Freebird

Members-

Posts

334 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Freebird

-

The parts are the correct parts, must be camera angle. I did like Jean-Marie and placed each of the frames into its own separate baggie so there wouldn’t be any mixup of the parts. That was a great idea. I’ll add a few more frames and see how they seat before making a decision. If I do trim, it’ll be from the floor. Thanks for chiming in, Chuck. Best Regards …. Rick

-

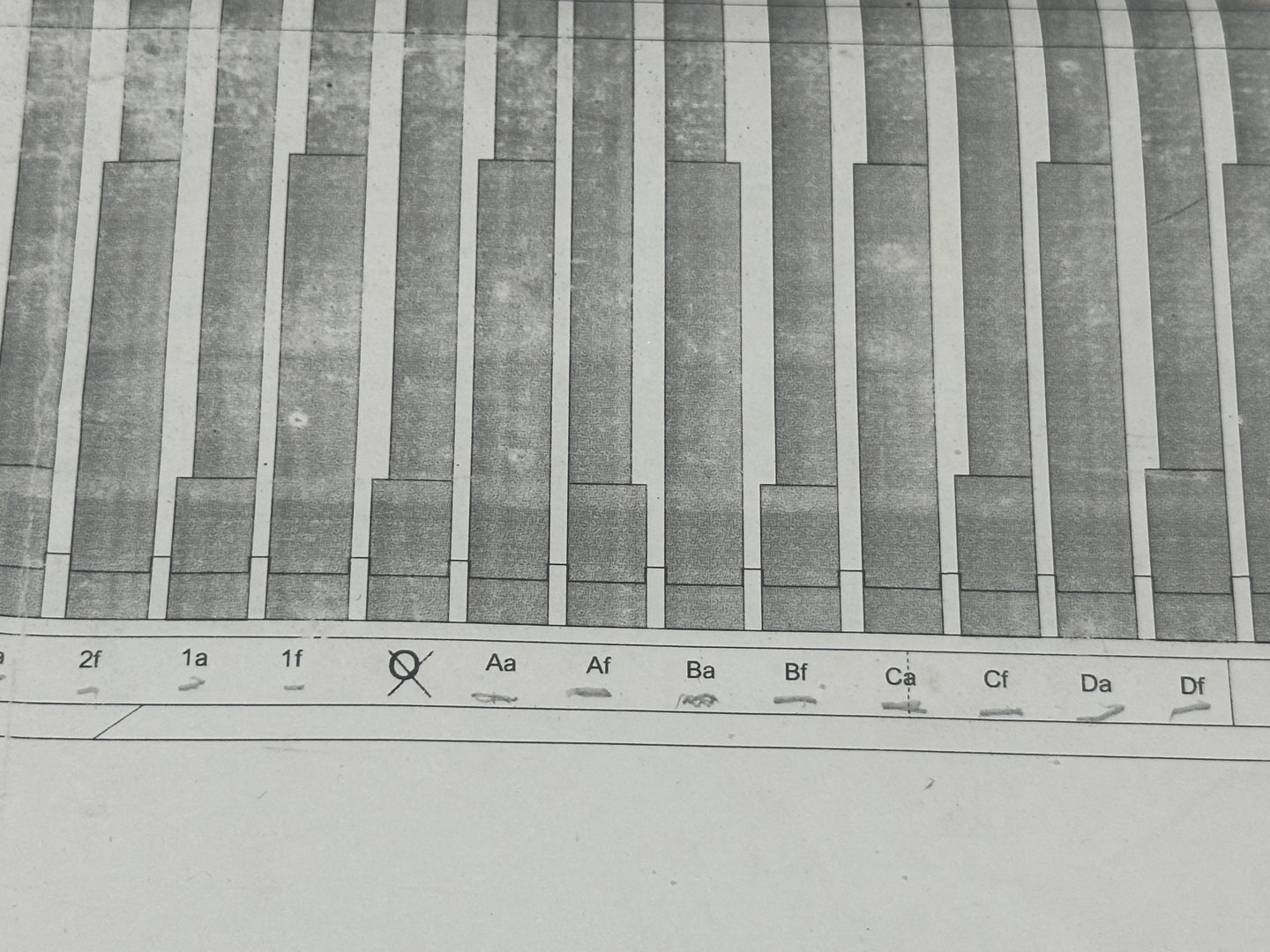

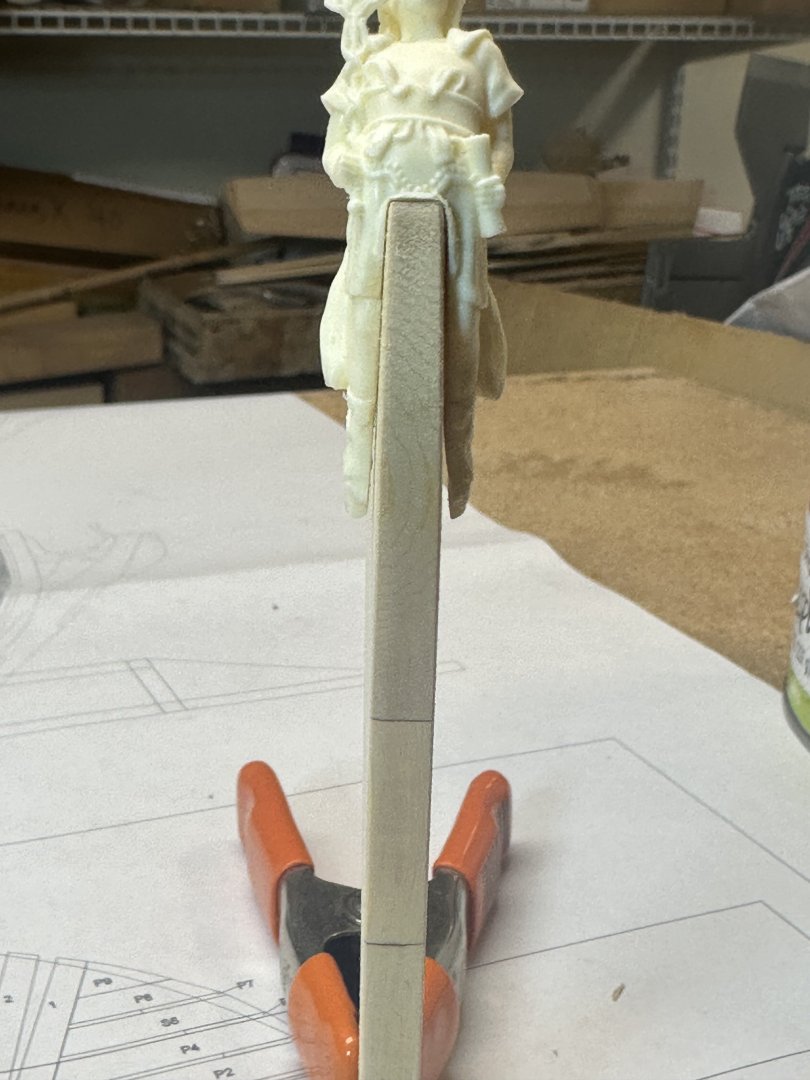

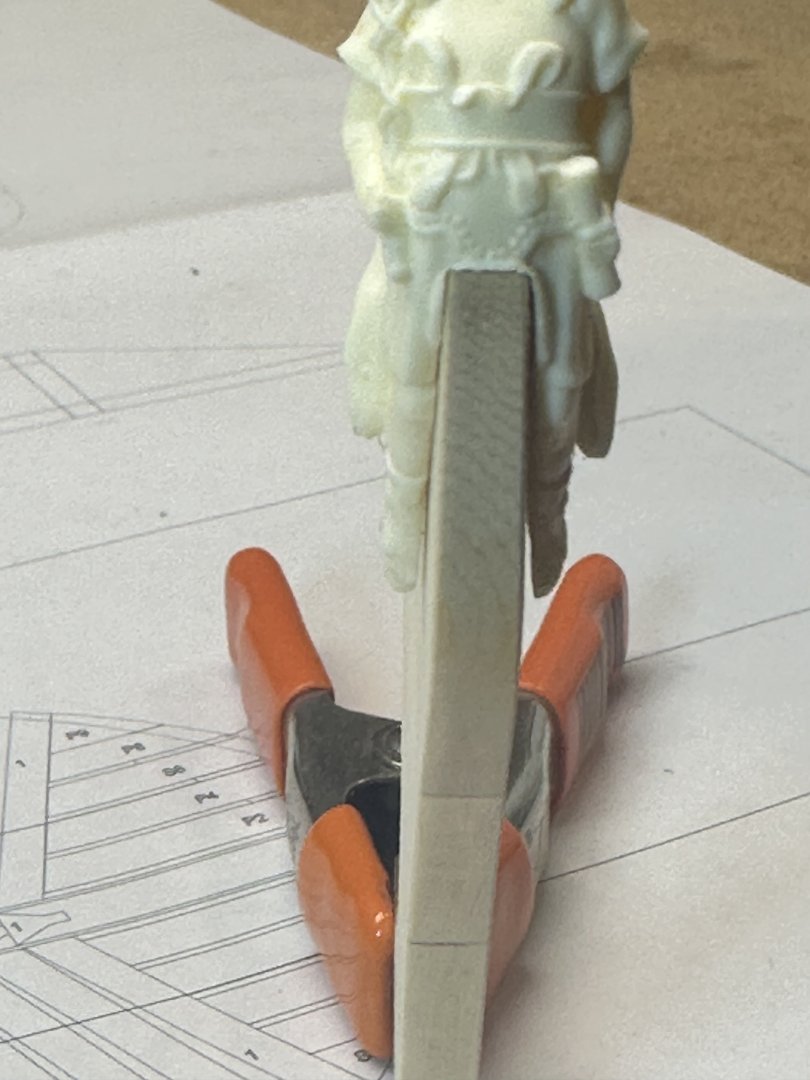

Question: I had a little time this morning to mess around and decide to assemble the frame with the O and X thru it. Assembly was easy and gave me an idea of how much sanding is in front of me. But me being me, I had to fit the frame on the keel. Small adjustments were needed as it was a very tight fit. Once fitted, I noticed the bottom of the frame didn’t quite seat to the top of the rabbet, in other words, flush with the rabbet. Is this an issue? The plans clearly no space from the bottom of the frame to the top of the rabbet. So, question is, if the frame is to be flush with the top of the rabbet, do yo adjust the notch in the frame, or the notch in the rising wood? Best Regards …. Rick

-

Rusty, Your work looks awesome! I'm at the stage of sanding the deadwood down and adding the wedges. I hope whatever was keeping you down is in the rearview mirror. Getting old isn't for the faint of heart. Two days before the Conference, I had some minor surgery and certainly wasn't going to miss that day! Keep up the good work! Best Regards .... Rick

-

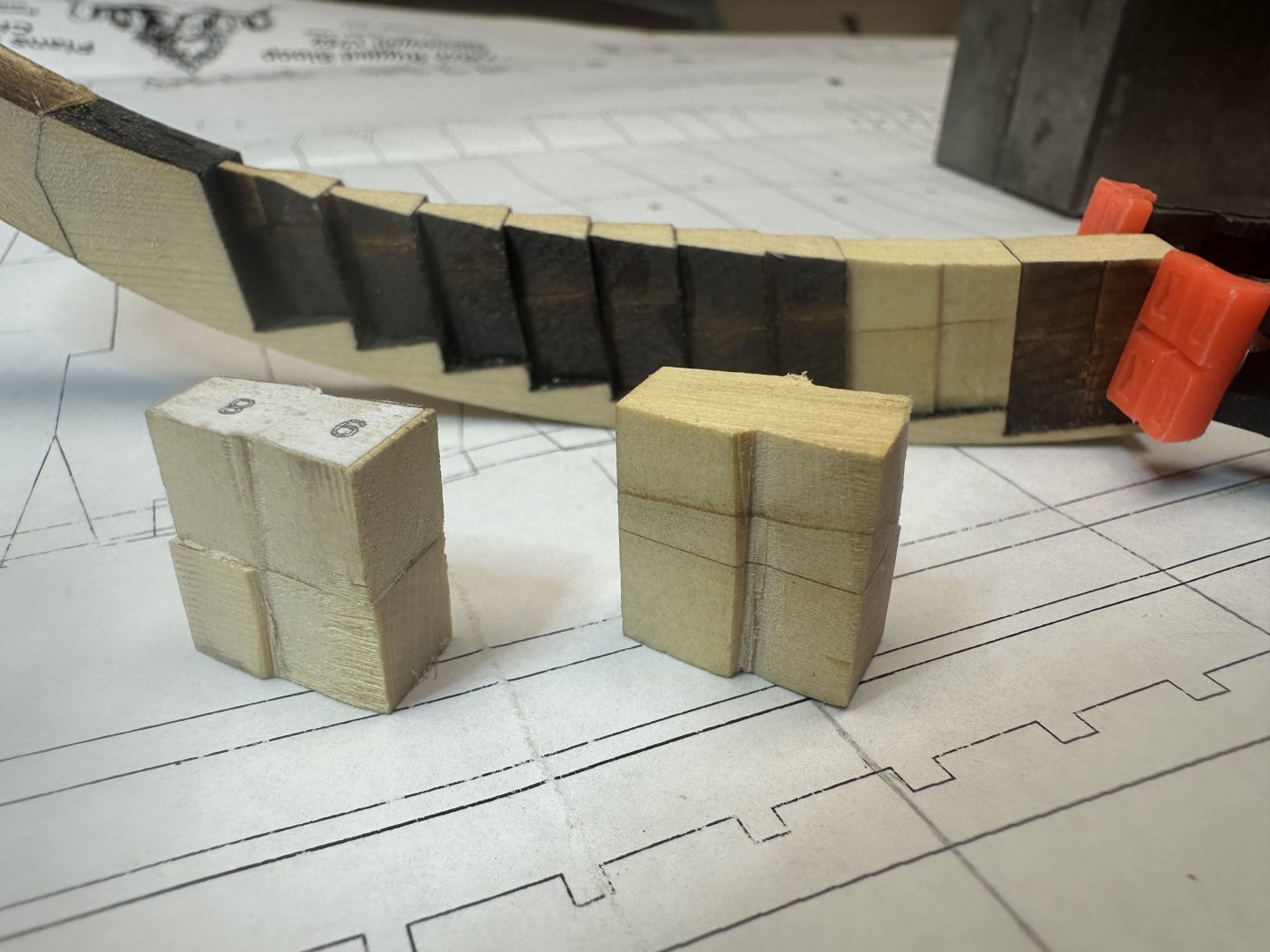

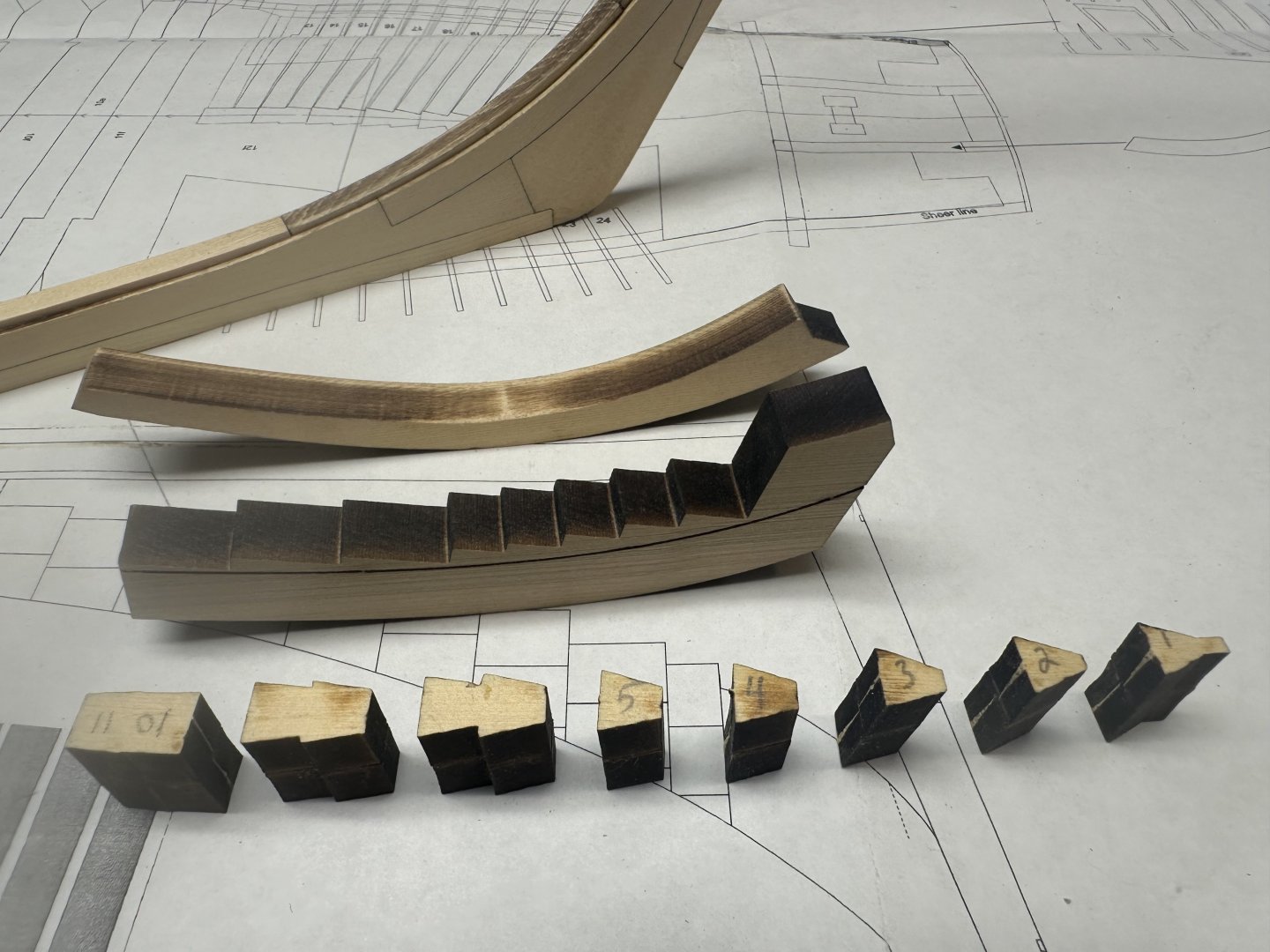

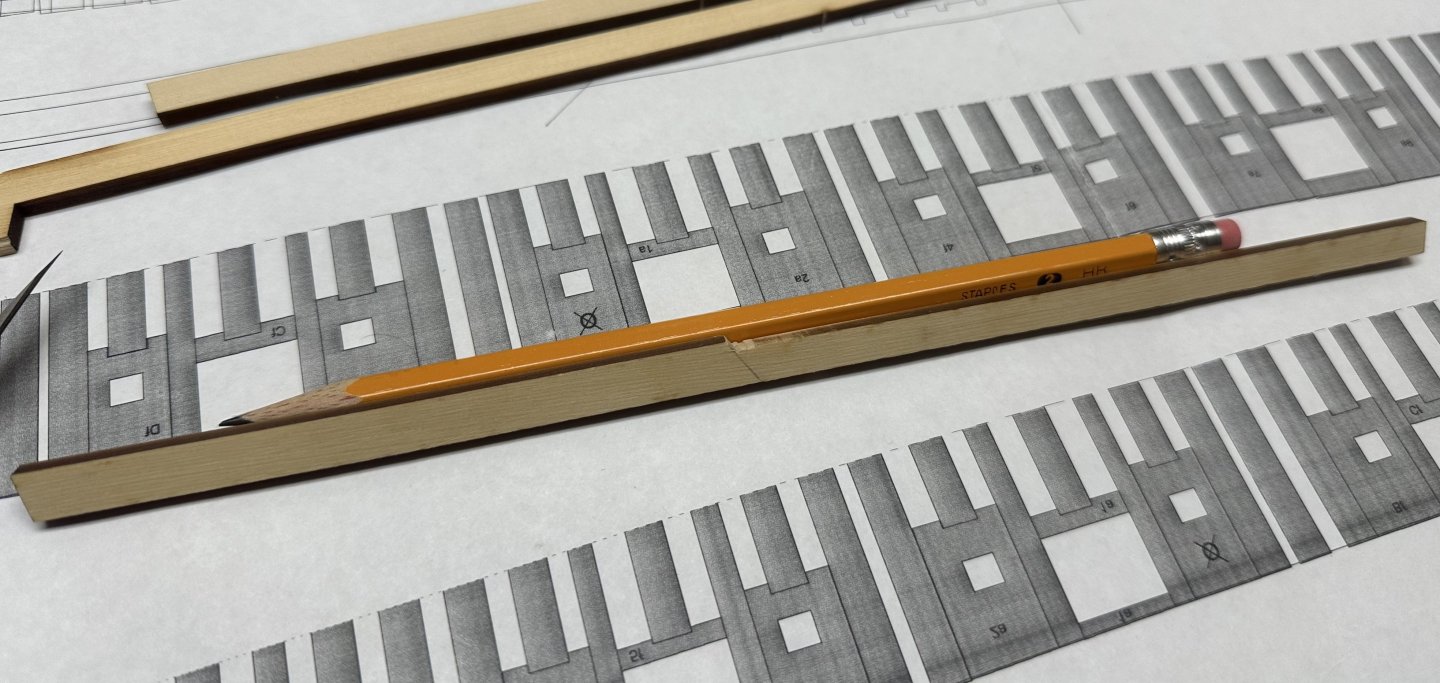

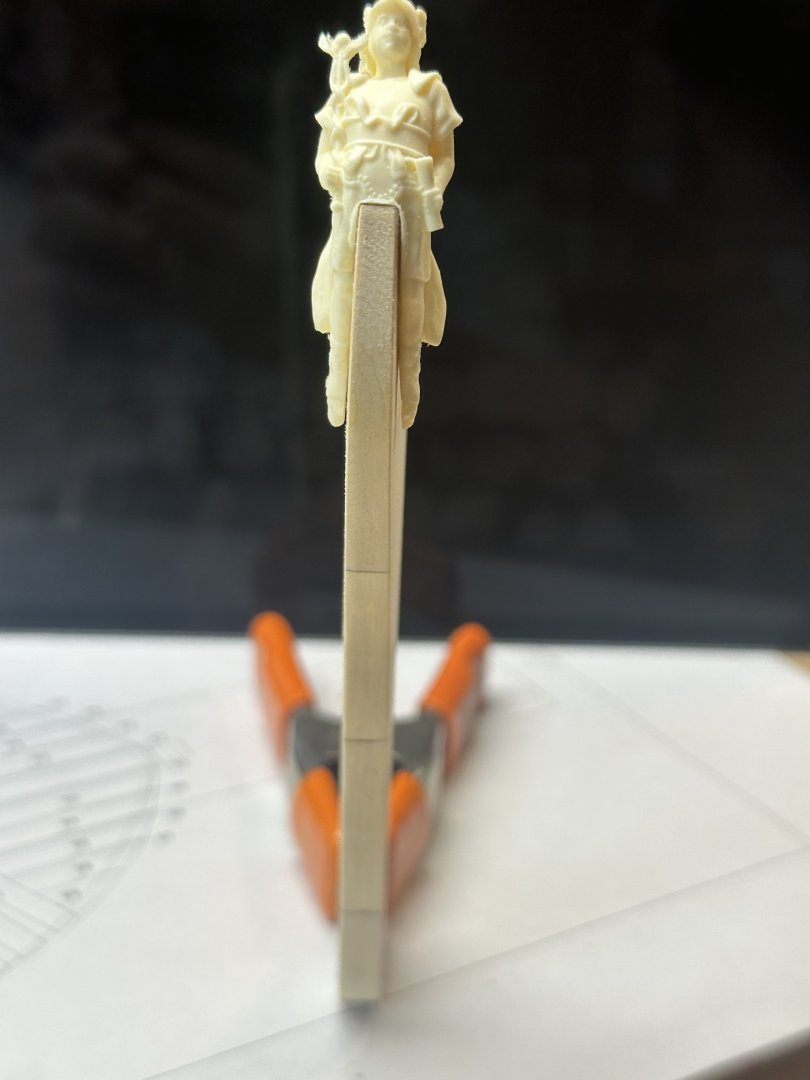

Yesterday, I tackled the upper/lower apron. I had glued the wedge halves together a few days ago and had them lined up in the proper order on my workbench. However, I noticed that 8/9 wedge was missing! What the heck! Over an hour of searching produced negative results, swear jar was very happy. Only thing I could think of was the family cat took it as she likes to spend time with me. So, do I get a hold of Chuck and wait for replacement, or forge ahead. I really didn’t want to contact Chuck as he’s headed out for some R&R. I decided to make a replacement. I first tried the make the wedge by hand, I mean it’s all straight lines, right? Well I forgot that I can’t draw a straight line using a ruler. The results were very pathetic and not worthy. Well I forgot that I have a Proxxon mill, perfect! After about 1/2 hour of milling I dropped the part into the appropriate hole in the billet and it was a perfect fit. Yea! Sorry, but in my haste to move on, I forgot to take pictures. As you can see, the replacement really stands out on the apron. Best Regards …. Rick

-

Chuck, quick question before you head out. The bolts for the box joints, are they in the same position on port/starboard of the keel? In other words, would drilling the holes completely through the keel and inserting the bolts be accurate? Or should the bolt pattern be shifted to match the joints on each side? TIA! Best Regards .... Rick

-

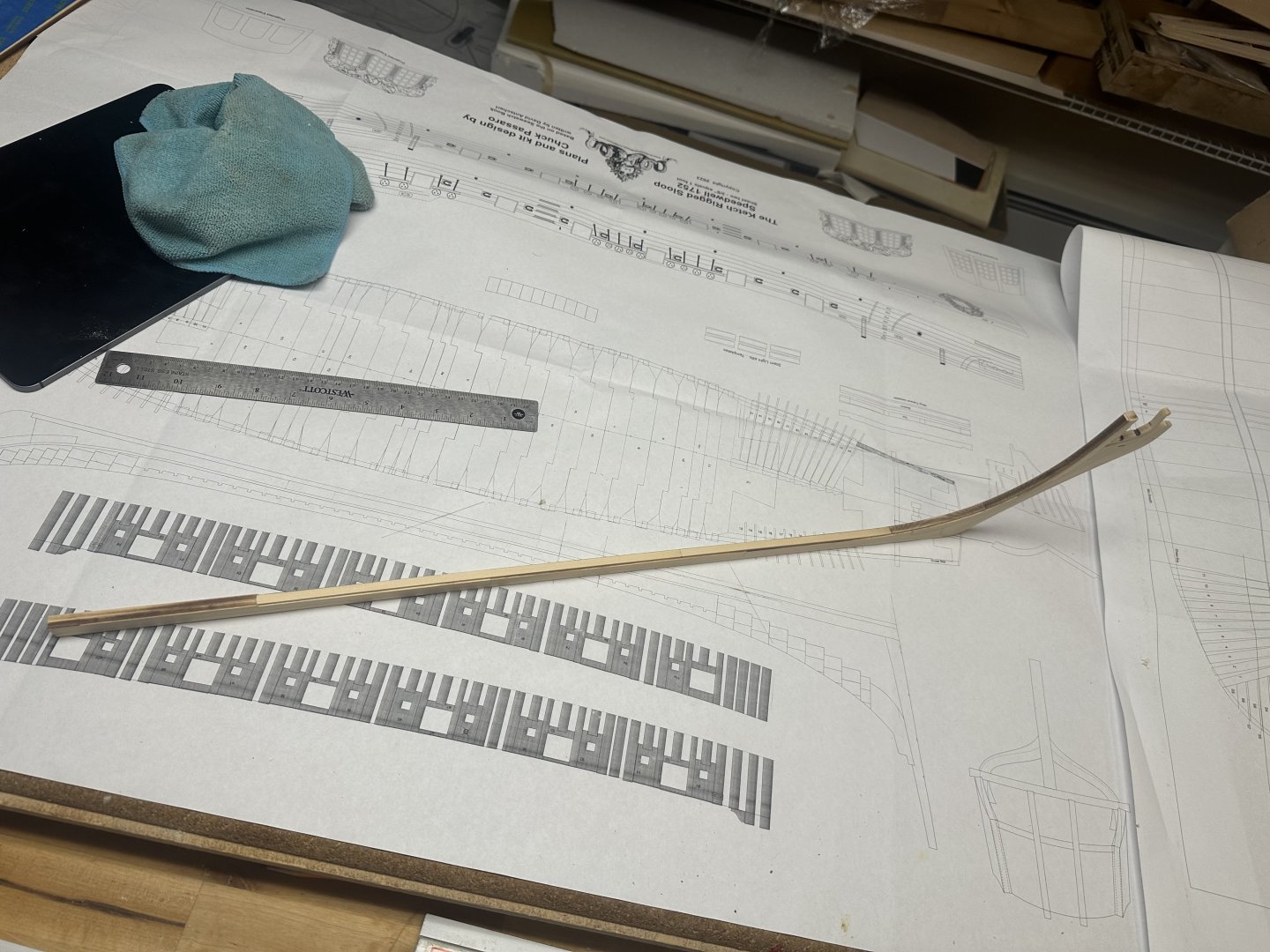

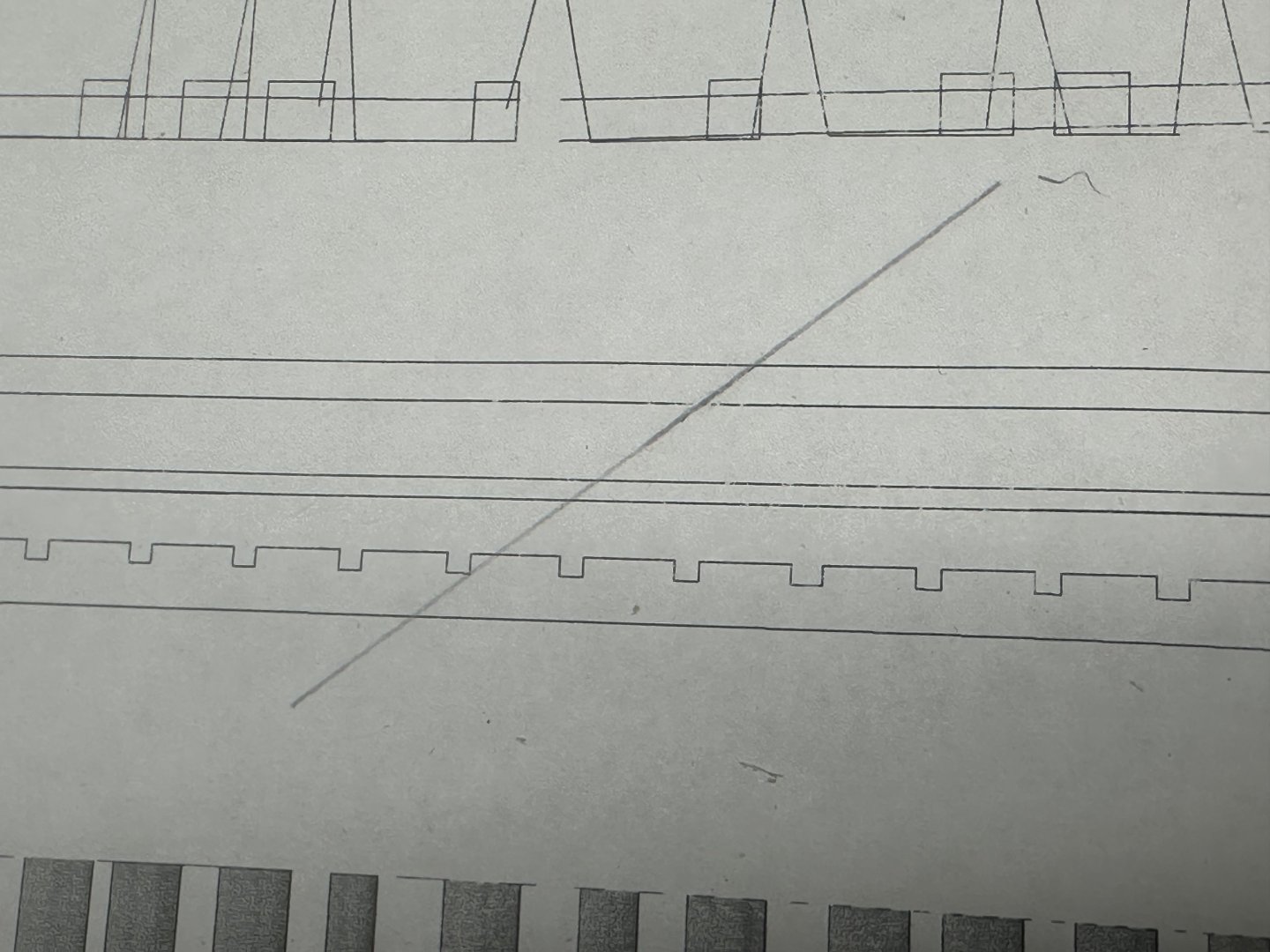

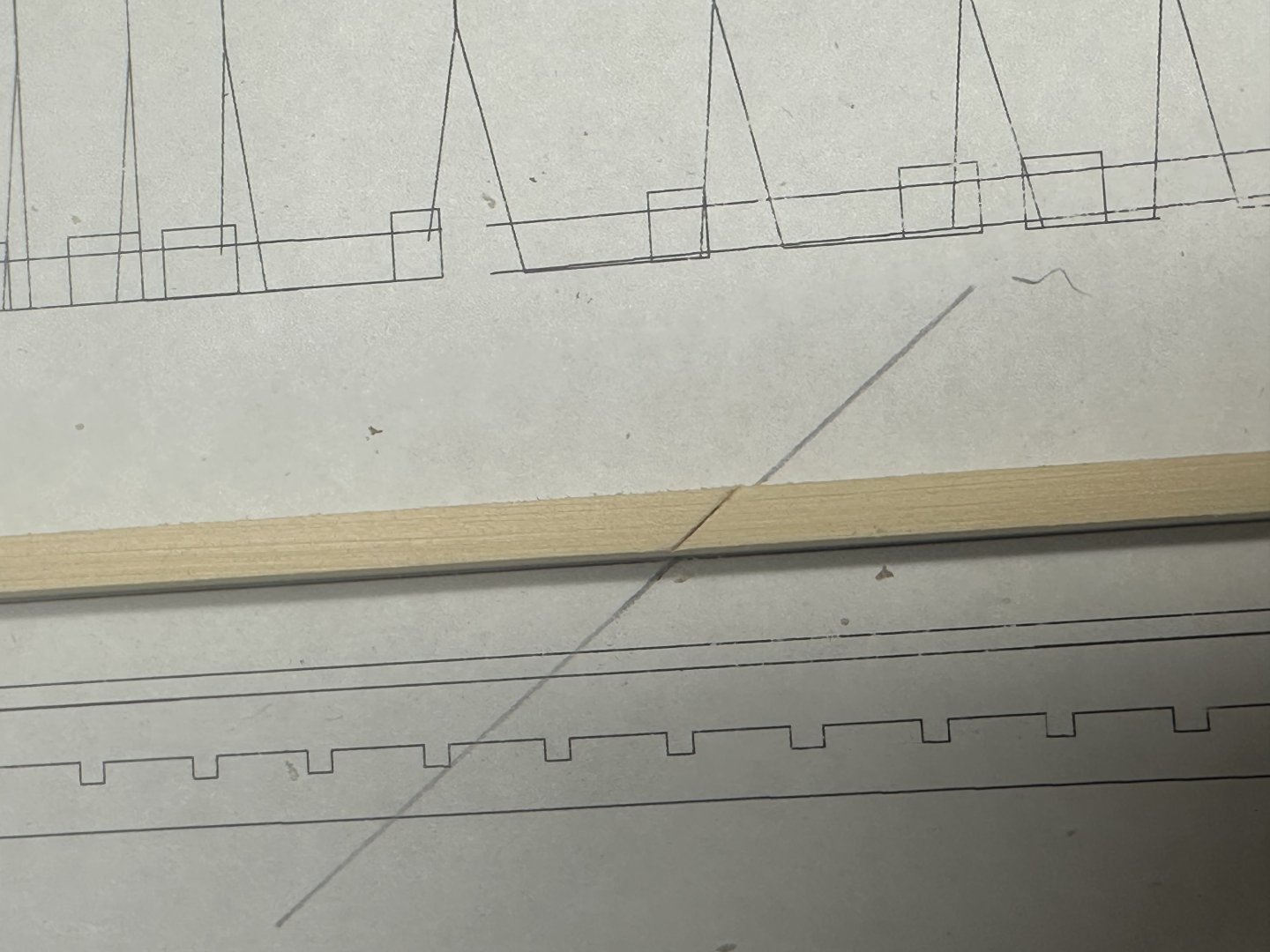

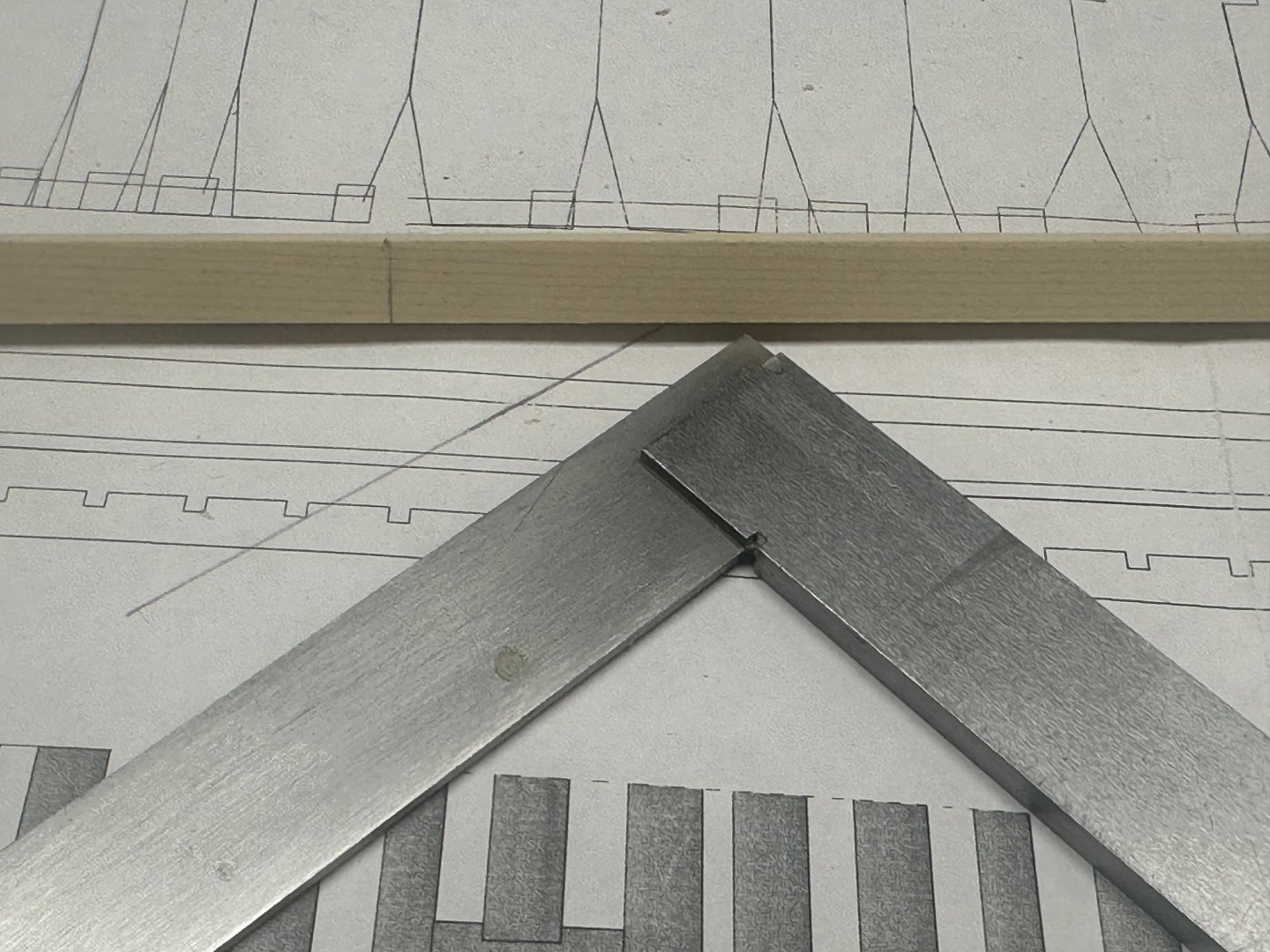

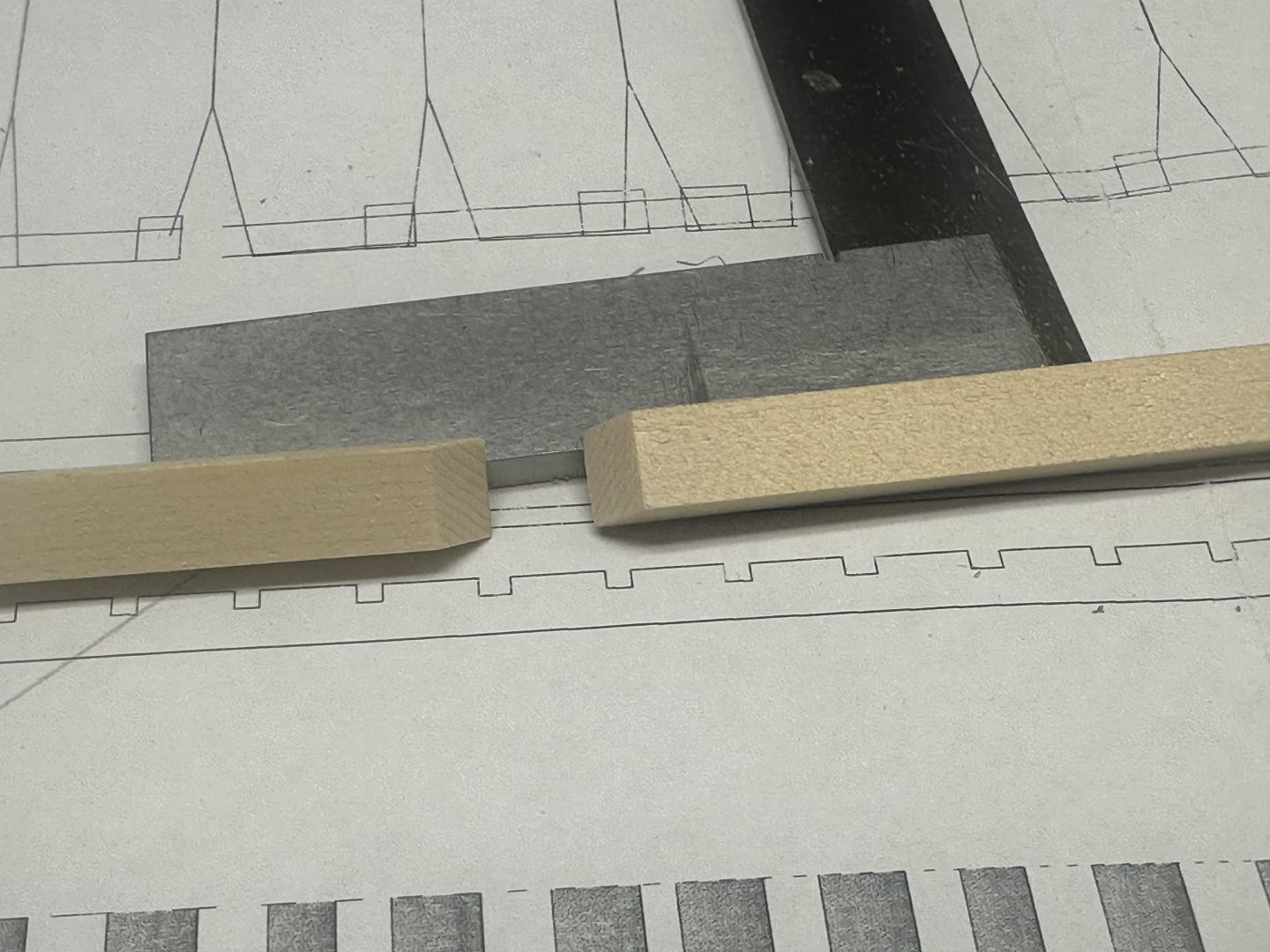

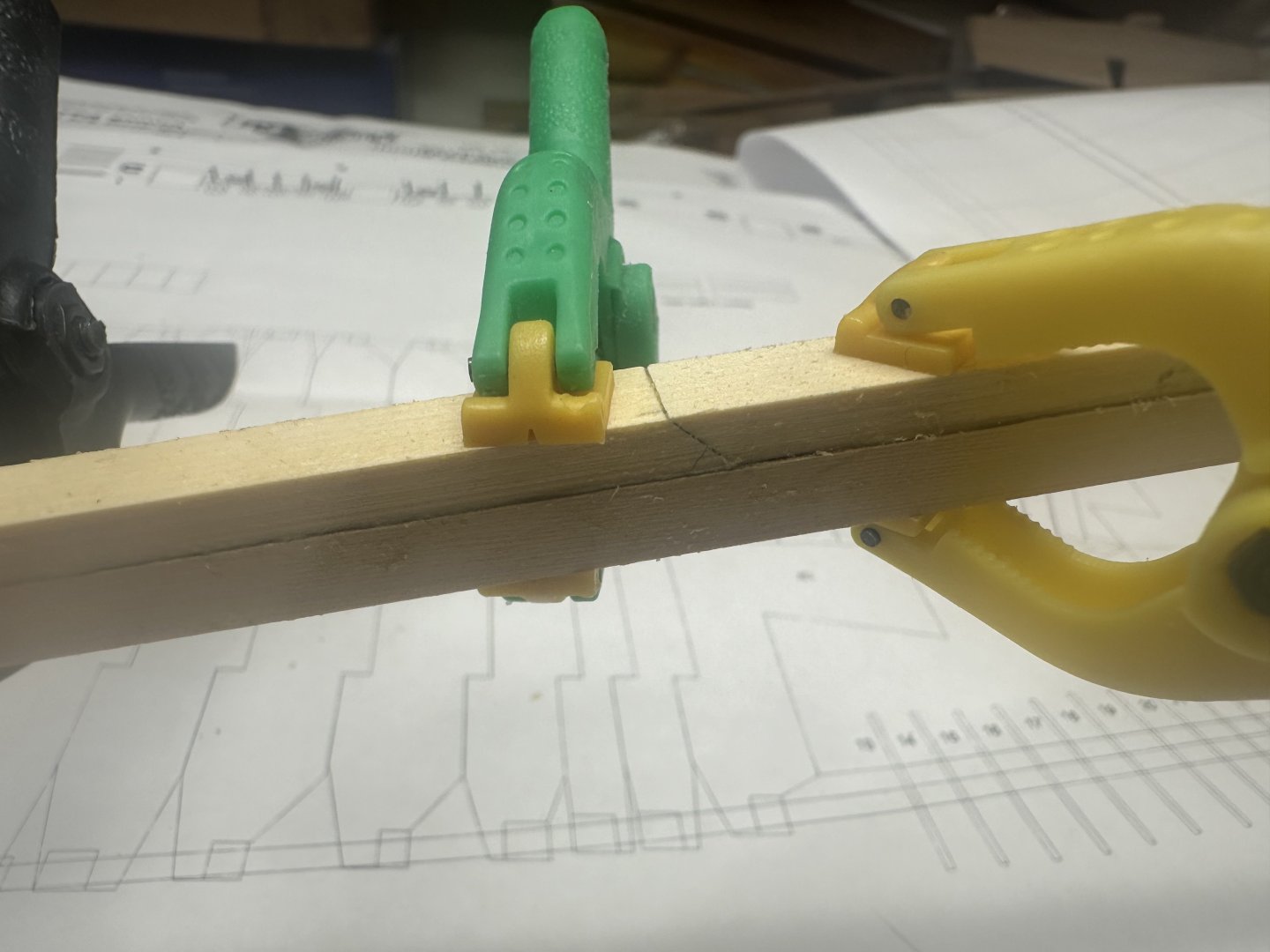

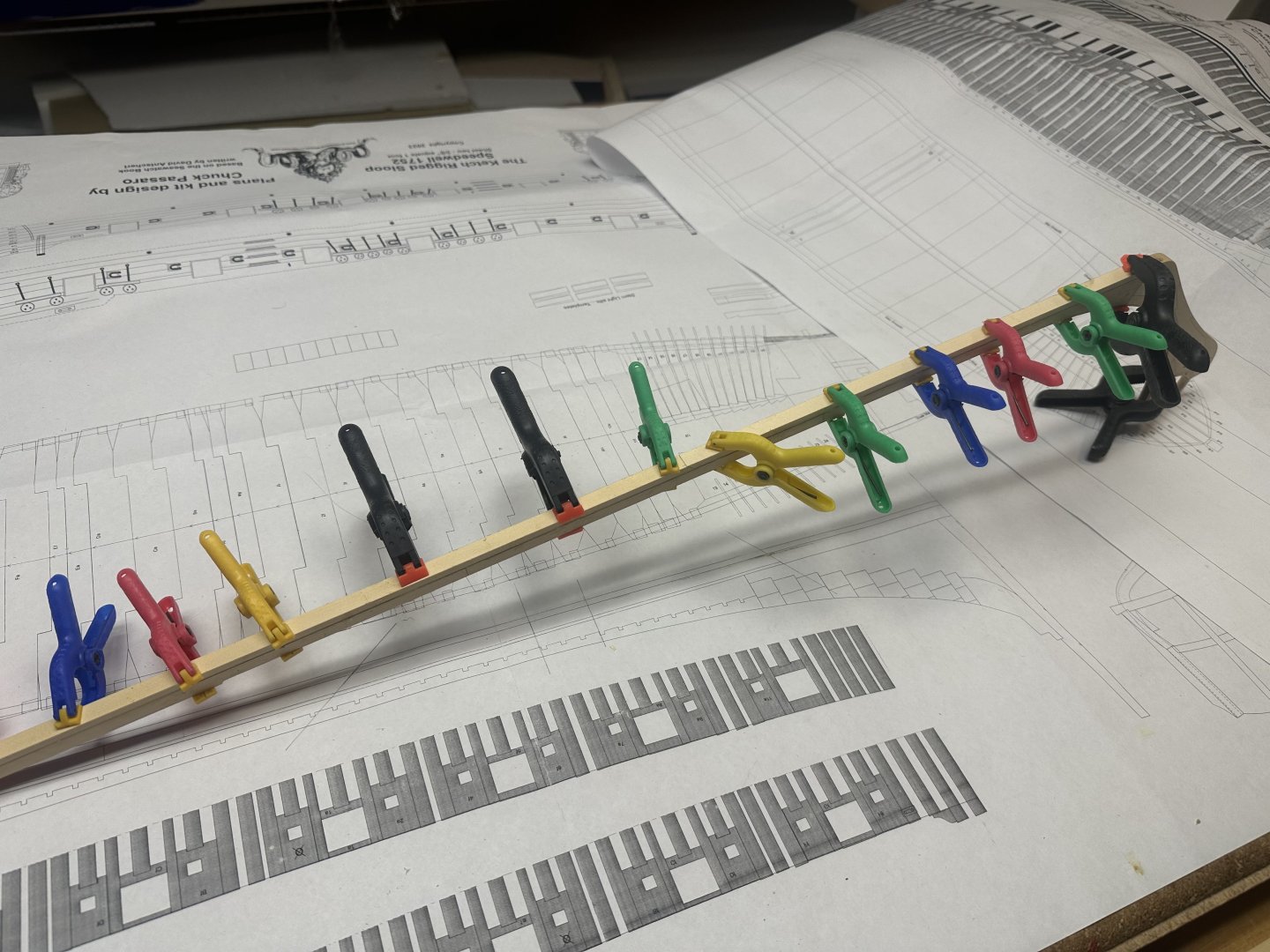

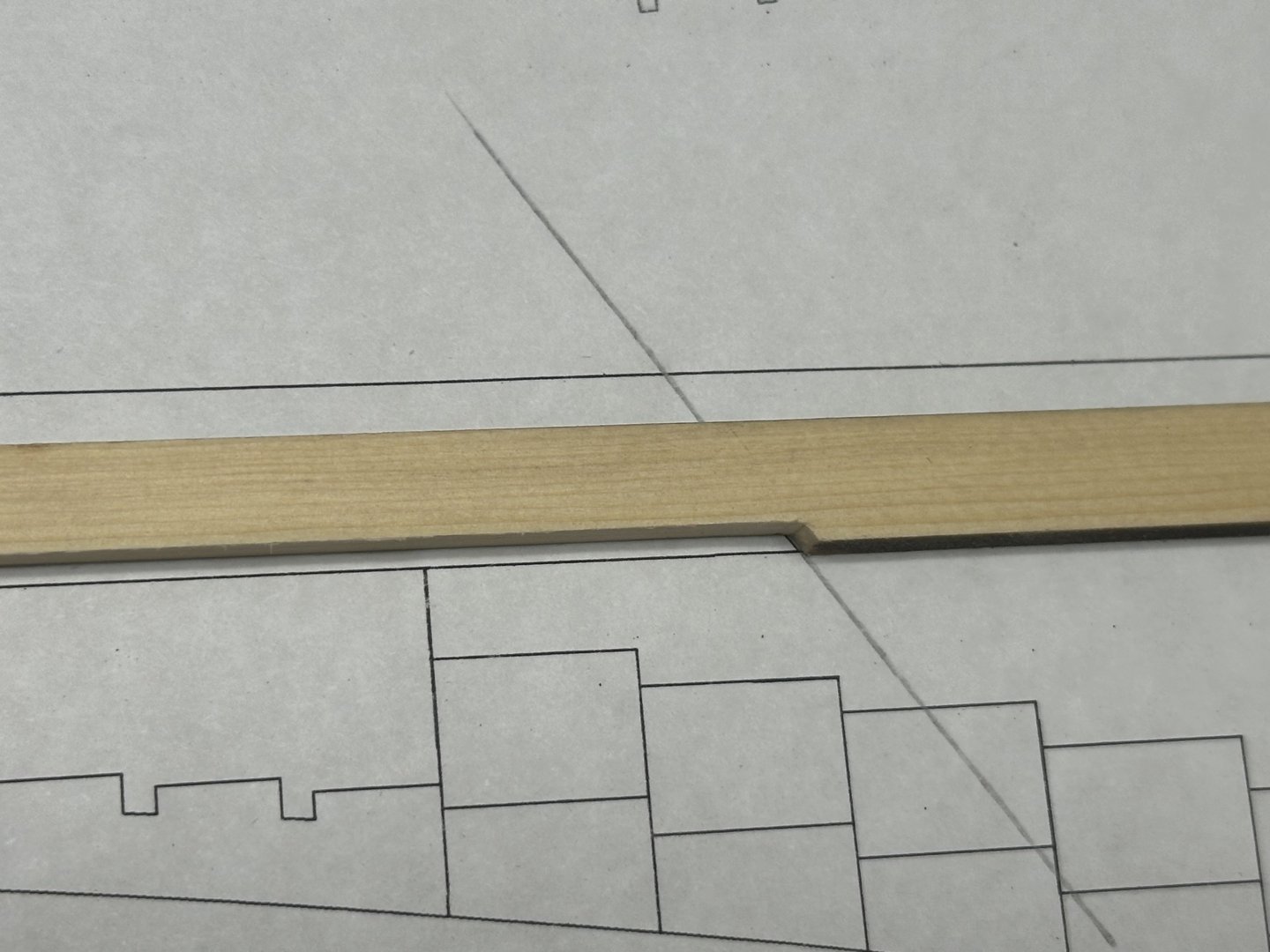

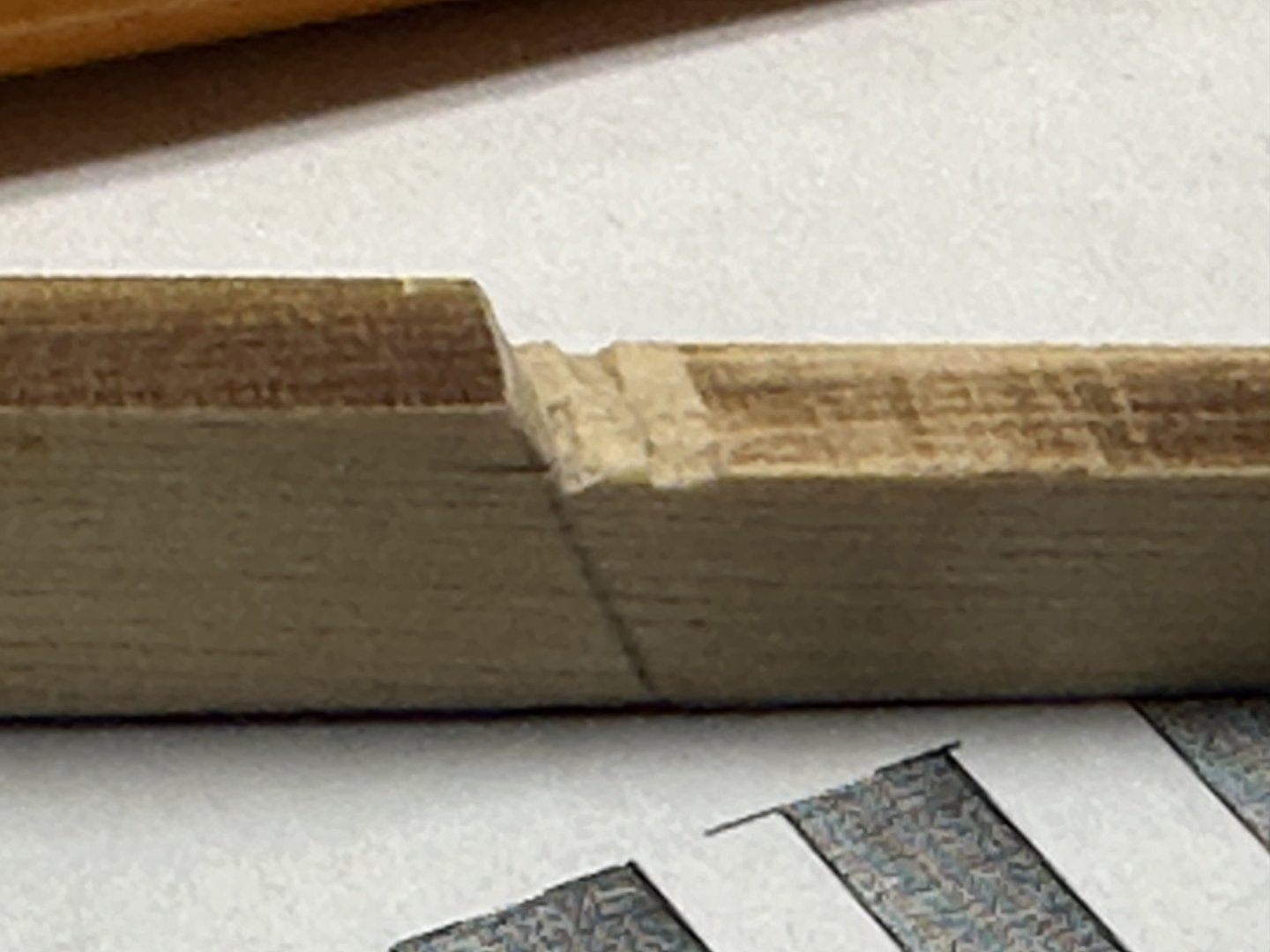

Here’s this morning’s efforts. I added the bottom of the keel, but first had to make the angle cut. To make the cut more accurate, I drew a line on the plan extending the required angle. Then placed the wood over the line. Next, using your favorite cutting utensil score the wood using the lines on each side as a guide. After that, use a machinist square to draw a line across the wood. Now you have a guide for a straight cut. I used a new razor blade to make the cut and only needed a quick touch with sandpaper to make a perfect cut. Next, I used that cut to set the angle on my Byrnes disk sander for the mating part. All parts lined up perfectly for gluing in place. Best Regards …. Rick

-

Outstanding Nic! Building something that has special meaning for someone is very heartwarming! Best Regards …. Rick

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

When it comes to scrap wood, I very rarely throw it away, especially AYC. Digging around in the scrap box I found a perfect piece. It only took about 1/2 hour to make a replacement, now to continue with the build. The swear jar is happy as is the scrap bin, it got the messed up part. Best Regards …. Rick

-

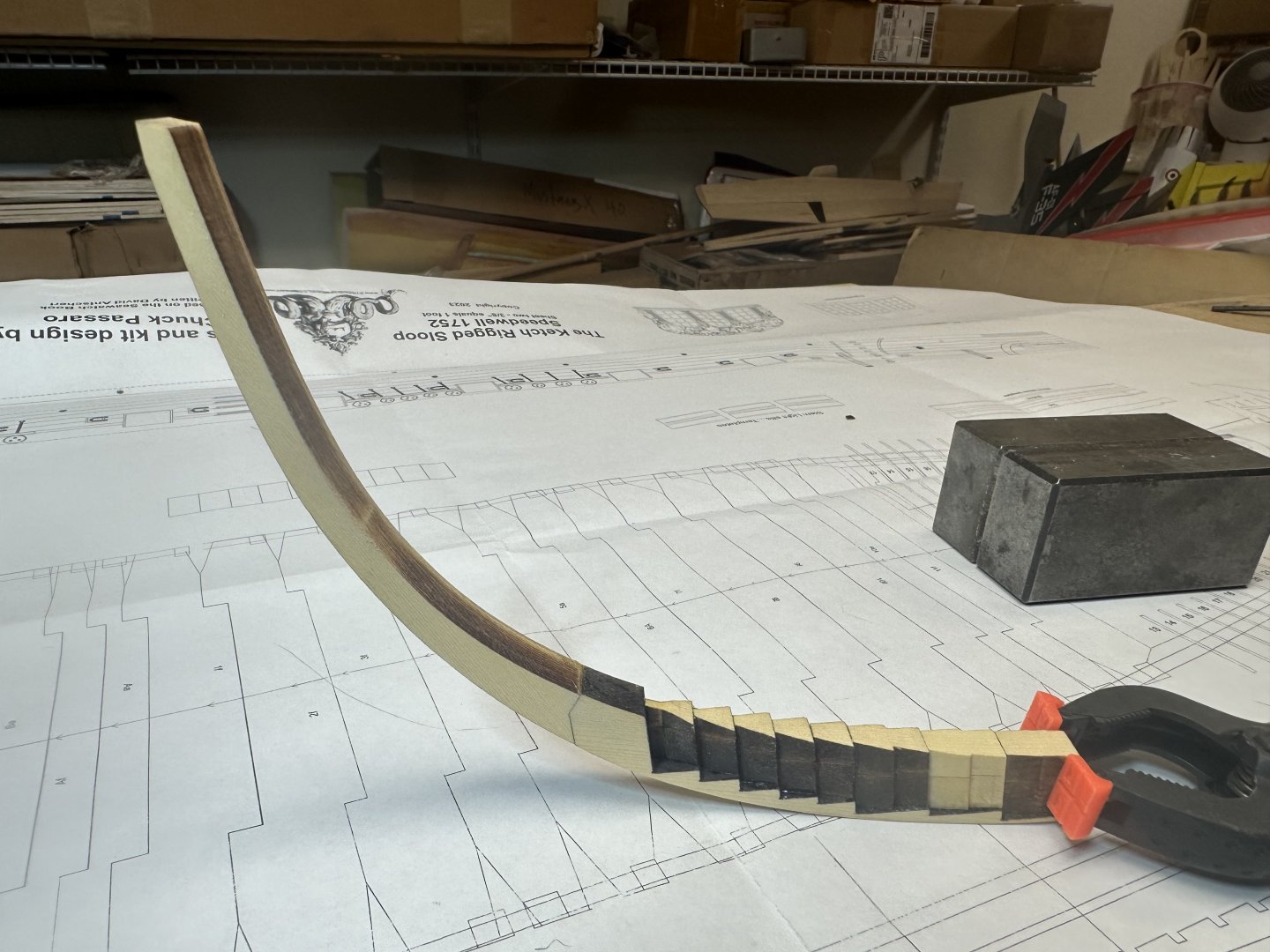

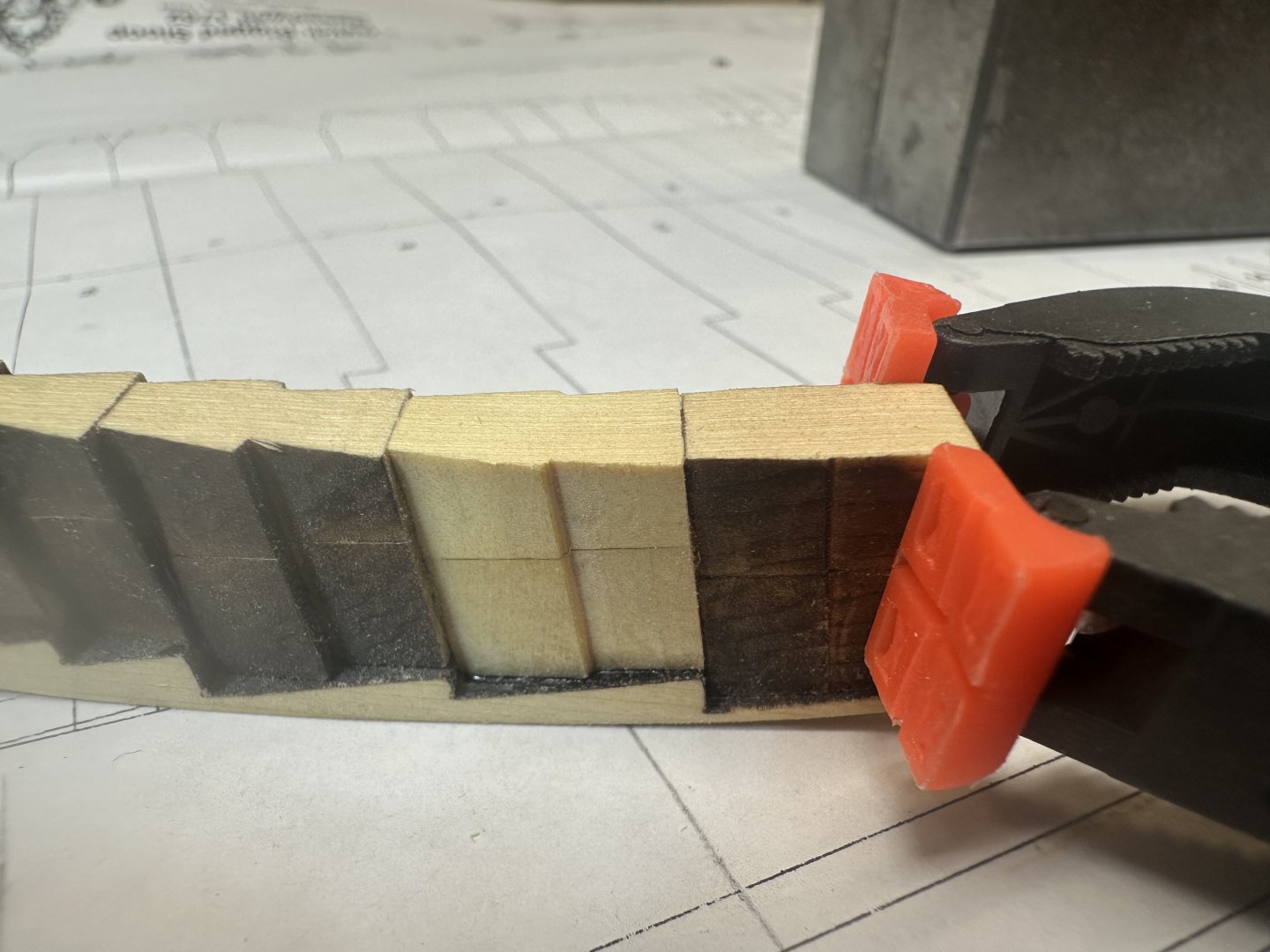

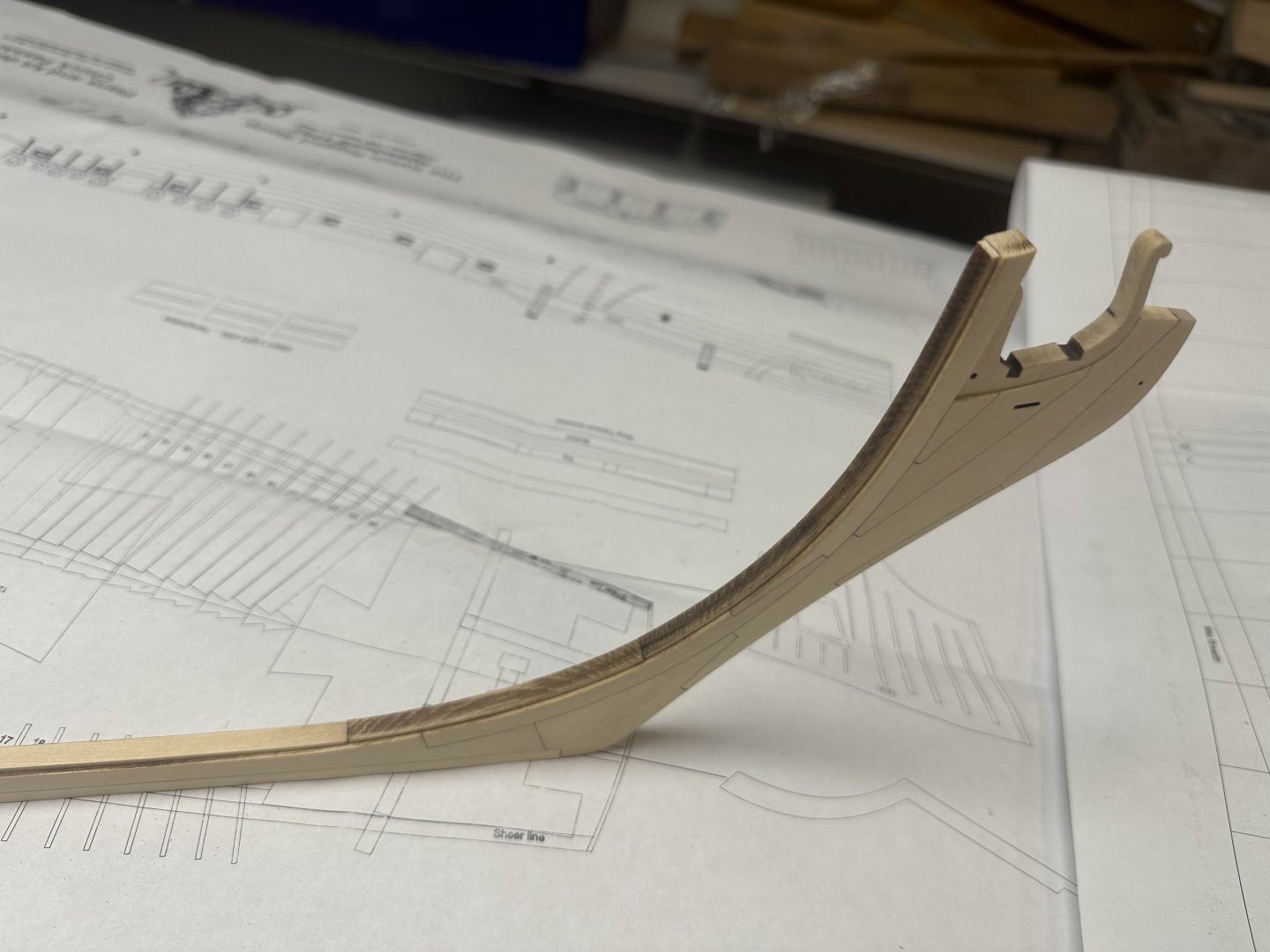

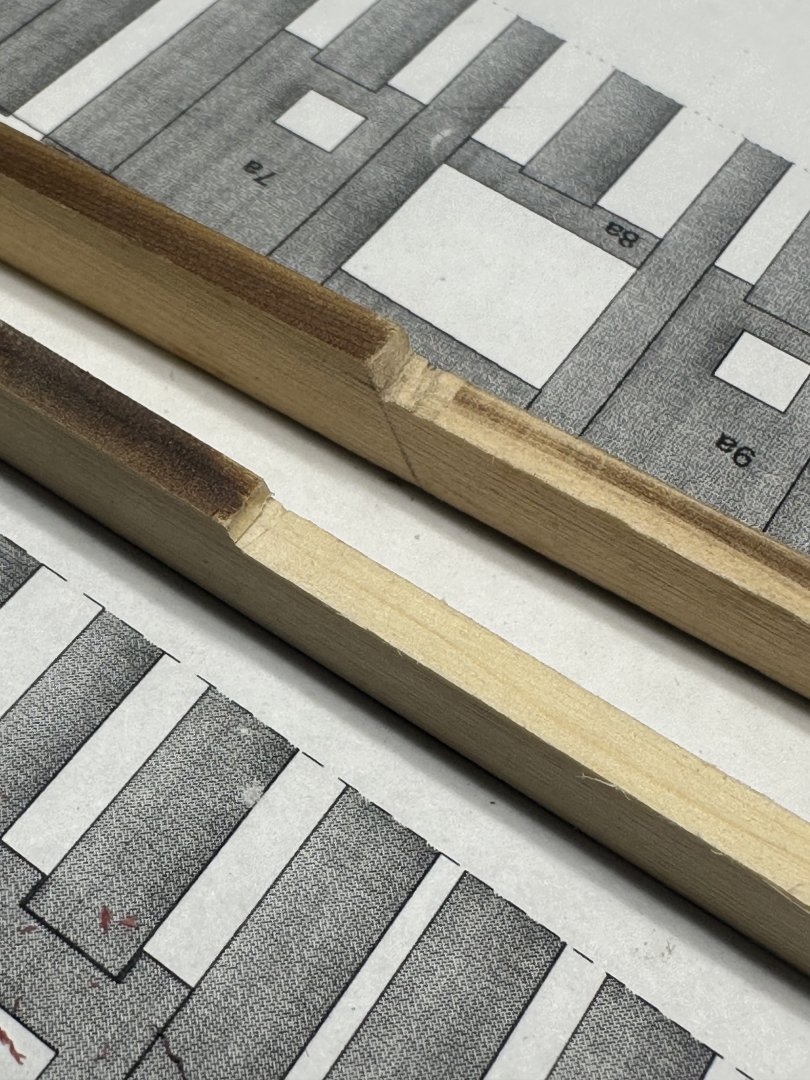

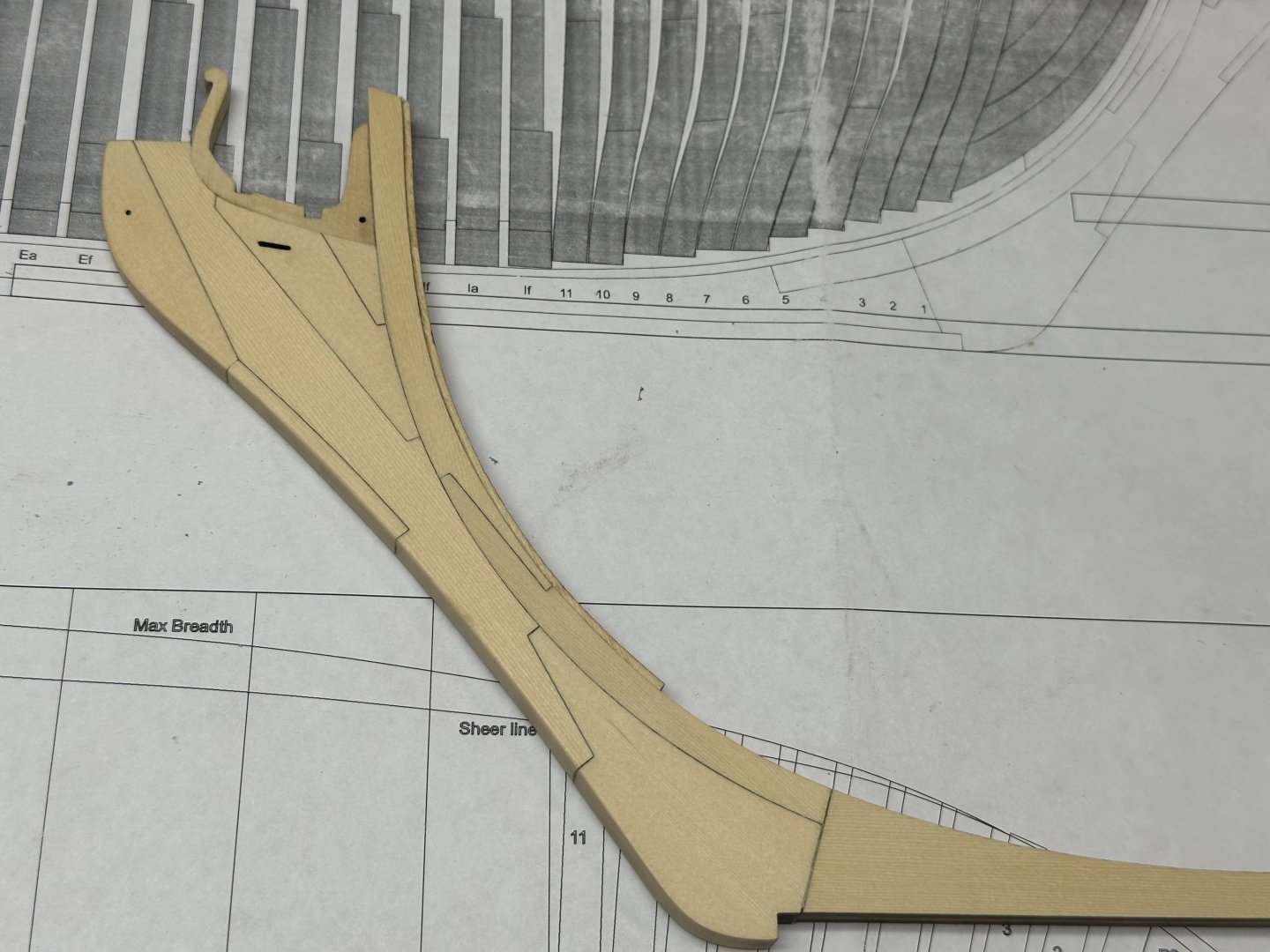

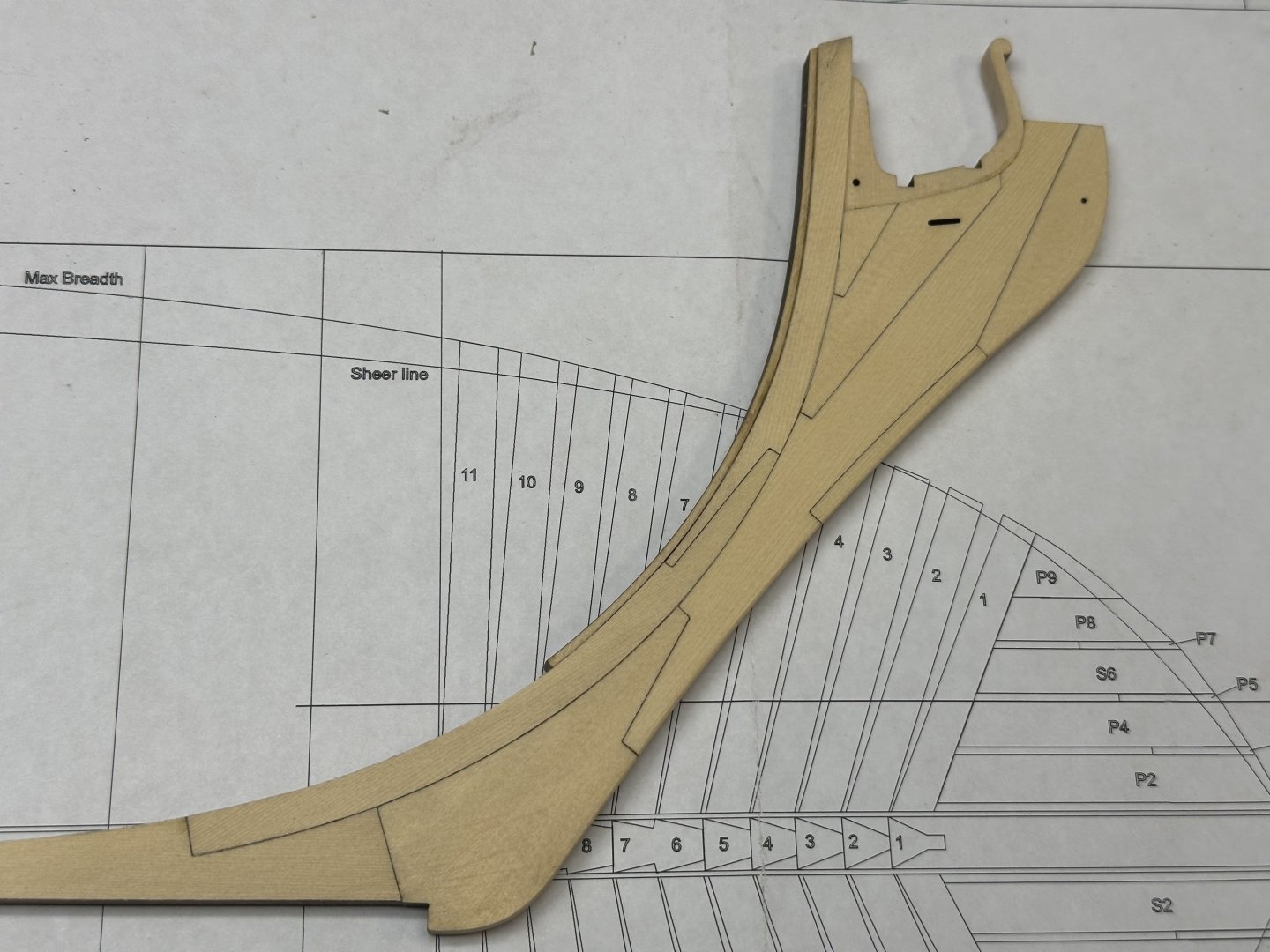

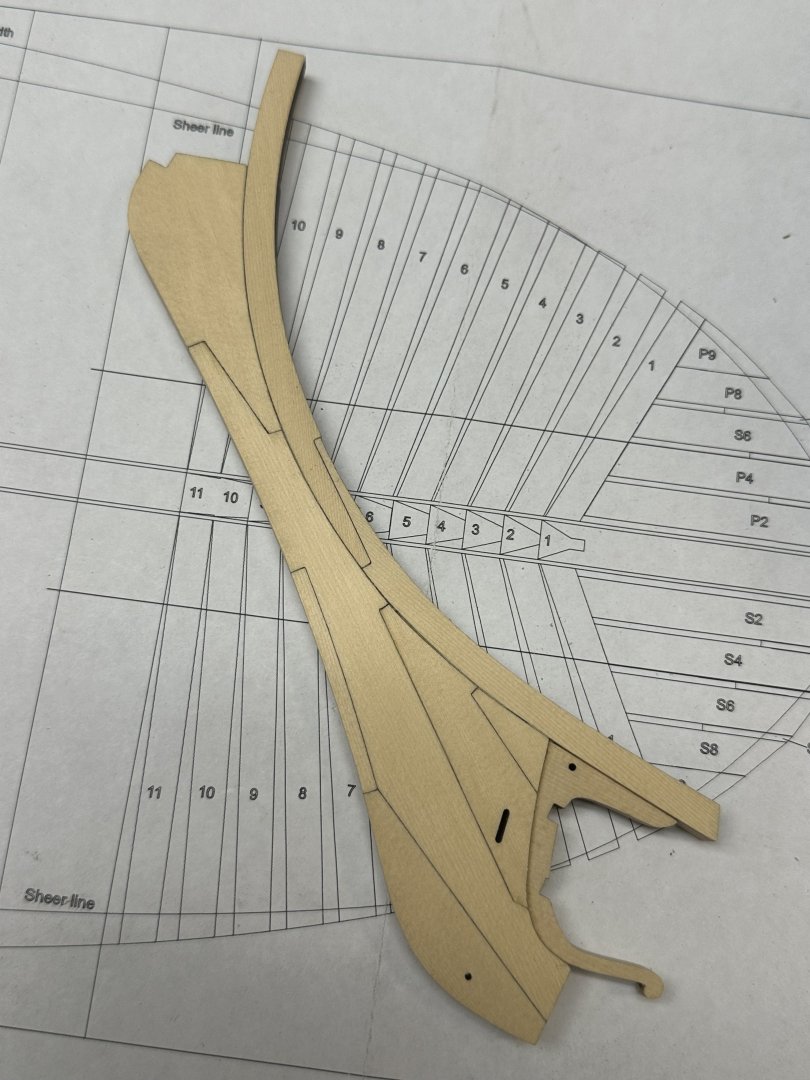

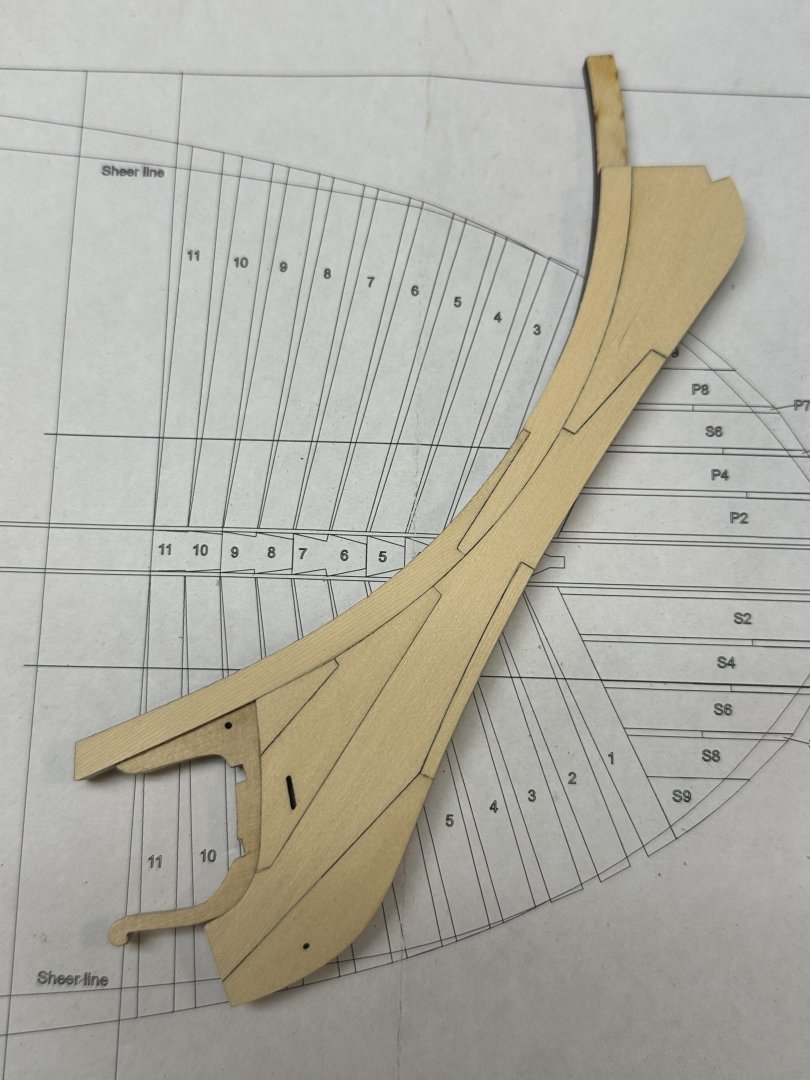

Here’s last night’s effort, the stem. It took a fair amount of time to get the parts to fit well, the angle cut of the laser is a bugger and careful sanding is required to get gap free joints. I mostly used a file and sanding sticks, I also used with excellent results my Byrnes 4” sander (RIP Jim, we miss you) for trimming down the joints that Chuck points out is his build. Overall it was a pleasant experience. Now to start the taper... Best Regards …. Rick

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.