ECK

NRG Member-

Posts

635 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ECK

-

- 73 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

- 73 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

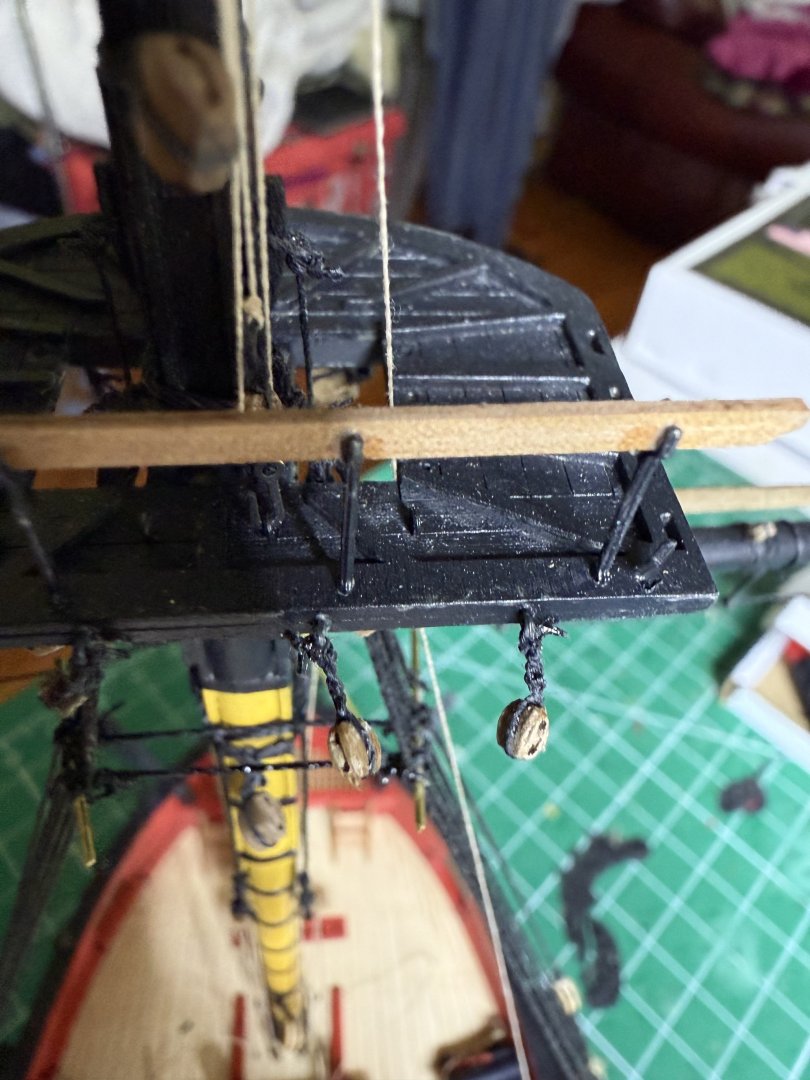

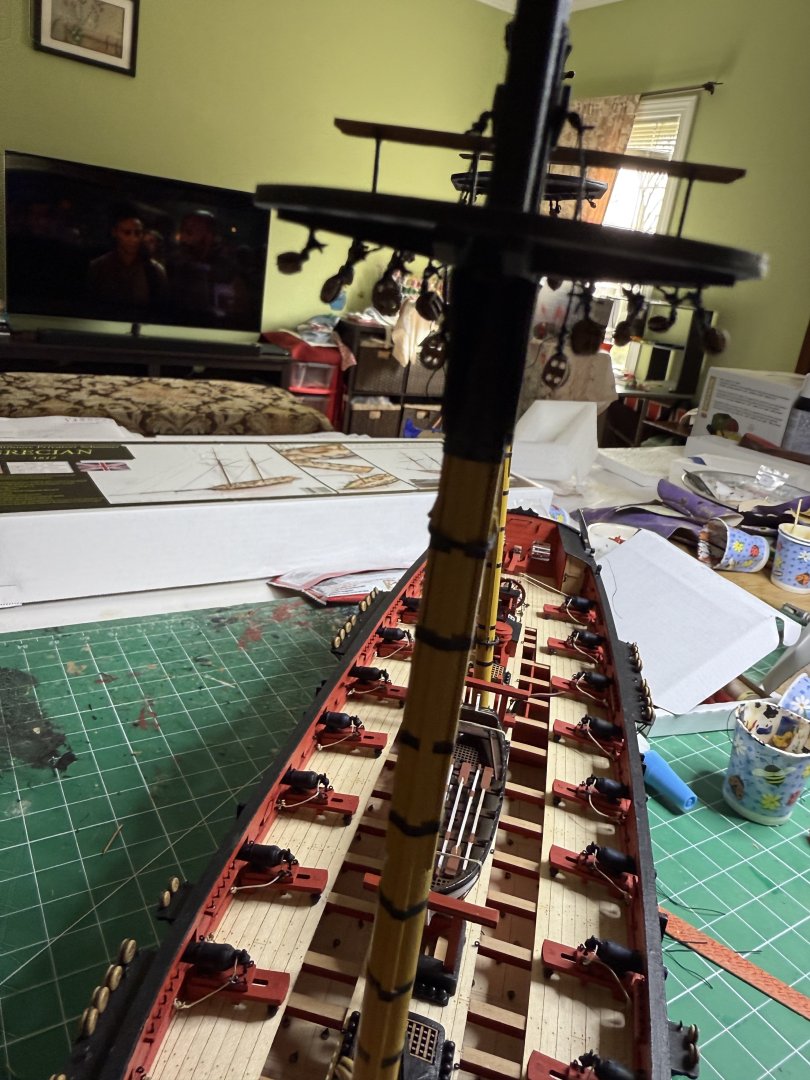

I prefer to attach the yards to the masts first as there is more room to maneuver. Next job will be the shrouds

- 73 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

You can also paint the below the waterline white as many of the other Vanguard models, pre-copper so to speak.

- 241 replies

-

- Vanguarrd Models

- Harpy

-

(and 1 more)

Tagged with:

-

I painted the hull copper before plating. The plates stuck pretty well with the cyano after.

- 241 replies

-

- Vanguarrd Models

- Harpy

-

(and 1 more)

Tagged with:

-

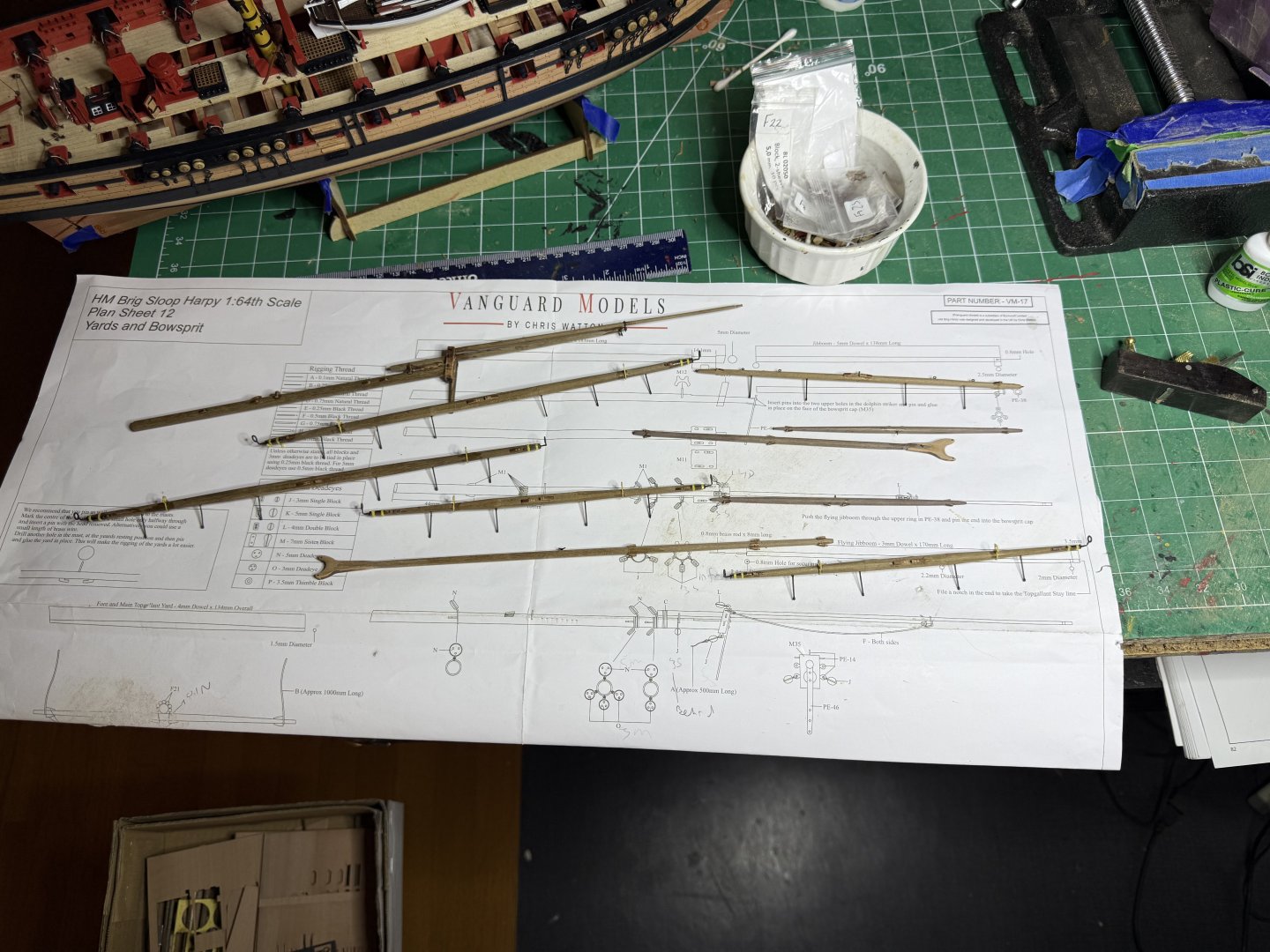

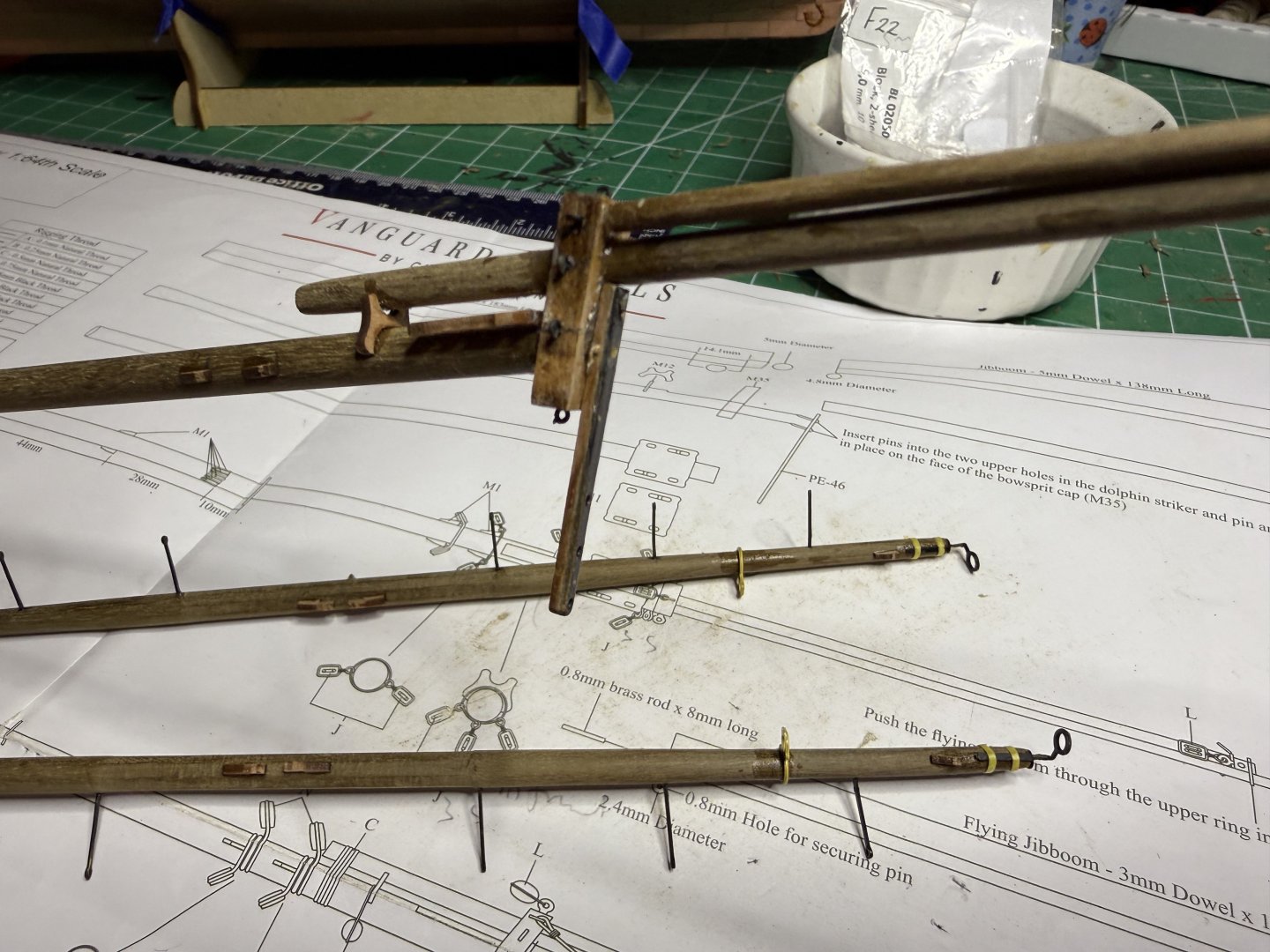

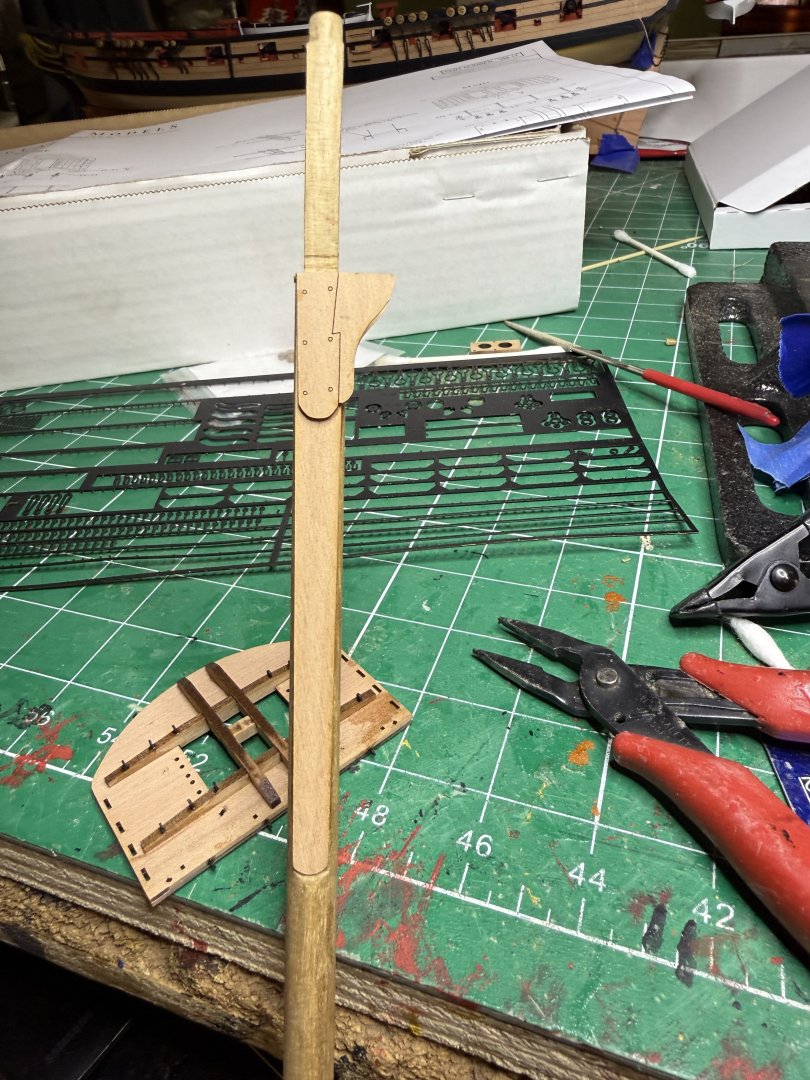

Finished attaching the various blocks to the yards. Here they re temporarily pinnegn to the masts. Next is rigging the spritsail then i will mount the yards to the masts properly before starting on the shrouds.

- 73 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

- 73 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

- 73 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

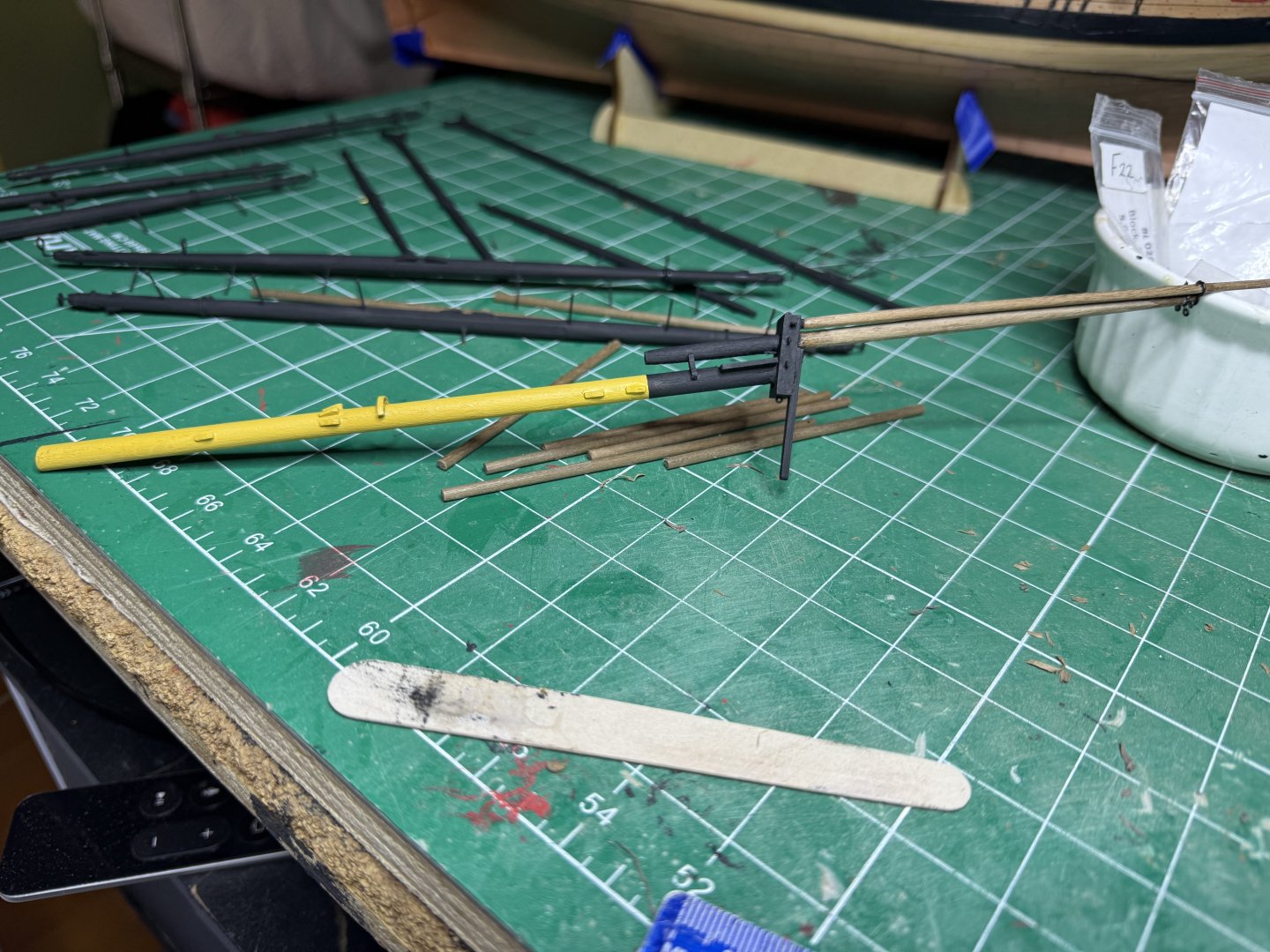

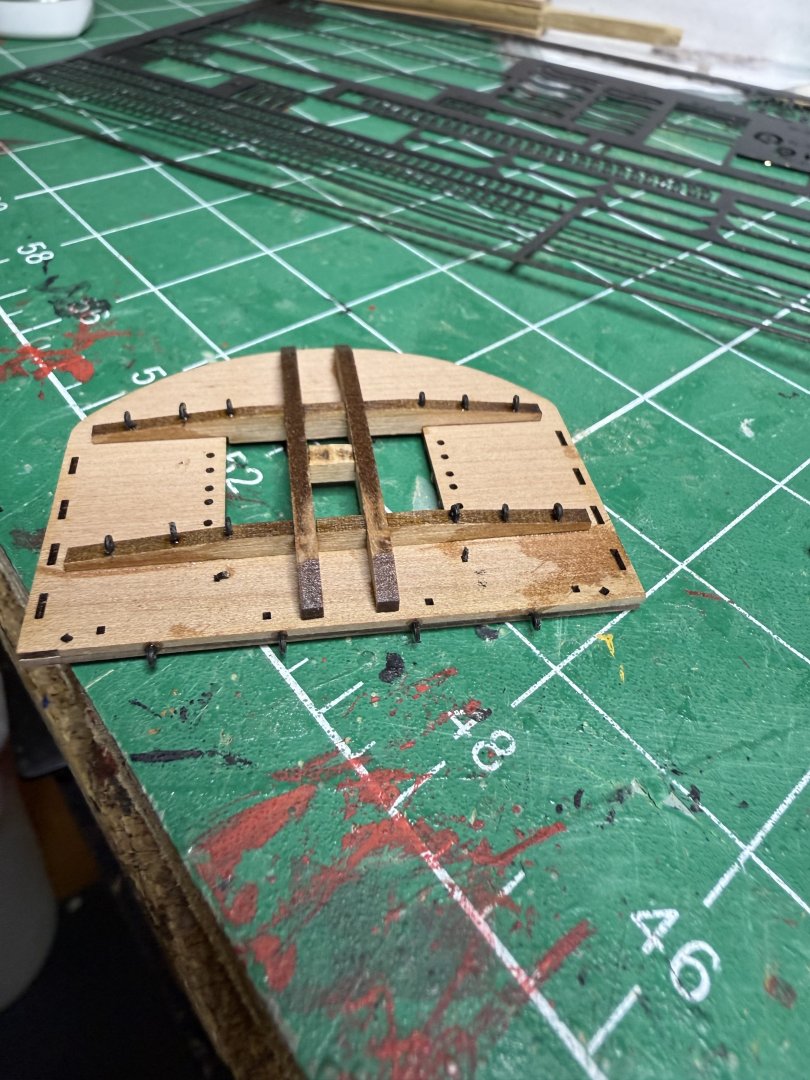

Pent my time today making the t'gallant and topmast yards. I prefer using tape over the cardboard as all will be painted black and stick together better. Also added pin to help attaching later to the mast.

- 73 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Well done ! It is a good way to clear the mind

- 241 replies

-

- Vanguarrd Models

- Harpy

-

(and 1 more)

Tagged with:

-

- 73 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

- 73 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Very nice. Only issue is given the wood nature of the pintles. I banged it and broke the rudder off resulting in my gluing the rudder back on and taping it until the end to prevent another bump and brake

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

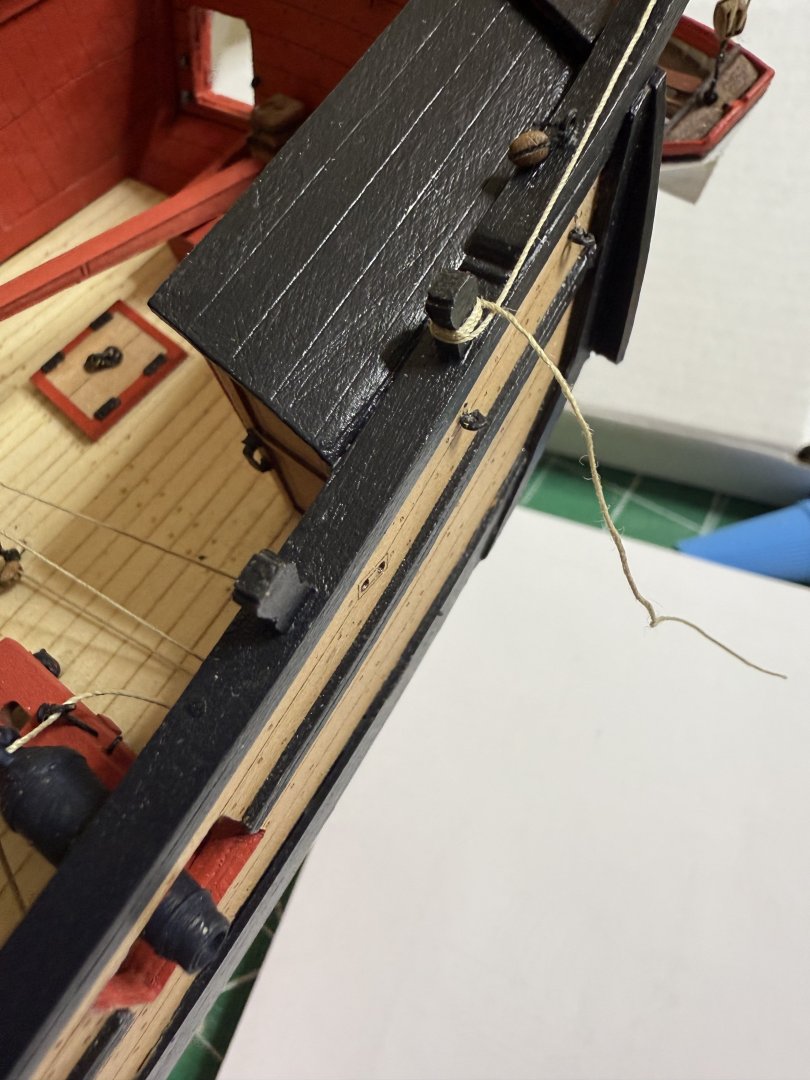

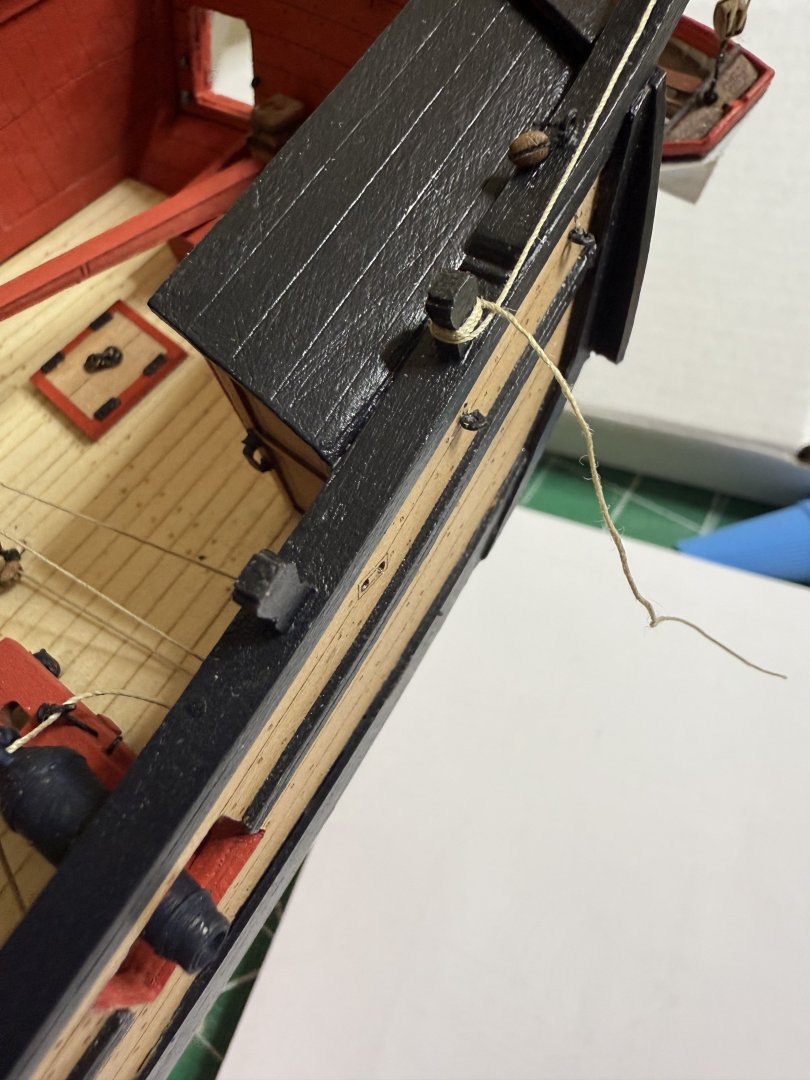

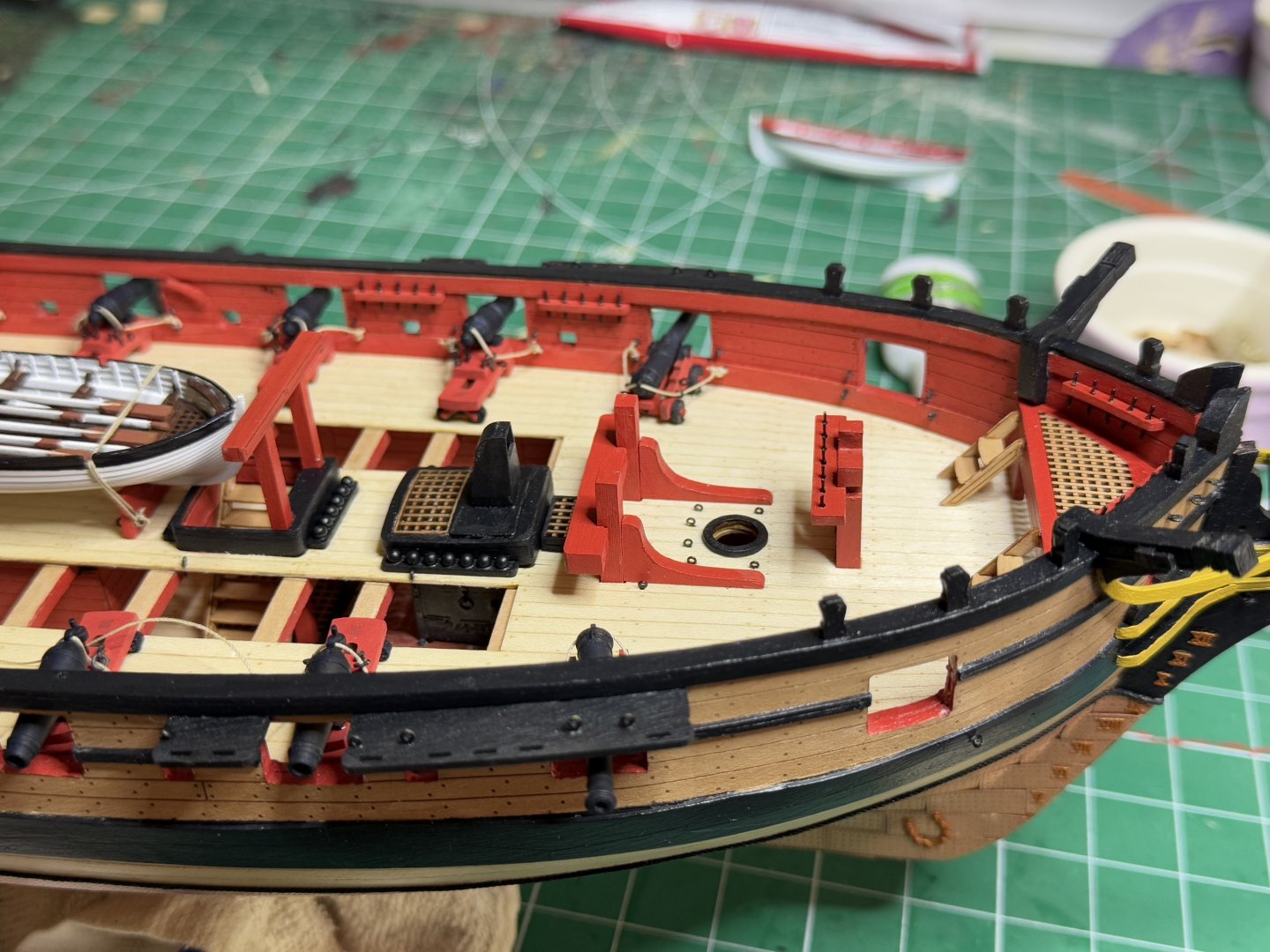

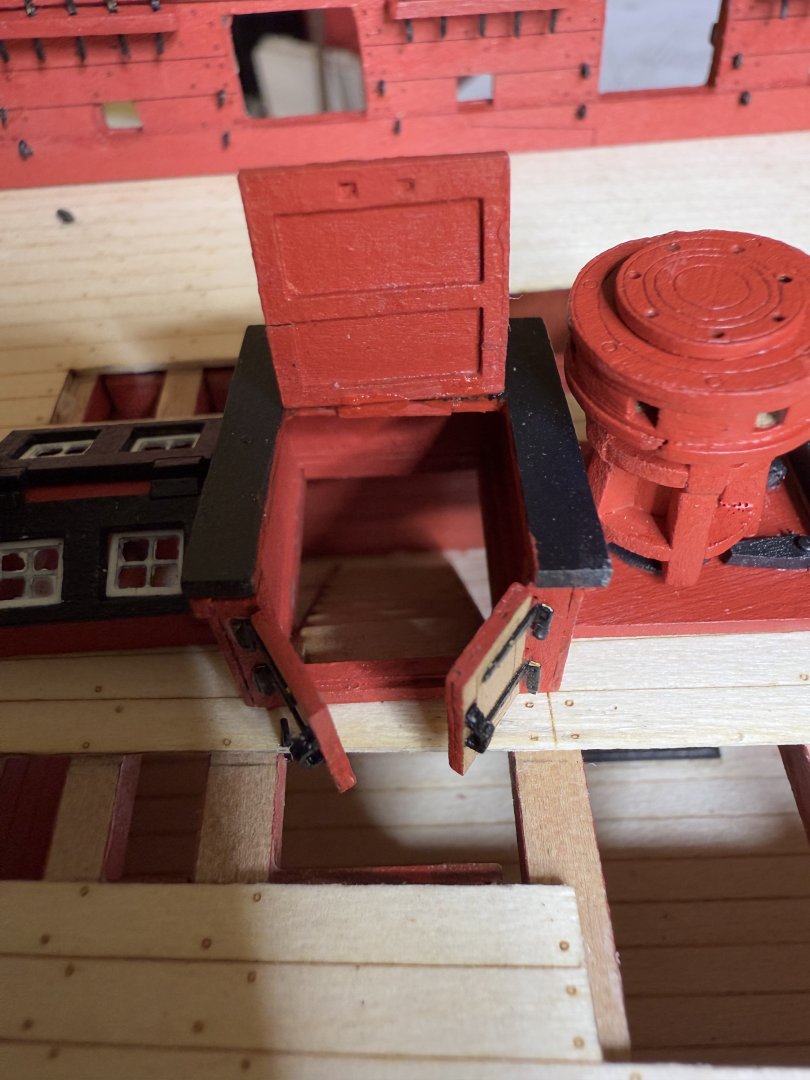

I replied to Blue Ensign about the issue. I sanded back the edge of the roof and lowered the angle a bit of bulwark a bit as the davits take up the whole width of the capping rail.

- 241 replies

-

- Vanguarrd Models

- Harpy

-

(and 1 more)

Tagged with:

-

I actually sanded the roof edge back and also sanded down the bulwark down as the davits later take up the whole width of the capprail. See below

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

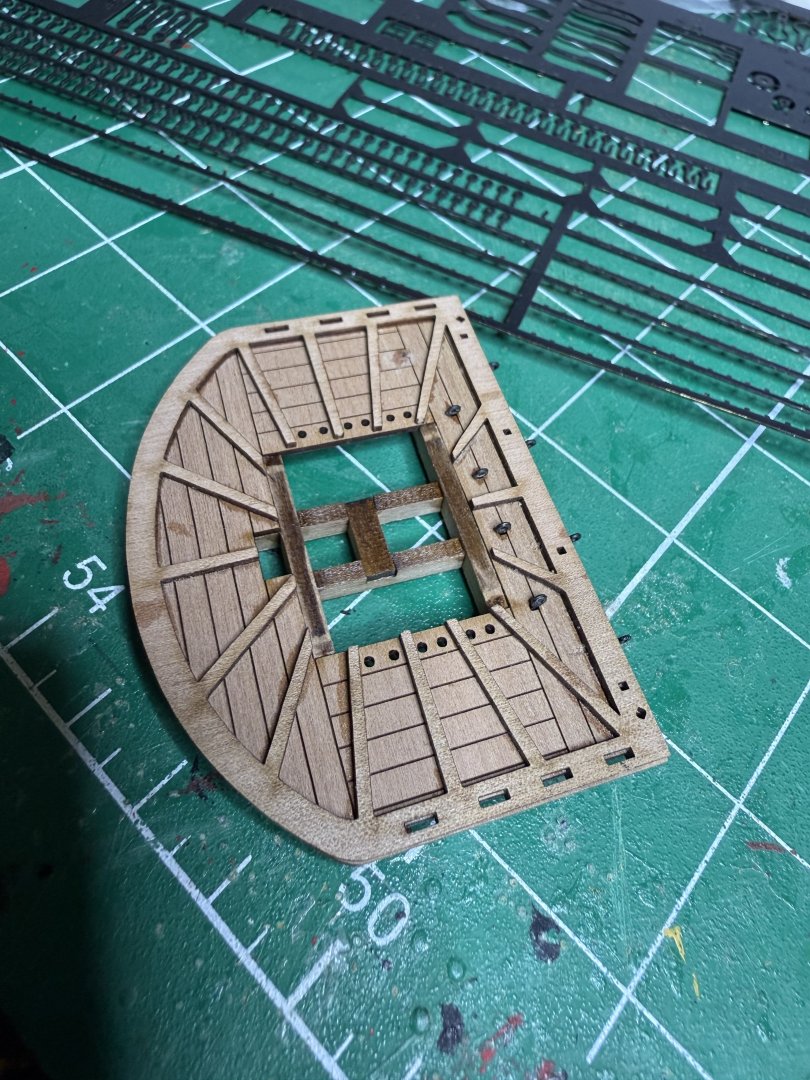

Thanks! They are included if you want to mount them on the stern. There also 2 stairs not mentioned in the instructions but in the kit to go from the deck to the rails where the battons for boarding on the side are. As they cover a cleat, will add them later once I tie off rigging to the cleat.

- 73 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

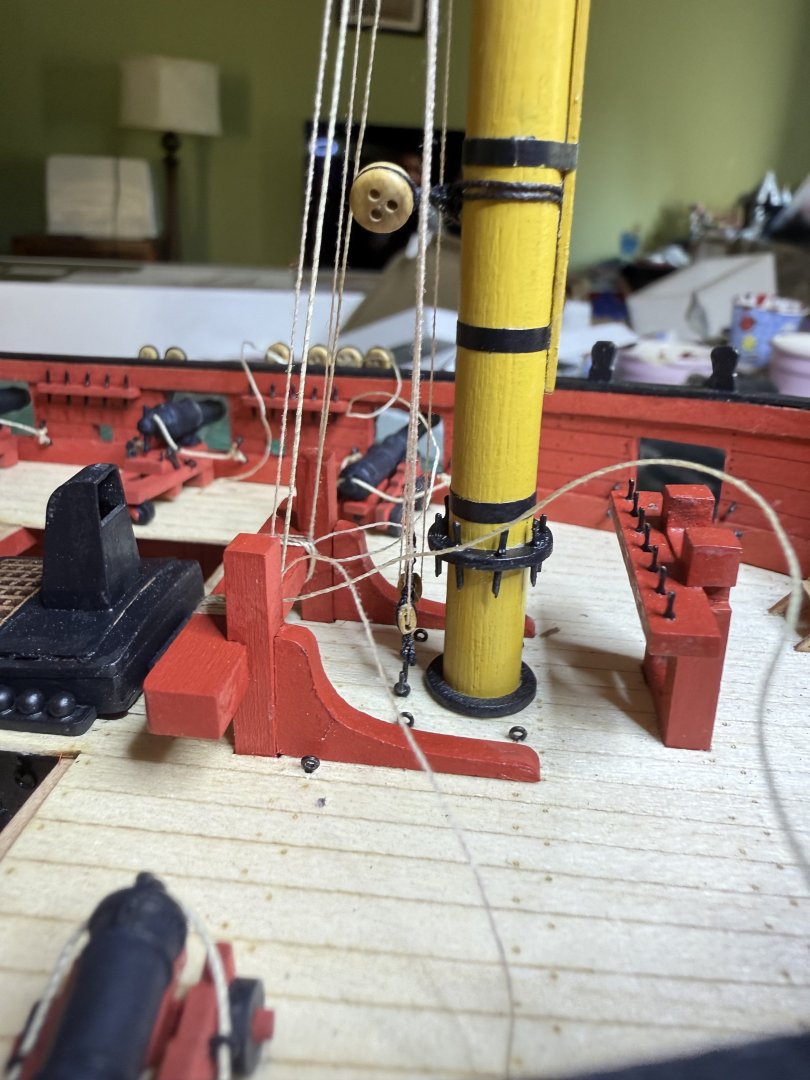

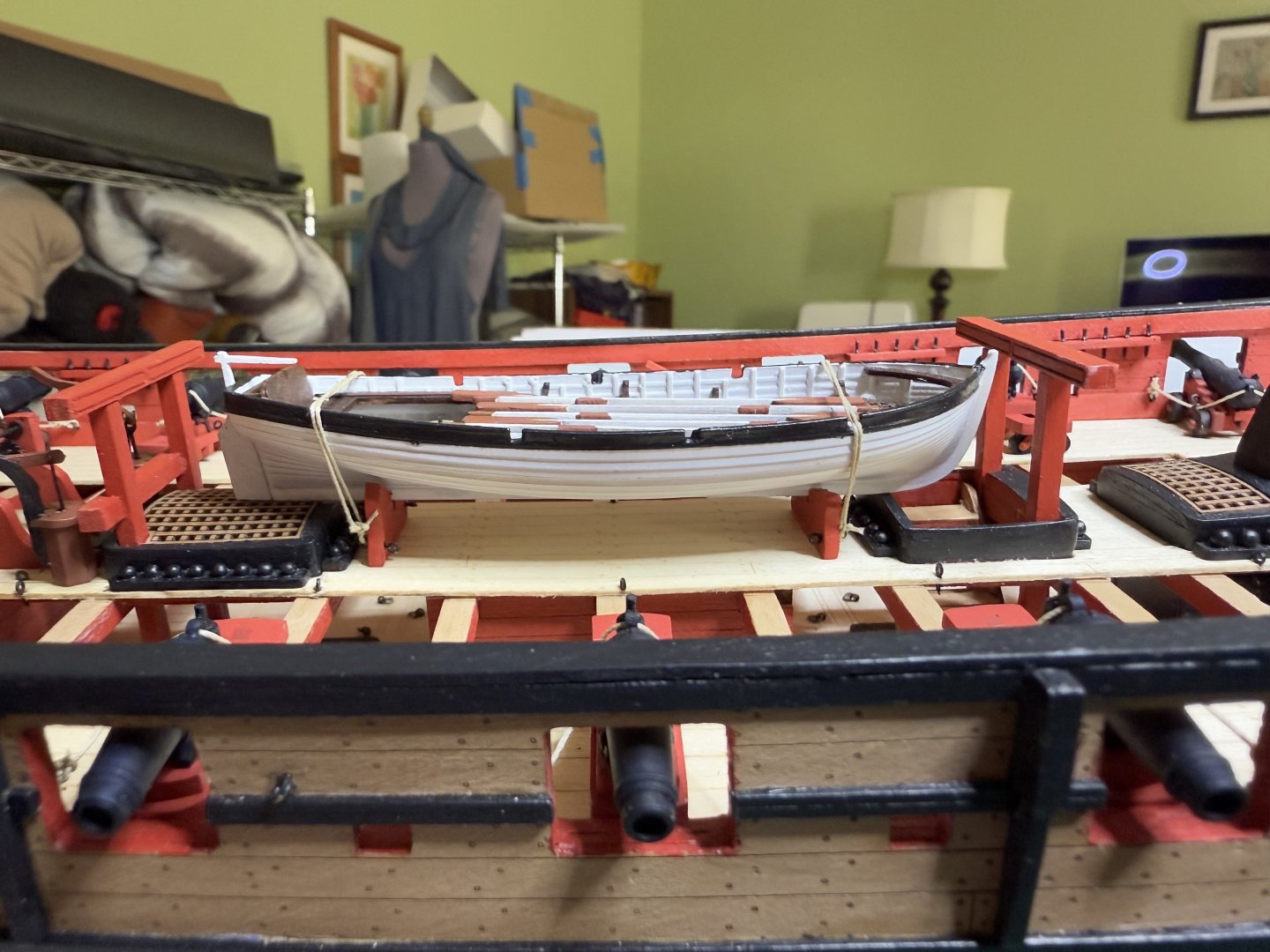

So the hull is pretty well done. Few things I will add at the end as I usually break anything sticking out while I do the masts/yards/rigging. May not get much work done this weekend being on call. Fitted the 18ft cutter to the stern davits.

- 73 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

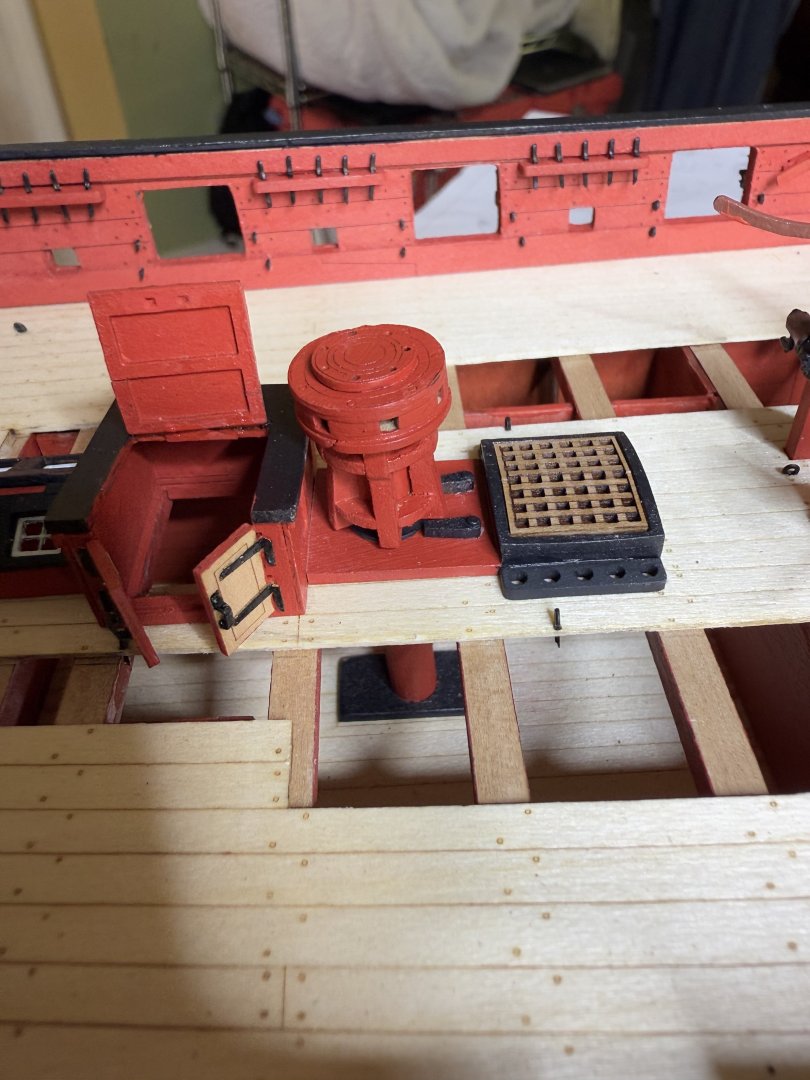

Take heart. I had to sand down quite a bit . There is a small gap but not easily seen unless you look real close. The sides of the cabin needed quite a bit of sanding to fit. Initially looked a lot like yours. See below at the lines of the edges, so I chose option C

- 241 replies

-

- Vanguarrd Models

- Harpy

-

(and 1 more)

Tagged with:

-

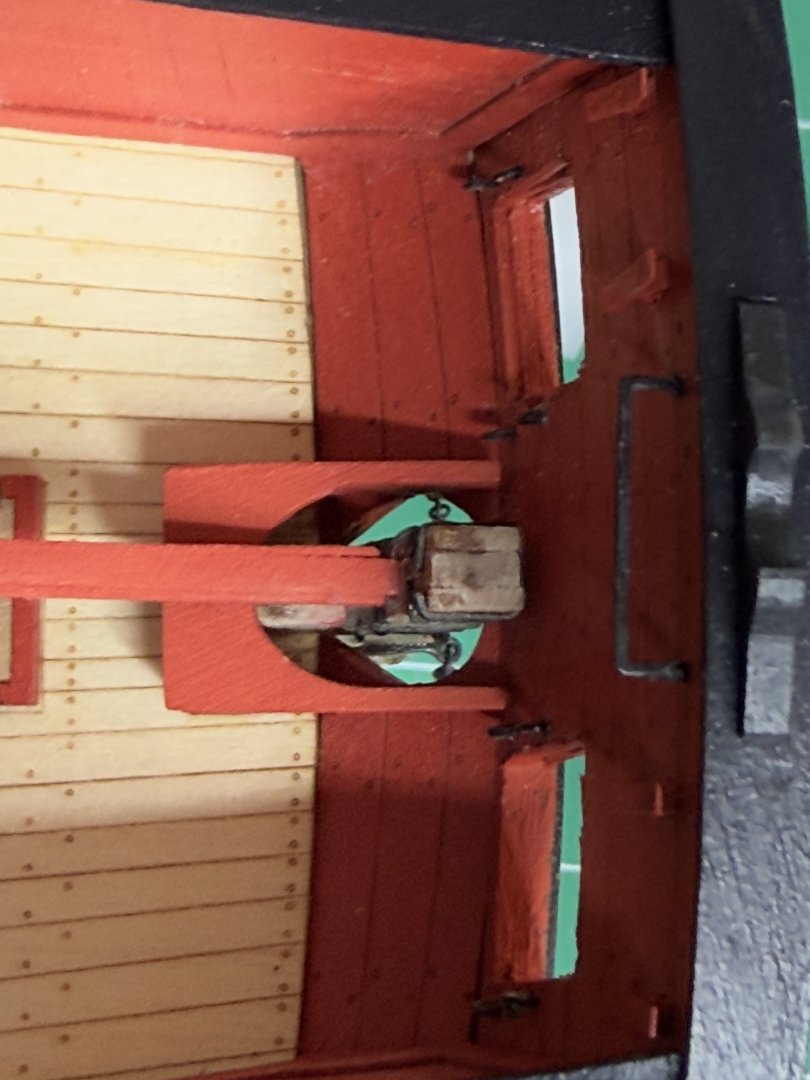

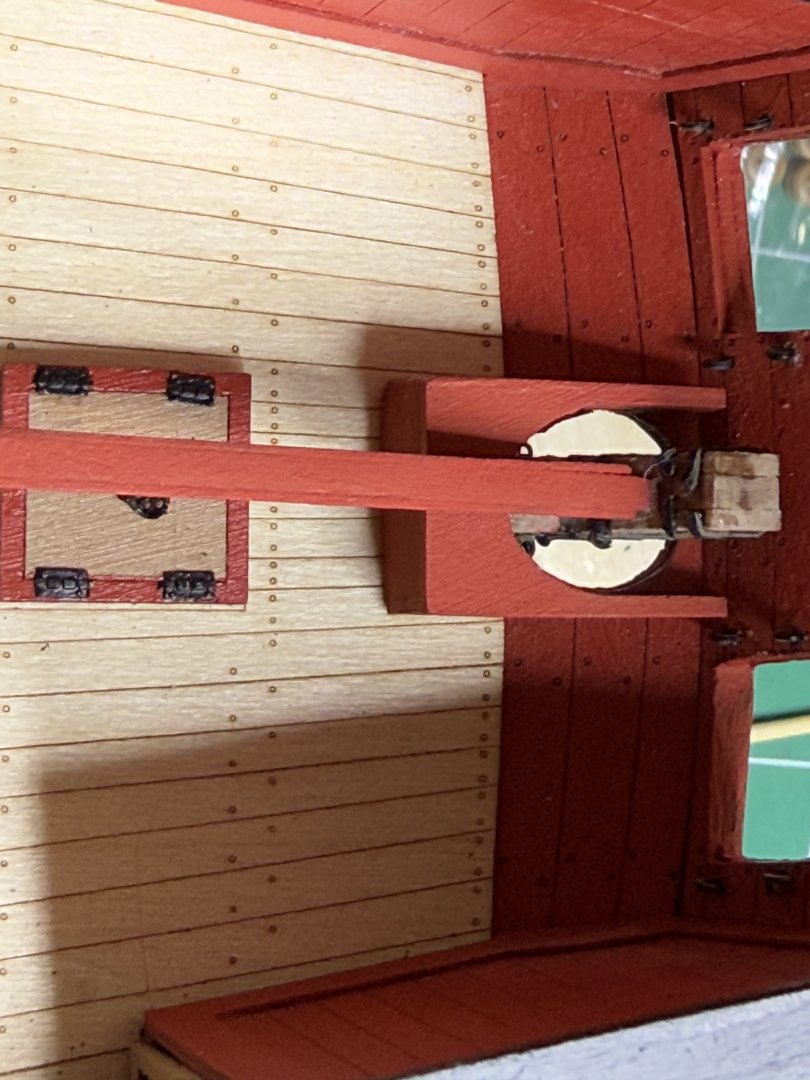

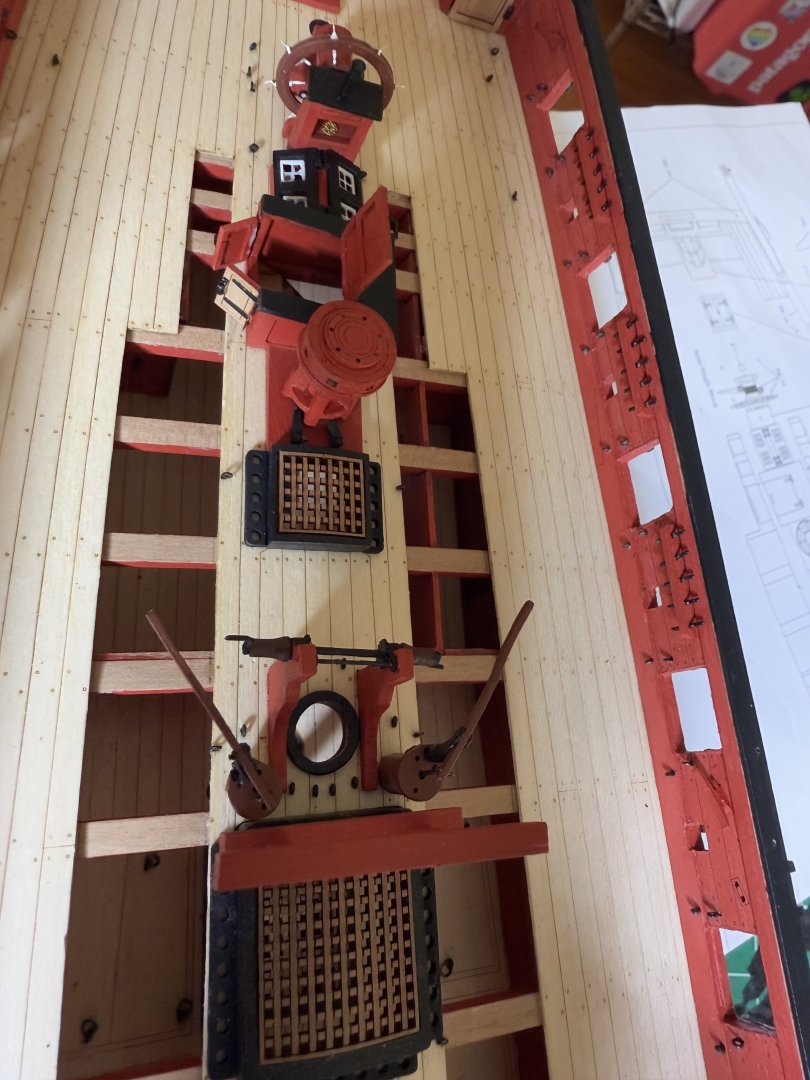

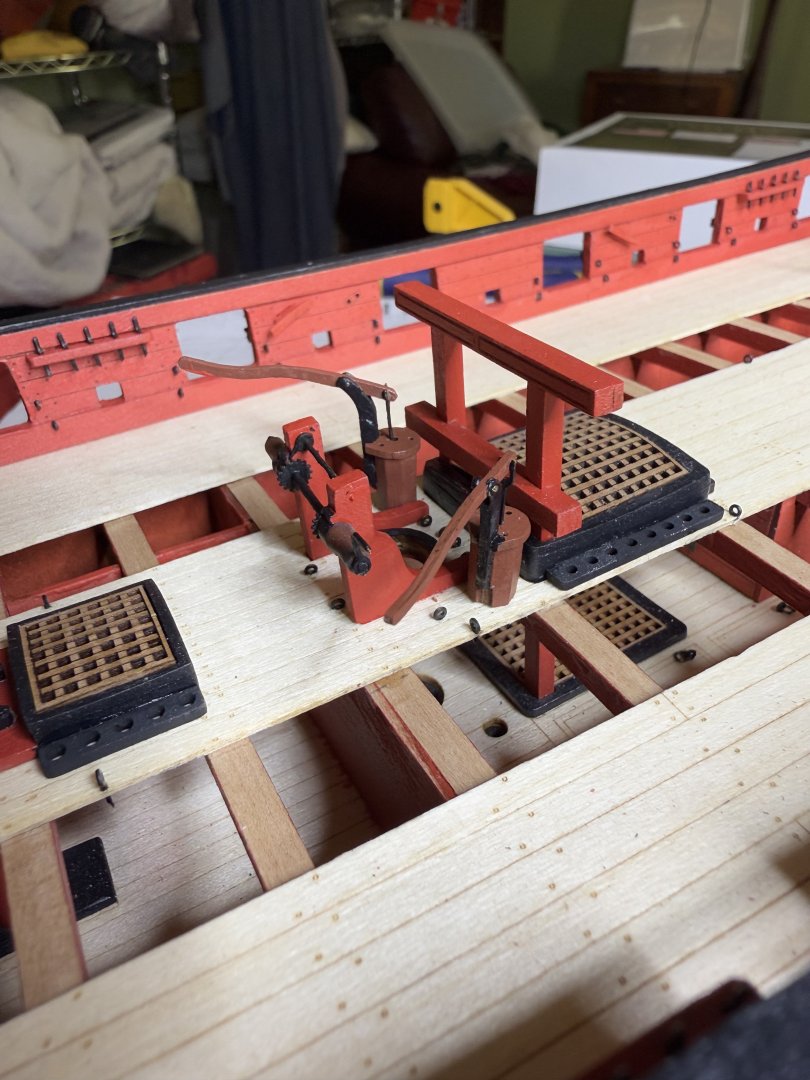

Finished the steering gear, guns, rudder chains and ships boat. Next is installing the deadeyes and putting the second ship's boat on the stern davits. Admiral Cochrane paid a visit.

- 73 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks! I am jealous of your skill set as not sure I would have the patience to your more historically accurate approach to ship building. Your skill set is amazing and certainly gave me good ideas during the build so far. Your and Glenn UK planking skills definitely much better although for the next one I will try and incorporate some of your tricks of the trade

- 73 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

- 73 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.