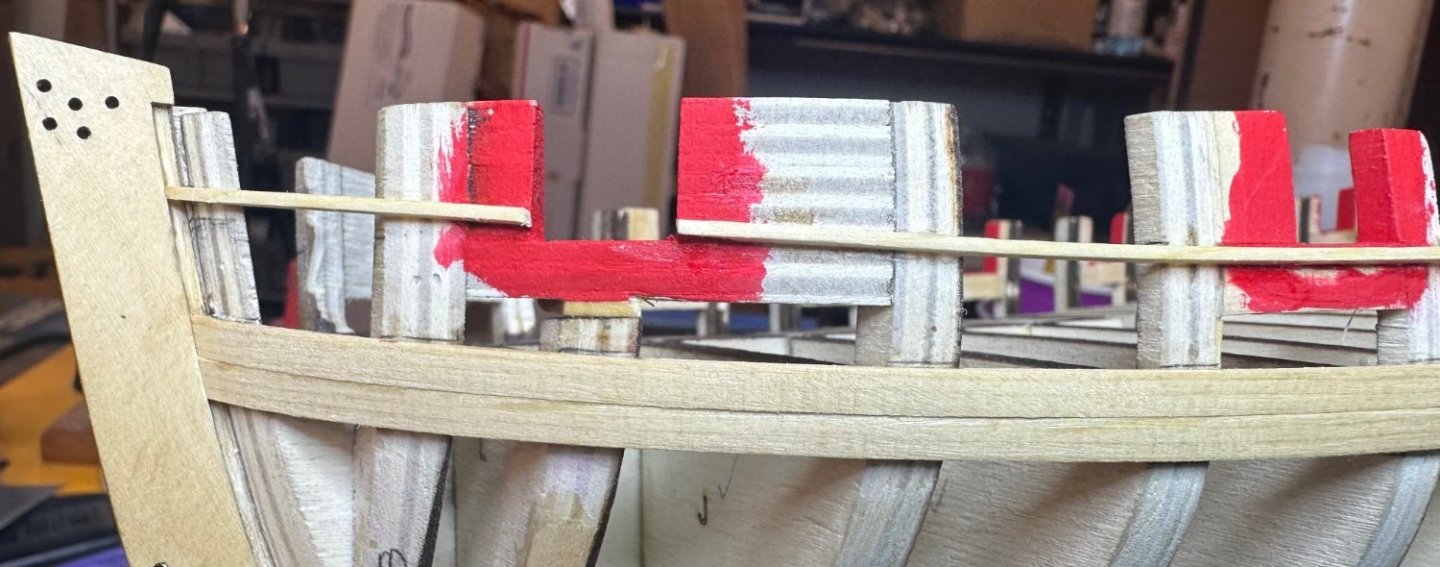

Glen - what pain, hardest part was making the decision and making the first cut. After that, business as usual. Already completed the lower strake and working on the upper strake. Looks better than before, but we’ll see when the strakes are completed. These are lessons learned and probably like your Cheerful, I’ll have 3 sides before I’m done. Best Regards …. Rick

-

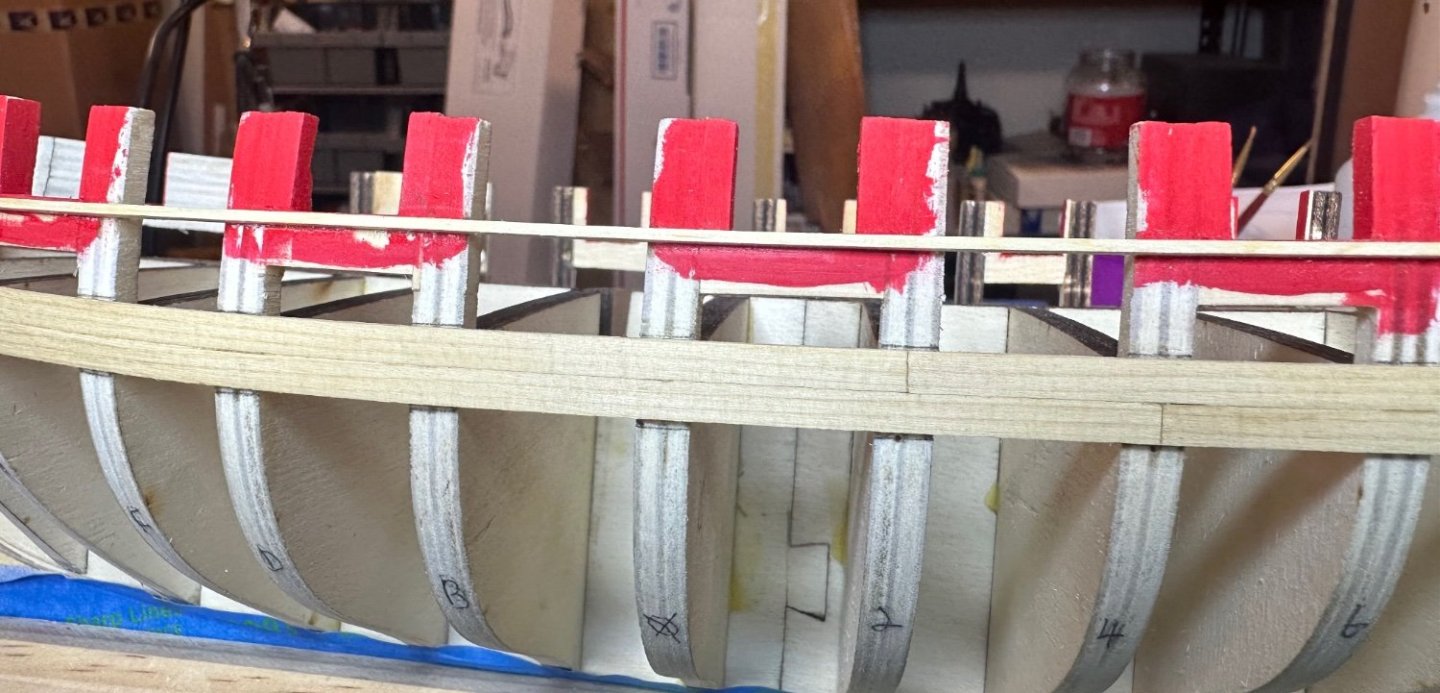

Guys, thanks for the encouragement and the ideas. Also to all of you guys for the likes, much appreciated! Glenn - I have read your Cheerful log many times, and with this in mind, I ripped off the offending planks. Like Chuck does (BTW Chuck, I hope you’re getting better quickly!), I use CA and only glue the plank to the bulkhead, much easier to remove. Paul - thanks for pointing out the molding on the aft side on the gun port is too high. It was located correctly before I removed the scrap from the opening. Another error to fix. Best Regards …. Rick

-

I took some time off to do some much needed yard work. Now I’m back and added the 2 strakes between the molding strip and the wales. Without referencing the practicum I slapped them in. While they look good, it didn’t look “right”. So, I went back and read the practicum and see where my mistake is. My dilemma is rip do I them off and start over, or leave as is? I’ve only done the port side and is most obvious at the stem. Deep down I know what the answer is, but wanted some feedback. Best Regards …. Rick

-

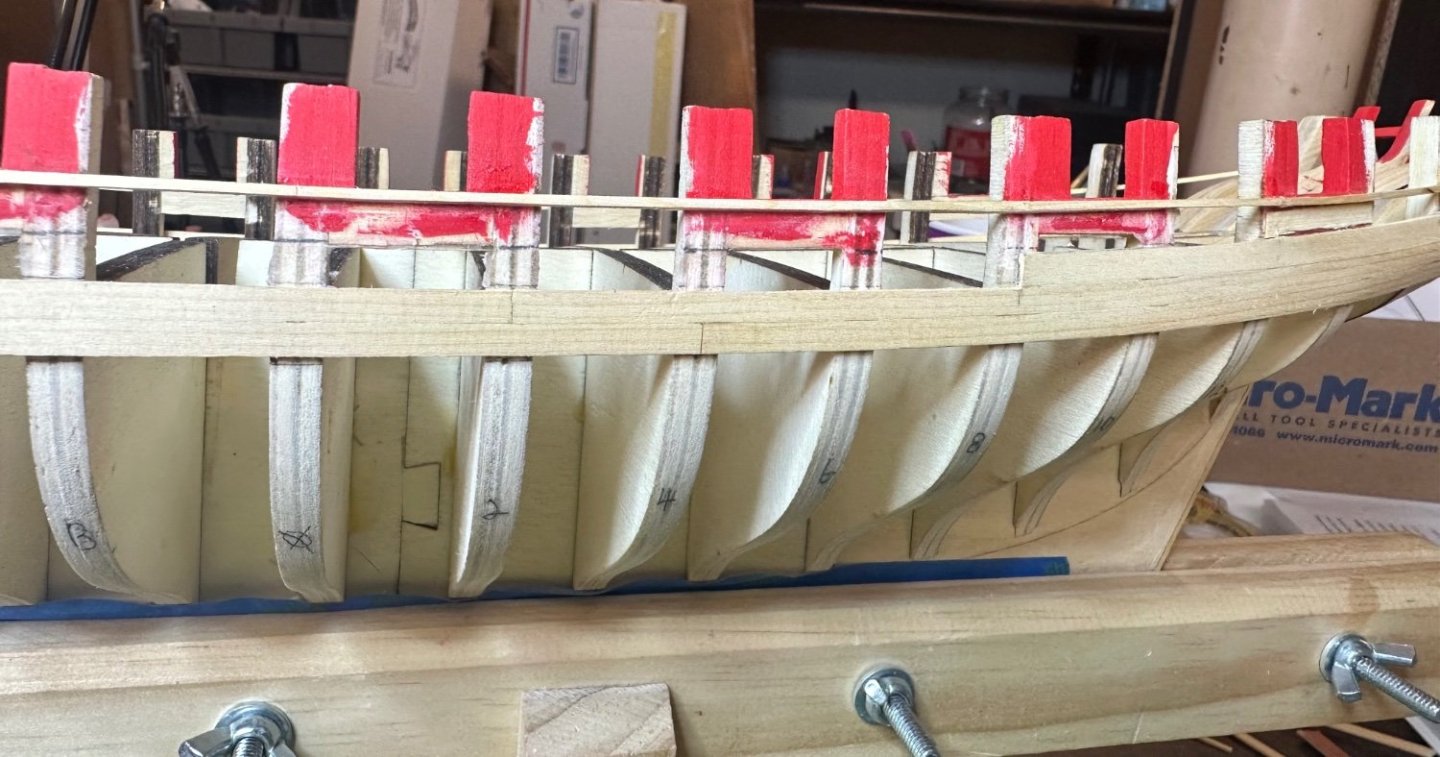

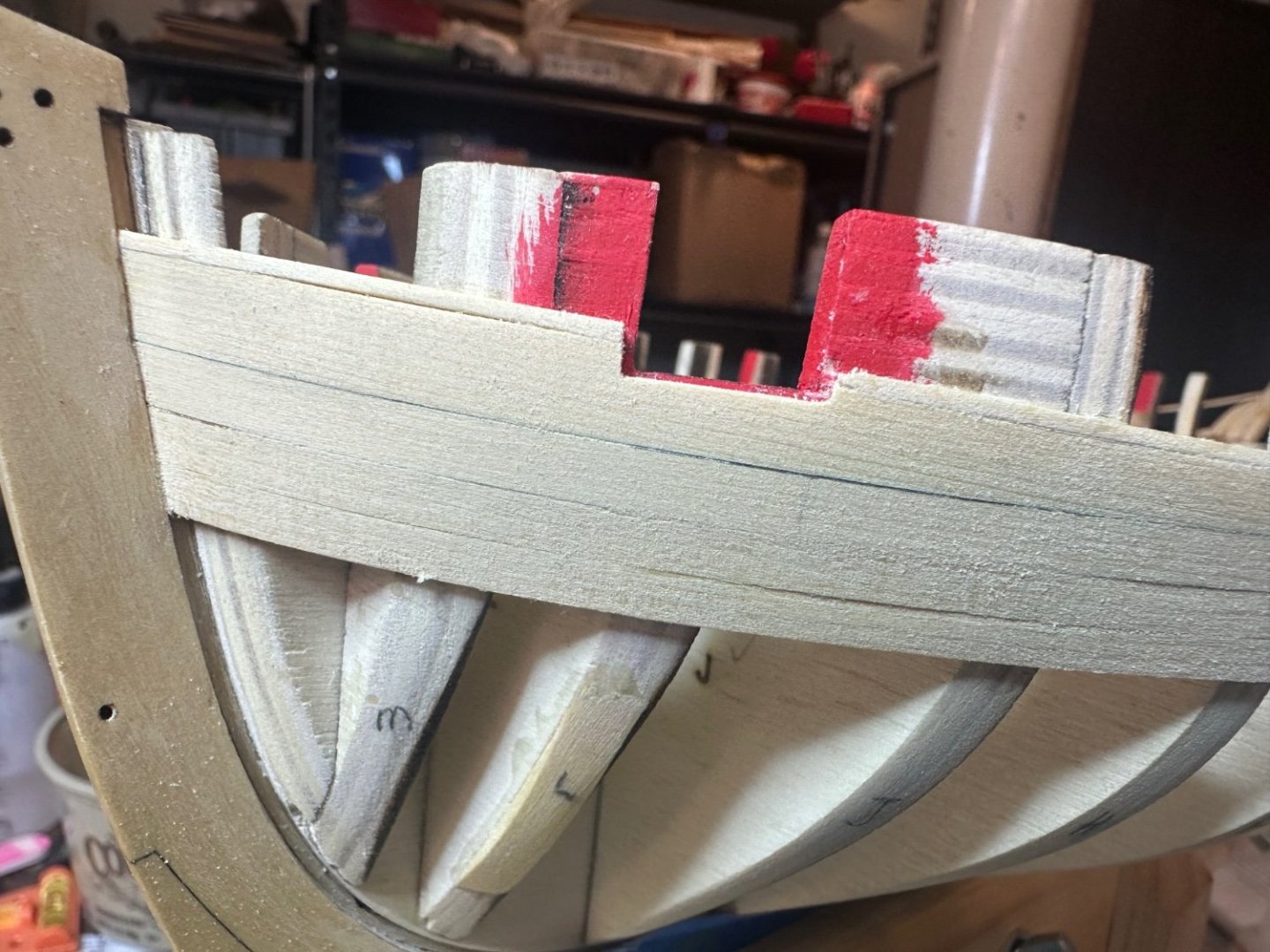

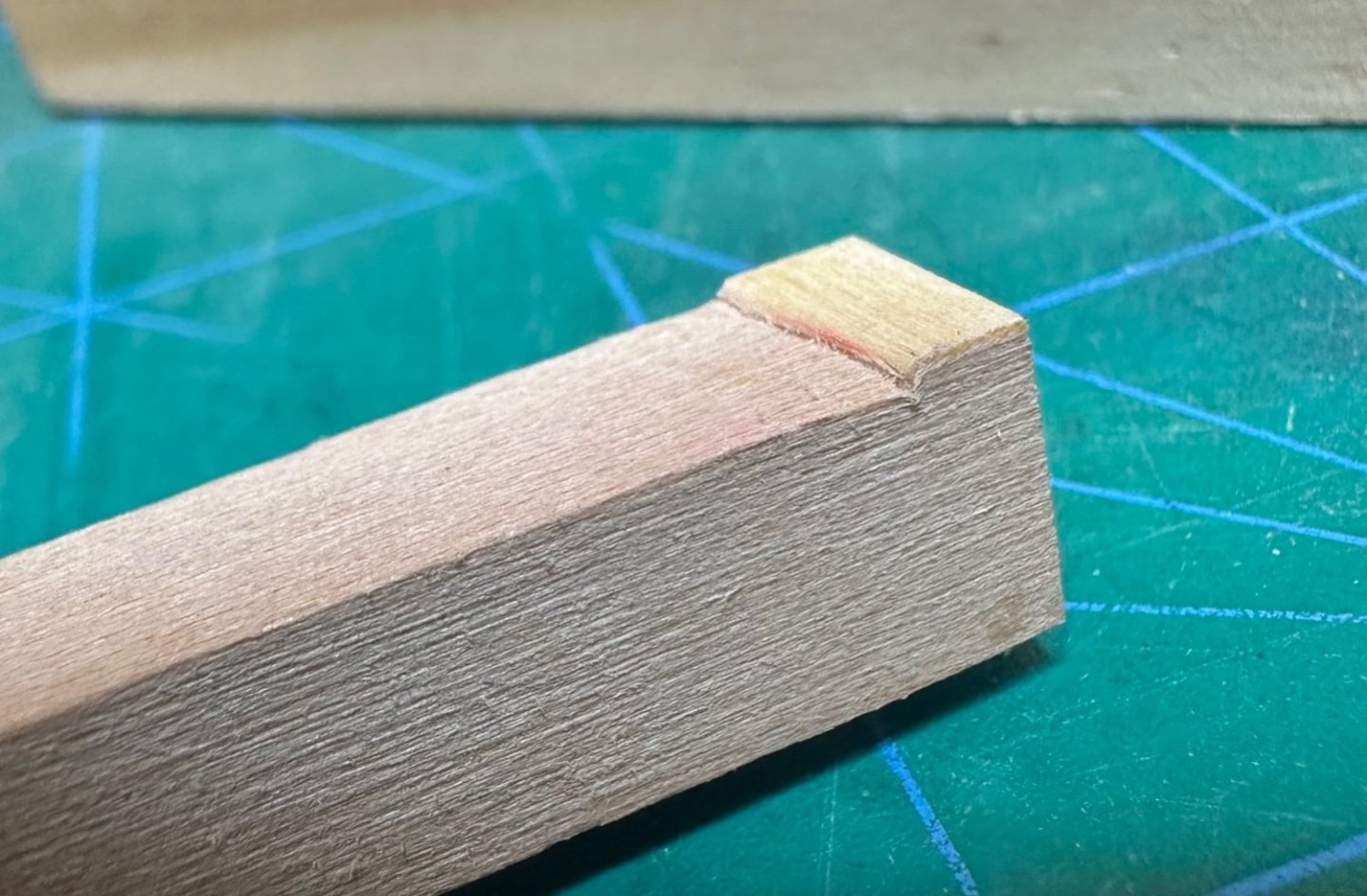

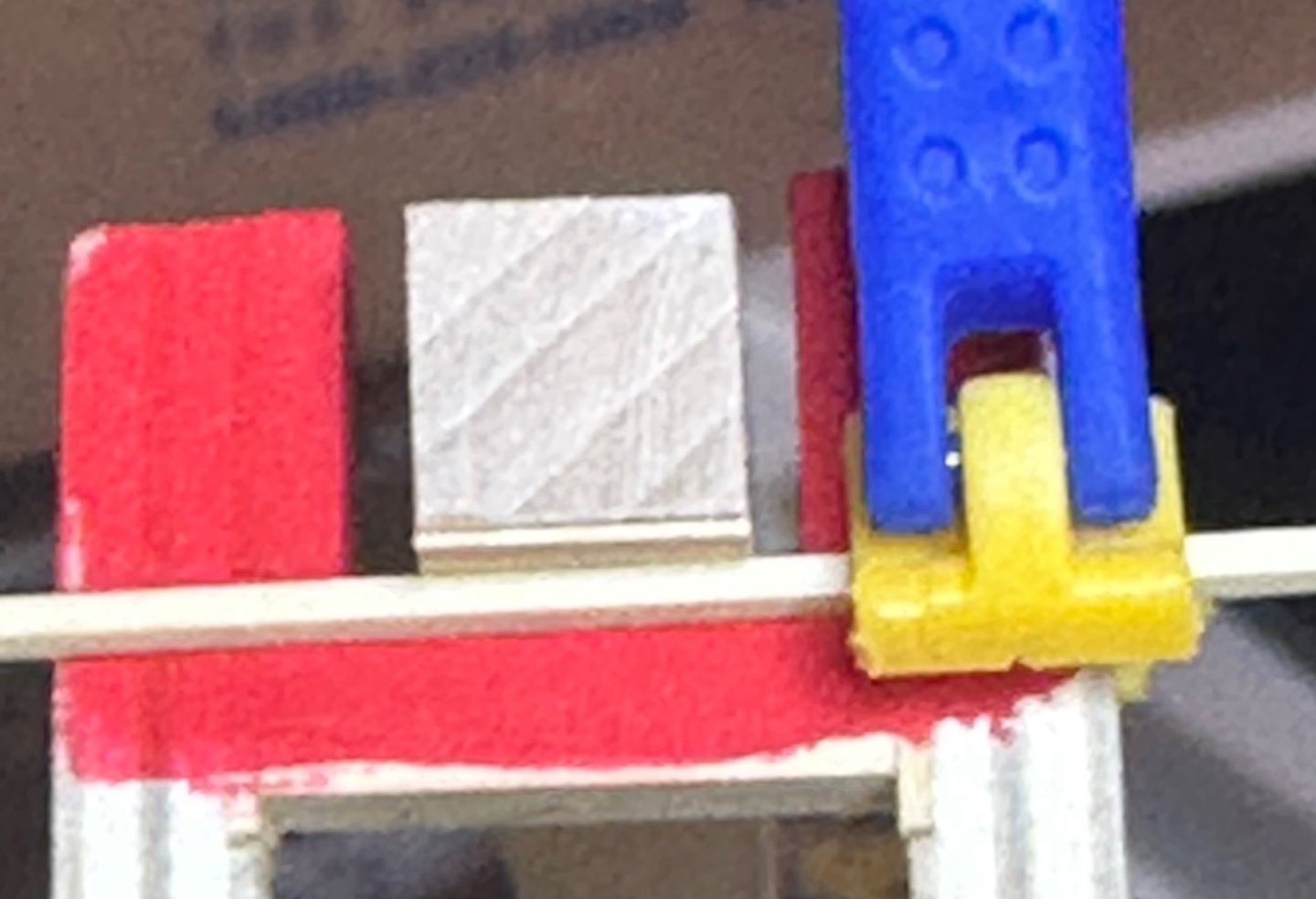

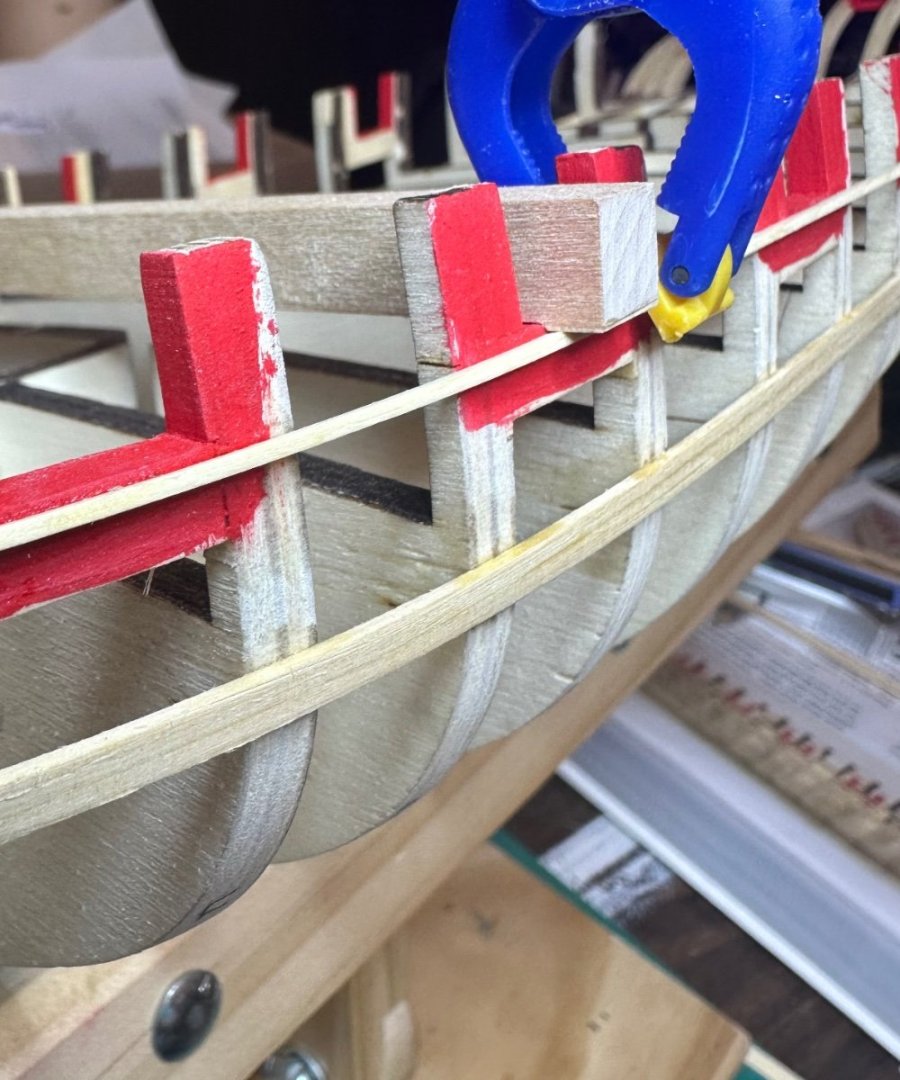

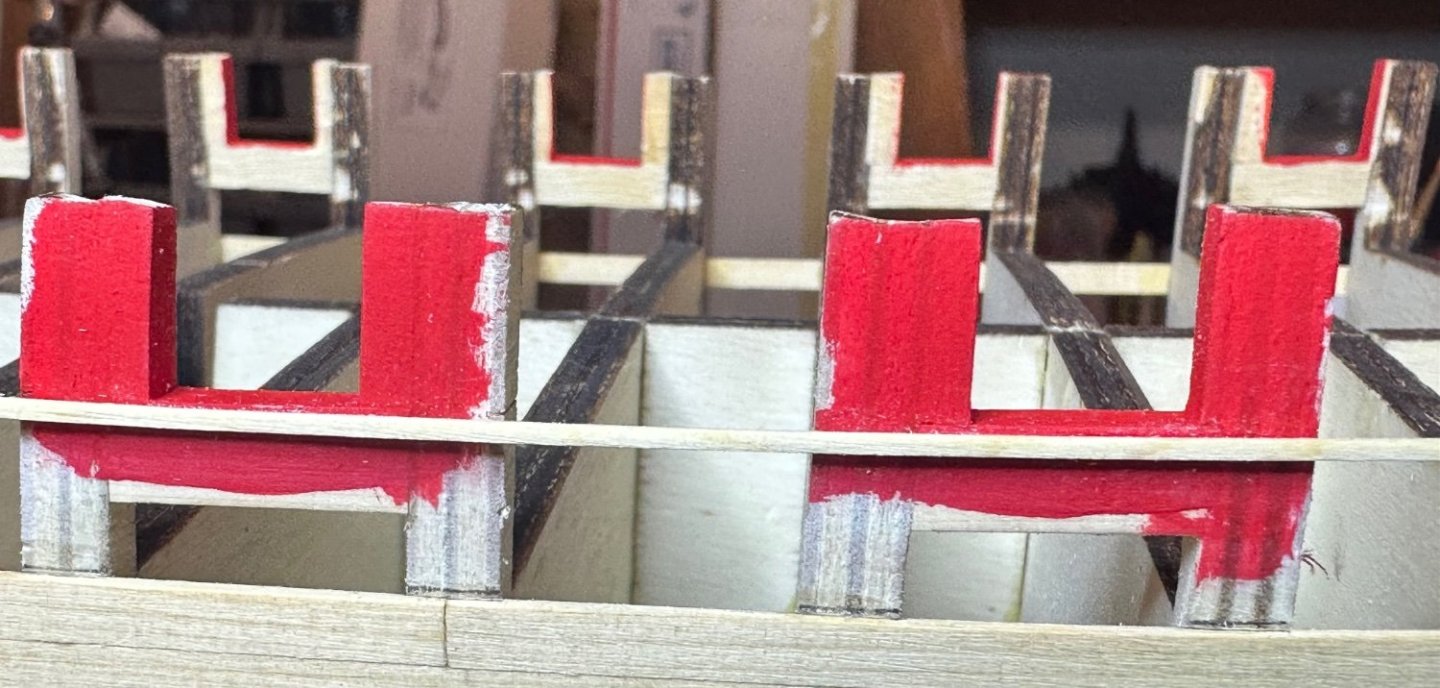

Here’s todays progress, the wales and molding strip have been installed on the port side and the lower wale is installed on the starboard side. I’m amazed by the amount of work necessary to get this far, I’m mentally fatigued for sure. For the molding strip, I made a jig that worked pretty good at making a 1/64” rabbet on the bottom of the gun ports. The jig pictures are self explanatory. I’d like to thank everyone for the likes and to Chuck for pointing the wale run was a little off. Best Regards …. Rick

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.