ECK

NRG Member-

Posts

646 -

Joined

-

Last visited

About ECK

- Birthday 10/08/1963

Profile Information

-

Gender

Male

-

Location

North Carolina, USA

Recent Profile Visitors

-

Scott Crouse reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

Scott Crouse reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

-

Ryland Craze reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

Ryland Craze reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

-

brunnels reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

brunnels reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

-

Ronald-V reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

Ronald-V reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

-

Ian_Grant reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

Ian_Grant reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

-

RossR reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

RossR reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

-

HMS Victory by ECK - OcCre - 1/87

ECK replied to ECK's topic in - Kit build logs for subjects built from 1751 - 1800

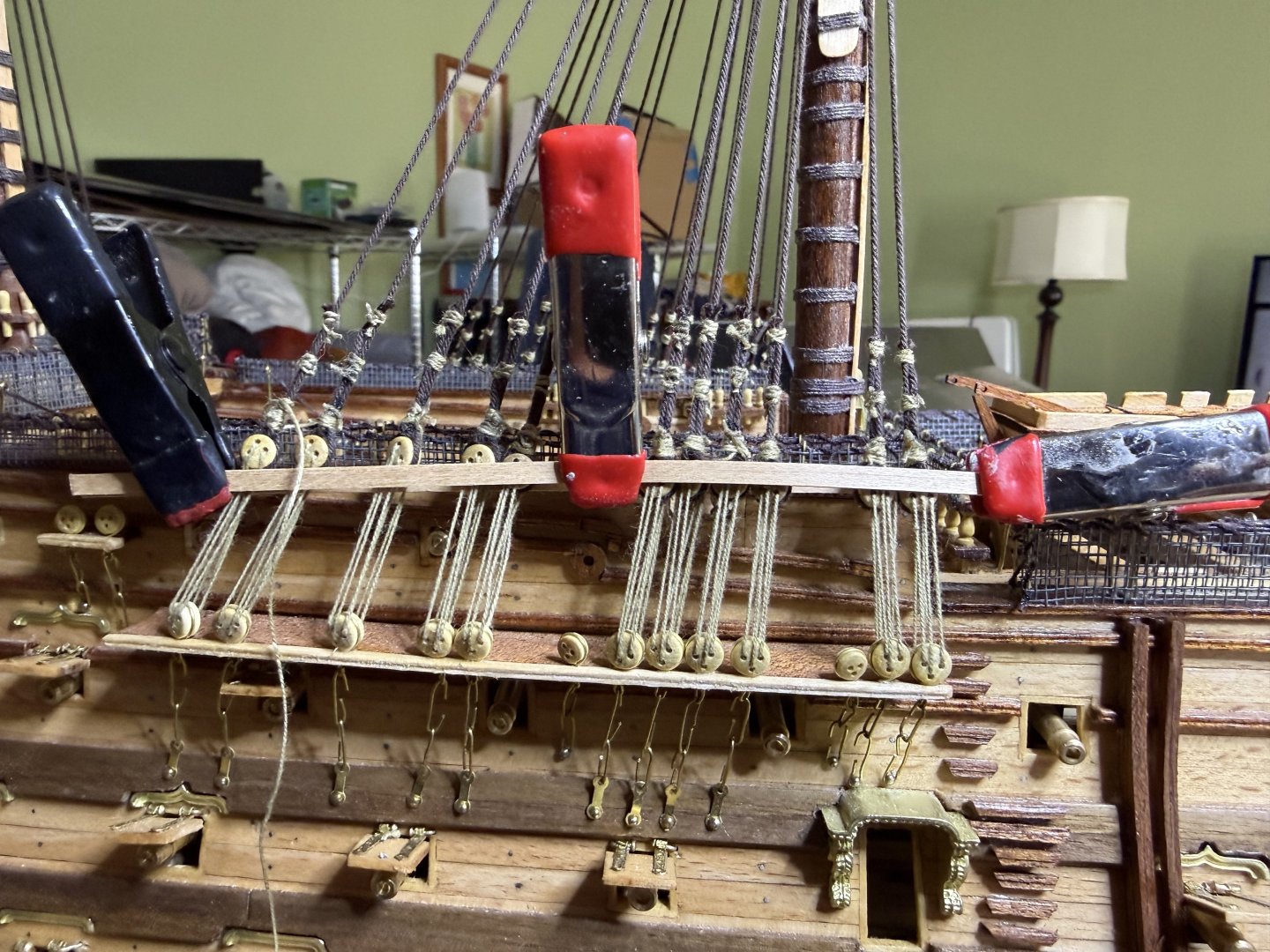

Work over the last week include completing the foremast backstays, yard lifts and starting the sail rigging. -

Geordie Tyne reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

Geordie Tyne reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

-

ECK reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

ECK reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

RossR reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

RossR reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

-

vvvjames reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

vvvjames reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

-

HMS Victory by ECK - OcCre - 1/87

ECK replied to ECK's topic in - Kit build logs for subjects built from 1751 - 1800

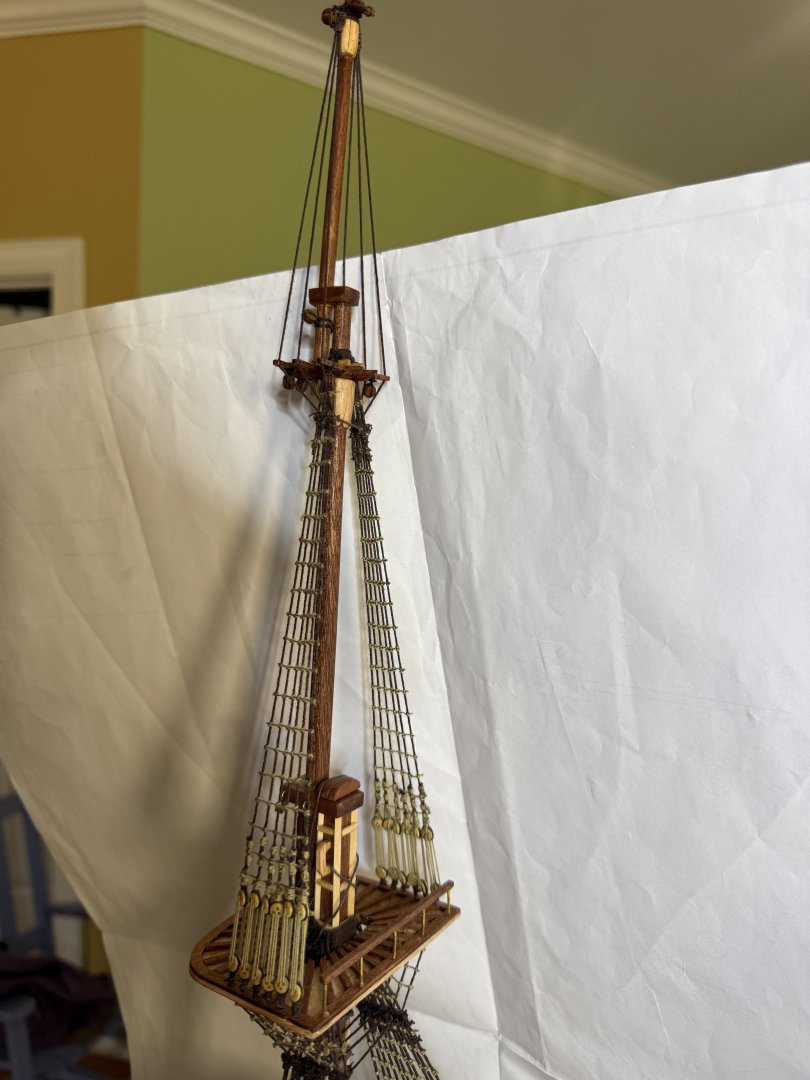

Meant to say weekend work. Foremast work today, main yards and back stays friday afternoon and saturday. Spent ab out 6 hrs on it today, very relaxing for me. -

Scott Crouse reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

Scott Crouse reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

-

HMS Victory by ECK - OcCre - 1/87

ECK replied to ECK's topic in - Kit build logs for subjects built from 1751 - 1800

For Maid of the Mist: Sorry, did not see your note until now. Occre has 3 threads here, 0.8 and 0.5 brown and o.15 natural which is the one for ratlines and running rigging. -

HMS Victory by ECK - OcCre - 1/87

ECK replied to ECK's topic in - Kit build logs for subjects built from 1751 - 1800

-

ECK reacted to a post in a topic:

HM Gun Brig Adder 1797 by Geordie Tyne - Vanguard Models - 1:64

ECK reacted to a post in a topic:

HM Gun Brig Adder 1797 by Geordie Tyne - Vanguard Models - 1:64

-

ECK reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

ECK reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

-

HMS Victory by ECK - OcCre - 1/87

ECK replied to ECK's topic in - Kit build logs for subjects built from 1751 - 1800

Weekend work involved attaching the mizzen yards with sails then adding the mizzen fore and back stays. Next will be the spanker rigging before finally adding the bowsprit to complete the other stays. I try to wait as long as possible before adding the spritsail yard as it sticks out so far. -

ECK reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

ECK reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

-

ECK reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

ECK reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

-

ECK reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

ECK reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

HMS Victory by ECK - OcCre - 1/87

ECK replied to ECK's topic in - Kit build logs for subjects built from 1751 - 1800

-

ECK reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

ECK reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

ECK reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

ECK reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

HMS Victory by ECK - OcCre - 1/87

ECK replied to ECK's topic in - Kit build logs for subjects built from 1751 - 1800

Thanks but unfortunately the plans show them going all the way across. -

ECK reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

ECK reacted to a post in a topic:

HMS Victory by ECK - OcCre - 1/87

-

ECK reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

ECK reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

HMS Victory by ECK - OcCre - 1/87

ECK replied to ECK's topic in - Kit build logs for subjects built from 1751 - 1800

Merry Christmas! Sooooo some 1300 knots later the lower shrouds are done. Also attached cleats to the appropriate shrouds. -

HMS Victory by ECK - OcCre - 1/87

ECK replied to ECK's topic in - Kit build logs for subjects built from 1751 - 1800

First job with the lower shrouds is to straighten the deadeyes as they tend to twist given how close they are. Next 2 rows of ratlines to lock into place Now to straighten out the upper part of the shrouds by adding the clatharins which also align bring in the back part of the shrouds which tend to flare outward. -

HMS Victory by ECK - OcCre - 1/87

ECK replied to ECK's topic in - Kit build logs for subjects built from 1751 - 1800

Lower shrouds done. Occre need to switch to a better way to attach the lower deadeyes like Vanguard several other manufacturers. The instruction do not mention or show the clatharpins. Only shows the upper deadeyes attached to a ratline. I will add the appropriate clatharpins. -

HMS Victory by ECK - OcCre - 1/87

ECK replied to ECK's topic in - Kit build logs for subjects built from 1751 - 1800

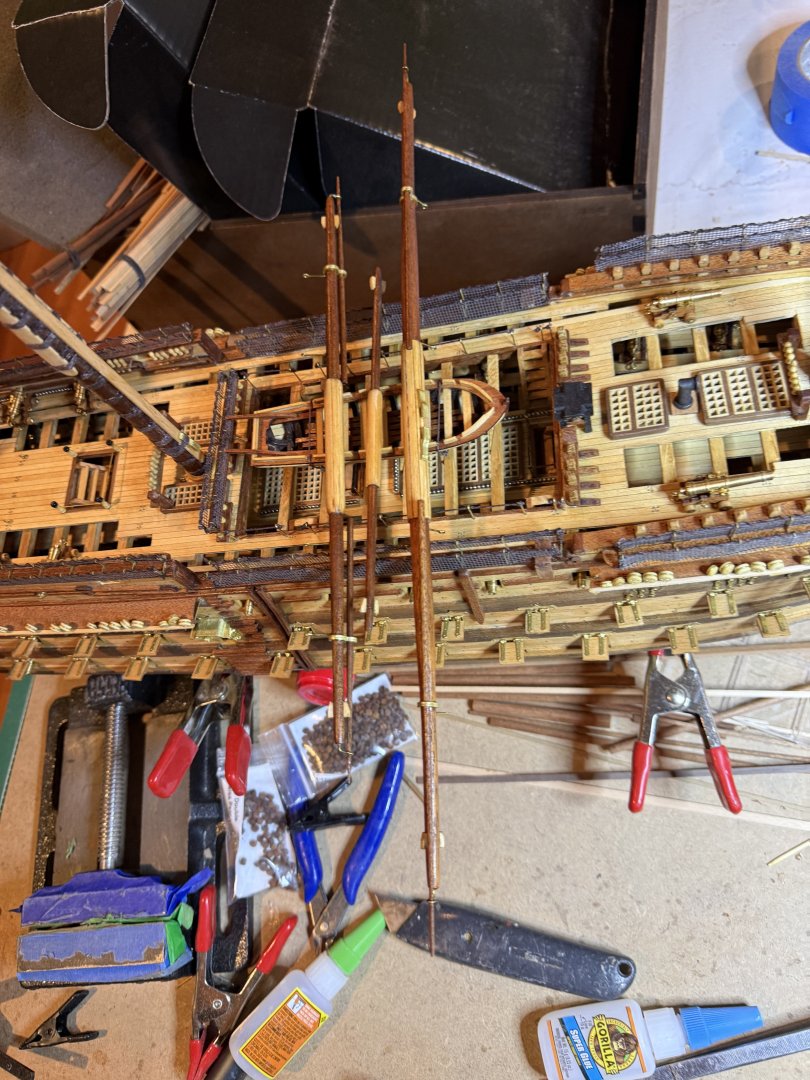

82 cm or 32 1/4 inches keel to main top -

HMS Victory by ECK - OcCre - 1/87

ECK replied to ECK's topic in - Kit build logs for subjects built from 1751 - 1800

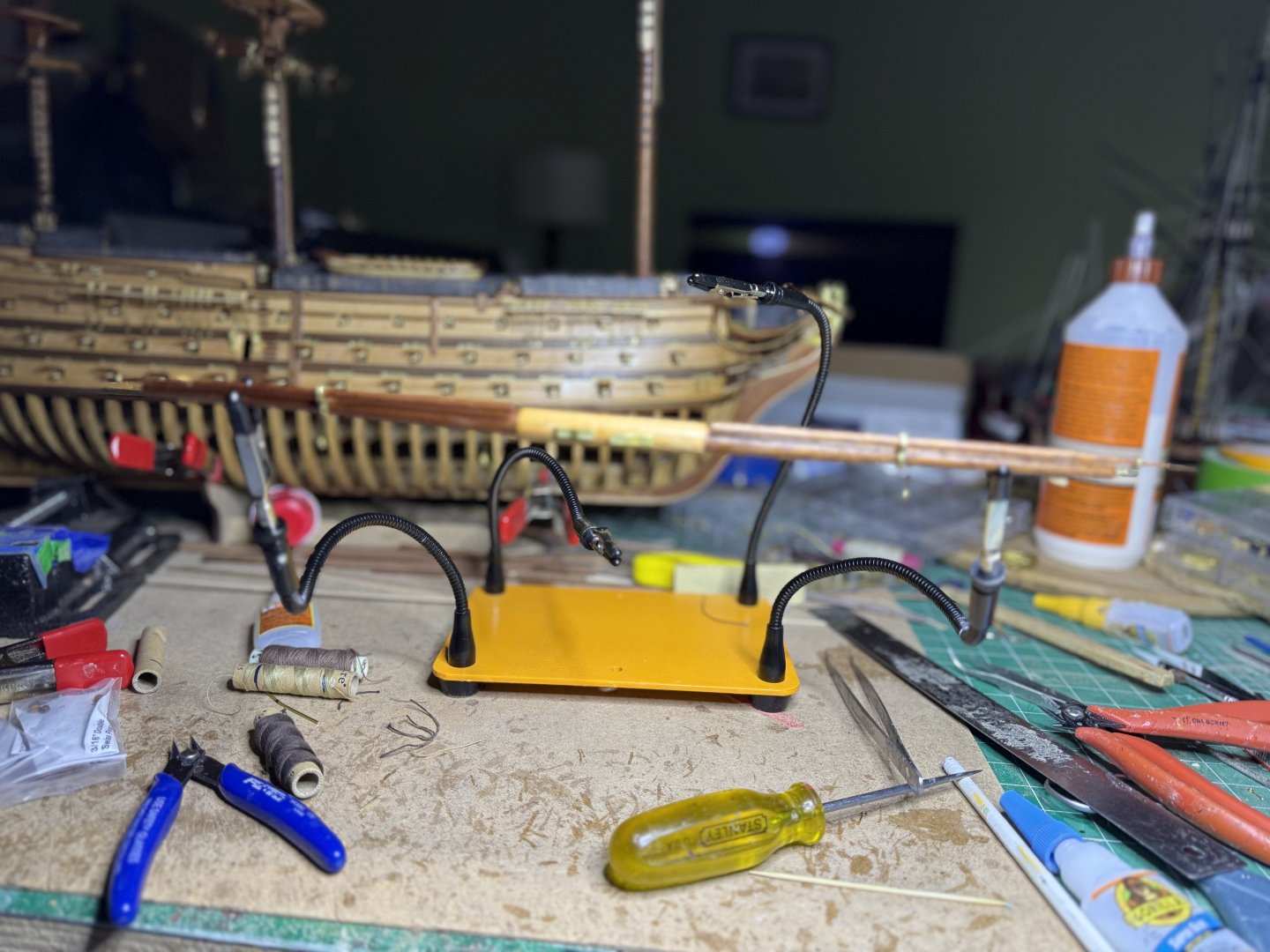

Spent the week rigging all the various blocks to the yards. Finally got to use my new gadget, a quad hands,making the whole process easier Here with yard in place Also used third clamp to hold blocks for tying Sorry for the focus. Finally pinned the yards temporarily in place. Usually at this point I like to attach the yards then do the shrouds but as this model will have sails, I will do the shrouds first as it is easier to bend the sails onto the yards with the yards off the mast and the sails would get in the way of setting up the shrouds. -

HMS Victory by ECK - OcCre - 1/87

ECK replied to ECK's topic in - Kit build logs for subjects built from 1751 - 1800

For the weeks work, Masts rigged, example below Yards all made , sealed and poly'd. Next will be putting all the blocks on. In this model there are only 2 kinds of blocks 4mm single and 4 mm double. i opted to buy realistic ones from Syren as once I got used to using them on my Vanguard builds I just could not go back to the cheap single holed ones as the ships look much better in the end.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.