-

Posts

216 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rudybob

-

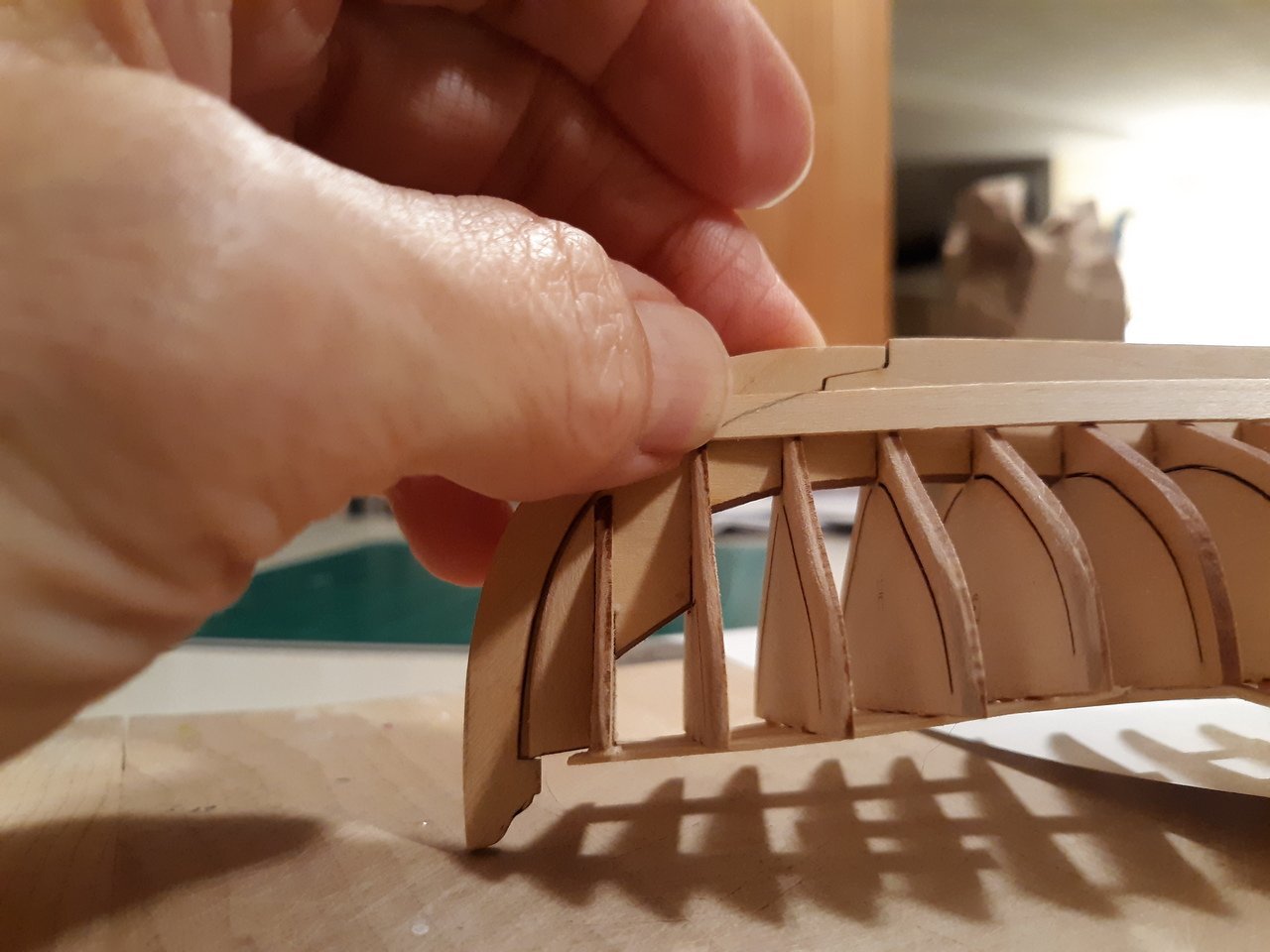

We may very well have. I don't remember which is part of my issue. I don't retain things as well as I would like. Nothing for it at this point. I took your advice this time and bought two clamps like in your photo. I should have bought three. I didn't think I had to worry about bending the second strake. I see that I do. I learned. My next chore and don't laugh to hard was figuring which way to bend it. Also, what point on the strake I begin the bend and how much bend to put in it. Through trial and error, error and error I bent it the right way and what now appears the correct amount. Thank You so much for your advice and patience.

-

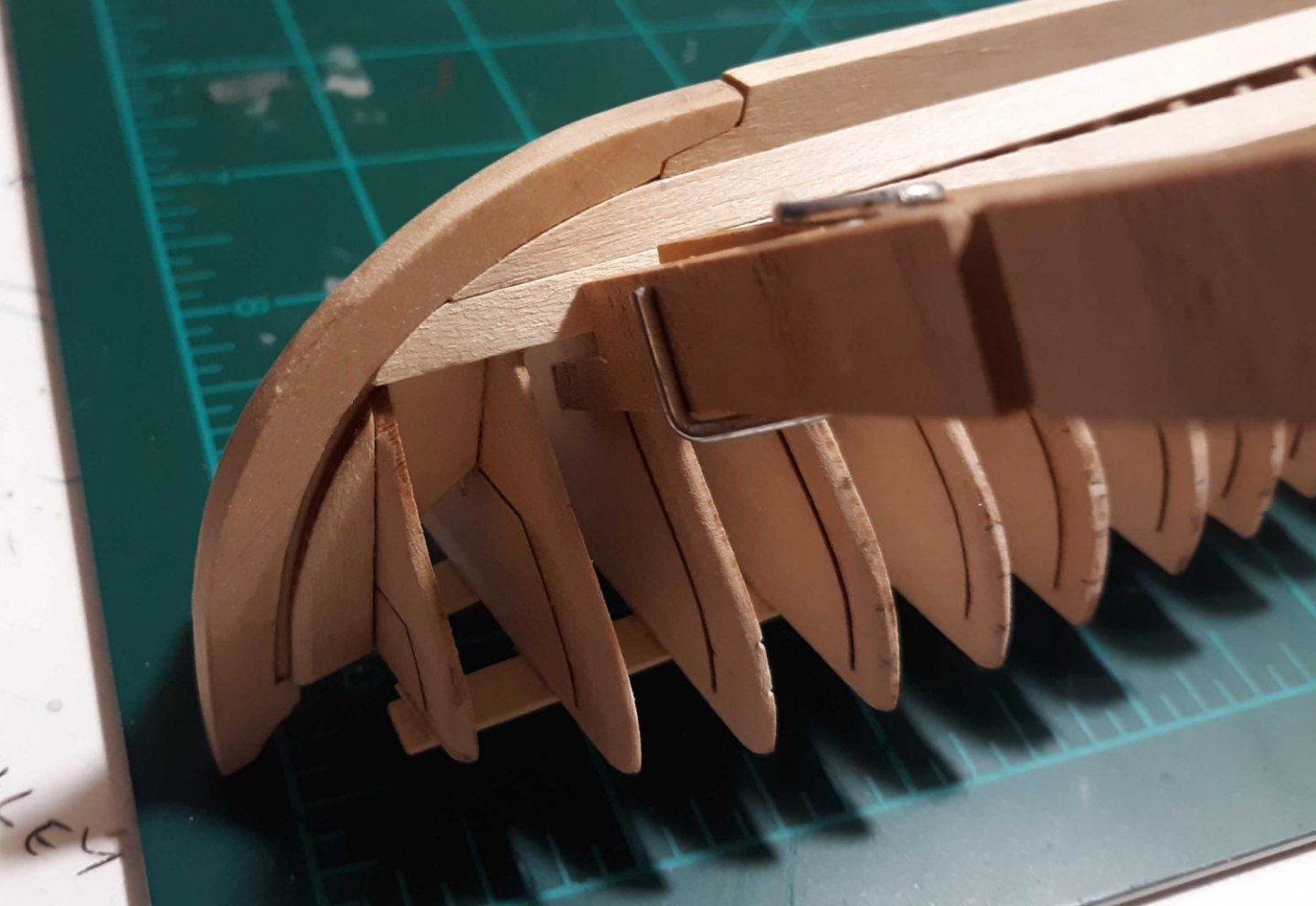

The garboard is installed on both sides. I am fitting the next plank up. In the series of pictures my problem is evident. I cut the front of the strake from the plans using my logic, LOL. It fits rather nice but the strake will not butt against the garboard without it being raised (it's raised more than the picture shows) as seen in picture four. That is either because I need to fair the bulkhead more (I do) but that doesn't mean it's my sole issue. If I don't fit the front of strake two into the rabbet it will lie flat and butt against the garboard nicely. I have done a lot of sanding, filing, scraping and bending in many directions. The problem has been decreased but not eliminated. At this point I don't know which I should be concentrating on. The problem may very well have arisen from my previous shoddy work and not some cut I just made. If more bending is called for fine if more fairing is called for fine. I just don't know which. What would you recommend I do at this point? Besides get out the matches :-) Thanks Pictures 1 and 2 go together as do 3 and 4

-

Two strakes of planking. I have been dry fitting two stakes on top each side and one at the garboard both sides and the one above the garboard strake. I move back and forth which may not be good practice. I do it because I don't want to overdue anyone piece which I have found is a shortcoming of mine. If I leave something for a day and come back to it I can see it in a different light and realize something like...no more off here, it needs to come off here. I have found that a problem may not be originating from where I think it is. For example: the plank doesn't need to be any thinner that groove it is going into needs to be deeper. I can also be really unclear when asking questions even with a proofread. I have been keeping bottom strakes as straight as I can so they don't ride up the stem. I hope I answered your question. And thanks for asking

-

Thanks for the in situ heat and water tip. When I thought of it, since it was my idea, I thought it goofy. Now that I see you doing it I tried it and it helps.

- 77 replies

-

- model shipways

- pinnace

-

(and 1 more)

Tagged with:

-

My problem at this time is making the clips we all see in the posts. They are easy to put together the problem is making them so they work for me on this model. Mine are too loose. I have thought all along and still believe I can final attach the planks with CA and holding but I would rather not. The clips would also serve for dry fitting each plank as accurately as possible . I could see where additions and subtractions to the bulkhead will be needed. If any of you Mavens can send some clues my way regarding clip production and usage that would speed me along. Thanks. More Info: I have not achieved a tight fit using two different brands of clips. I am using the smallest I can find I also have larger ones and my one attempt (with what I would call a midsize) was not satisfactory.

-

I was looking at the parts list. There are six 1/32 x 3/16 x14 " planks and thirty four of the 1/32 x 3/16 x 12". Did you use the 14" for your first strake? Also, in some of your pics I see some CA glue. Which of those did you use to attach the planks. Are you glad you used that one or would another have been preferable now that your done. Thanks

- 123 replies

-

- Model Shipways

- Pinnace

-

(and 1 more)

Tagged with:

-

Forming a garboard

rudybob replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

-

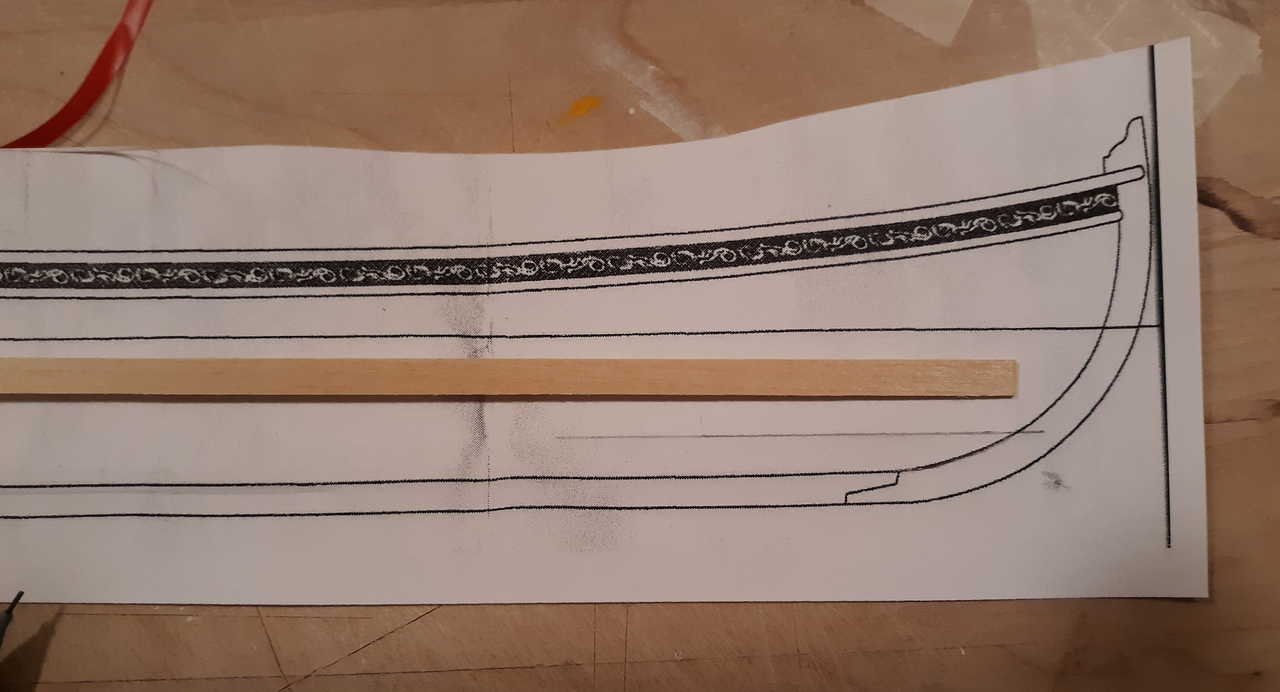

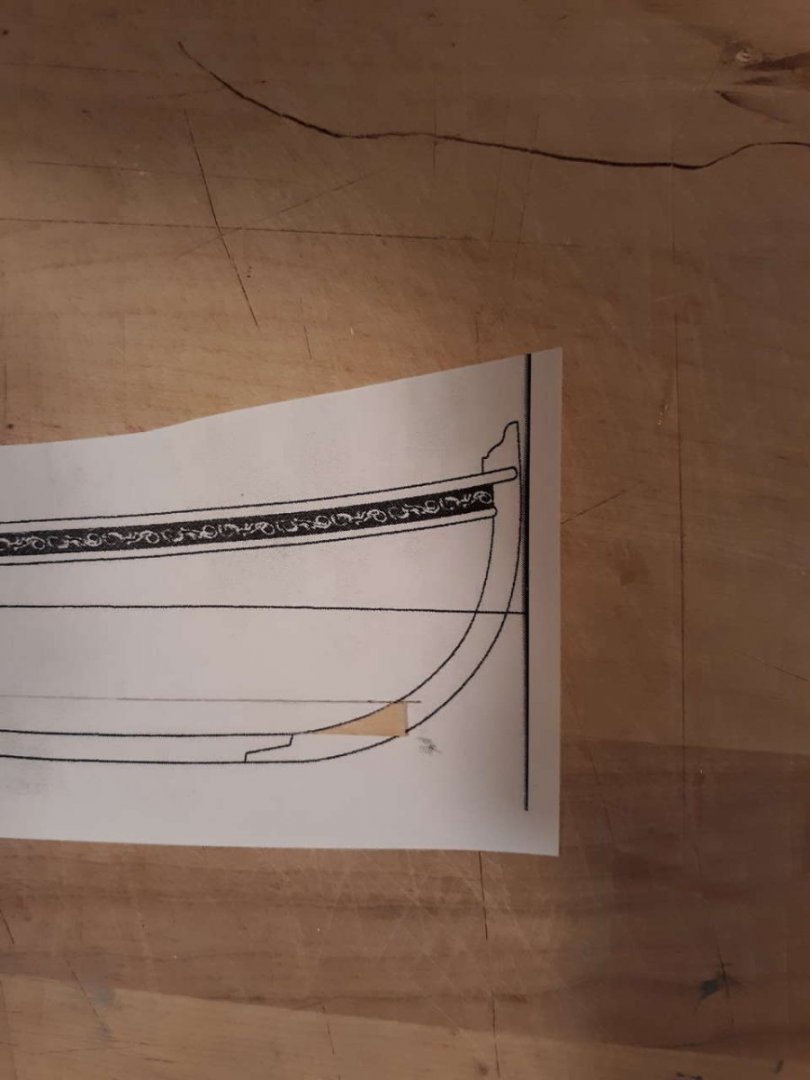

I am building the Model Shipways Pinnace. There is a log at this site but I wanted to ask the question here. The garboard (along with most else) has been vexing me. Today while looking at the plan sheet I thought maybe this would work to give me as good a garboard as possible. I laid a strake on the plan and traced (2D I know) how it would lie on the model. I then xatco cut the line where it would attach and slipped the strake through the back. I have an instant and pretty exact angle which makes my life easier. I realize there will be some twist in the garboard but can't see any reason this isn't a good idea. OF COURSE, I have had plenty a good ideas. LOL. So I wished to ask the group where I am going wrong. Thanks

-

On this model I promised myself I would work on it daily if at all possible. One day off can turn into a week far to easy then I forget what I had been thinking and planning. A few days back I was looking at the included directions and I saw one of the strakes bent around a bottle cap. I grabbed a Vernor's bottle cap and it matched the bow curve pretty well. I held that cap up to the plans and marked that cap in a matching arc. It fits pretty well. Good tip there. At least for the top strake the length and bend can be taken directly from the plans. I scanned the sheet and now have something I can cut and from the cut picture I can make a jig to get my top strake bends as accurate as I can. Everything flows from the initial build and since I have done such a poor job to this point I want my top strakes as accurate as possible. I will spend the time to see if my scheme bears results. I don't like wasting time and this may end up as wasted time but I won't know that until I try. Time to watch hockey and eat brownies

-

Hello. Doing a build log requires time which I have. I don't know about my skill level at writing or building except to write it isn't there yet, if ever. I do enjoy both and and want to advance my abilities with each project, whatever media. I did a build log on an airplane once and I found it wanting at the end. I will do better here.

-

Looks like an informative place. Great Just Great

rudybob replied to rudybob's topic in New member Introductions

I like the log idea. I am looking into it -

Gotta tell ya Man. Your build is great but what I really appreciate is your presentation. You are clear and concise. I am working on the same kit and you have answered the questions I had that I was having difficulty finding. I am getting ready to plank. I took your advice and am glueing in extra wood between the frames to stop flexing. Did you ever apply CA to damp wood during your build?

- 123 replies

-

- Model Shipways

- Pinnace

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.