Don Case

Unsubscribed-

Posts

482 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Don Case

-

Chocked frames

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

Thank you for that link Alan. I took a shot of it, enlarged a chock and now I can do some proportional measuring and come up with a plan. Edit- That was easy. Using the molded dimension (MD) below the chock the length of the chock is 4MD. The depth is 3/4MD and the bits on the ends are 1/5MD. These are rounded out a bit. Actually I think if I had used the upper end of the chock as the MD the numbers would have been closer but on a 1:48 we're talking a few thou. Thanks -

Here's the first try. It works well. Not only does it keep the wood secure it is kind of a gauge as to blade sharpness. The back of the slot is a reference point so you can see the blade getting pushed back as it gets dull. The foot is just soft soldered on the post so the vibration will probably break that. I attached it with the clamp that held the dust blower on. The dust blower went the way of the guard many years ago.

-

Thanks Kurt, I did that and got here En1340225-3-1-91.max (mikestools.com). I don't remember this saw ever having this guard. It's a very old saw. I call it a guard because in this case that's what I think it is. It doesn't seem to have any up/down adjustment. Anyway the drawing pointed out some tapped holes that I can use to cobble one up

-

I have a cheapo Delta scroll saw. It does the job but every so often I lose my grip on the wood and it jumps up and down with the blade. I thought I could put some kind of a presser foot like a sewing machine but never got to it. I noticed a thread the other day about scroll saws and there was pictures showing a foot. I just looked up some and all the newer saws seem to have them. Is this a worthwhile addition? For those that have a saw with a foot does it help? Does it get in the way? Any comments please🙂

-

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

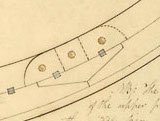

I've spent the last few days building this jig and setting in a few frames. As it turns out the room and space is very close to the station spacing so at least midship I can just copy the station shape. I started at station 0. The first two stations on the body plan are 0 and (D). Three frames fit in between them. I made a 0 and (D) according to the body plan and made three more 0's. Clamped them together and roughly faired them. The first 5 frames fit nicely. Then I moved to station D with the idea of just repeating what I did on the first five. Station(frame) D wouldn't fit. It's 3/16" to narrow. The jig is the 5th waterline which I lofted using the original body plan. I've measured and re-measured and double checked my lofting. All I can figure it that all the minor errors are adding up rather than averaging out but 3/16" is a lot. The only other thing I can think of is that on the body plan the upper part of the midship stations all come together in a big blurry line. Maybe that massed me up but if I lofted the waterline from the body plan and my dividers went back in the same holes every time this should work. A plank seems to lay nicely on the frames but it's a big jump (about 2" or 4 frames) between station (D) and D and that could be fooling me. Anyway it's fun although this stumbling block is getting a little tiresome. I can either modify the frame or the jig but I think they're both right. Dunno. Maybe spend another day trying to sort it out. Edit- I've decided it's the jig. I'll fix it with a bit of 1/32" plywood. -

I used oven cleaner on my Thurston blade. It worked great. Spray it on wait a half hour and rinse it off. I came to the conclusion that because the blades have little or no set even a little burnt gunk is a no-no. It will just get worse. Mine is a home made saw and cleaning the blade made a world of difference. I didn't try to sharpen it. Did you just use the stone straight across( no angle)? To me the teeth just looked like a bunch of chisel points.

-

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

If you come across anything interesting please post it here. There is not much to go on. I'm hoping for a few gems from the book. I don't know if you're old enough but I was a big Capt Puget fan when I was a boy, 60 years ago. -

Making frames

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

OK now I'm thinking about it. Does anyone have a recommendation for free CAD? It's got to be pretty easy to learn. I used to use Hullform from Blue Peter. I tried Delft but got no where with that. Someone gave me a copy of Rhino and that was worse than Delft -

Making frames

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

I don't have CAD and I don't really have a big desire to try to learn it (again)😃. I have this gut feeling that old stuff should be done in old(ish) ways within reason. I made a scarfed frame today and I can see that with a little practice I could make 2-3 a day. There's 50 of them so a month or two. That said, I have heard that there is some free CAD software out there that I might try but my computer is quite old. it would make things more precise. -

Making frames

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

I've been using carbon paper(remember that stuff?) and it sorta works. All I have to work with so far is a blurry body plan. if i want to make patterns I would have to loft three frames into an 1/8" space. I could get it closer by just hand drawing two frames into that space. Any way I do it, if, as you say, cut outside the lines, I would actually be cutting the next largest frame. This is why I asked how much I should expect to be sanding off. A related question, because the inside of the frame has to be considered, how do you fair the inside? The best idea I could come up with is one of those sanding balls. I guess you fair the inside every time you've added 3-5 frames or something. -

I'm starting to make frames. On the body plan the center 6 stations only differ by 1/4" max. There are 15 frames to fit in that 6 station length. Is it feasible to make one or two patterns to cover the 15 frames and sand them to fit during fairing? Two or three of the stations are only 1/8" or less different and I have to put three frames in there. Even if I made a pattern for each frame I'm sure I wouldn't be able to saw them any closer so i would end up sanding them anyway. How much would a good(not excellent😉) craftsman have to sand when fairing?

-

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

Here's a couple of trial chock joint frames. They actually went pretty well. They would have to be reduced in the moulded dimension. I'm surprised how small(skinny) they are. I'll try and do some scarfed ones tomorrow. -

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

I've noticed that Kevin Kenny and Dan Vadas use a mixture of scarf and chock joints on their frames. Their Swan class ships are about 10 years earlier than mine. My copy of Steel is 1812, about 20 years later. He calls for scarfed or "framed" joints. I'm wondering what "framed' means? Was there a change of methods in this 30 year span? I've also seen frames constructed using overlapping layers of half thickness parts. These seem stronger but less realistic. Probably easier to build but I would have to mill a bunch of 1/8" thick wood. -

Hawse Pieces

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

Done😃 -

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

Hazel so far. I have quite a bit of it from when I was making bows (archery). It seems to work well. It does get dirty though, I'll have to figure out something there. I have Maple, Crabapple, Dogwood, Saskatoon(Serviceberry) left over from bowmaking. It's all probably good for boats. I have Yew also but it's a little soft. The panelling is left over from when we moved into the house before I was finished it. That was 45 years ago. Still isn't completely finished. I have 3 4x8 sheets of it left so I can waste all I want. -

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

I'm reasonably pleased with how they look. Now to number them and store them away as patterns. Little bit of a dip in one or maybe a lump on five. -

I live on Discovery Passage named by Capt George Vancouver after his ship in 1792. I was thinking of building the Leopard but the local history of the Discovery made it more interesting. (plus I wouldn't have to make 50 guns). I've done a dozen or so POB so I thought I'd do a scratch POF to really challenge myself. I'm 73 and have shaky hands. That's one challenge. I also have very minimal plans so far. I'm waiting for the Vancouver Maritime Museum to get back to me about John McKay's drawings Vancouver Maritime Museum : Ship plan : H.M. Sloop of war <i>Discovery</i> [2007.5000.0164] (vmmcollections.com) I have 4 drawings from here(way down the page) Category:Ship plans of the Royal Museums Greenwich - Wikimedia Commons. That's the second challenge. I started a preliminary build while I'm waiting for the museum. Their archivist left and the new one is starting in a week or so. If the preliminary build turns out to be close enough I will use it but I'm expecting to scrap it once I get some better info. The pre build is teaching me a lot. I thought I would start a build log so my questions wouldn't be shot gunned all over the site. Don't know if that's a good idea or not. Depends how entertaining I can be, I guess😃. Right now I'm mocking up cant frames. I'm using old wall panelling. I'm just in the process of tack gluing all this together so I call turn it over and see the outside. I can't tell if it's at all fair from this point of view.

-

Hawse Pieces

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

HMS Discovery1789. Maybe I should start a build log. -

If each space is a little small and each room is a little big then there is no harm done. I can see compounding errors being a problem some times but if there is a way around it why not take it. Setting anything up to cut wood that accurately is not easy although a thickness planer can skim off a tiny bit. Moving the fence on a saw .021", not with my hands🙂

-

Lofting cant frames

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

Thanks another PDF to read. -

Lofting cant frames

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

Thanks Alan. I saw that PDF from one of my searches but it seemed to be more CAD related. I looked a little closer this time. Another PDF for bedtime reading🙂

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.