-

Posts

692 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NavyShooter

-

I added some additional detail to the mast this evening. Various yardarms, antenna supports, etc. Looked good - but I could still see some tiny hairs from the filament printing process...so...I took someone's advise and grabbed a torch to quickly singe them away and make 'em go away. That worked well...until I noticed that the heat of the torch had also caused some of the yardarms and antenna supports to droop. So. The next version is headed to the printer over the next couple of days....I've got a few print jobs that are already in the queue.

-

Visited the Halifax Waterfront this afternoon with the family (in a non-RC boat) and snapped a picture of the Sackville as we passed by.

- 460 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

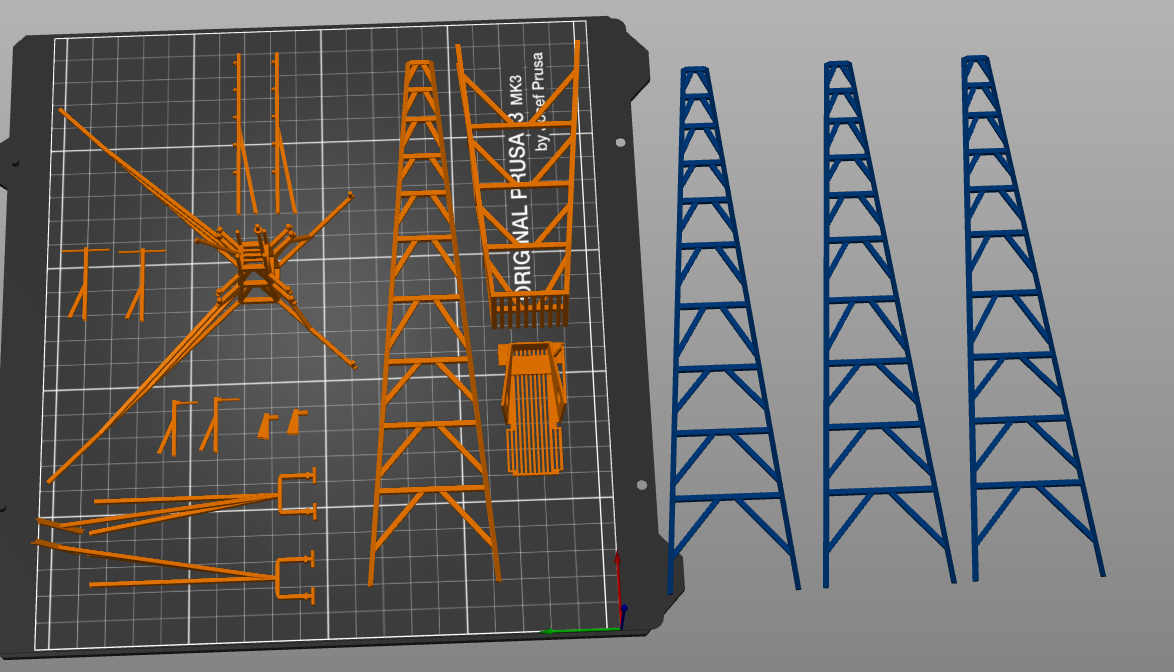

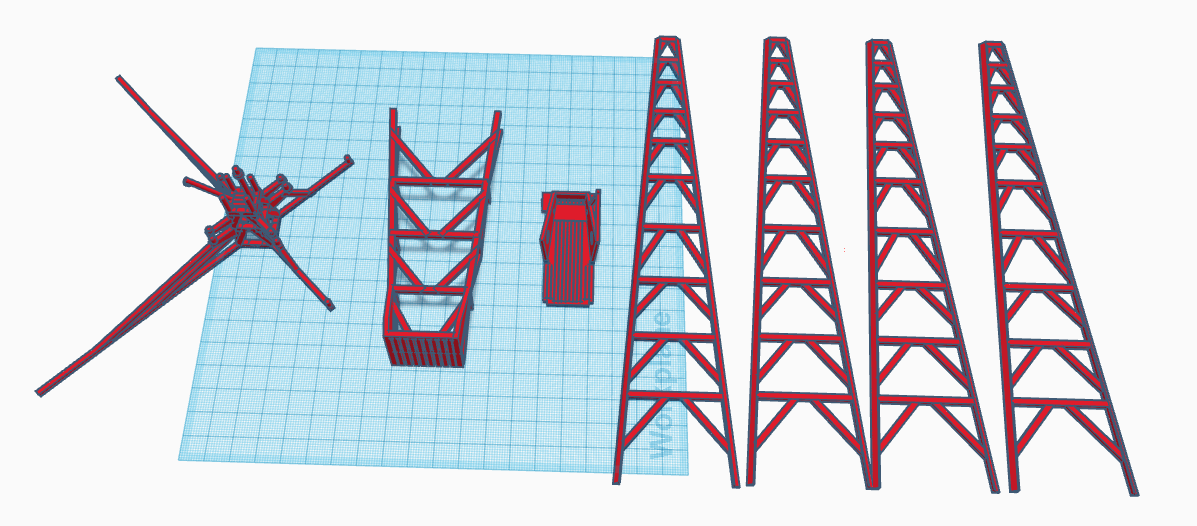

As a slow-time background activity, I've been puttering away at the 3D design of the main mast. It's most definitely still a work in progress, but I'm adding bits of detail slowly. Here's what it looks like right now. (Of note, at this point, I'm planning to chop off the top 3 sections and replace with the piece on the left that will simply glue straight on top.) There' still a bunch of work to do and add detail at the lower levels, but it's getting there. On the right we have the 'solid frame' that will be glued together. The small platform is for the SPS-10 Radar and sits at Level 6, and the large frame section in the middle goes between the main mast and the funnel, attached to the rear of the mast. I think I have to print this and assemble it to see what detail gets added next.

-

One of the running jokes we had in the Navy was that any ship can be a minesweeper. Once. Of note, my thanks for the earlier demo on how to make port holes higher up in the thread. I'm ordering some of the Canopy glue now and will see if I can use it to make windows for my HMCS Bonaventure aircraft carrier island.

- 88 replies

-

- Australia II

- Finished

-

(and 2 more)

Tagged with:

-

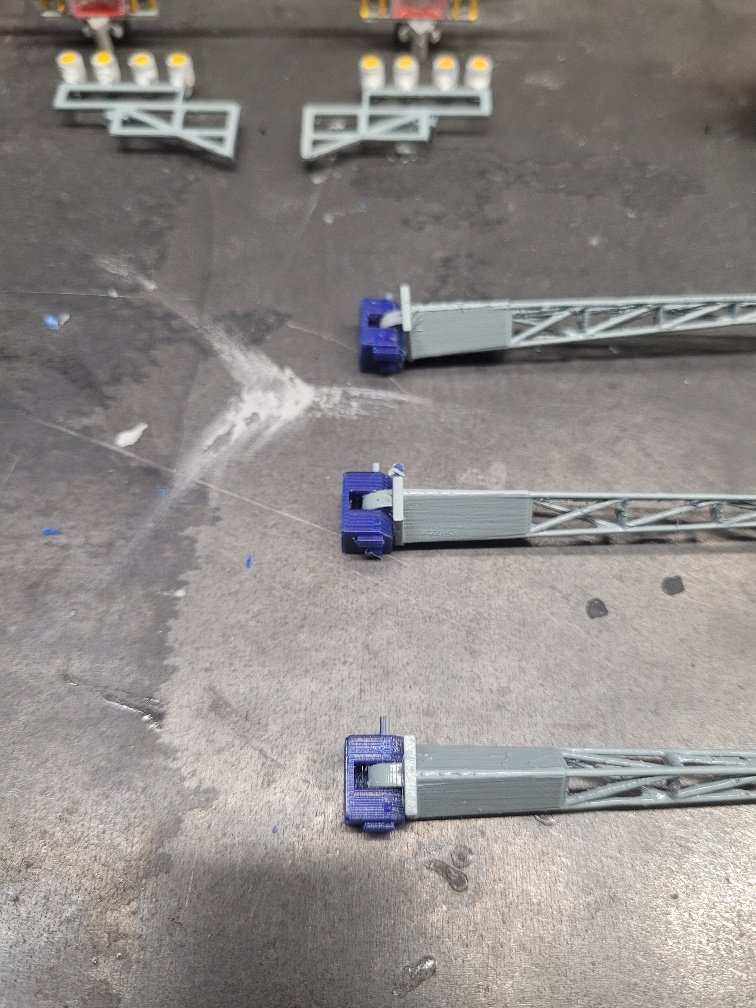

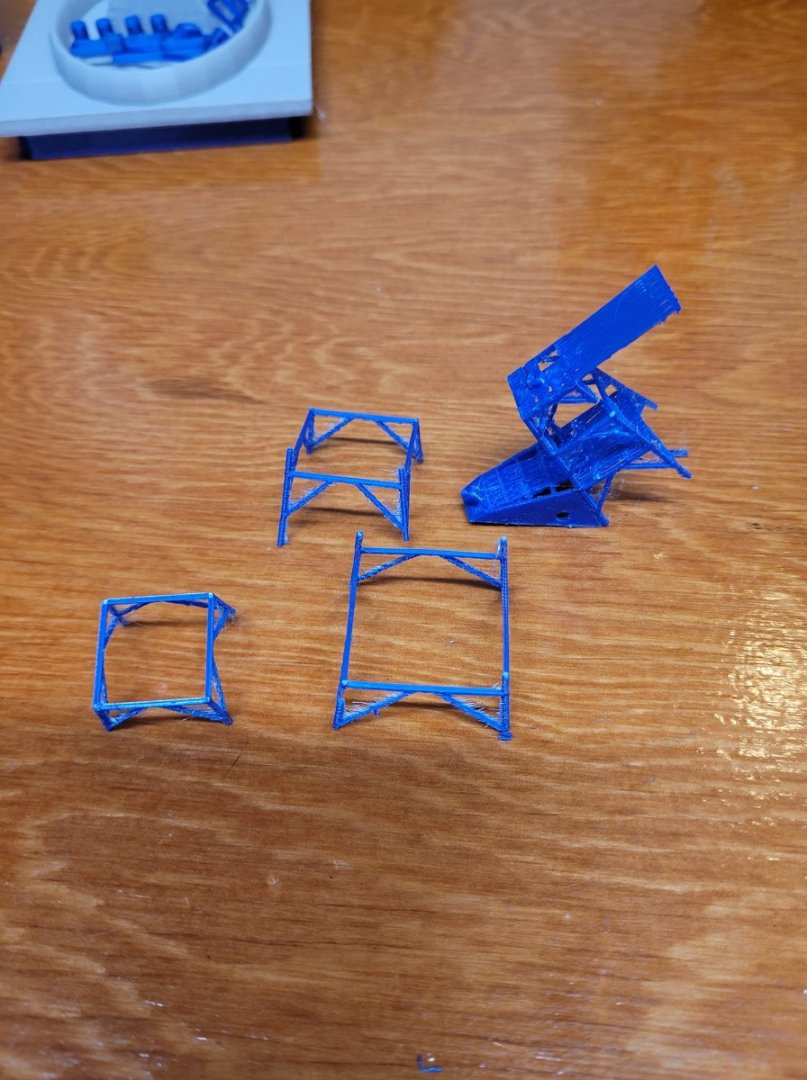

OK, so version 2 doesn't look very good even with a layer of paint on it...so we're on to version 3. For this one, I sliced the model up so that it could be printed and assembled. I'm much more pleased with the results. No cleaning off parts, no whisps of plastic, no support material to remove. It's got a layer of paint on it...more pictures another day!

-

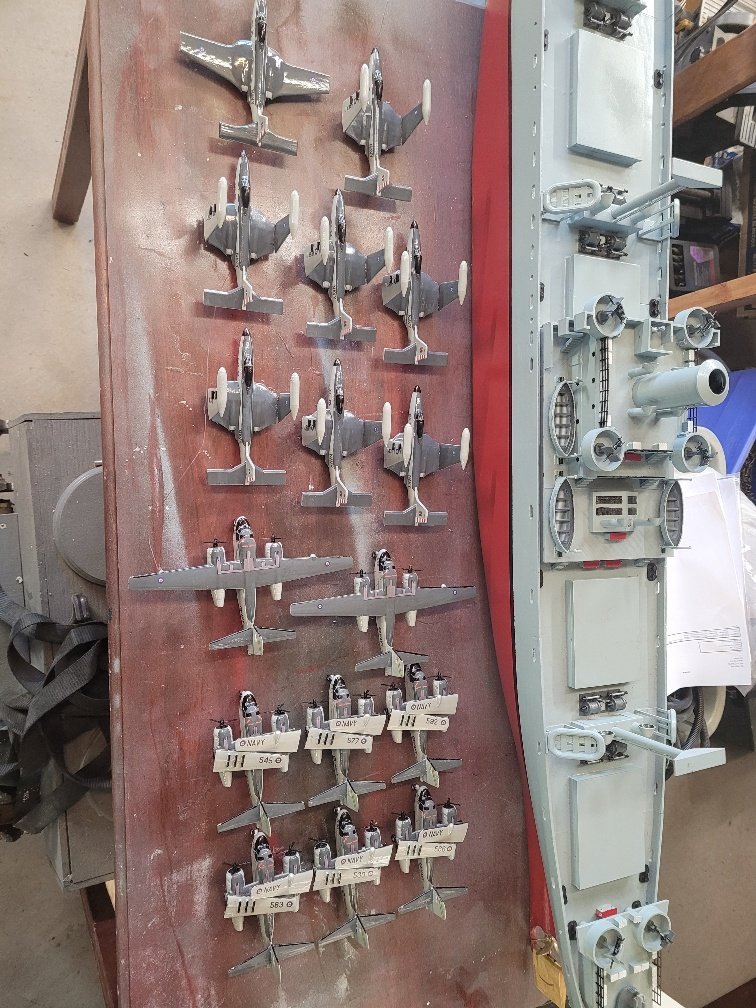

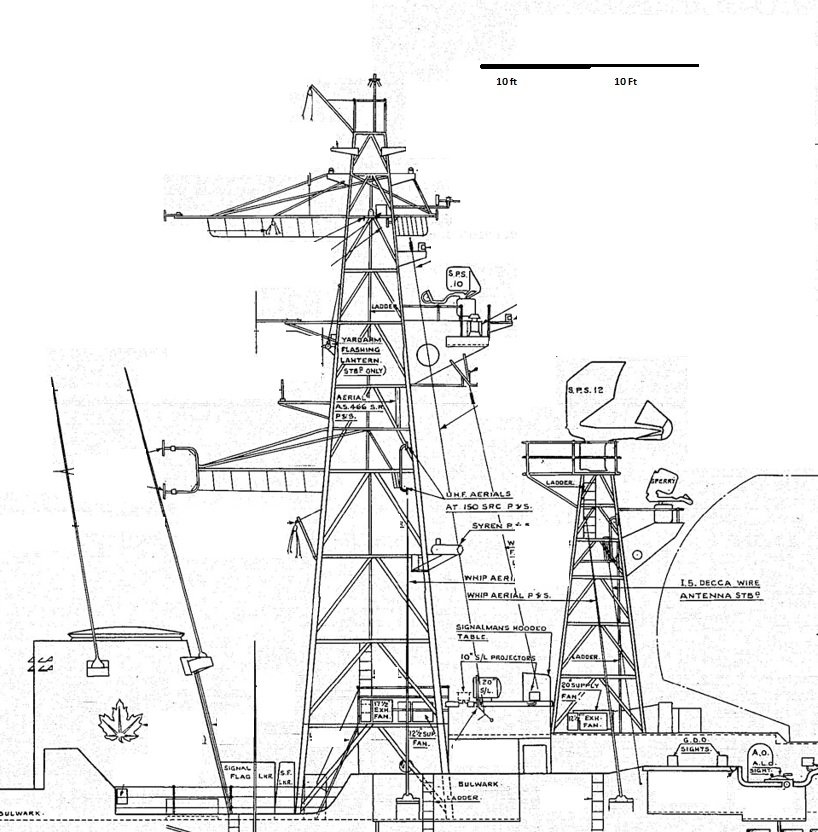

So...more progress...we have 2 Trackers with decals complete now. It's taking about an hour and a half per aircraft to do the decals. There's about 25 per plane to apply. It's...challenging...but rewarding when they're done. I got a layer of paint on the hockey sticks and the HF/DF antenna last evening, and retreated into the A/C for the night. Today, I had some time so I got some 3D work done on the RADAR mast on top of the island. I had previously attempted to use DSM to create the main mast, and that attempt failed rather miserably. So...today...I tried the 'simple' Tinkercad program and had some good success. Here's the plan view I worked from, and the 3D result ready to head to my printer tonight. We'll see how it goes.

-

New bases are on the printer now...we'll see how it goes. I've also spent an hour or so doing up the design for this antenna (circled in red) I took the base for the 'hockey stick' antenna, squished it down by about 15% in height, then built the 'funky' diamond bit based on a couple of other drawings I found. Had my Liberty Ship out on the lake for a bit this afternoon as well - problem with taking it out on nice days on the weekend...folks in big boats are out having fun too...and my little bateau doesn't have enough freeboard to last well in waves that big!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.