Freebird

Members-

Posts

334 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Freebird

-

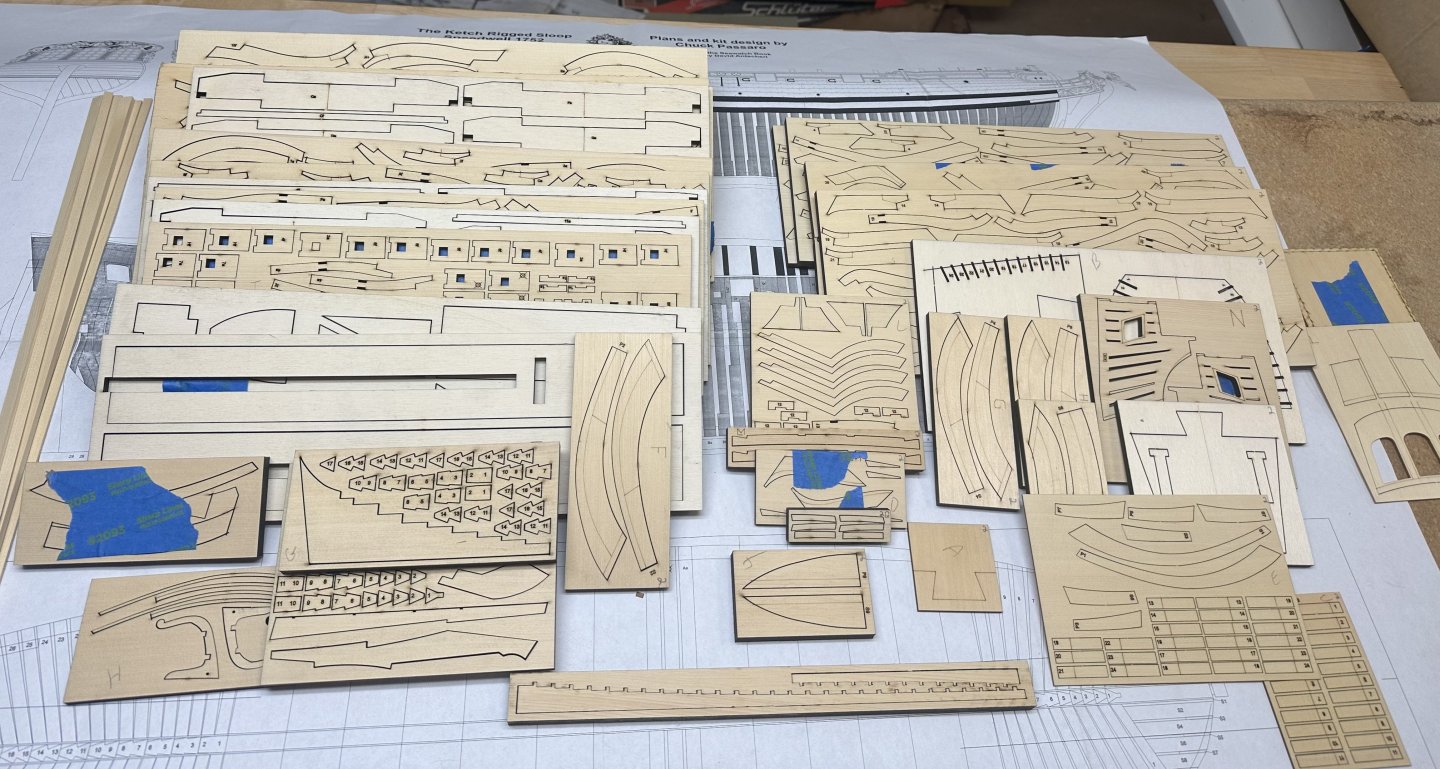

This marks the start of my Syren POF Speedwell! I’ve been dealing with some medical issues and am now close to being 100%, so here we go! A POF has been a bucket list build for a long time as I’ve admired this style of model. Most of the offerings out there just didn’t appeal to me with the scaffold type of construction. Enter Chuck with his Speedwell, Bingo! I’m a huge fan of Chuck’s designs and all the help he (and the other MSW modelers) provides, it gives guys like me a lot of hope. I’ve built Chuck’s Medway (my first wood build) and it came out awesome. Thanks Chuck! I’ve started Cheerful but a POF build has extreme attraction for me. I’ll probably work on Cheerful when a break is needed. Last month at the New London Conference I got to meet Chuck (and Rusty, Ryland and Olha and several others! Awesome to meet you guys!). Had some great conversations and it was nice putting a face to the name. Also, I got to eyeball Chuck’s Speedwell, pictures in the build thread don’t do it justice. A real beauty! Anyway, here we go! When Chuck said there was a lot of wood in the 1st 2 chapters, he wasn’t kidding! The laser cutting is the best I’ve ever seen in a model. A lot of the parts had fallen out of the billets, so I took some time to place them in their proper place and used some blue painters tape to hold them in place. Because the thickness of the wood, I see a lot of billet sanding to remove surface char in my future. Here’s a picture of the wood. Stem will be started tonight. Best Regards …. Rick

-

Given up, no. I had a major flood disaster in my workshop that required a foundation rebuild. Working with insurance wasn’t fun and things stalled for a while. But now things are settled and back in place, so I’m ready to go. While I’m still very enthusiastic about Cheerful, a POF like Speedwell has been a bee in my bonnet for a long time and nothing out there has captured my POF excitement until your Speedwell came along. Besides, having worked in the aerospace industry for over 40 years, your approach and design aspect's are extremely appealing to the detailed side of me. And yes, a build log will be created. Thank you. Best Regards …. Rick

-

Sure looks different from the first time I saw it! Wonderful model! Rick

- 200 replies

-

- Whaling Bark

- Charles W Morgan

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.