-

Posts

502 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SiriusVoyager

-

Hello and thank you for having me

SiriusVoyager replied to Danny_CZ's topic in New member Introductions

Welcome to MSW! -

My introduction on Model Ship World

SiriusVoyager replied to ANDY GRAY's topic in New member Introductions

Welcome to MSW! -

I have seen some of their videos on YouTube. I'm looking forward to seeing how this comes out.

- 19 replies

-

- Fischkutter

- Laser Creation World

-

(and 1 more)

Tagged with:

-

The latest to begin the Model Shipways 3 kit set

SiriusVoyager replied to Taken Aback's topic in New member Introductions

Welcome to MSW! -

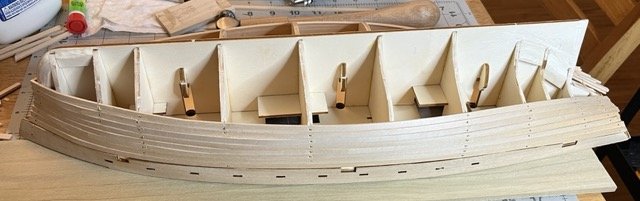

Wow, I can't believe that it has been over a month and a half since I lasted updated. It has been a busy couple of months with travel, kids marching bad, work, ect. but I have been slowly working on the first layer planking. In the past I have avoided using nails as much as possible. This time I used nails for most of the strips to try something different. It is definitely convenient and easy to hold the planks down, but I don't like having to file them down or sand over them. I think I will try to avoid them in the future. Like always, I am not too happy with my planking job, but its ok for providing the structure for the second layer planking. I looked back at my previous model and actually it looks quite a bit improved. First layer planking done. The wood got a little chewed up where I used a Dremel to file down some of the nail heads, but that is ok since it will all be covered. I am not sure why the keel pieces don't fit together snugly. This is cut straight from the sheet, no sanding or char removal. I am not sure if I missing something or if it is just not well designed. Fortunately it will be painted so I will just use some filler in the gaps. Much less wood filler than previous hulls. I also attach the keel to the first later of planking because I don't understand how anyone can get the shape of the hull so perfect that the keel, particularly the stem, lays on flush without any gaps. Next step is the second layer planking. 25:15/ 53:00

- 21 replies

-

- Cala Esmeralda

- Santa Eulalia

-

(and 1 more)

Tagged with:

-

With that supplied thread, a coat of beeswax can help keep some of that fuzz down. Great job so far!

- 75 replies

-

Welcome to MSW!

-

Welcome to MSW!

-

Warped Dowel for Small Masts

SiriusVoyager replied to acaron41120's topic in Masting, rigging and sails

Maybe a hot Iron and roll the soaked dowel on a flat surface? -

Welcome to MSW!

-

Welcome to MSW!

-

I repainted the deck and re-placed the bulwarks. It looks better now. I also started with the first layer planking. In the past I tried to avoid using nails. This time I decided to try using nails instead of CA glue.

- 21 replies

-

- Cala Esmeralda

- Santa Eulalia

-

(and 1 more)

Tagged with:

-

Welcome to MSW!

-

Drill bit suggestions

SiriusVoyager replied to SiriusVoyager's topic in Modeling tools and Workshop Equipment

I can't believe that I asked about this a year and a half ago, but I finally got around to trying out some drill bits from McMaster. I am pretty happy with them so far. -

Welcome to MSW!

-

Welcome to MSW!

-

Getting back on the horse....

SiriusVoyager replied to Sterling59's topic in New member Introductions

Welcome to MSW! -

Welcome to MSW!

-

Hi All - new member intro.

SiriusVoyager replied to Jezza from the UK's topic in New member Introductions

Very nice! Welcome to MSW! -

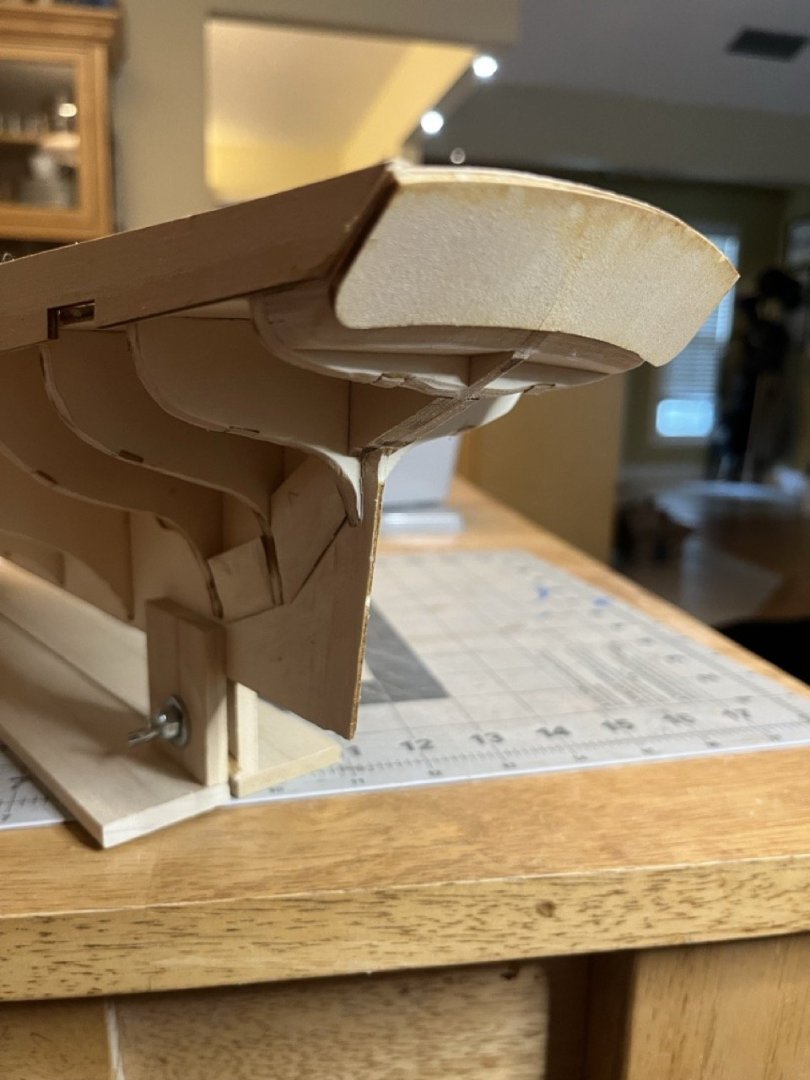

I am a little frustrated with myself on this update. Things are looking a bit rough. I have spent half of my time since the last update trying to redo my some of my work. At the end of the day, most of the rough parts will be covered up by planking. Painting the deck was a bit difficult for some reason. I kept getting two spots (starboard bow and port of the mizzen mast) that that always ended up significantly lighter than the rest of the deck.. Even after multiple coats, sanding and repainting, the color seems to be lighter. The camera is a cruel mistress as well as in person it looked more uniform. I will touch it up again in the morning. I have coated it with shellac. As far as the color, it appeared to me that the photos have two or three different colors. Some of it may have been lighting, but at times the colors look too different. Because of this I wasn't worried too much about the specific color. The edges of the deck aren't painted because the bulwark will be built up over the edge of the deck. I left the bare deck so that it can be glued directly to wood. The bulwarks took some struggle to get on, particularly on the bow. I should have started at the bow and worked my way stern. The tip of the bow gets removed to allow for the bowsprit so it didn't need to line up perfectly, though I would have preferred if they had. The transom was fairly straightforward. It had to be bent a bit to fit into place. The I used an iron to help bend the wood and it burnt a bit. Finally, The last issue I had was with faring the bulkheads. There are notches in each bulkhead. The instructions say to use them as a guide for the first plank. However, some of the instruction photos do not show them. I decided to use a little scrap to fill them in, as can seen in photos above. If I have to sand them away when I do the planking, so be it. Hopefully My future updates will look much better. 13:10/27:45

- 21 replies

-

- Cala Esmeralda

- Santa Eulalia

-

(and 1 more)

Tagged with:

-

First build competed – what next?

SiriusVoyager replied to Highlander's topic in Wood ship model kits

It really depends on what you want to build, how much you want to spend and how confident you are in building. -

Welcome to MSW!

-

Many of us have started with that very same series. Welcome to MSW!

-

Welcome to MSW!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.