westwood

Members-

Posts

279 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by westwood

-

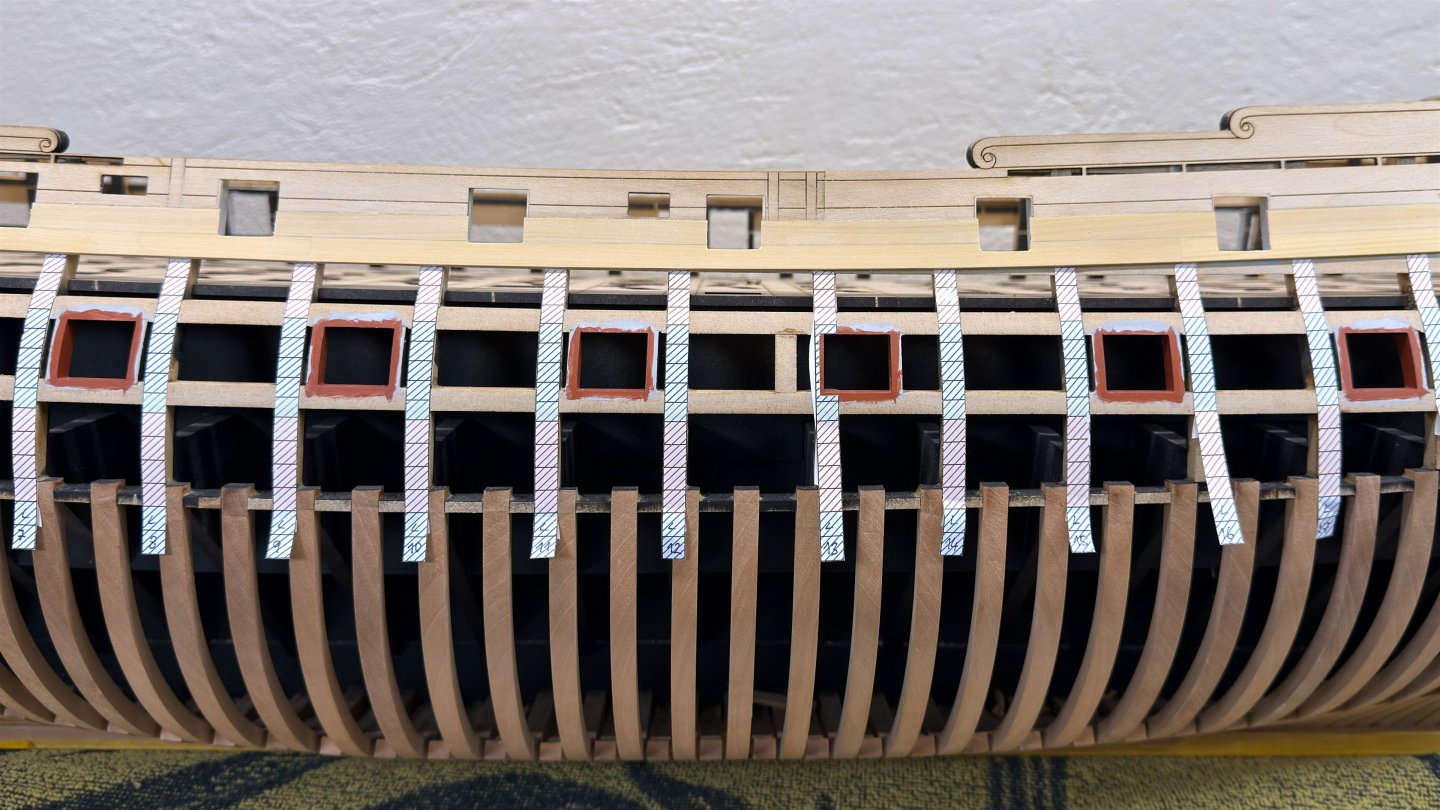

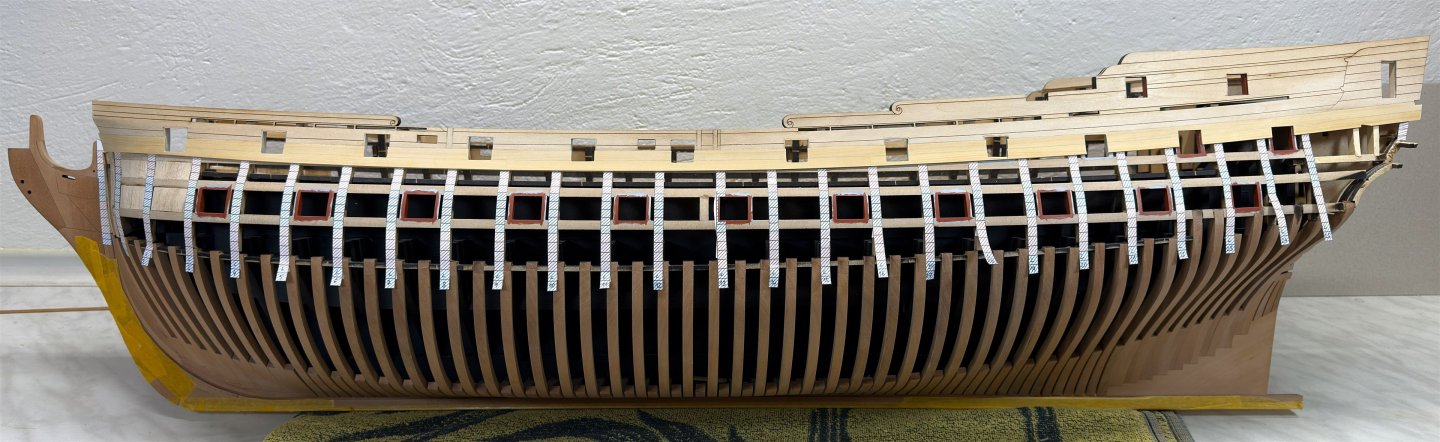

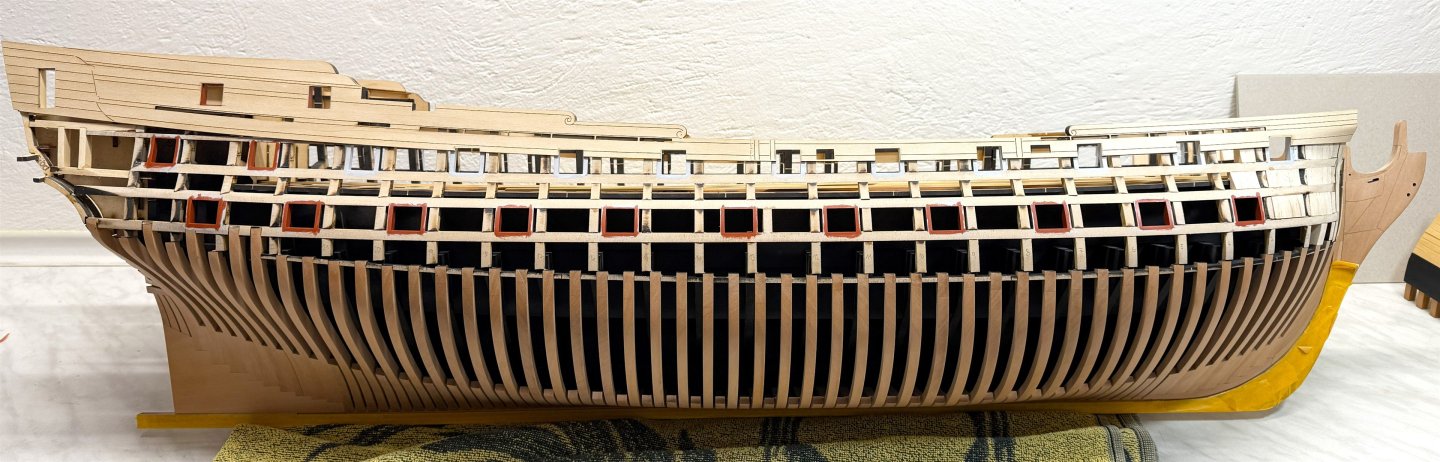

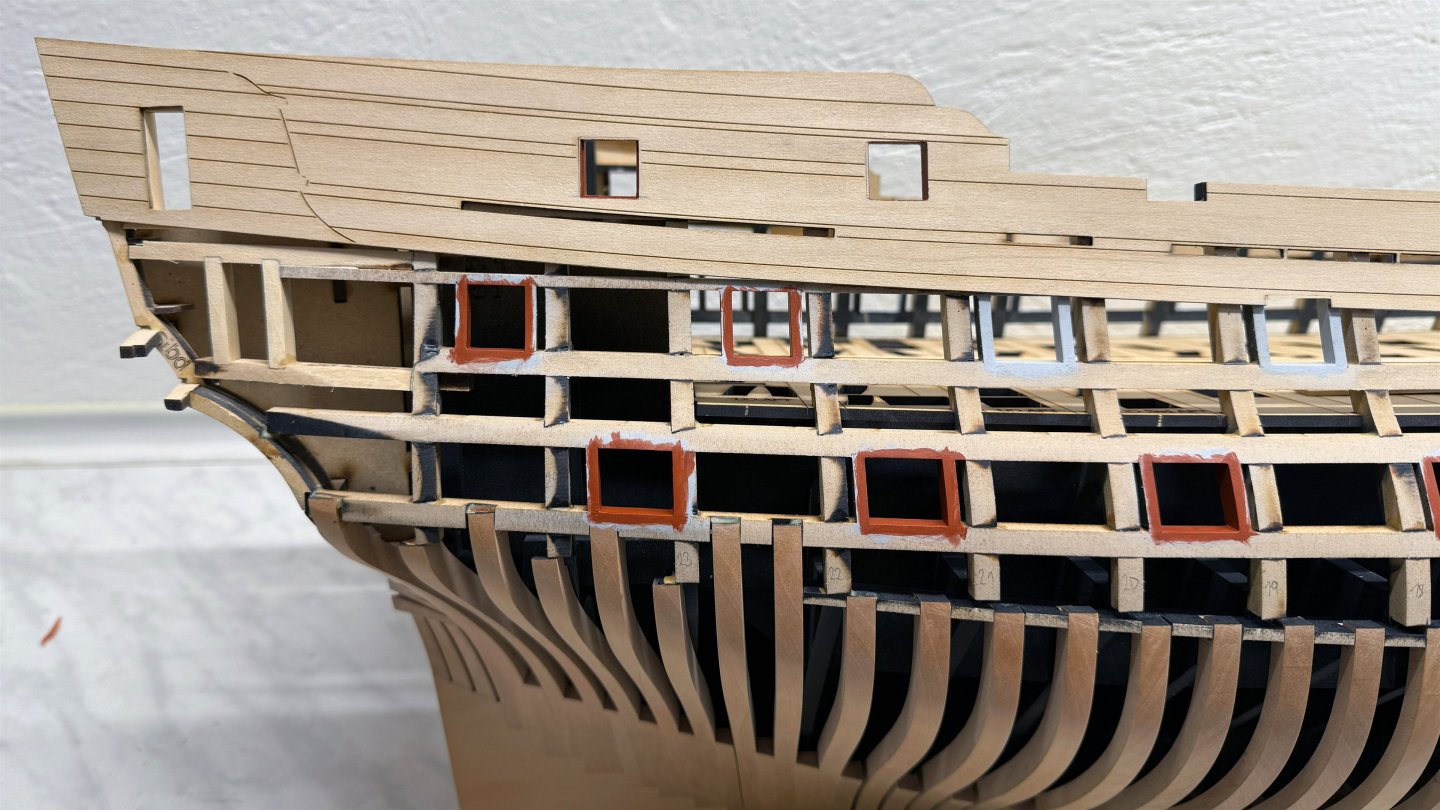

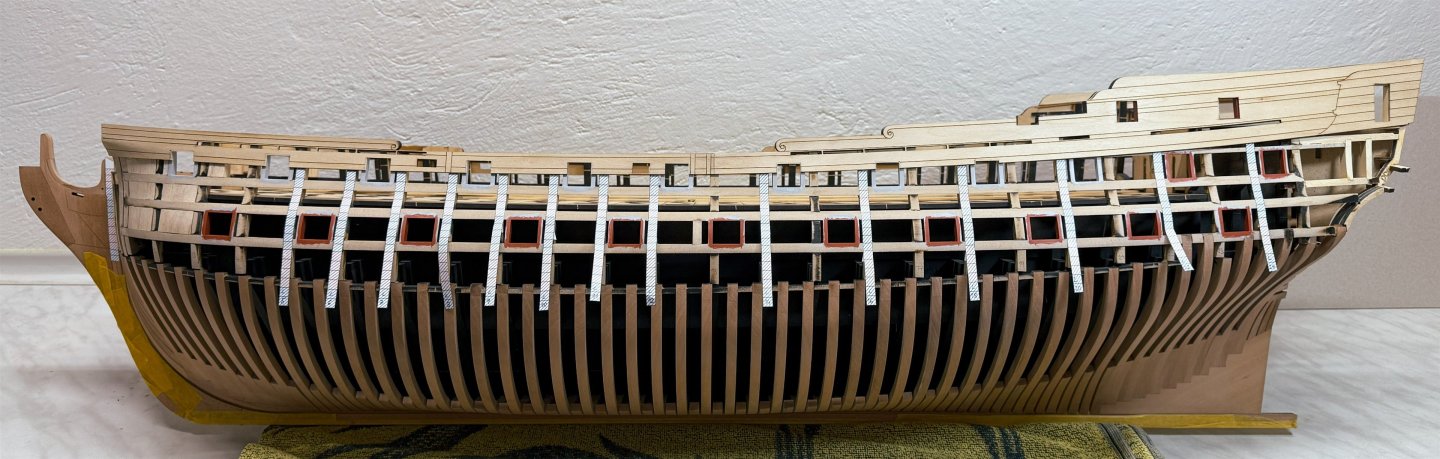

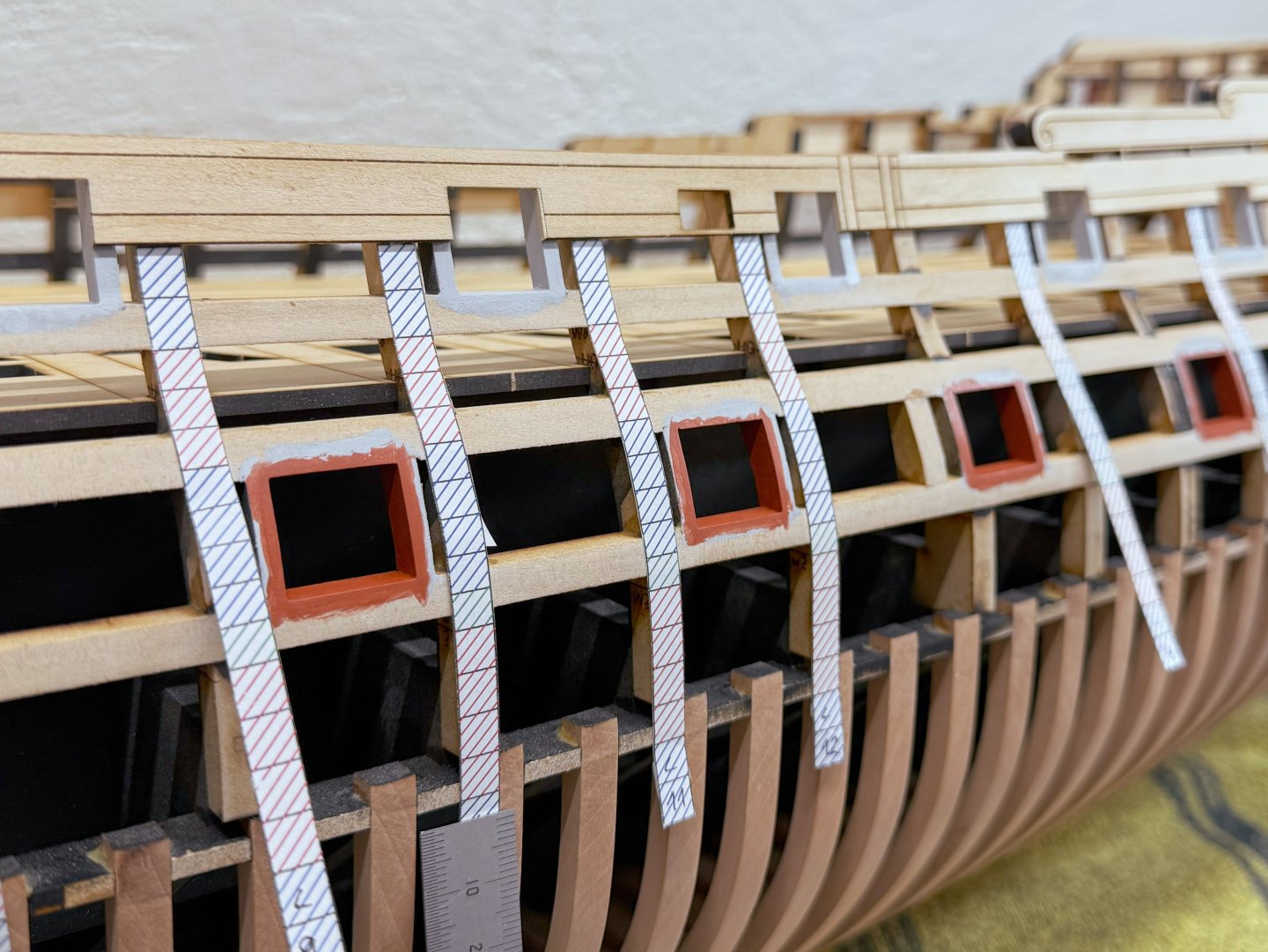

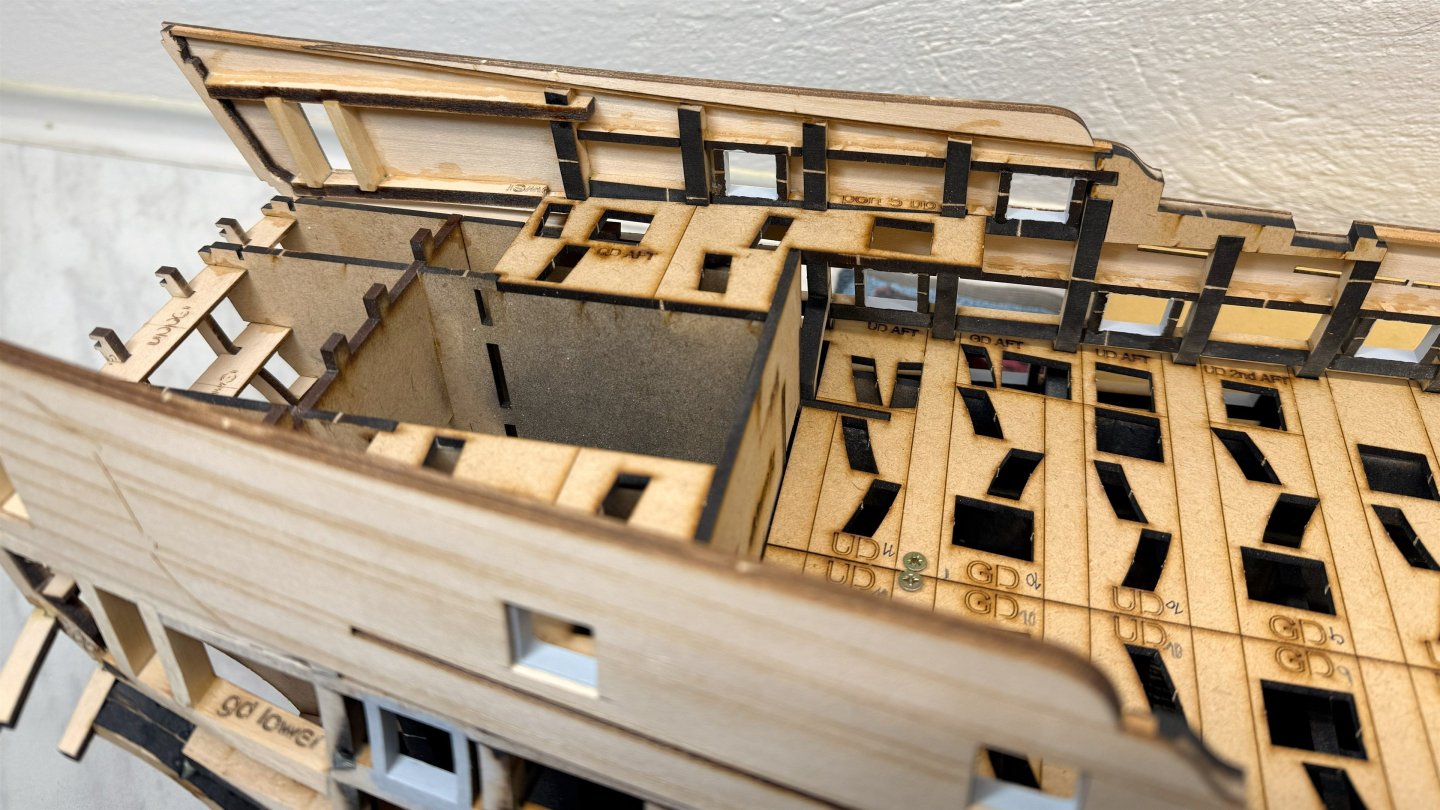

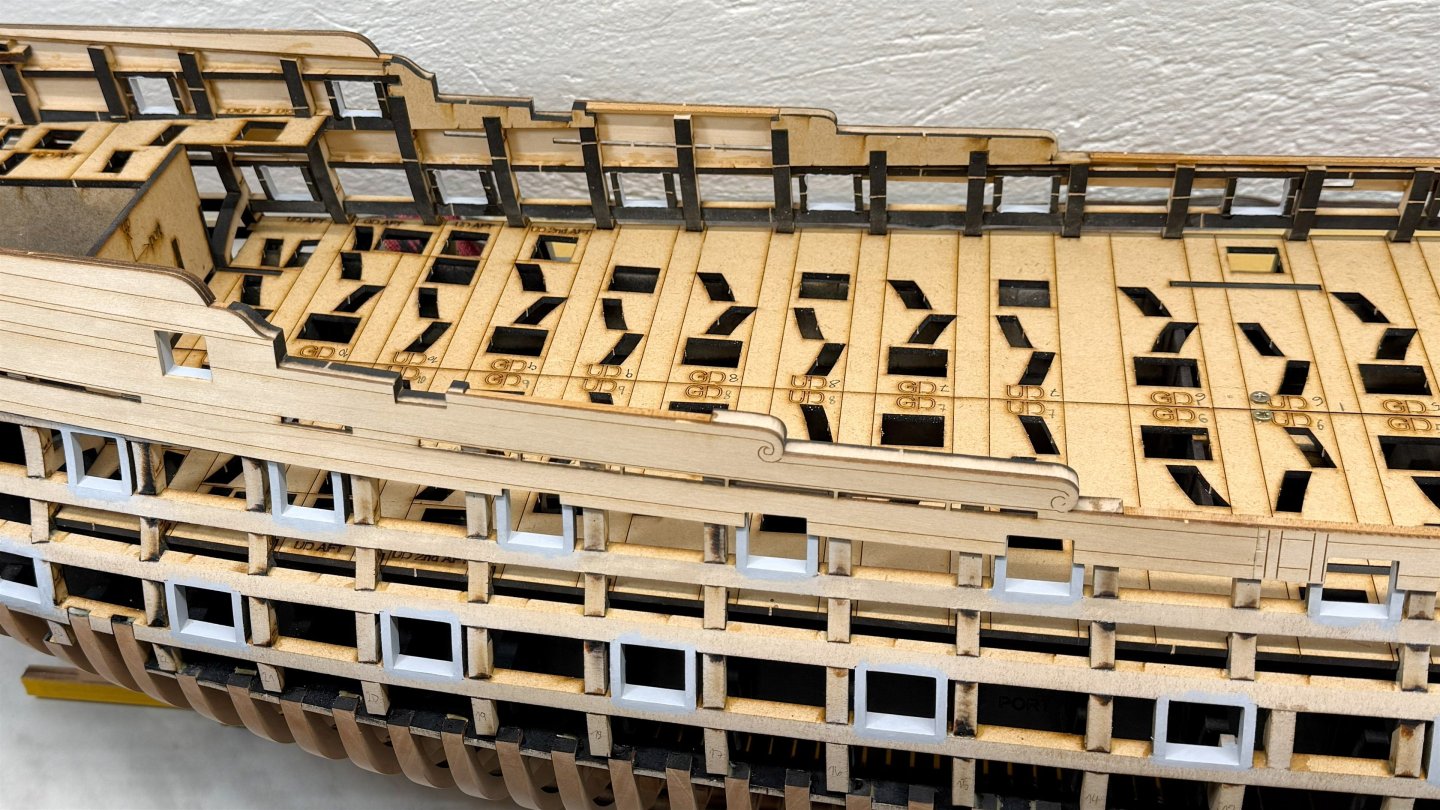

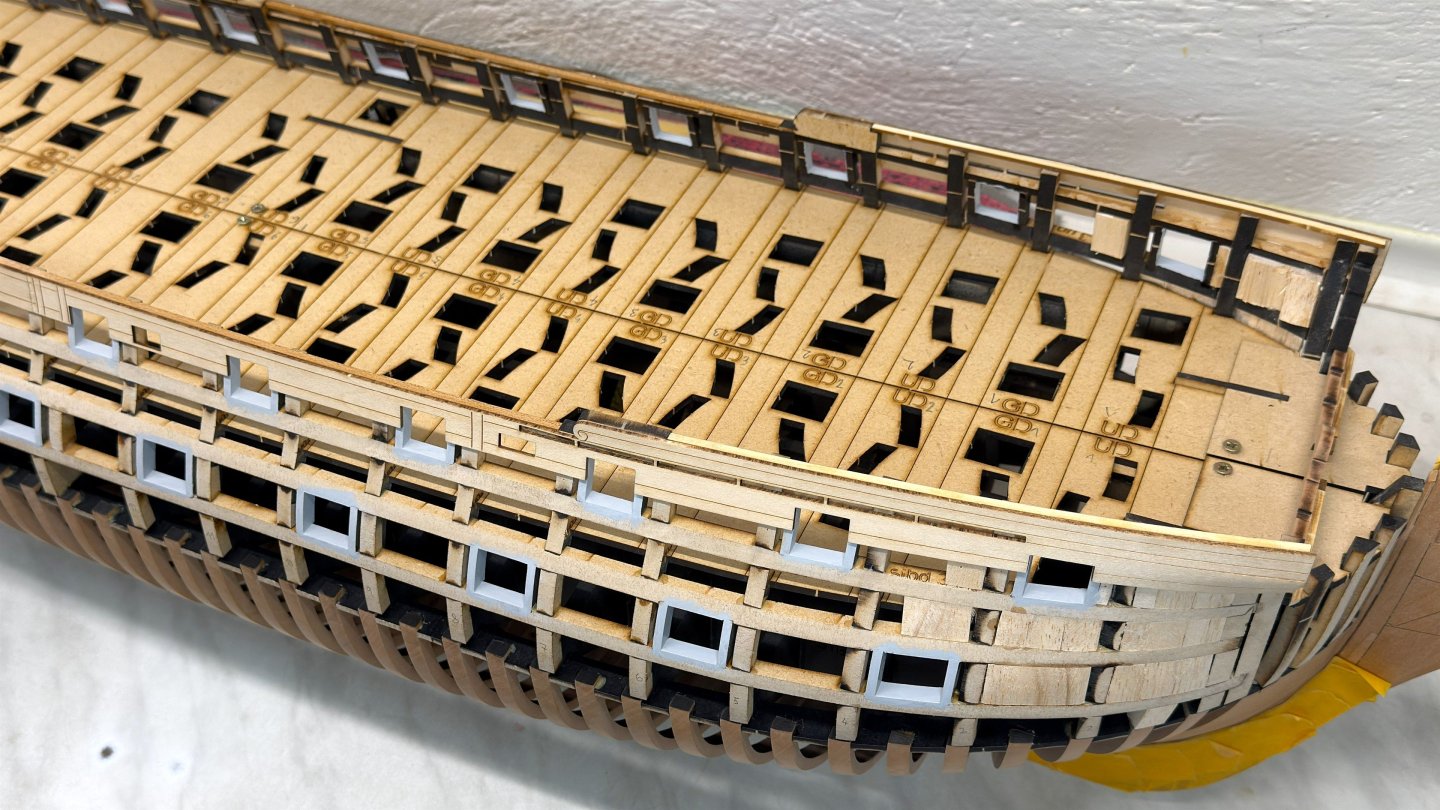

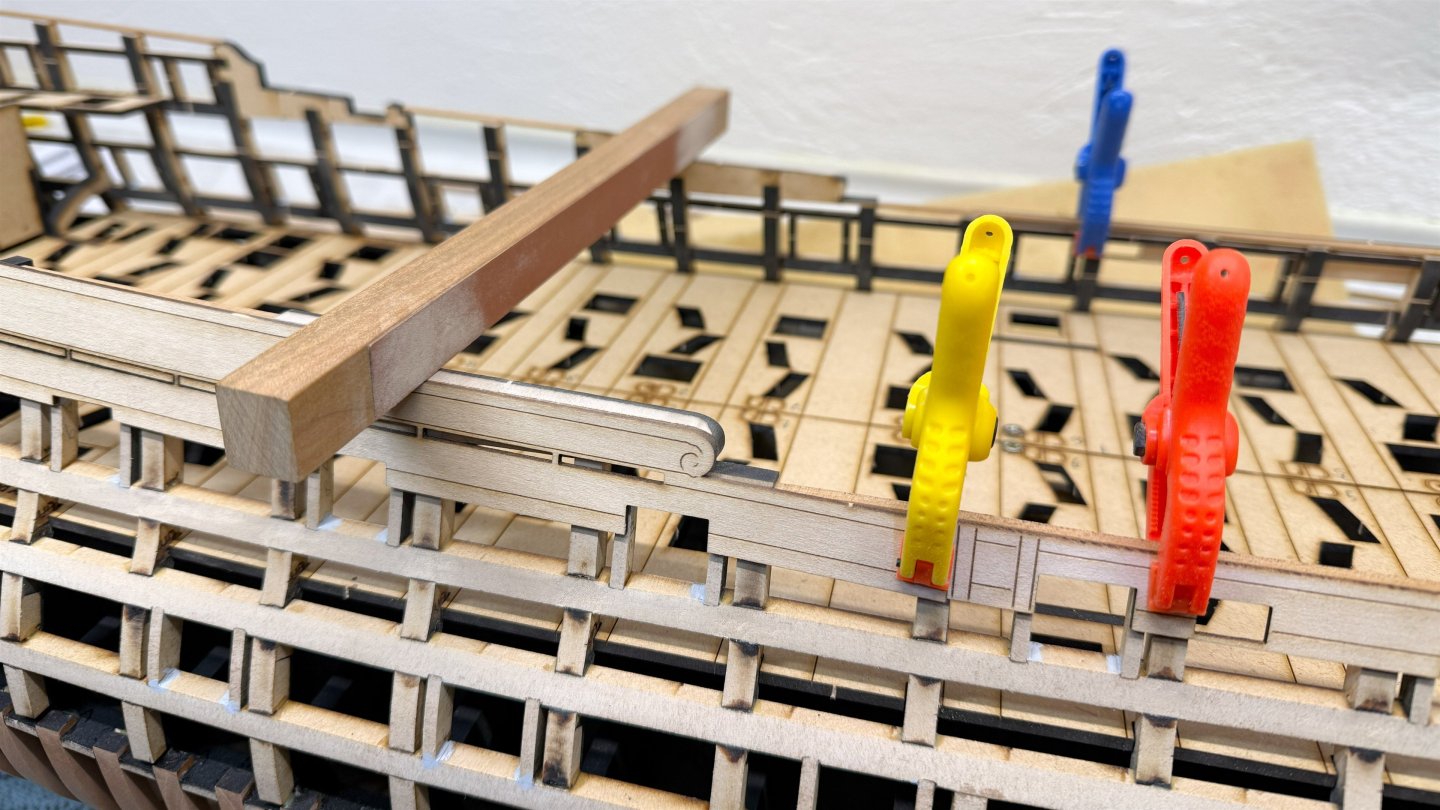

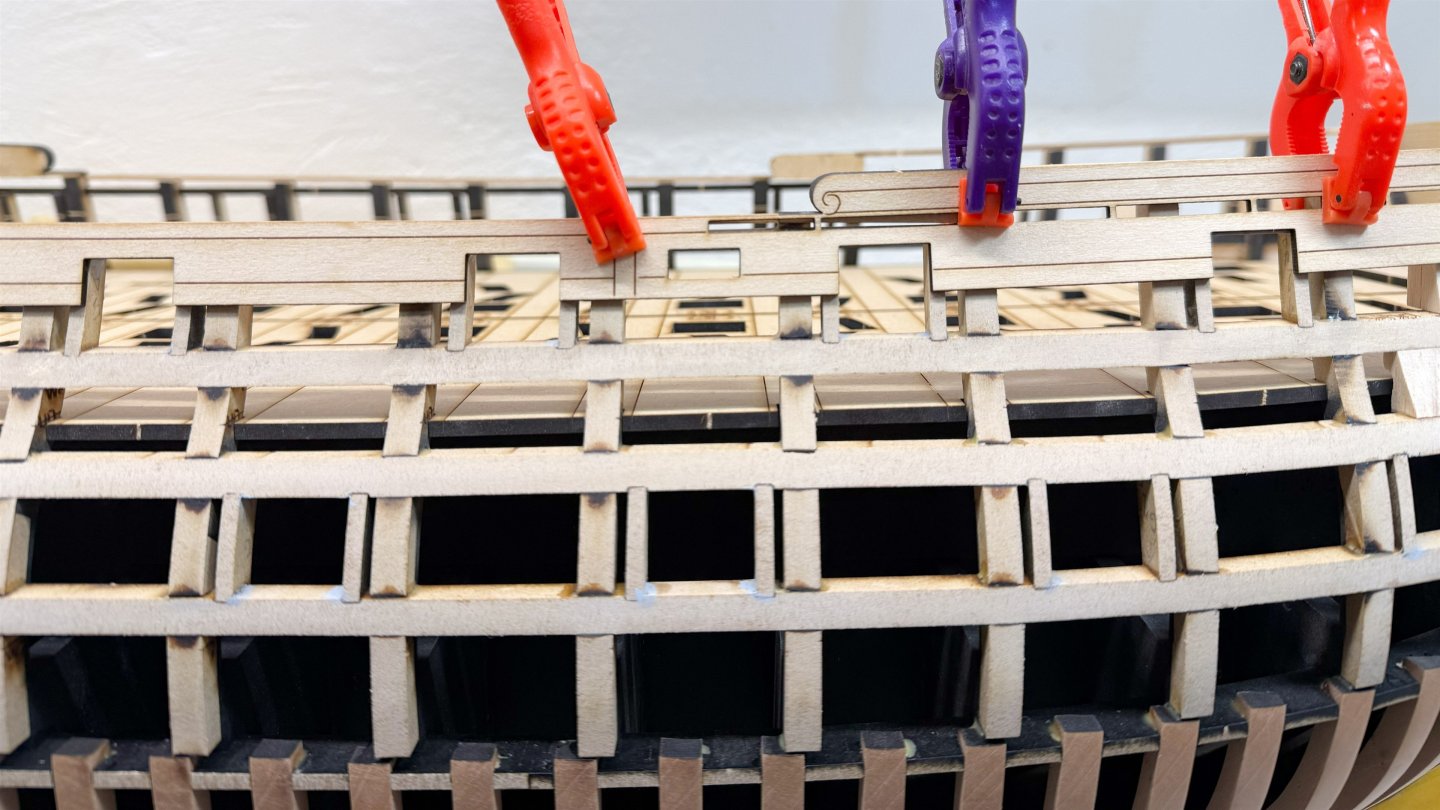

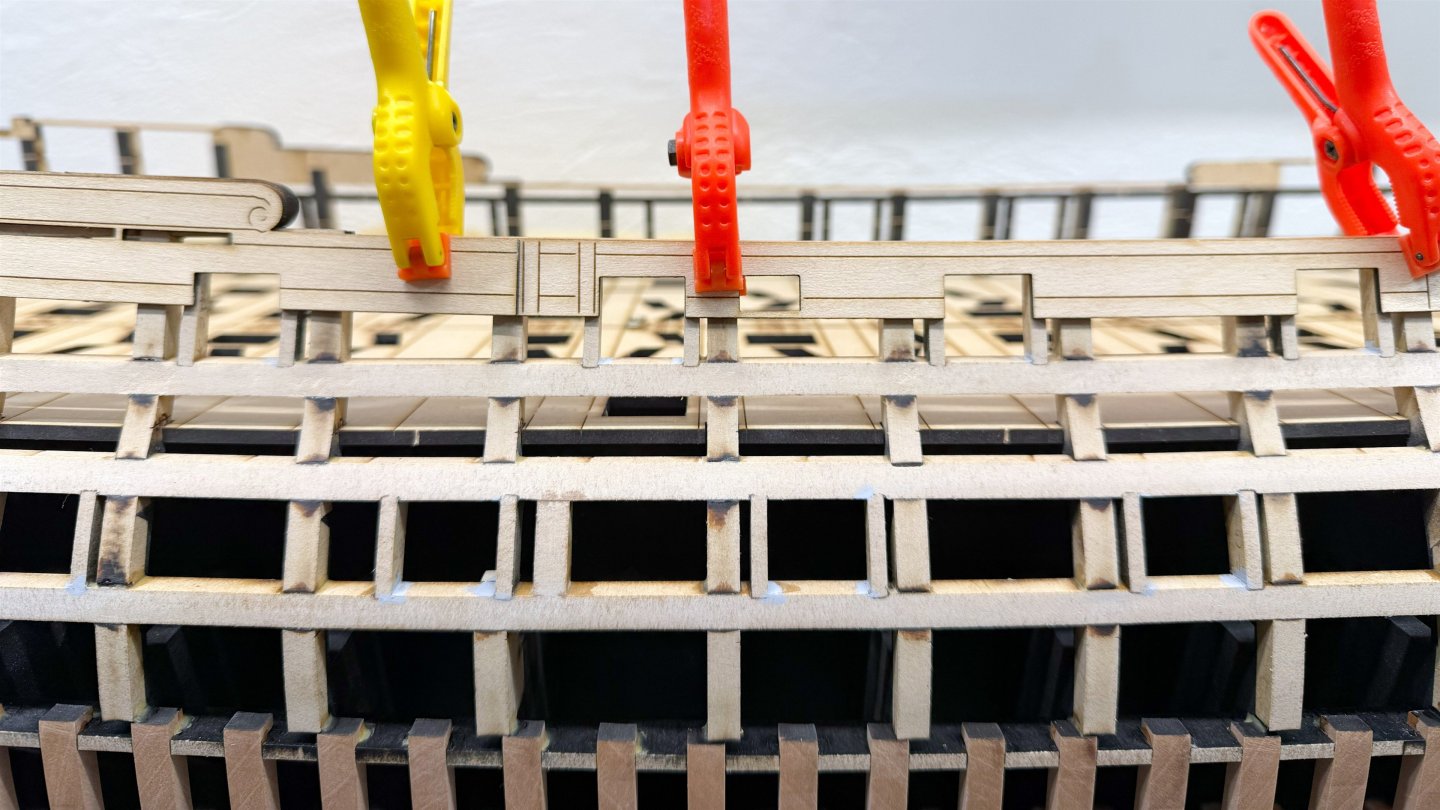

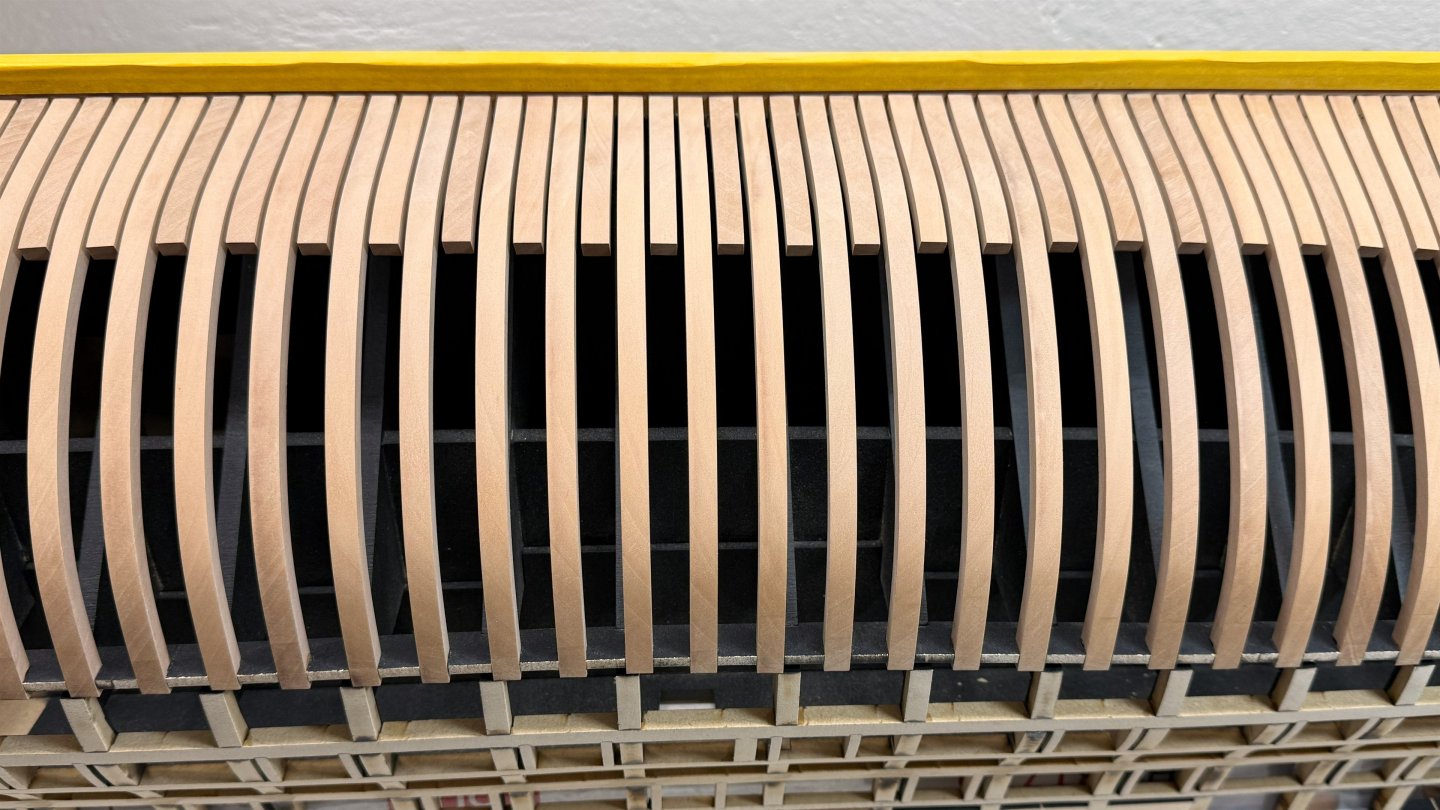

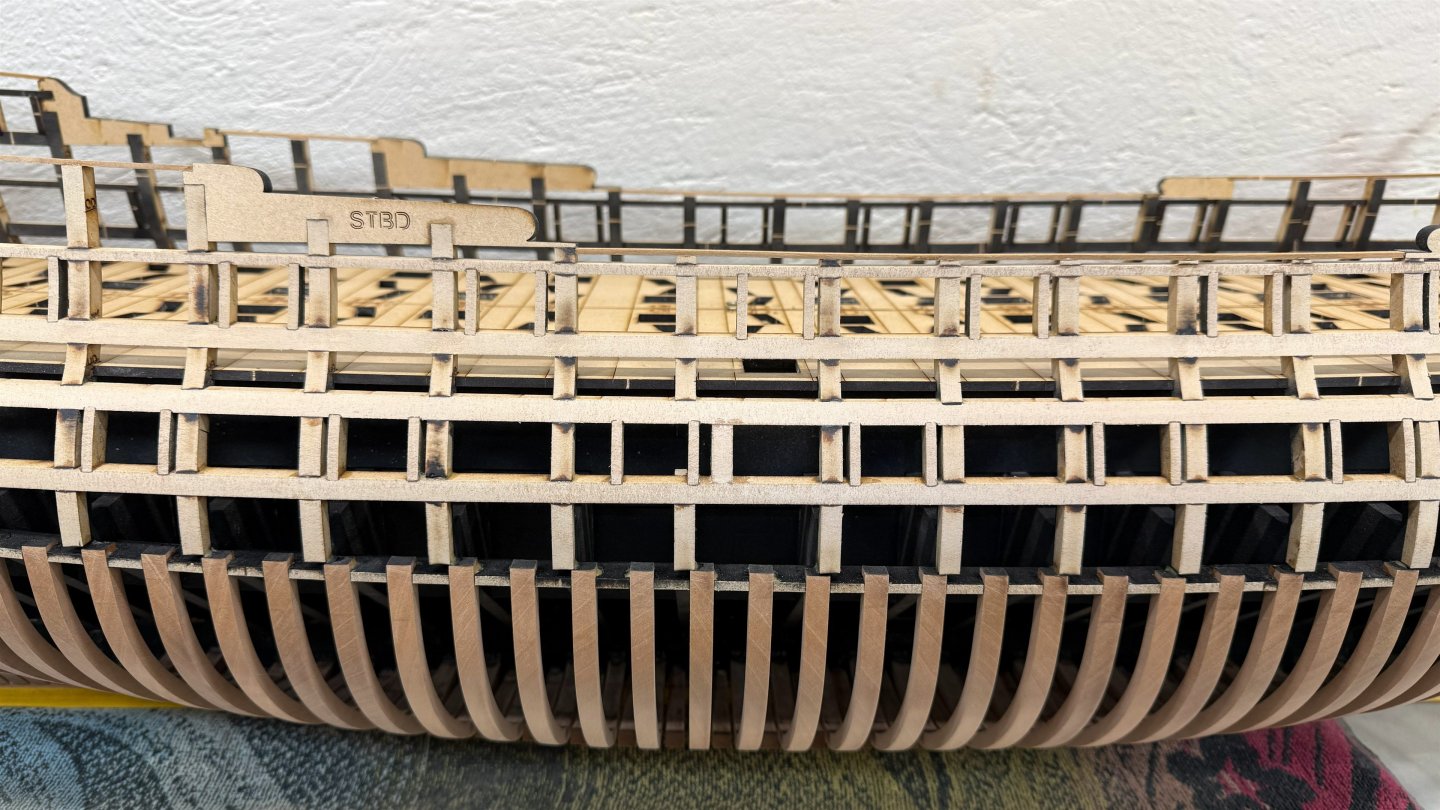

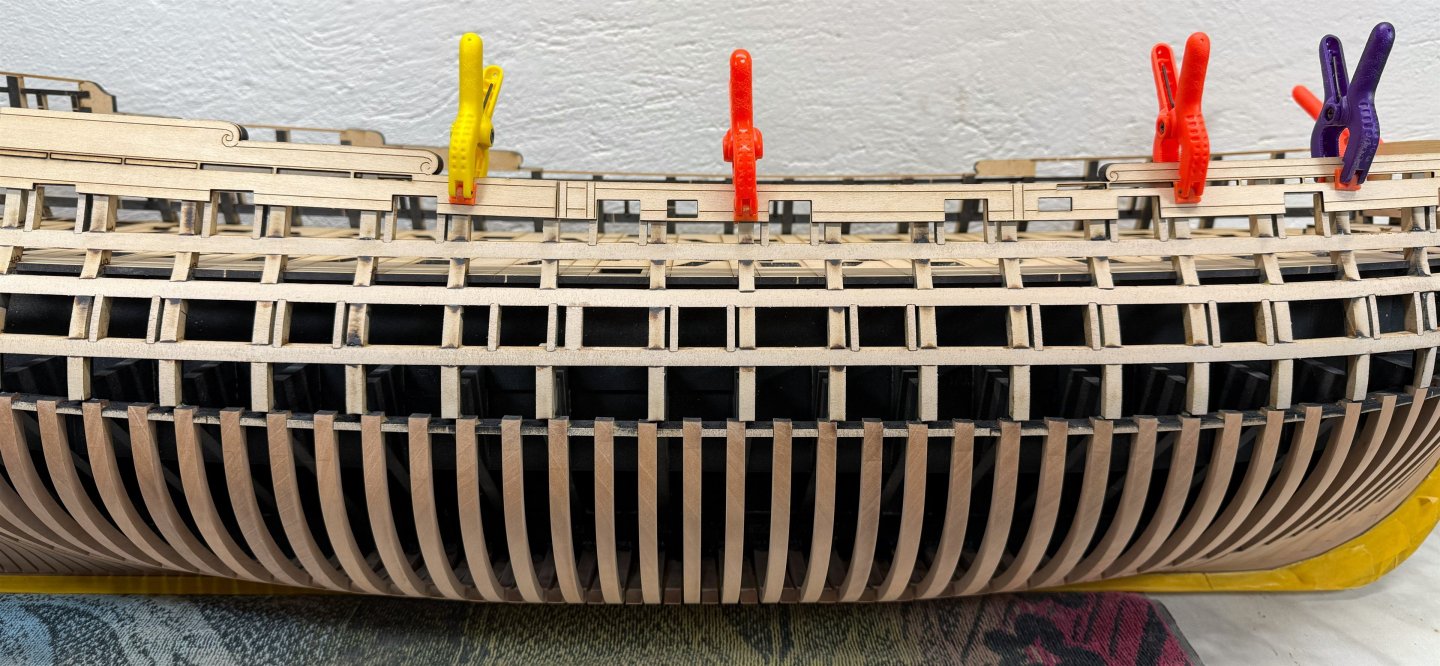

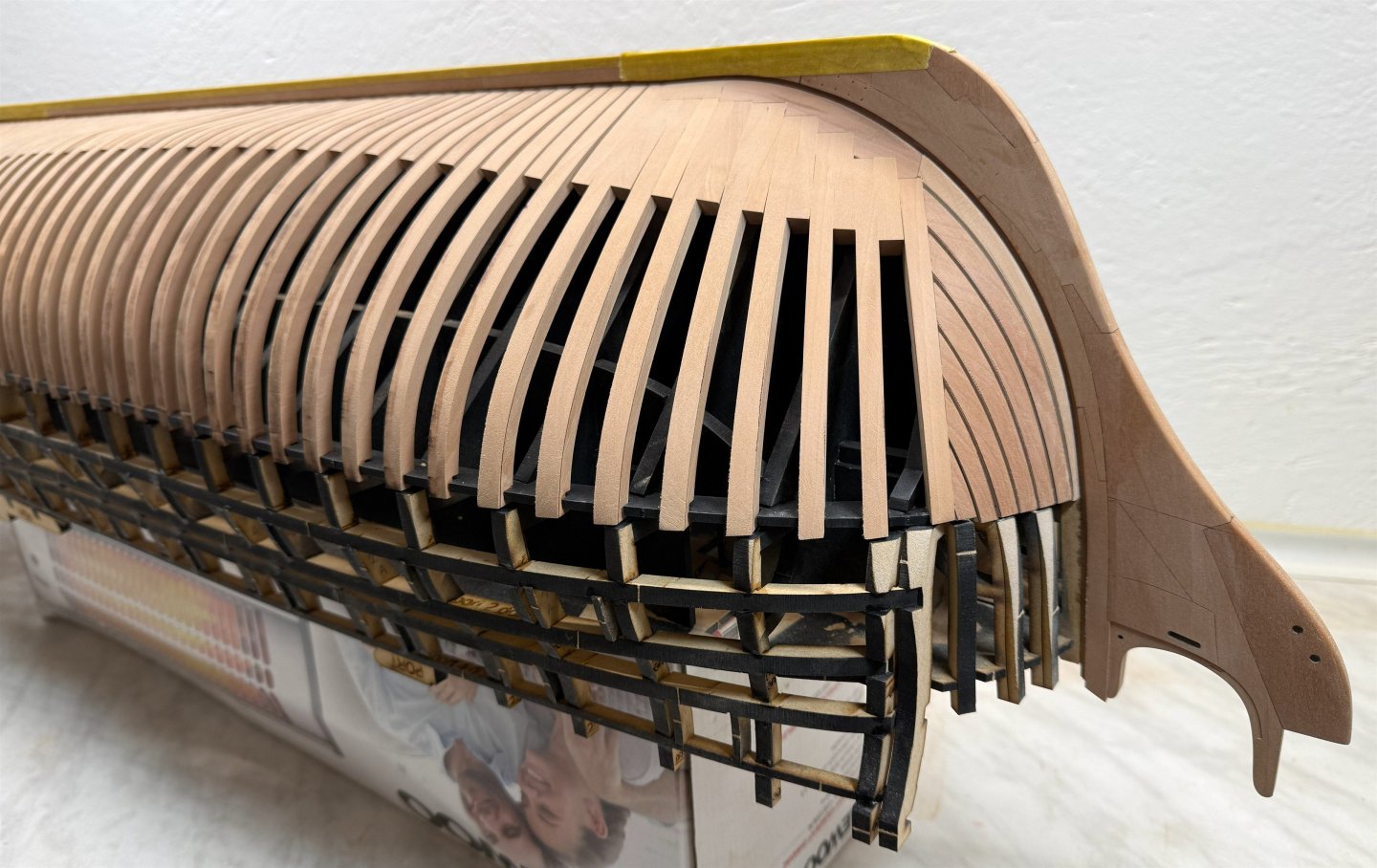

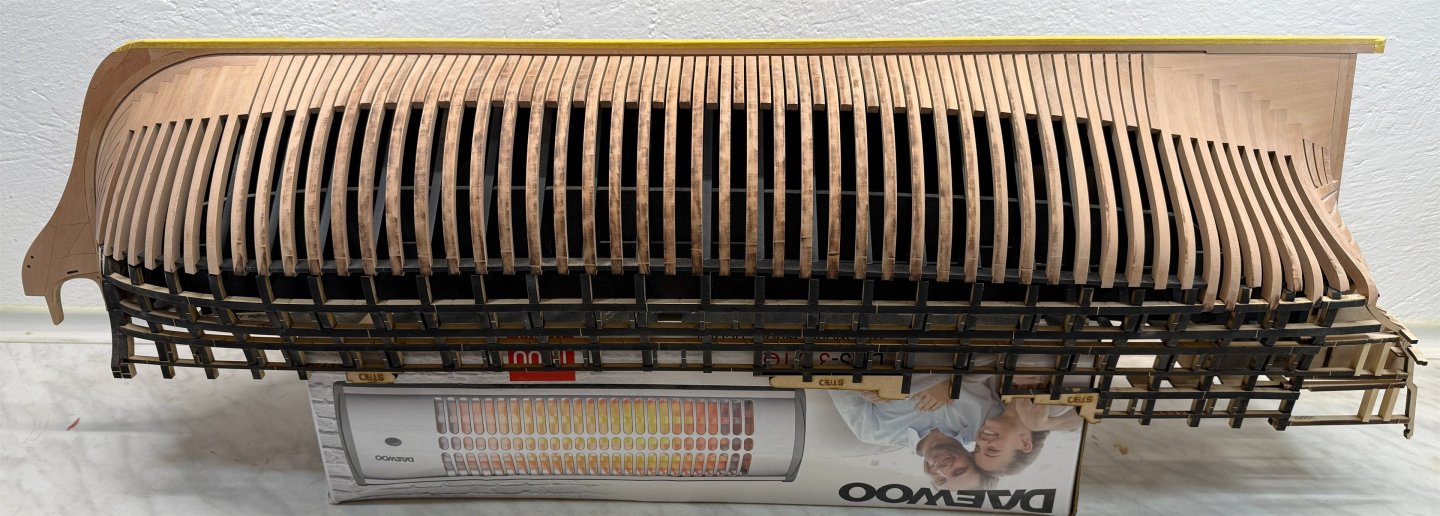

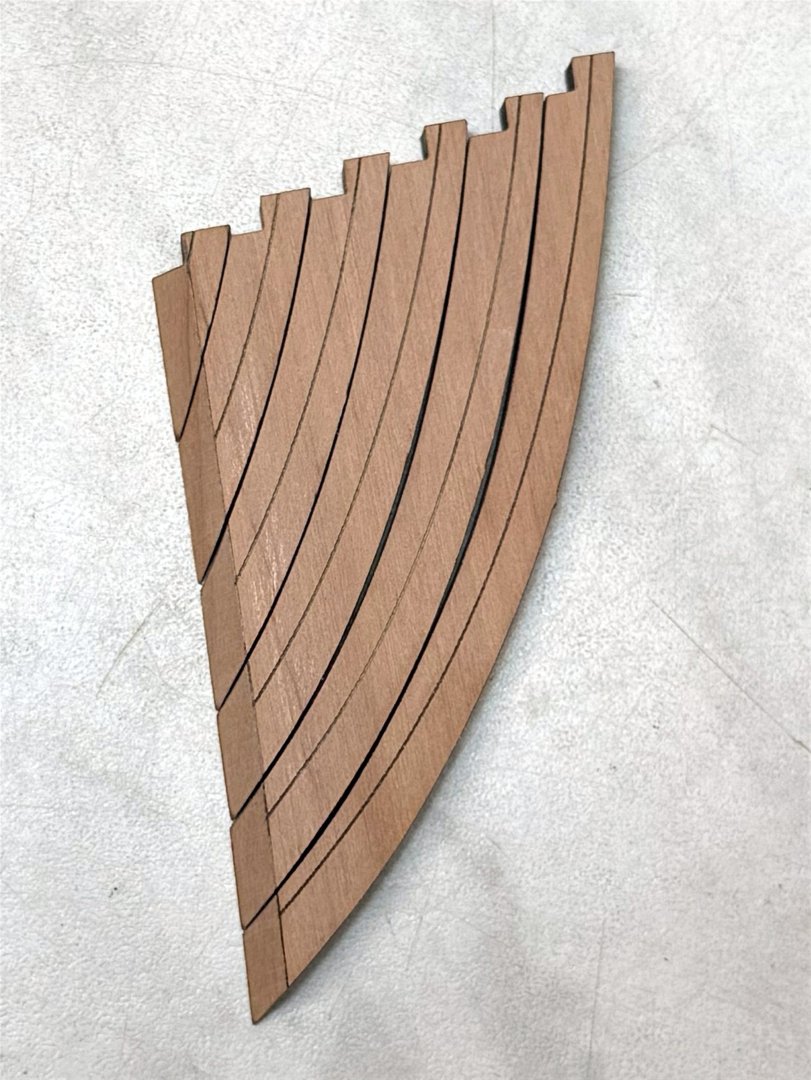

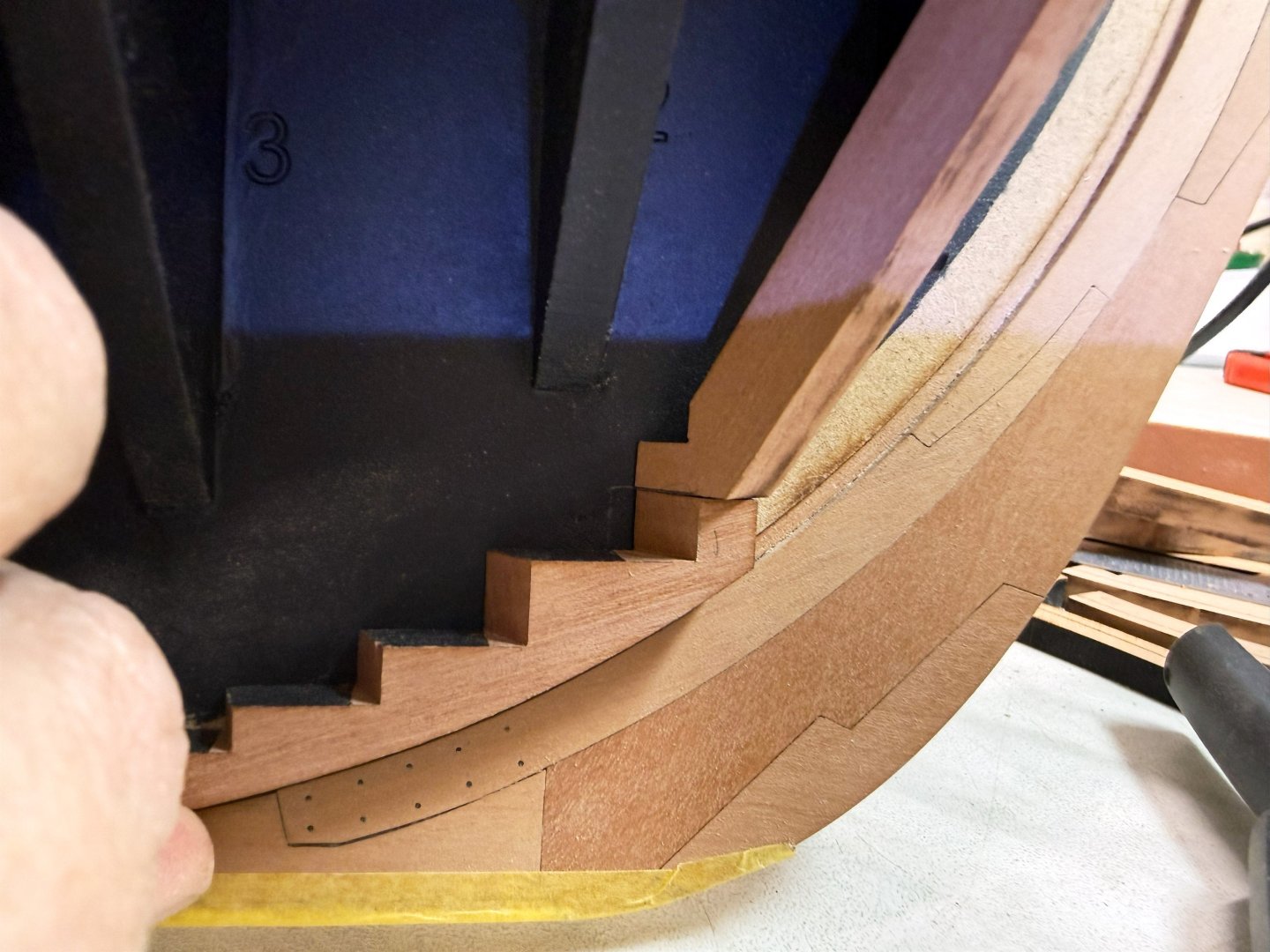

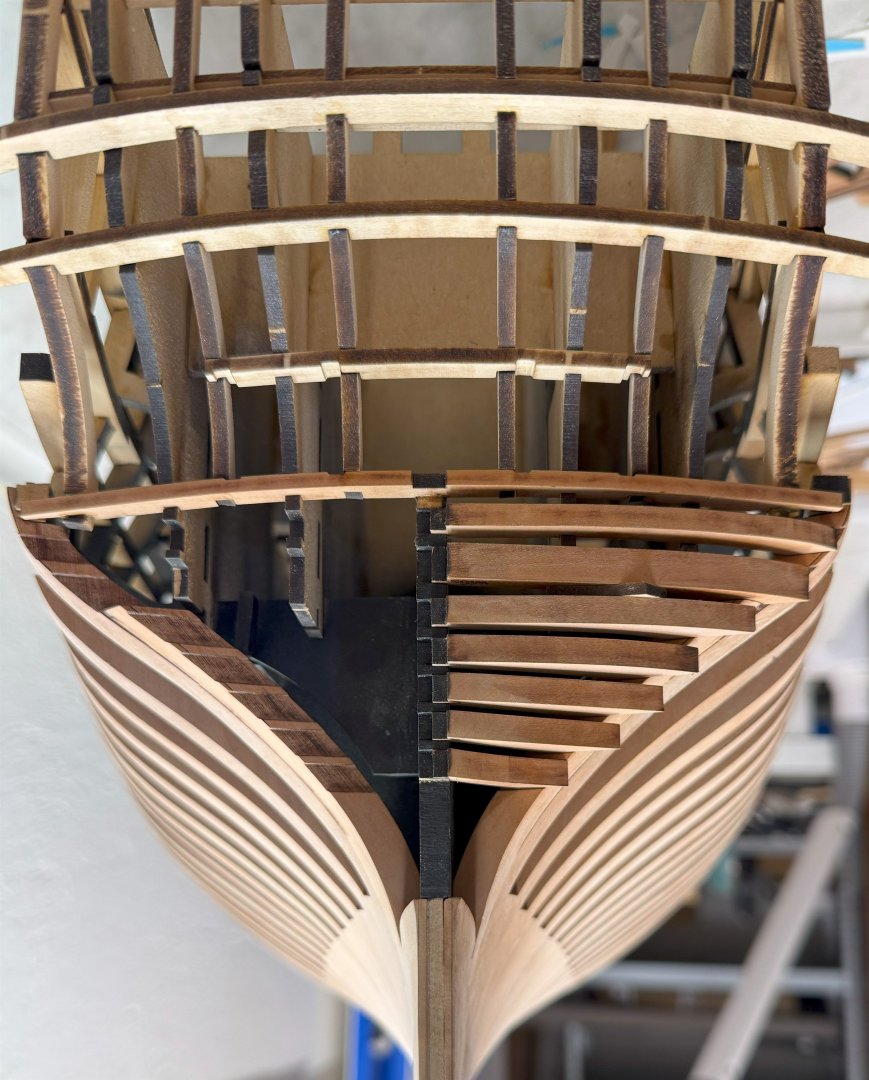

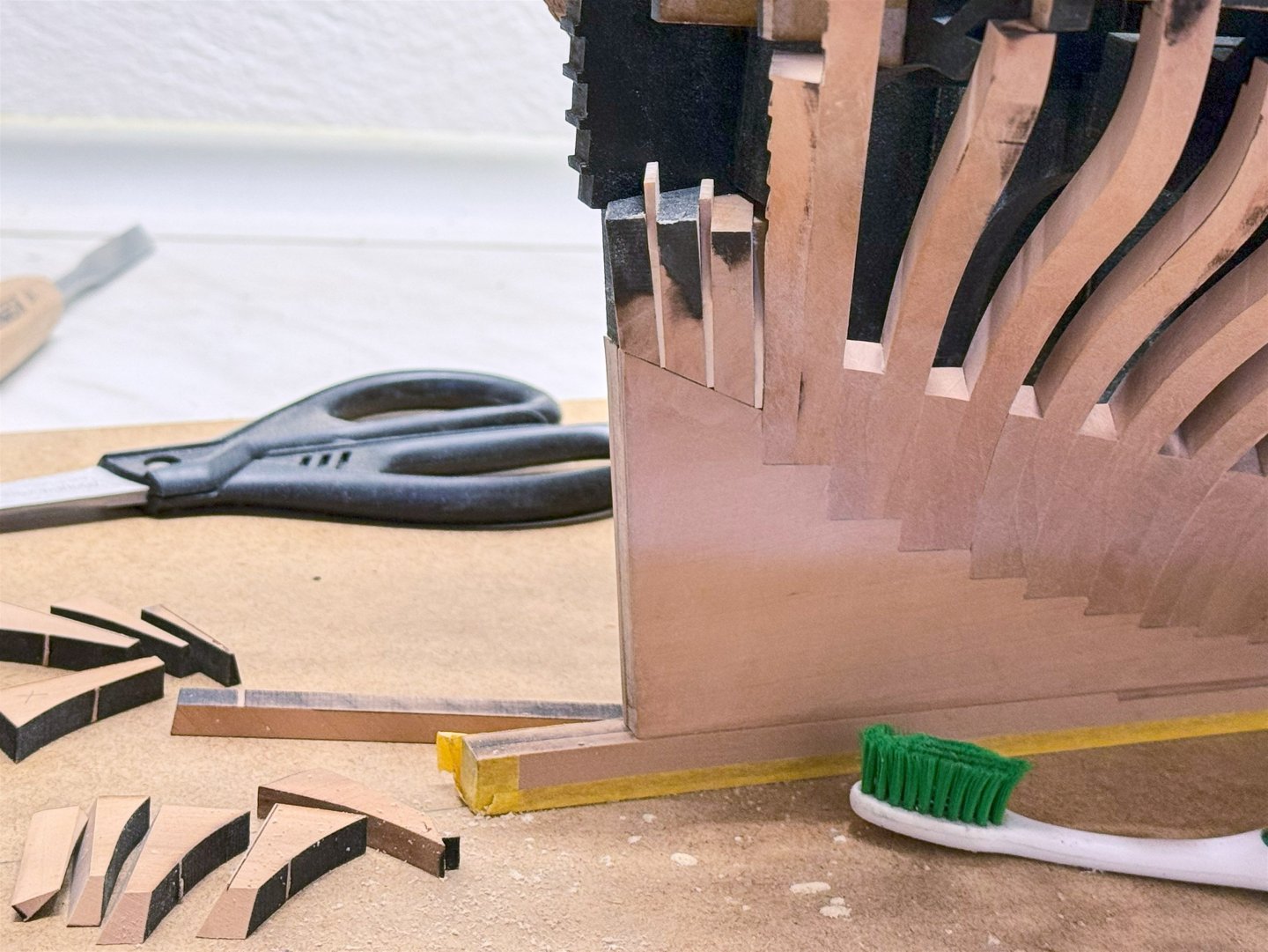

Hi guys, Finally, another update! I was waiting for a new order of Castello boxwood. I have it now, and the first strips are cut and ready. Originally, I planned to paint the gun ports last. However, I decided to paint all the ports with doors before planking. I chose Red Ochre from Caldercraft. I also tried Liquitex Soft Body Red Oxide, but it's too brown. Golden Fluid Red Oxide is a nice shade too, but it's glossy, and even the matting medium didn't make it matte enough — it almost made it transparent. I'm thinking about trying Winsor & Newton Gallery Red Ochre. Does anyone have a comparison with Caldercraft? After painting, I glued planking strips that I printed on self-adhesive paper to the bulkhead. I didn't glue them all on purpose, in case some fine-tuning is needed later. Now, the planking fun can begin!

-

Hi JJ, It looks good, I'm looking forward to the continued third chapter. I'm very curious to see what comes next. But for now, I want to wish you all the best, good health, and success with your new project!

-

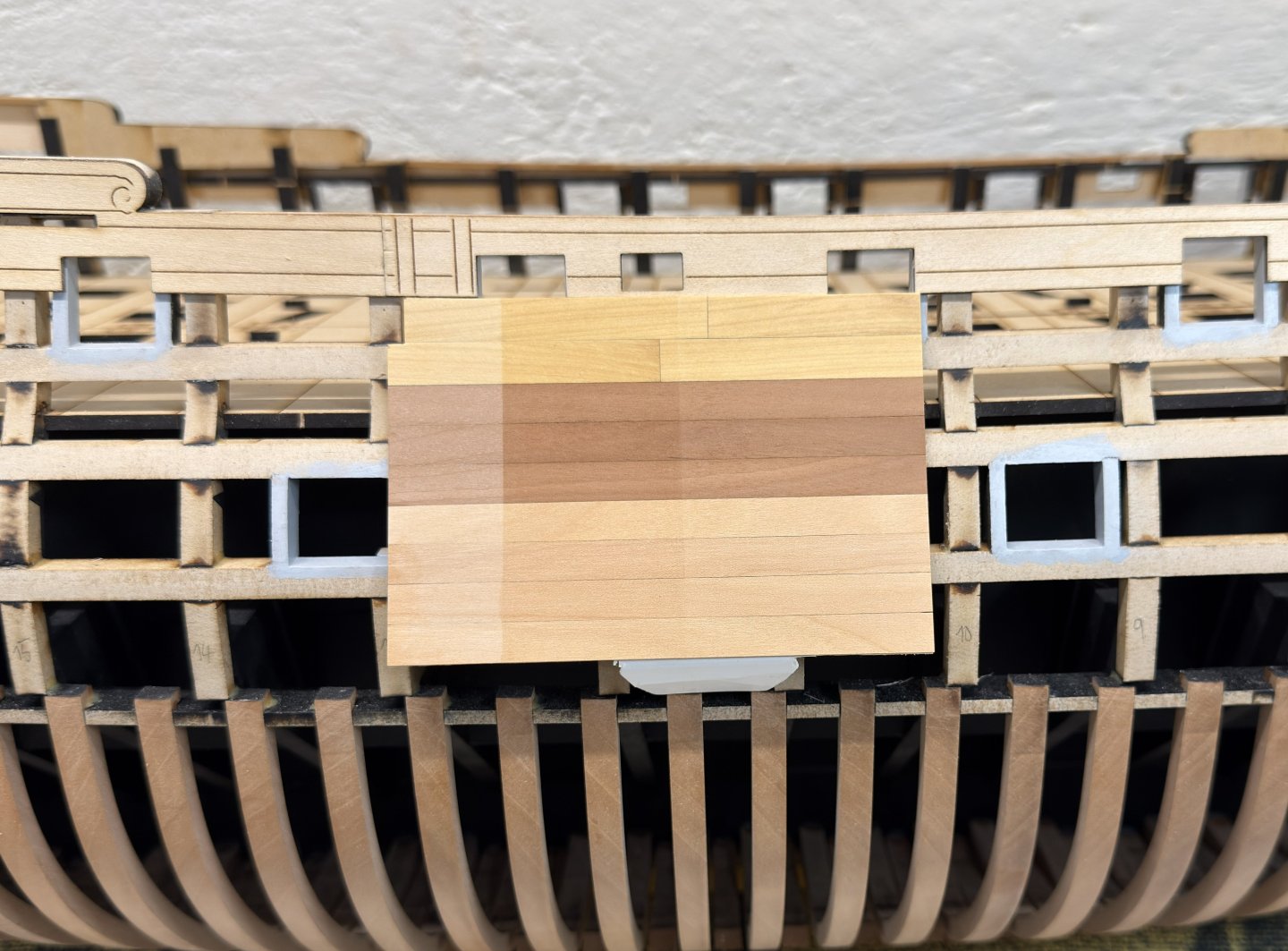

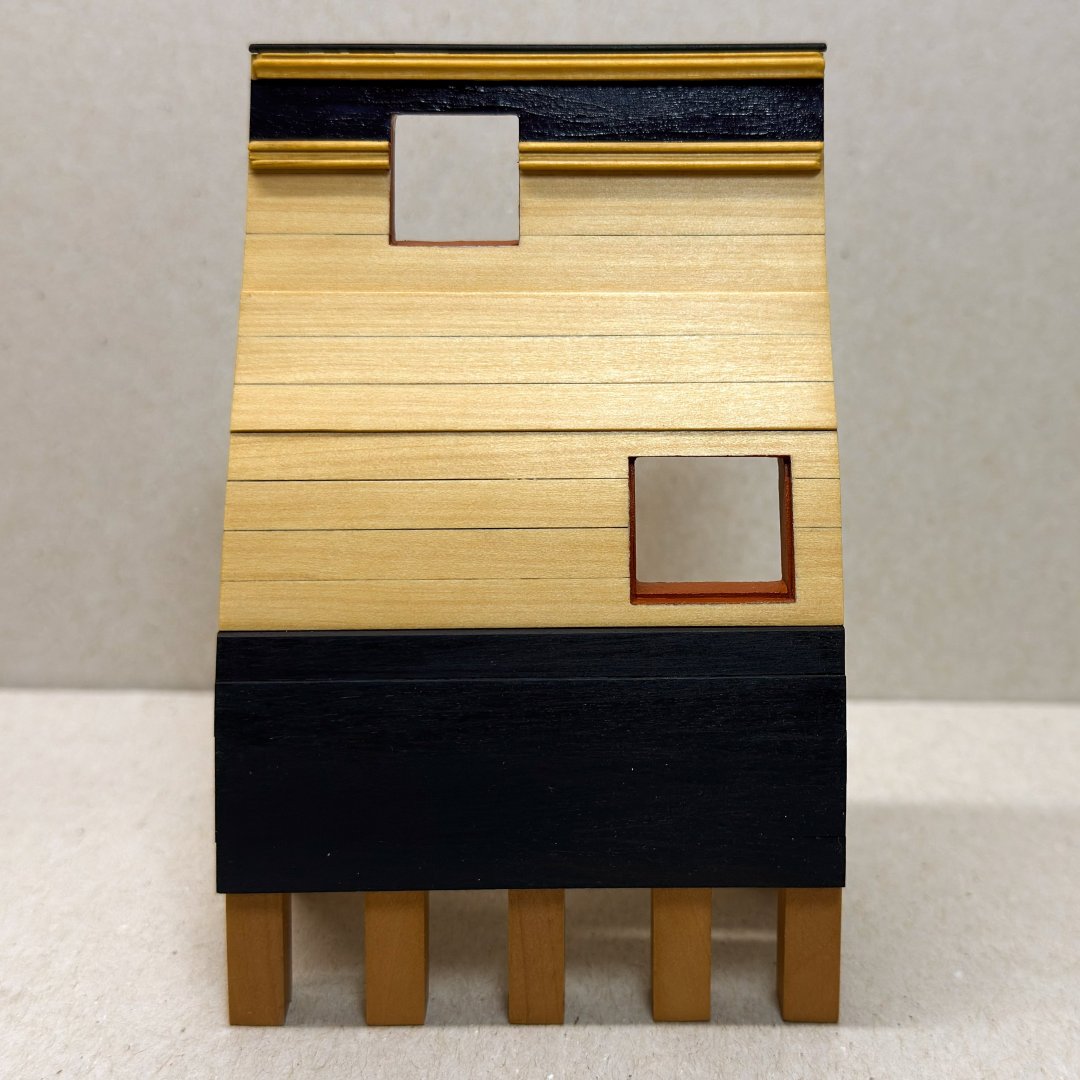

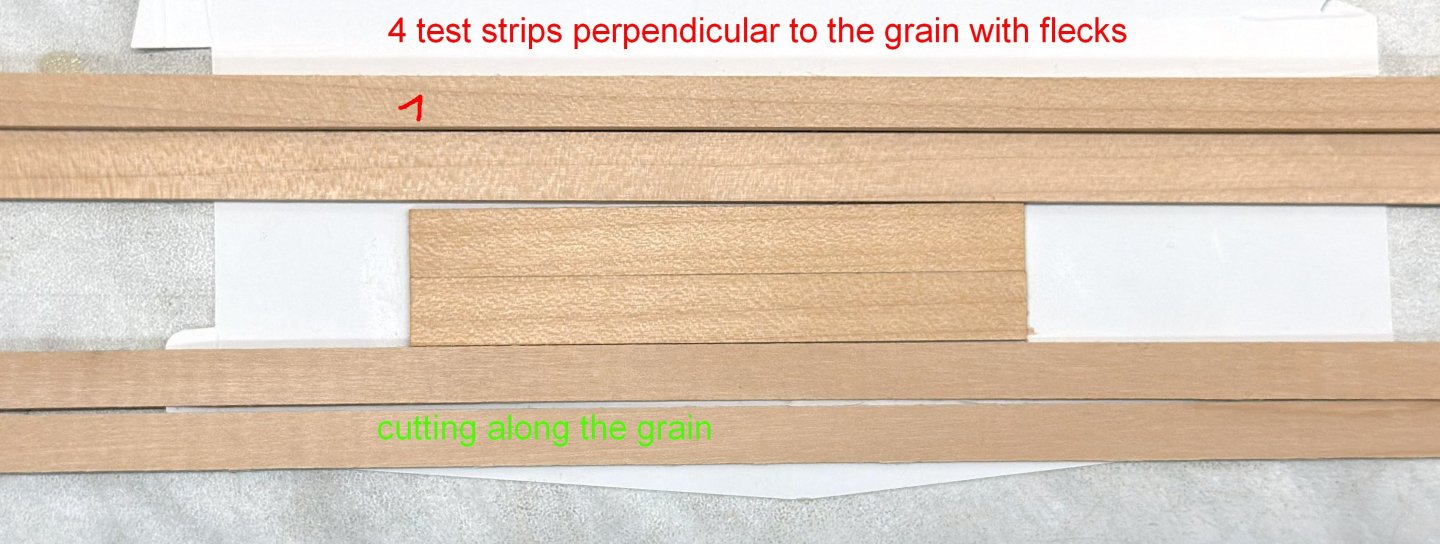

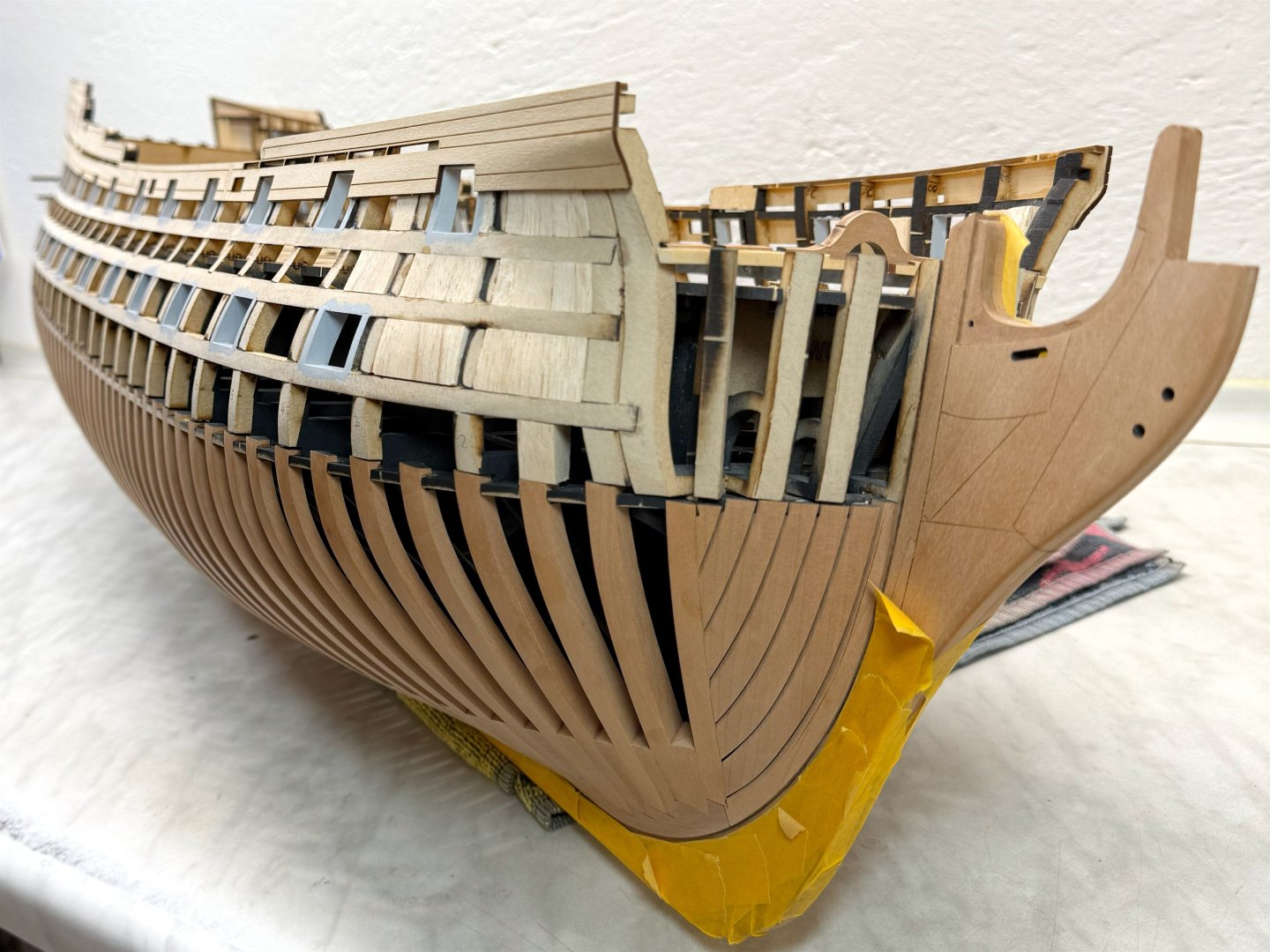

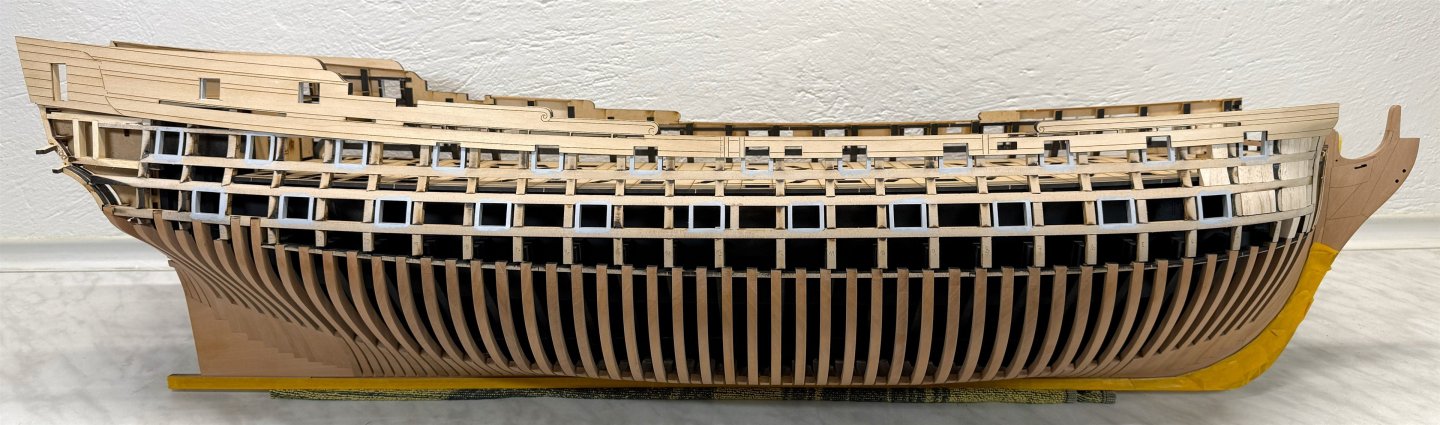

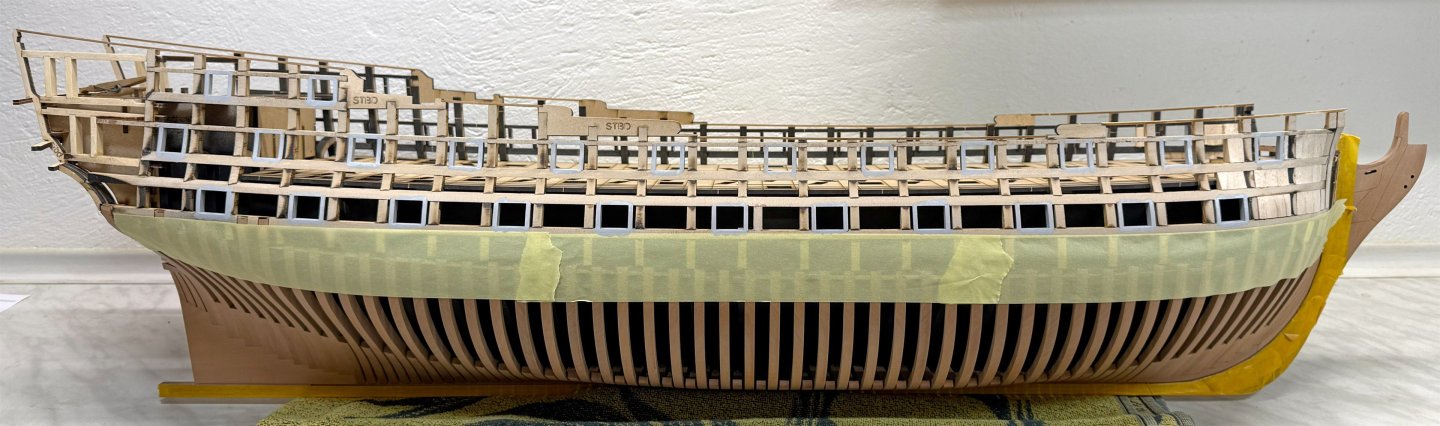

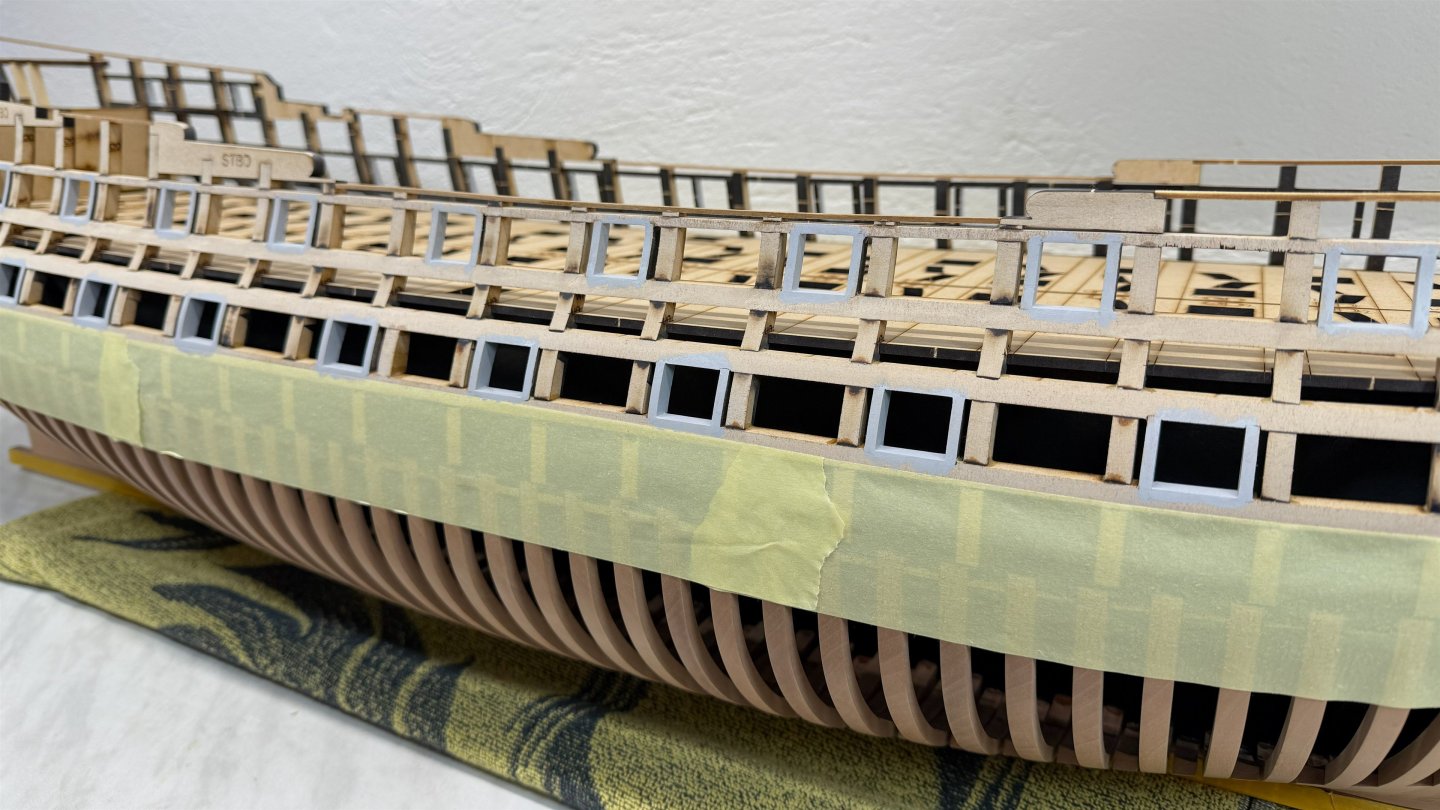

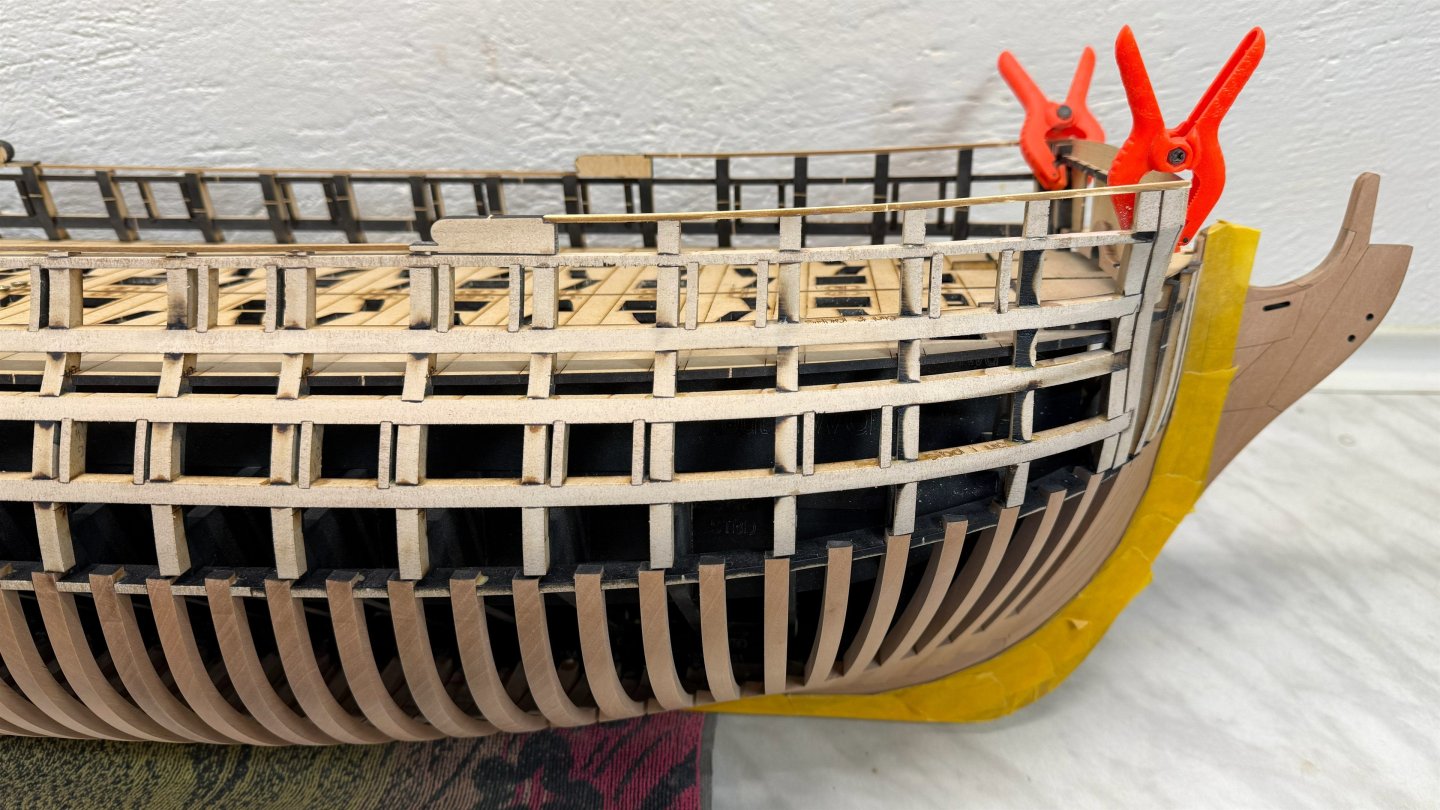

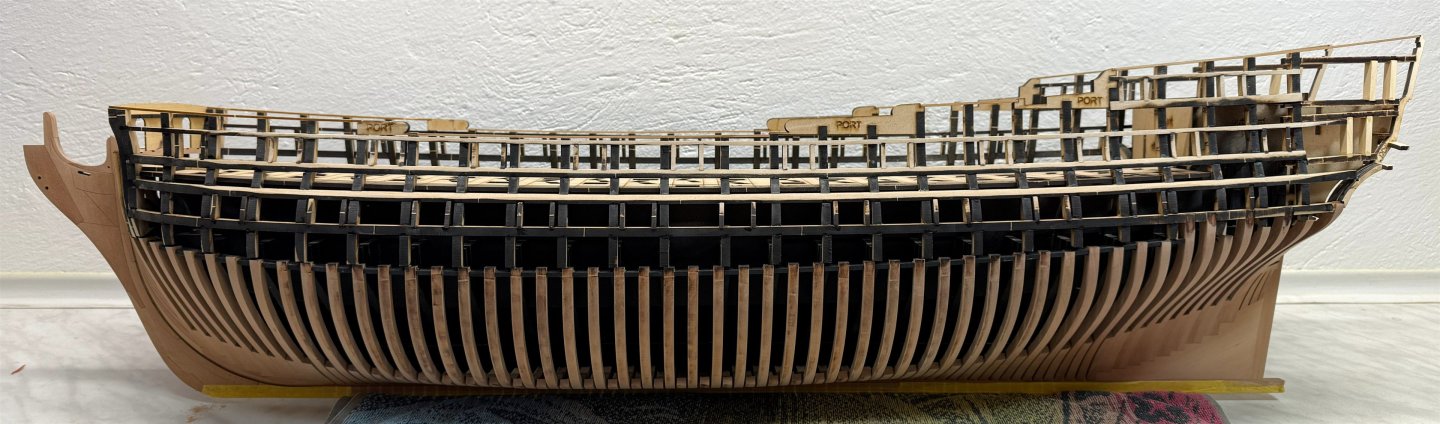

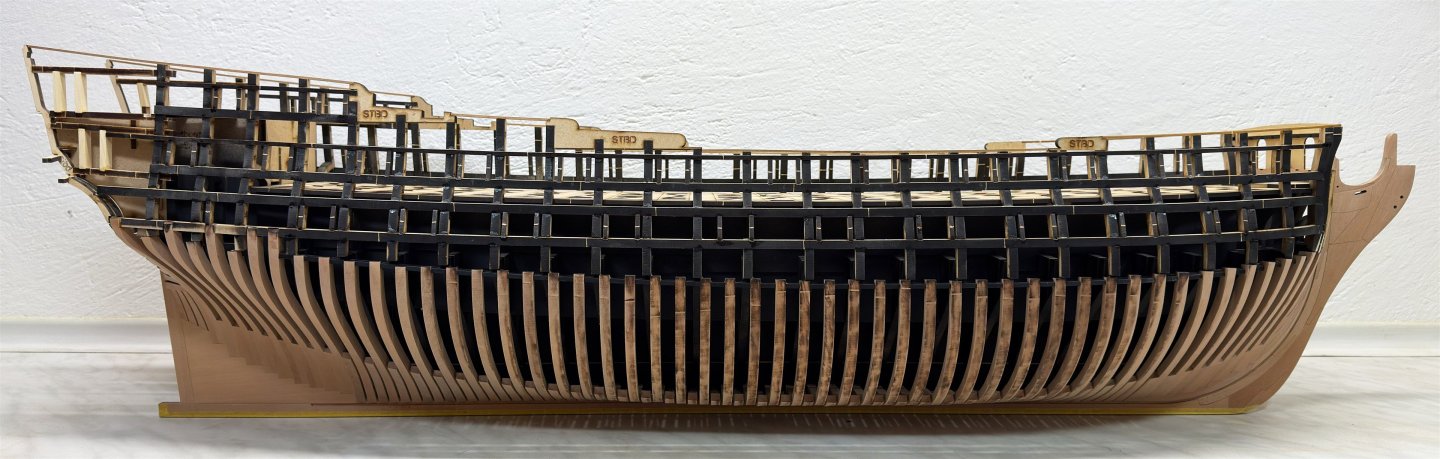

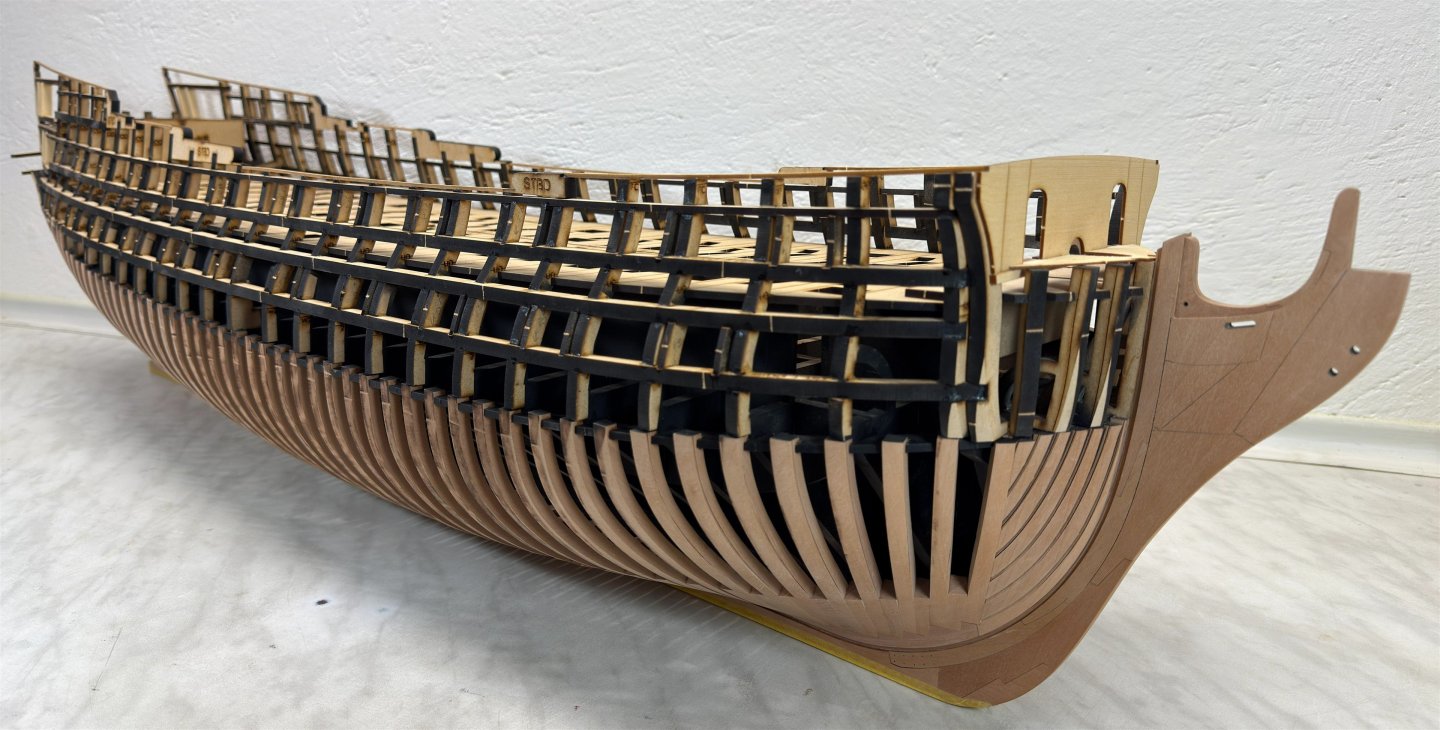

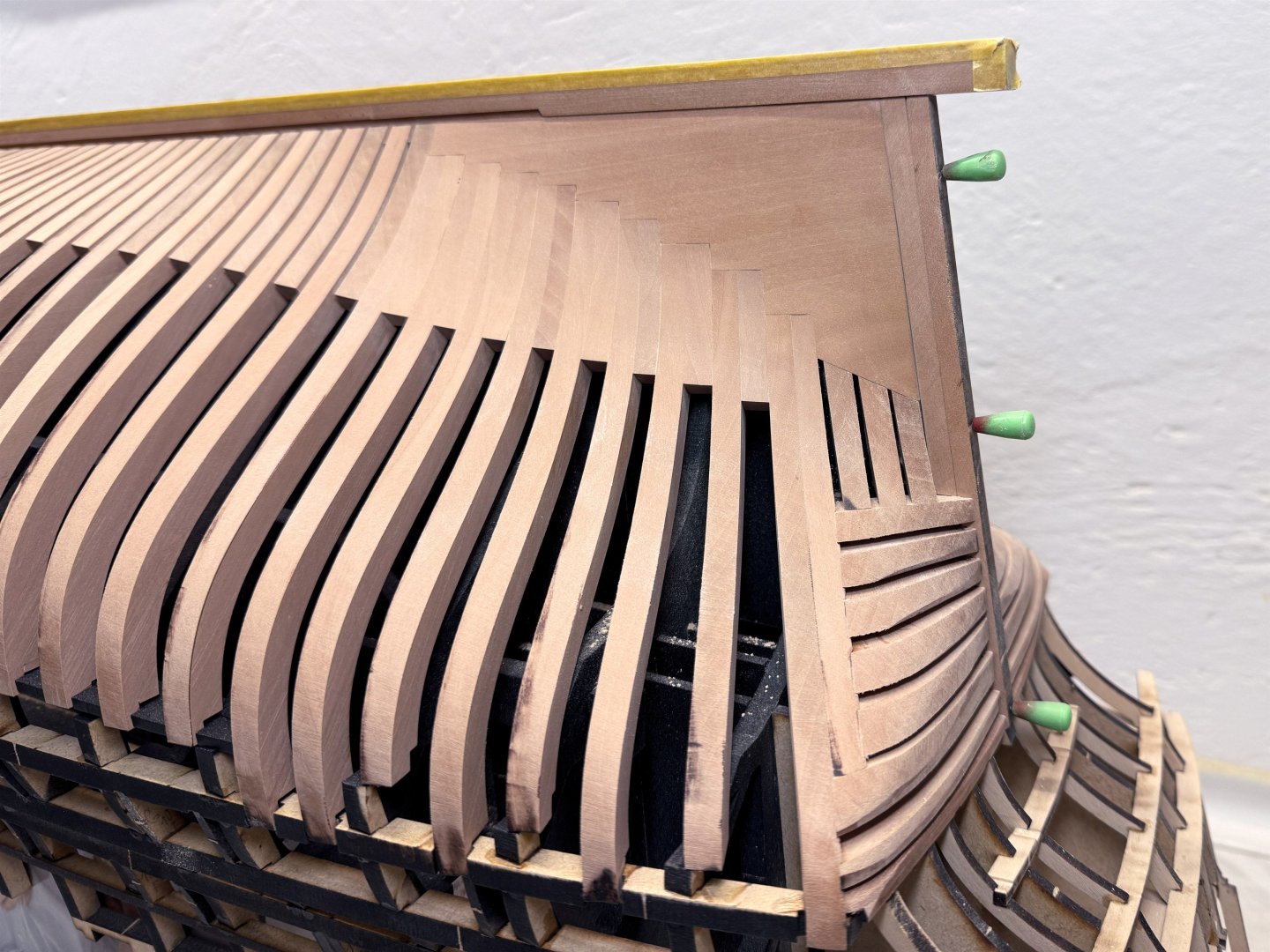

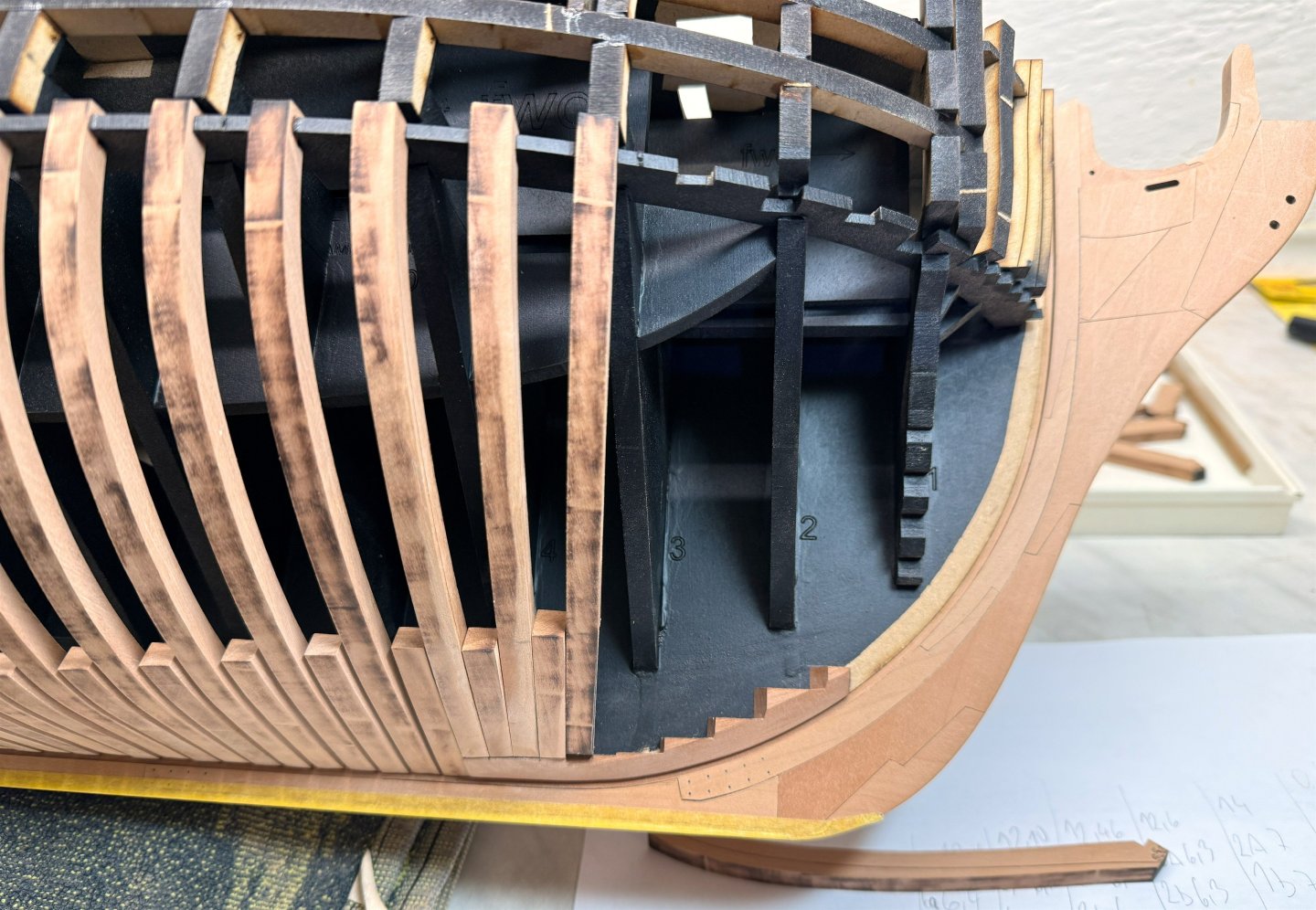

Hi guys, There's no major progress yet, just a small preview of what the planking might look like. It's a weekend project. The Wales is black hornbeam and the planking is Castello boxwood. It's coated with Osmo hard wax. The background under the friezes is Prussian blue. I'll try Cerulean blue, too. I can't decide. I originally wanted to make the planking from light pear wood, but I was disappointed with the material I had prepared. When I cut it perpendicular to the grain, the grain is very visible, and when I cut along the grain, the planks twist. In the end, I'll probably choose Castello boxwood. What do you think?

-

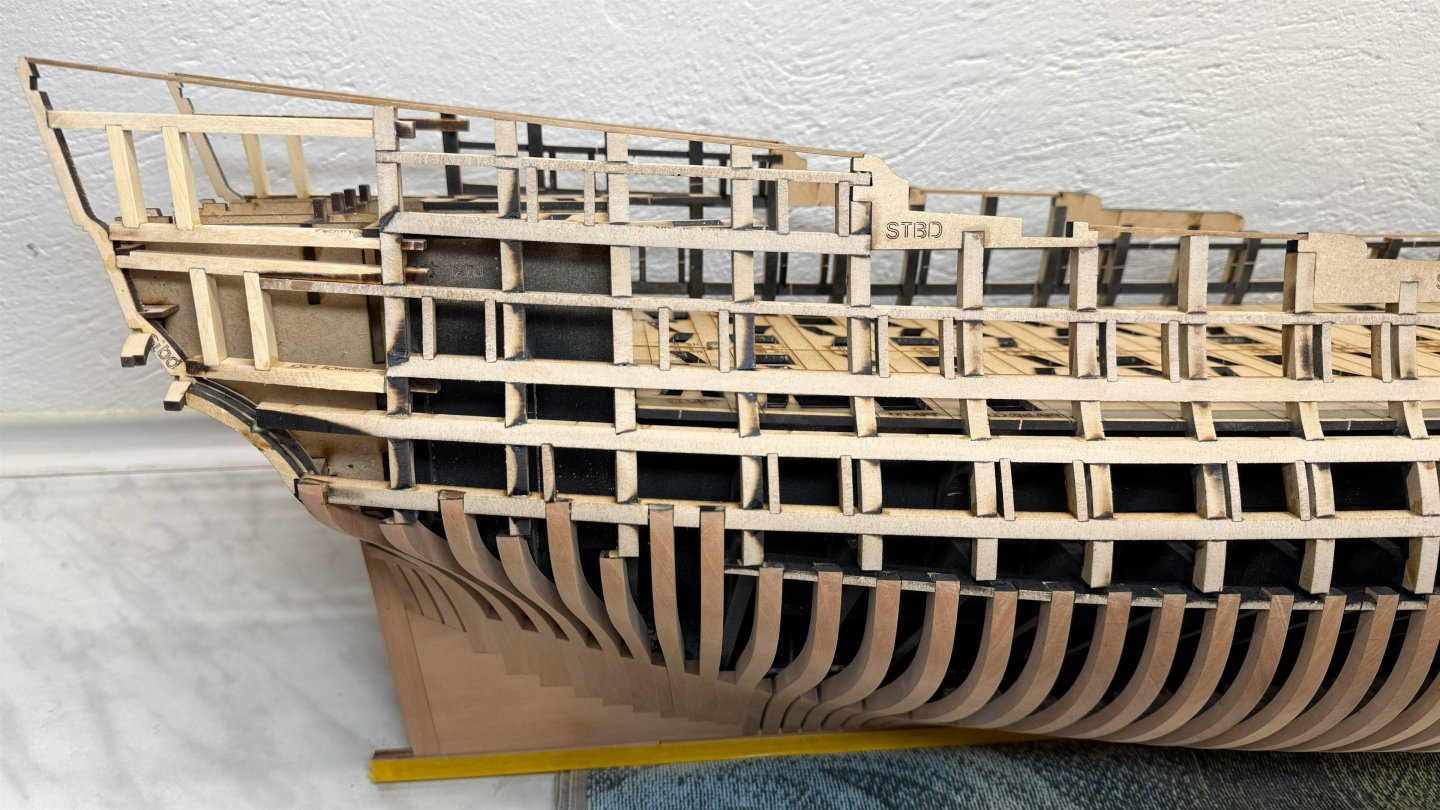

Hi guys, I finally managed to permanently glue the frieze panels. Now, I have to cut the strips for the planking. It was originally supposed to be light pear, but the boards that I cut the strips from are all warped, so I'm not happy with them. So, in the end, it will probably be Castelo boxwood. But more on that later.

-

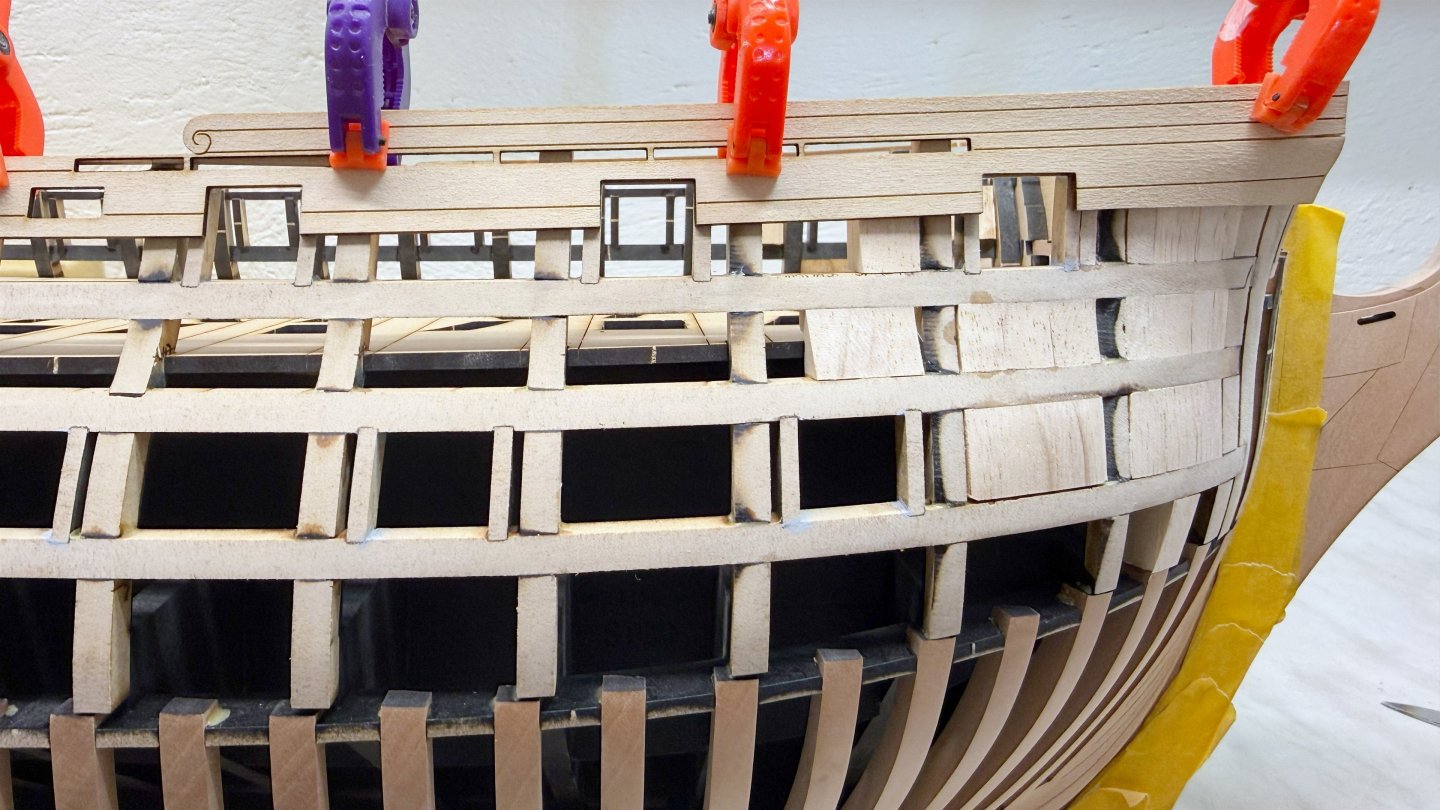

Another small update: I set the lower counter aside for now, but I shaped the front of the frieze panel similarly. I also did a dry fit of the bottom of the balcony to determine the placement of the panels. It was good not to have glued it yet because the overlapping parts could easily break off, and fairing the hull was also easier. After countless tests of placing these panels and the planking strips—which unfortunately did not make it into the photo, I managed to apply the first coat of Tamiya surface primer. So I'm getting closer to planking

-

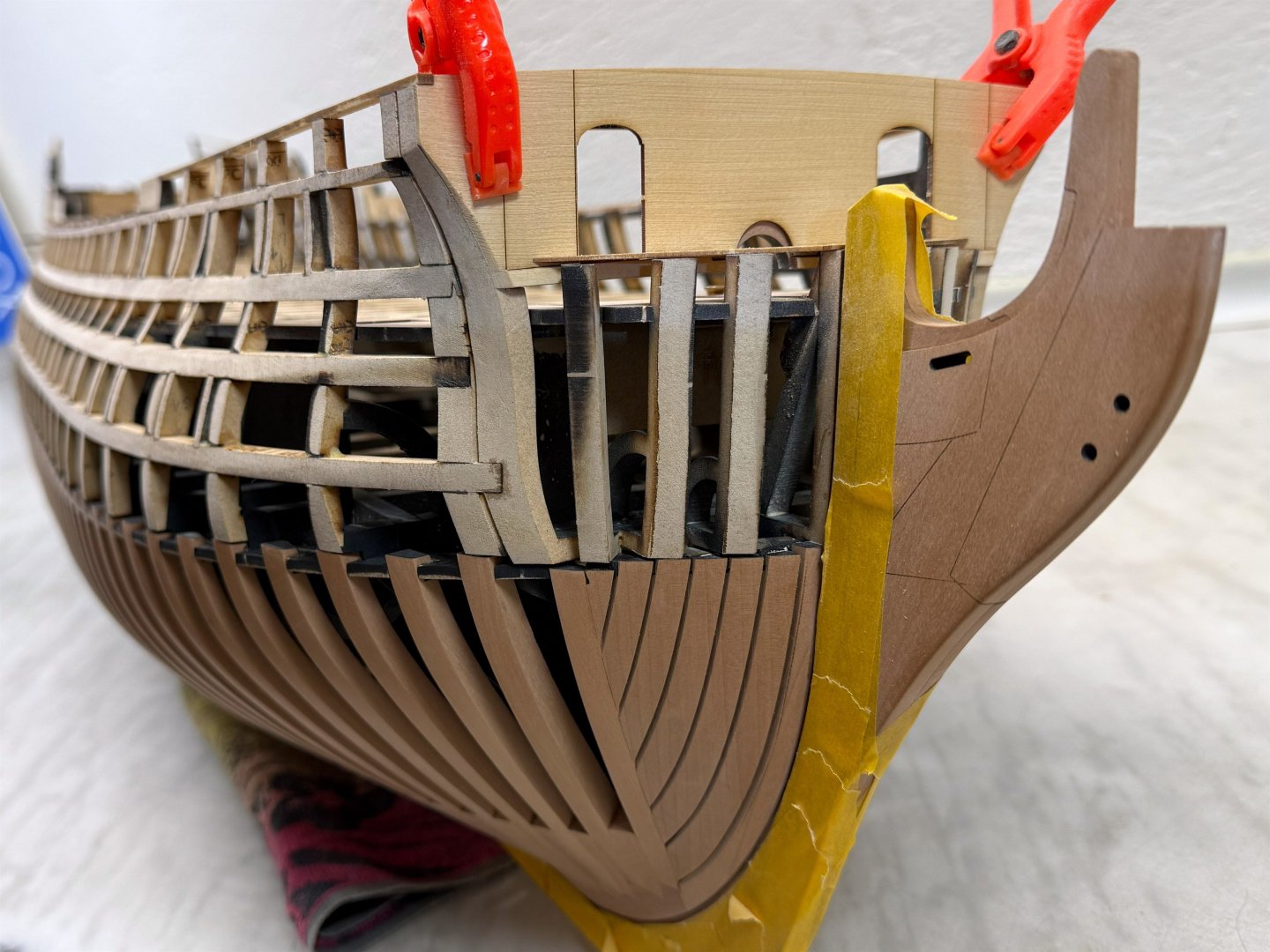

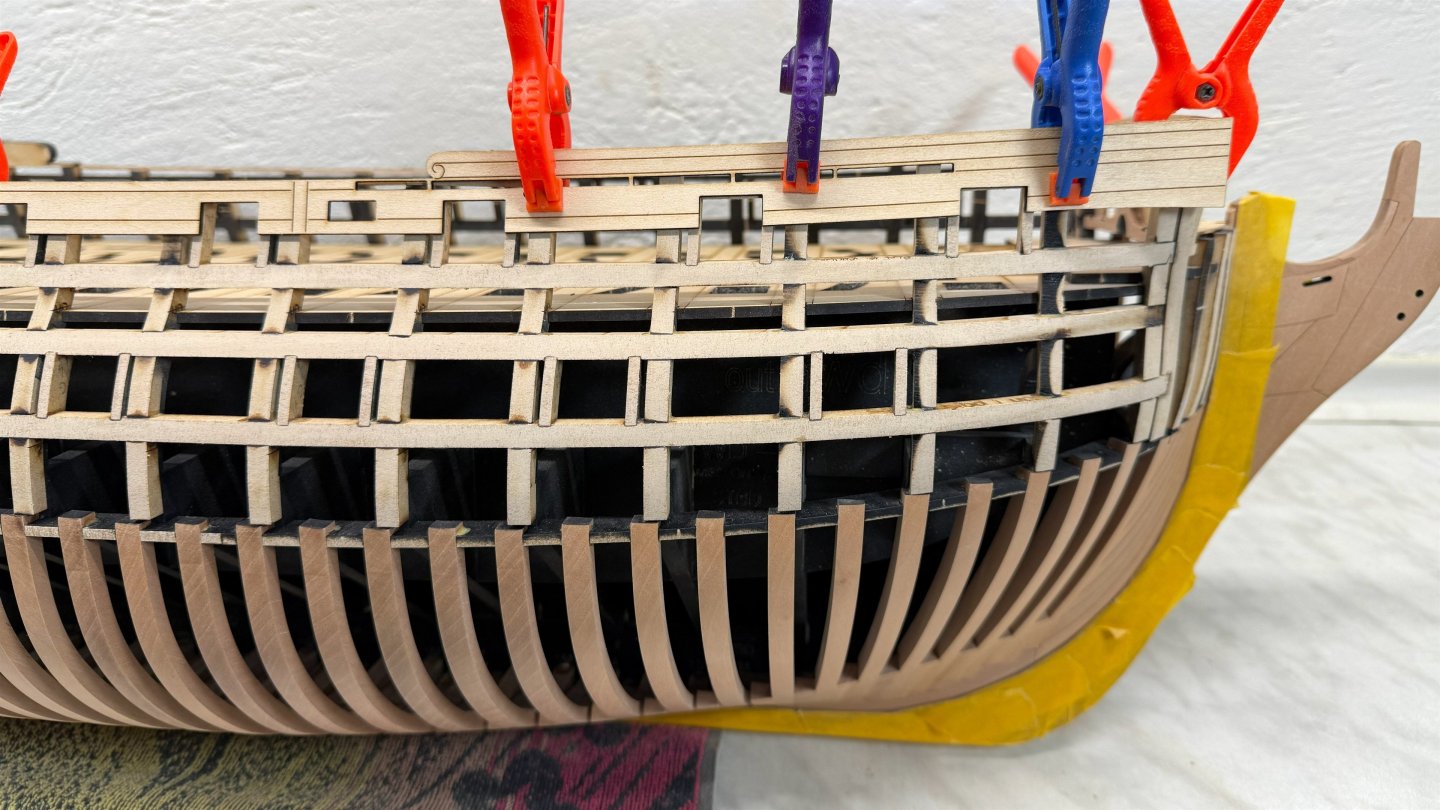

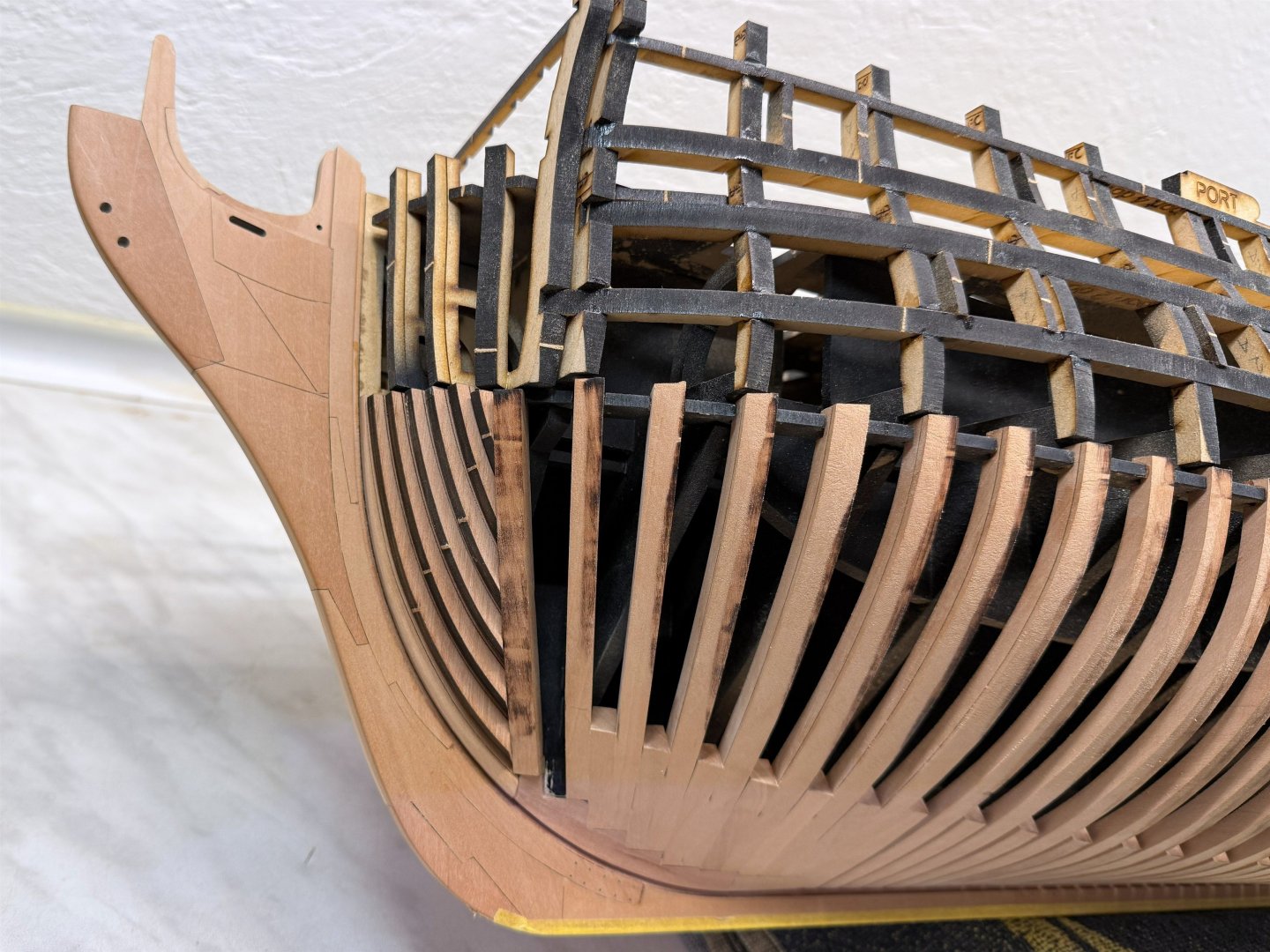

Thanks, guys. You're right, Ben, the modified apron with added material and bevel marks has improved it a lot and I think JJ did the same thing with dead wood. Before gluing on the side frieze panels I decided to shape the lower counter first. Although it could have been attached dry, I ended up soaking it and letting it dry overnight. Now that it holds its shape, I will make some adjustments to the edges. I also decided to add some fillers to the bow for better control of the hull fairing in this area.

-

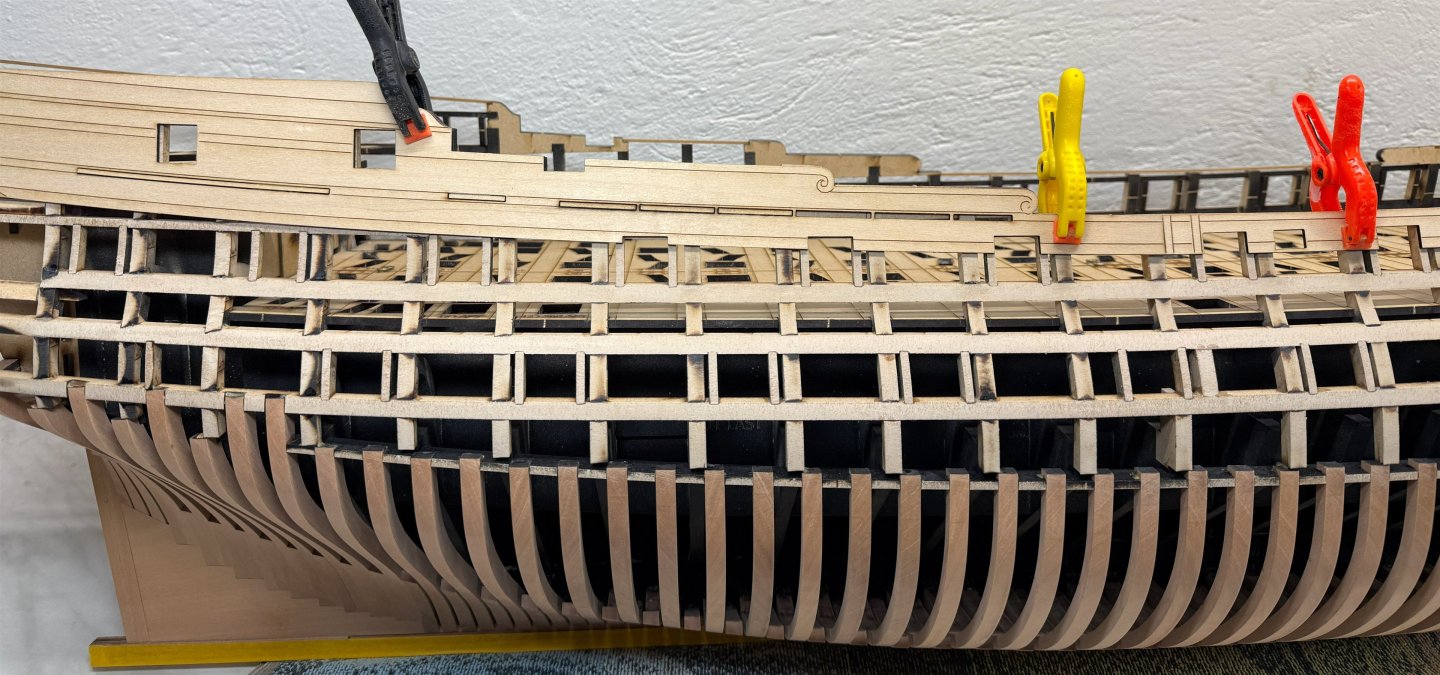

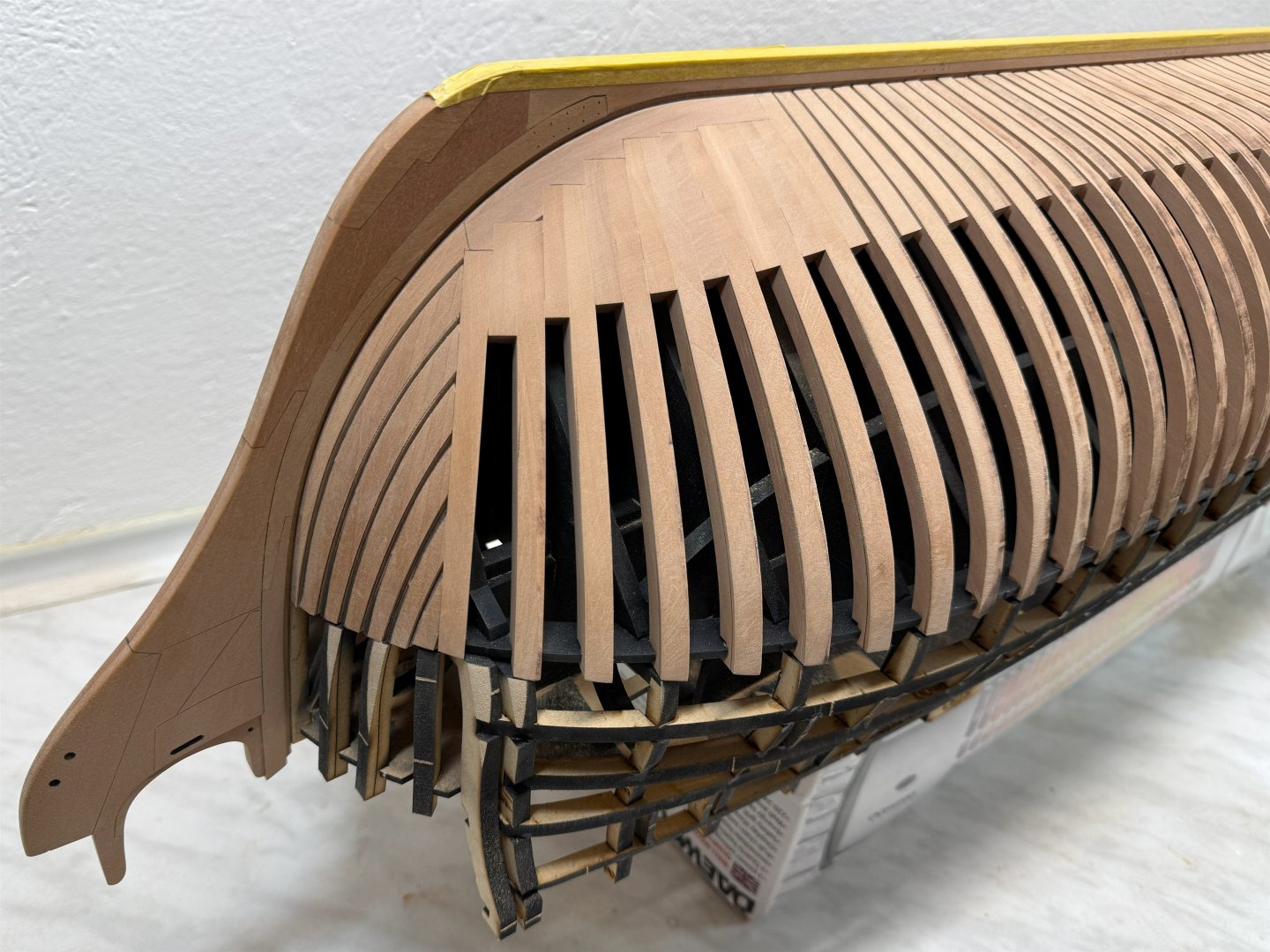

Thanks, guys. Today, I just continued sanding the stern. The post is only temporary. I might glue it later when it's time for the lower counter. I also need to finish the stern chaser ports. And to conclude the first chapter, I still need to add fairing caps. And finally then, I can move on to fairing the hull of the beast.

-

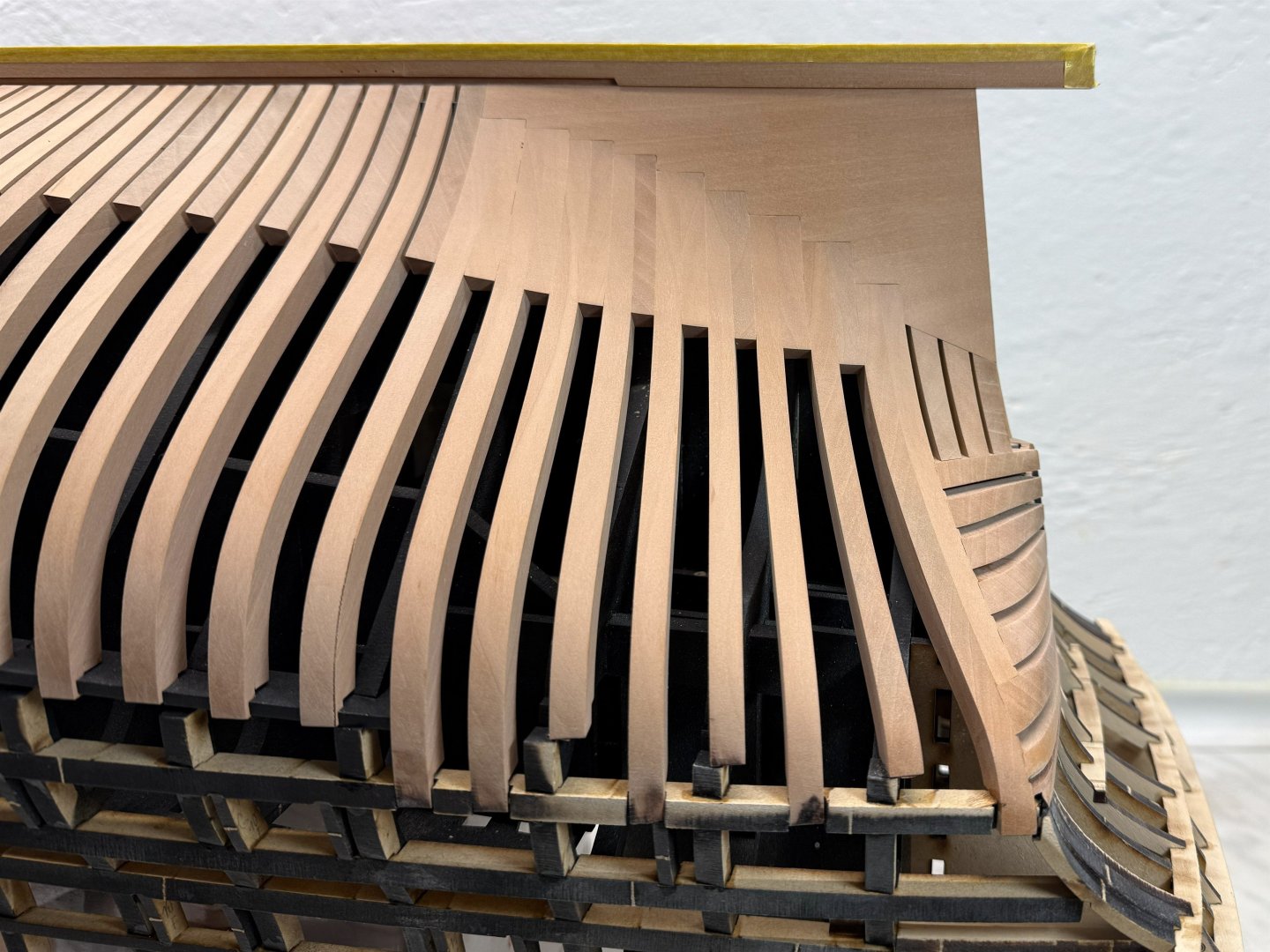

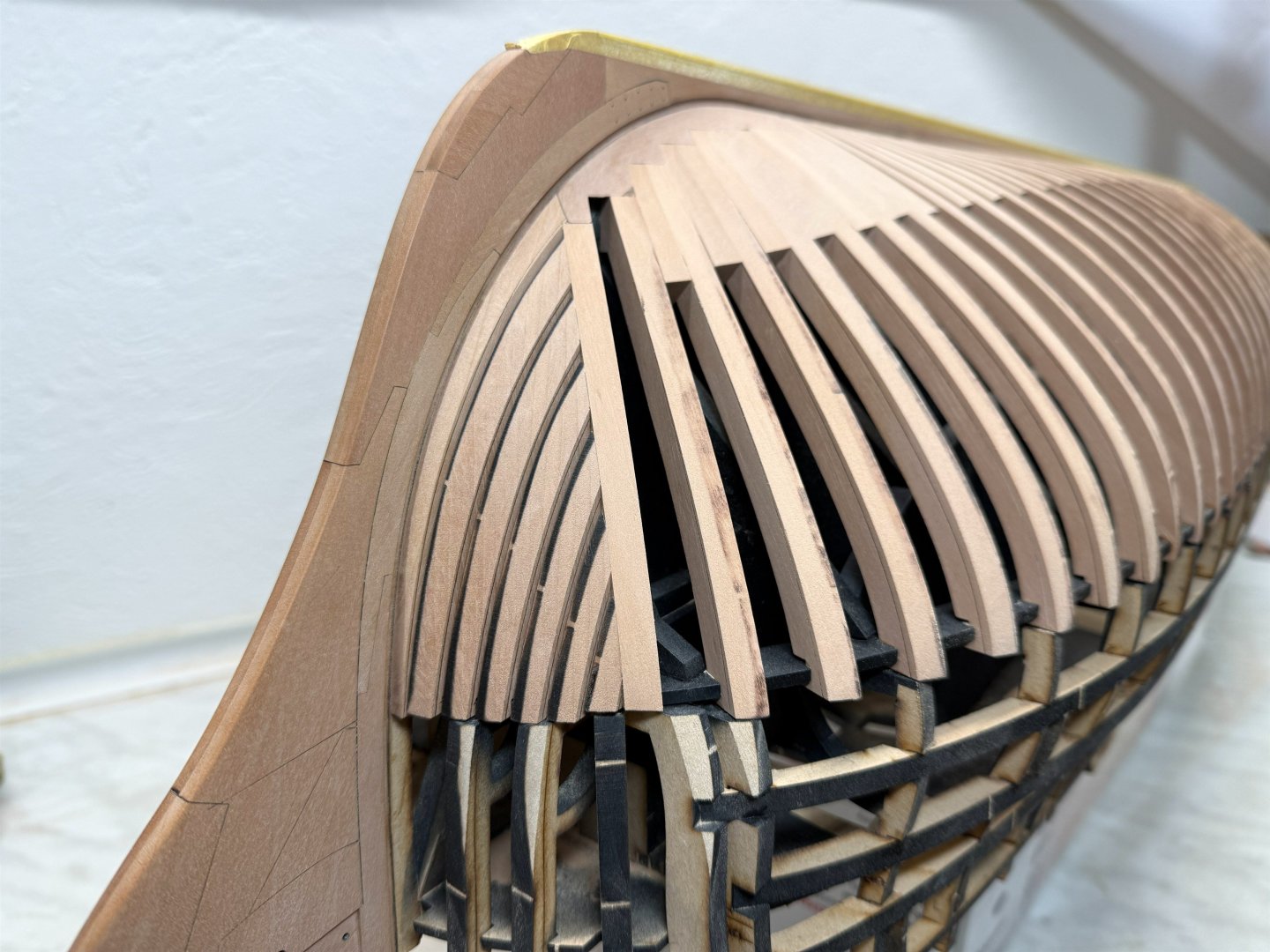

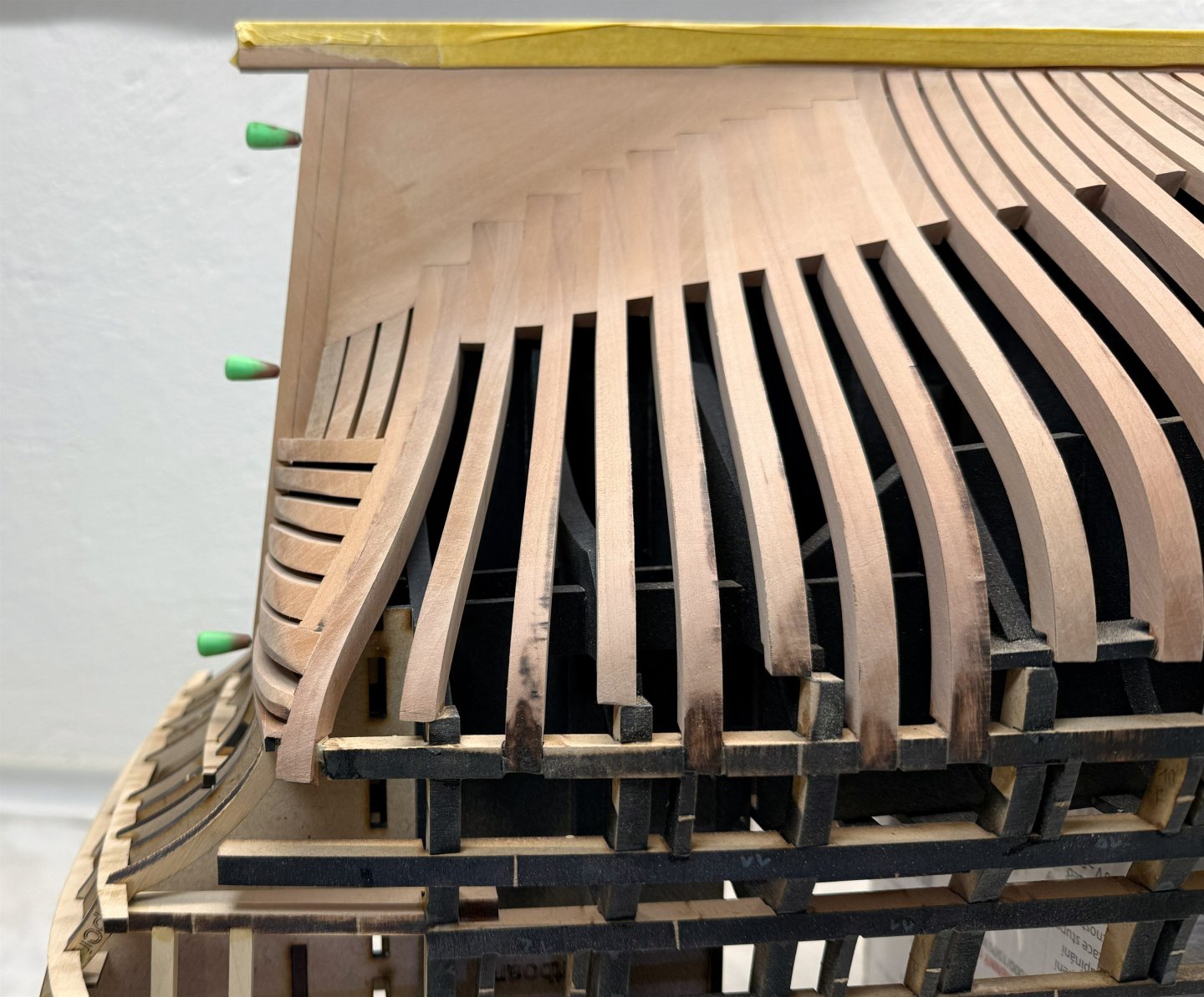

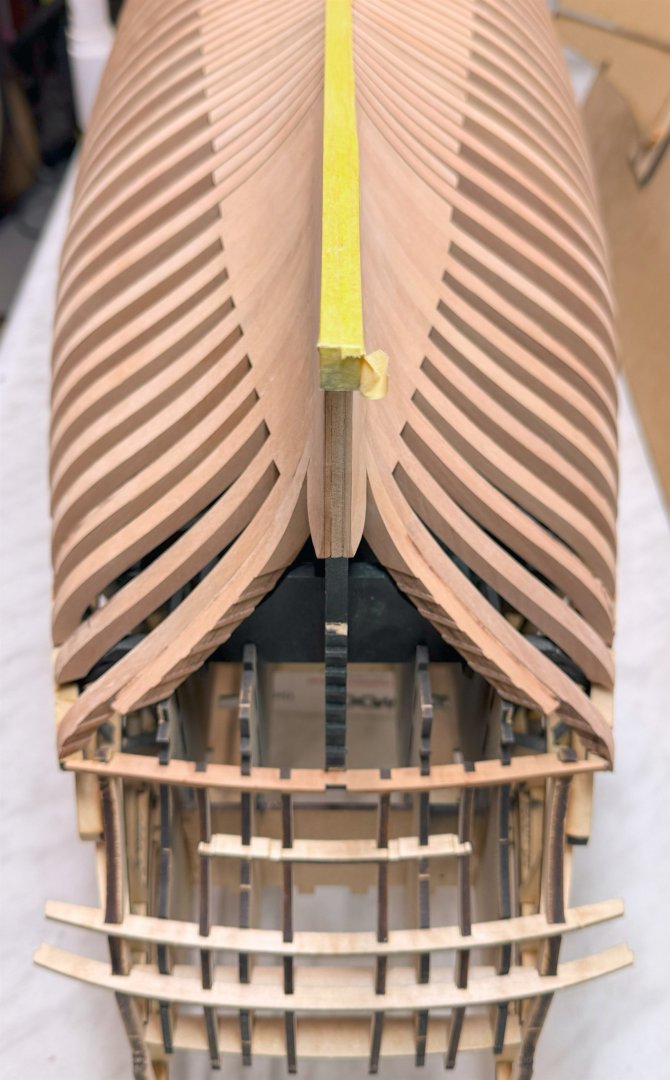

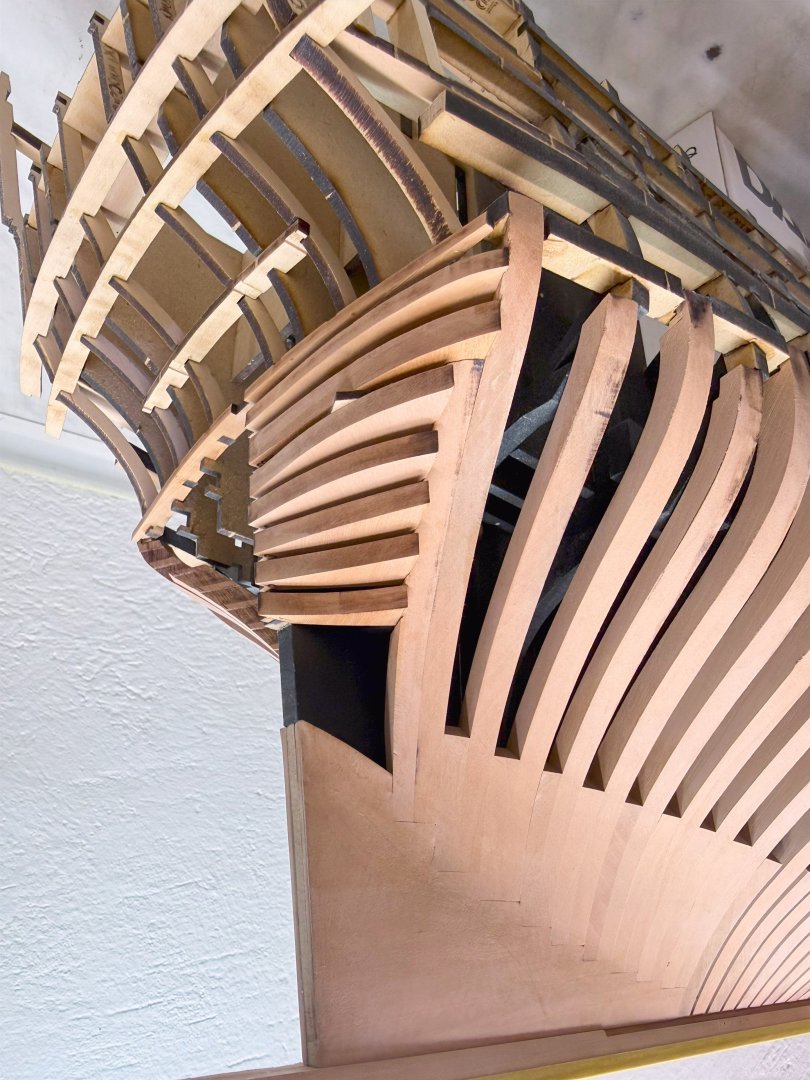

Thanks for the likes and comments, guys. Today, I glued the last short cant frame and then moved on to the fairing. The bow or cant frames and hawse pieces are about 80 percent sanded. Then I moved to the stern. After partial fairing, I removed the temporary inner and outer posts and continued sanding the wing transoms. This is a much more difficult part than the hawse pieces. Tomorrow I have to add some fillings and try to sand it down.

-

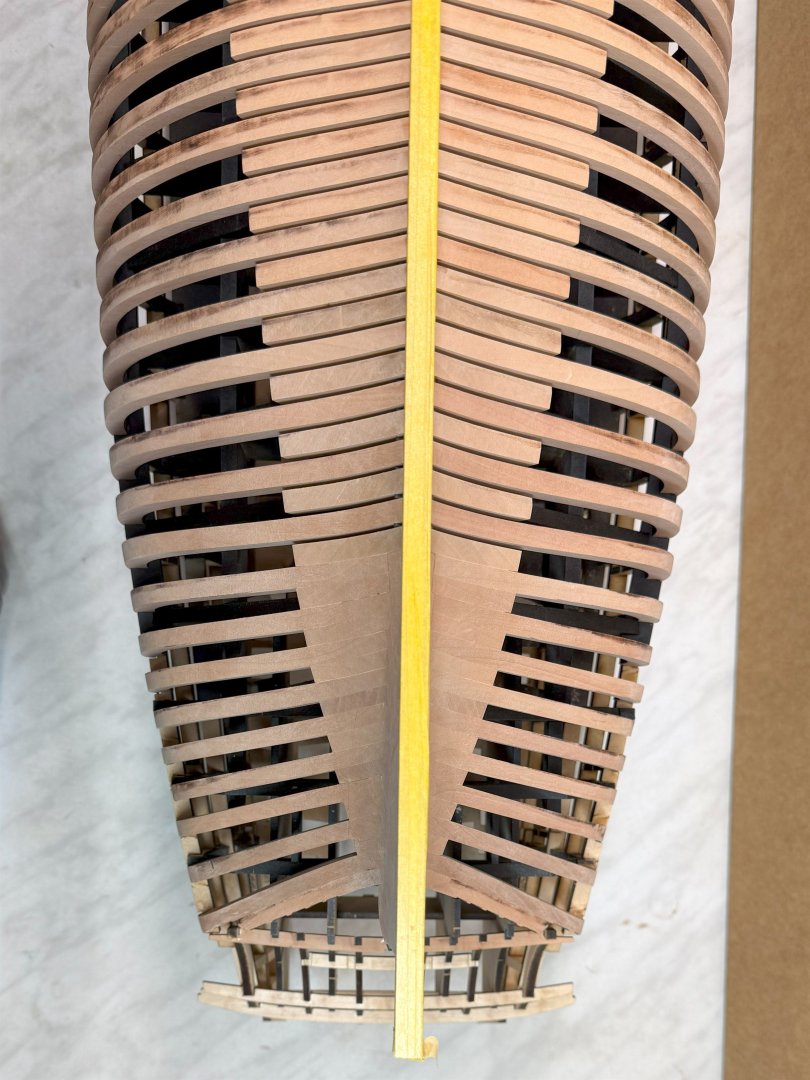

That piece was maybe 3 mm thick but now that I've sanded it down a bit, it's about 2.5 mm wide at frame 8a and gets even thinner towards the front. Wait a bit with the modification, JJ, while I do some more sanding. Then I'll check it, take a photo, and write to you. I'll also send a photo of how much I've adjusted the front step for frame 1a. Now, today's progress. I glued the last one, even though it's actually the cant frame no 1. And then the hawse pieces or bow timbers, which name is correct, or both? During assembly I used 0.8 mm foil and some scrap to support and define the same distance between them. And of course, I couldn't wait because I was curious to see how it looked, so I immediately started sanding. Now, however, the last half frame and the same thing awaits on the starboard side.

-

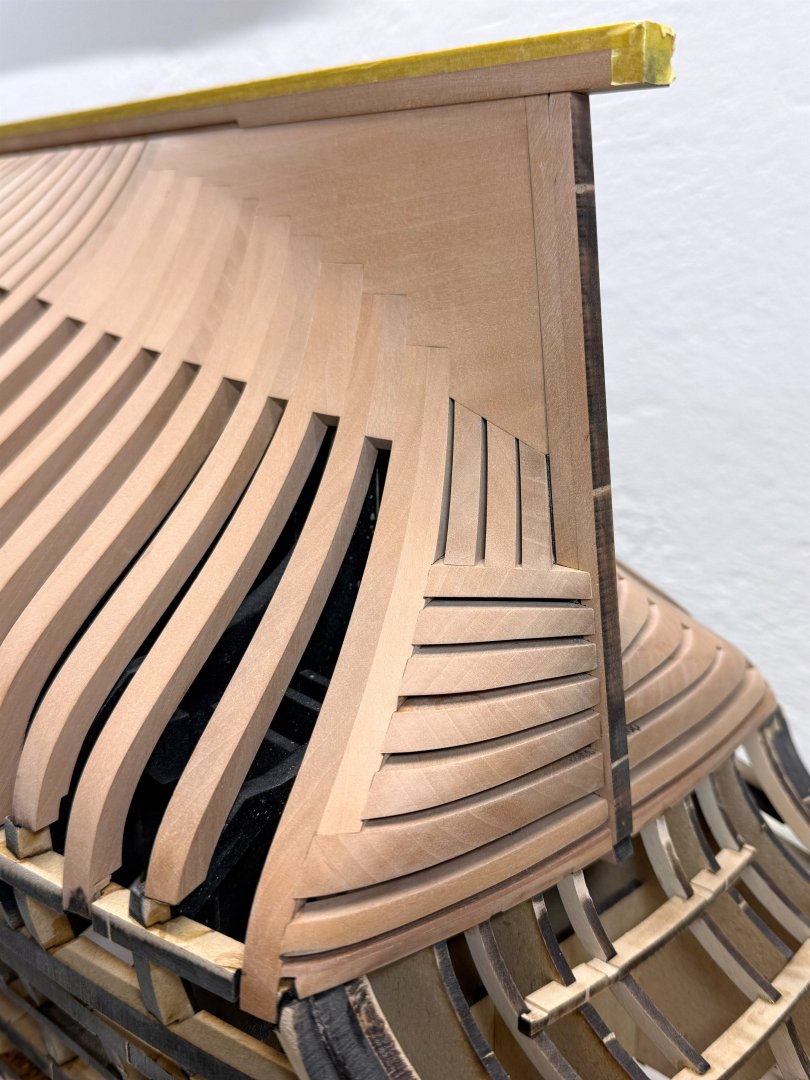

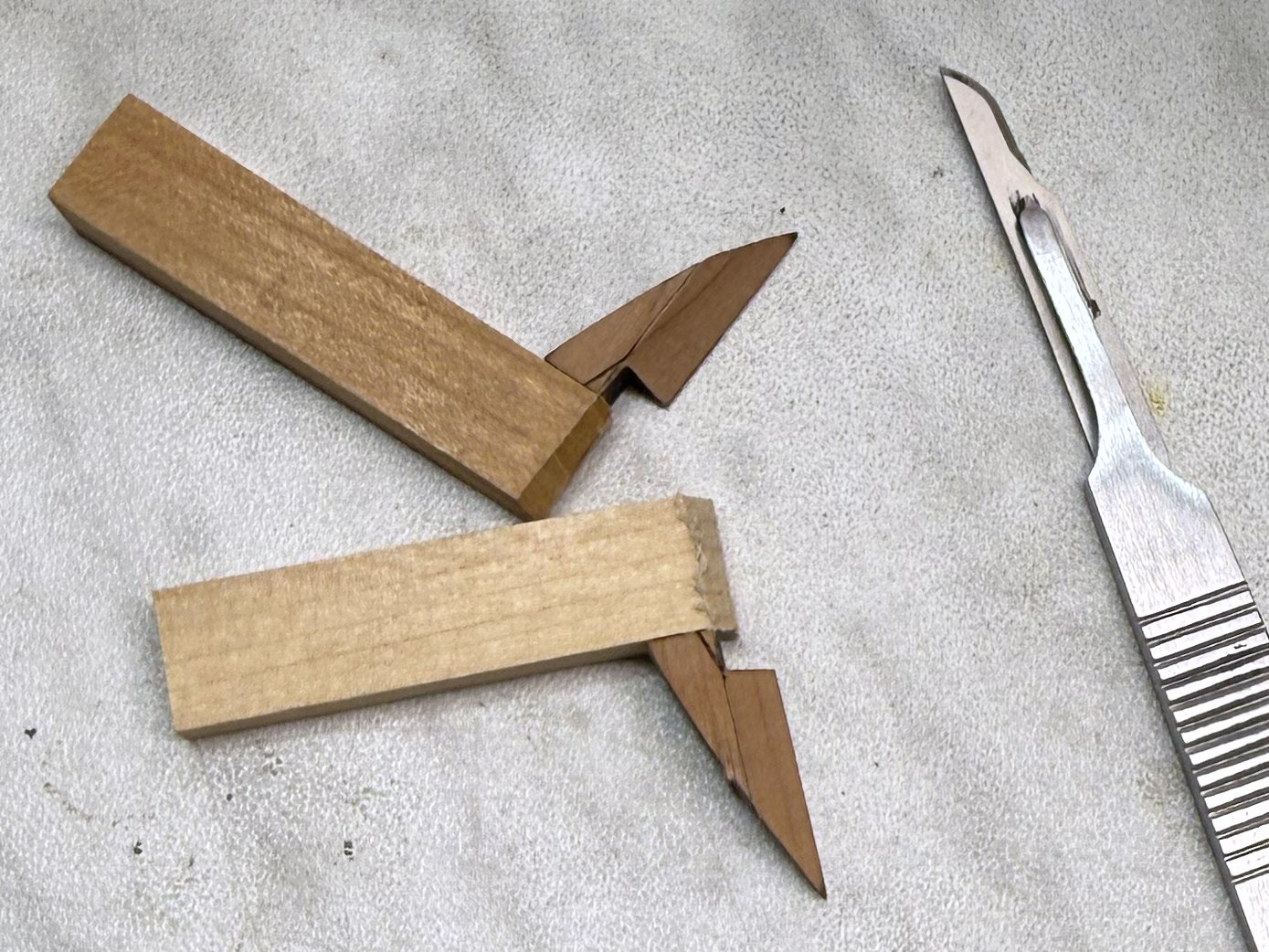

You're right, JJ, on the starboard side I used the whole bottom apron. And I made a less visible adjustment - widening the bottom step for the first four frames. I took a piece from the scrap board from which the apron was cut so that the color and grain direction would match, and glued it with transparent glue so that it is not even visible. Maybe it will be sanded down during the final fairing anyway, but just in case.

-

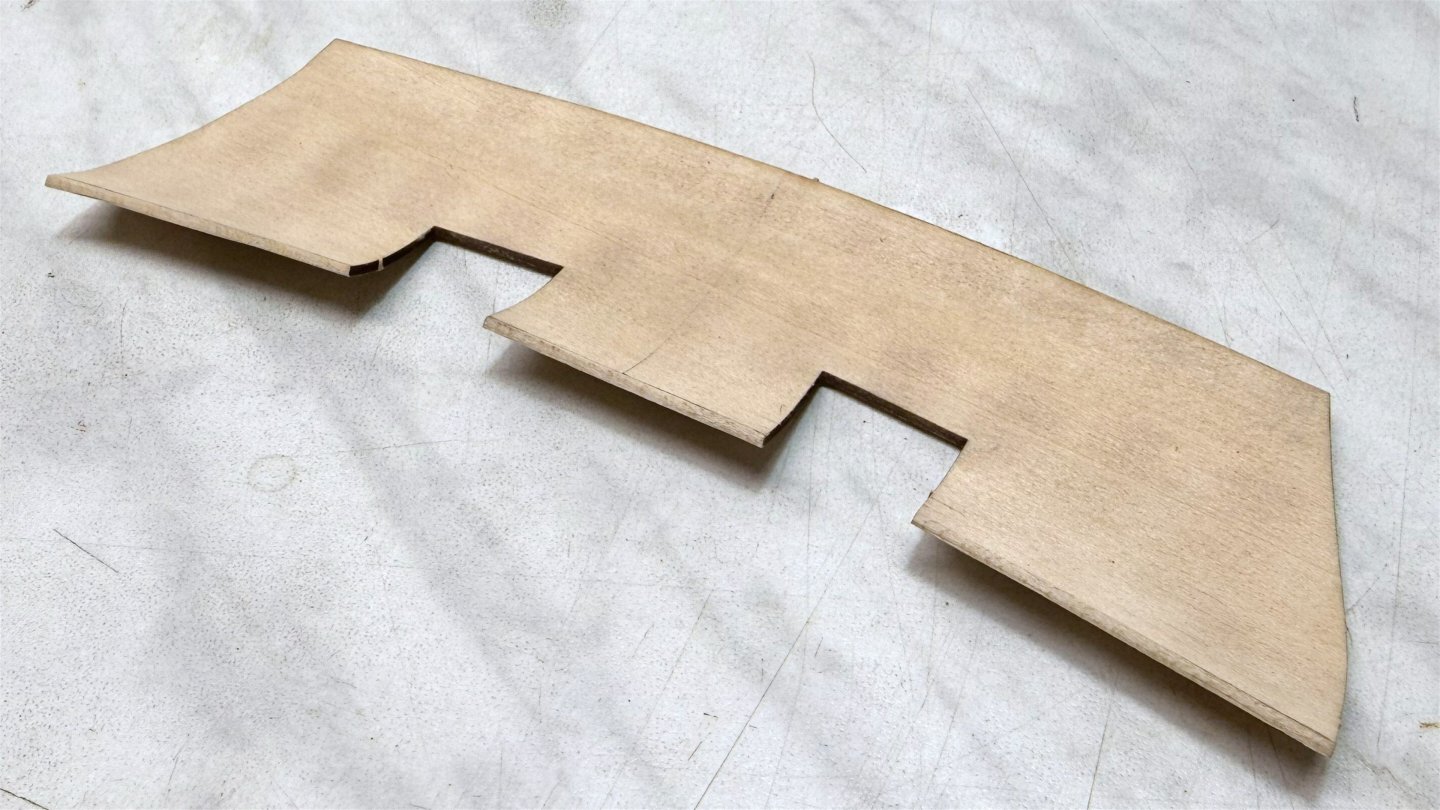

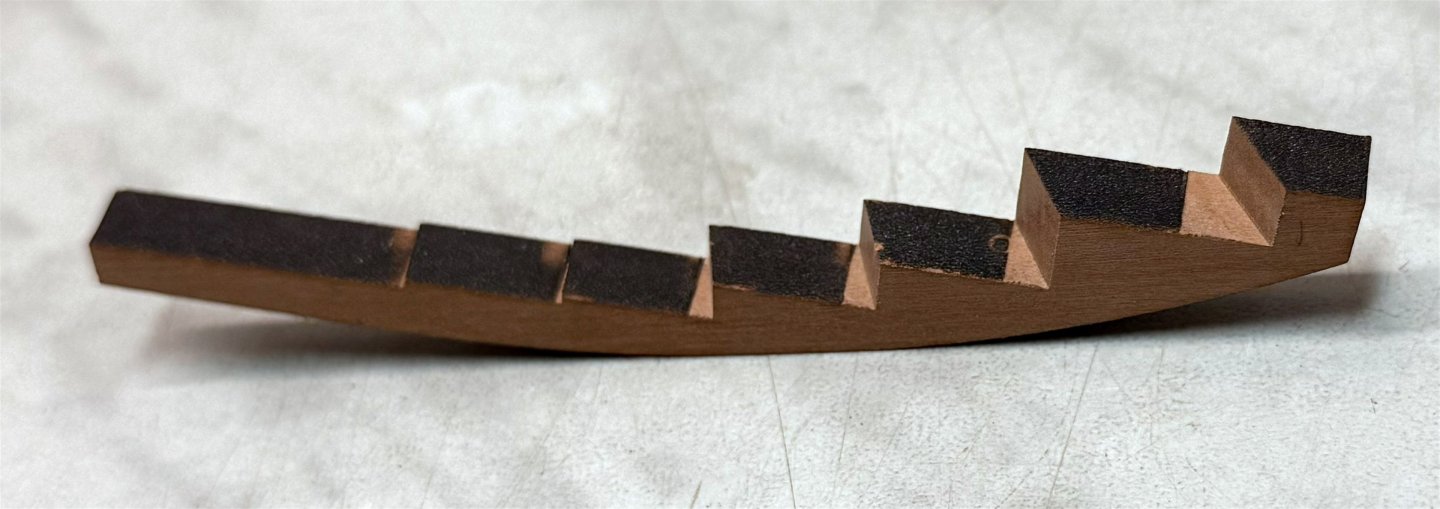

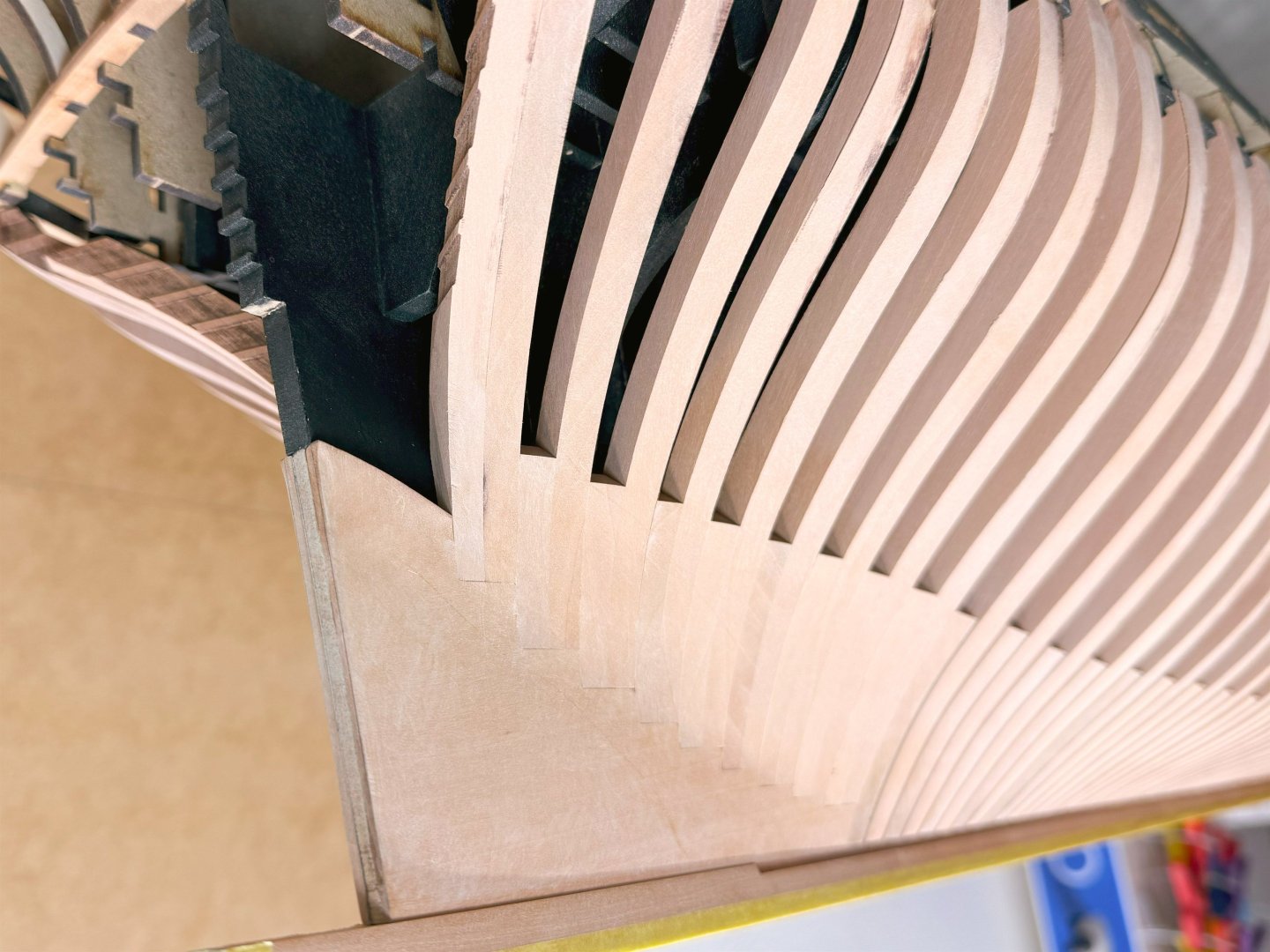

Hi guys, I finally started working on the forward frames. I started with the port side first. Now, all that's left is to glue the hawse pieces, but that can wait until the end. Today, I started working on the starboard side. First, I had to prepare the apron. Since the forward frames slope gradually forward, they require angles and tapering. The apron must be adapted to this, which is very important. I think the photos show what I mean. The apron is now glued on, and the first frames are ready to be glued on.

-

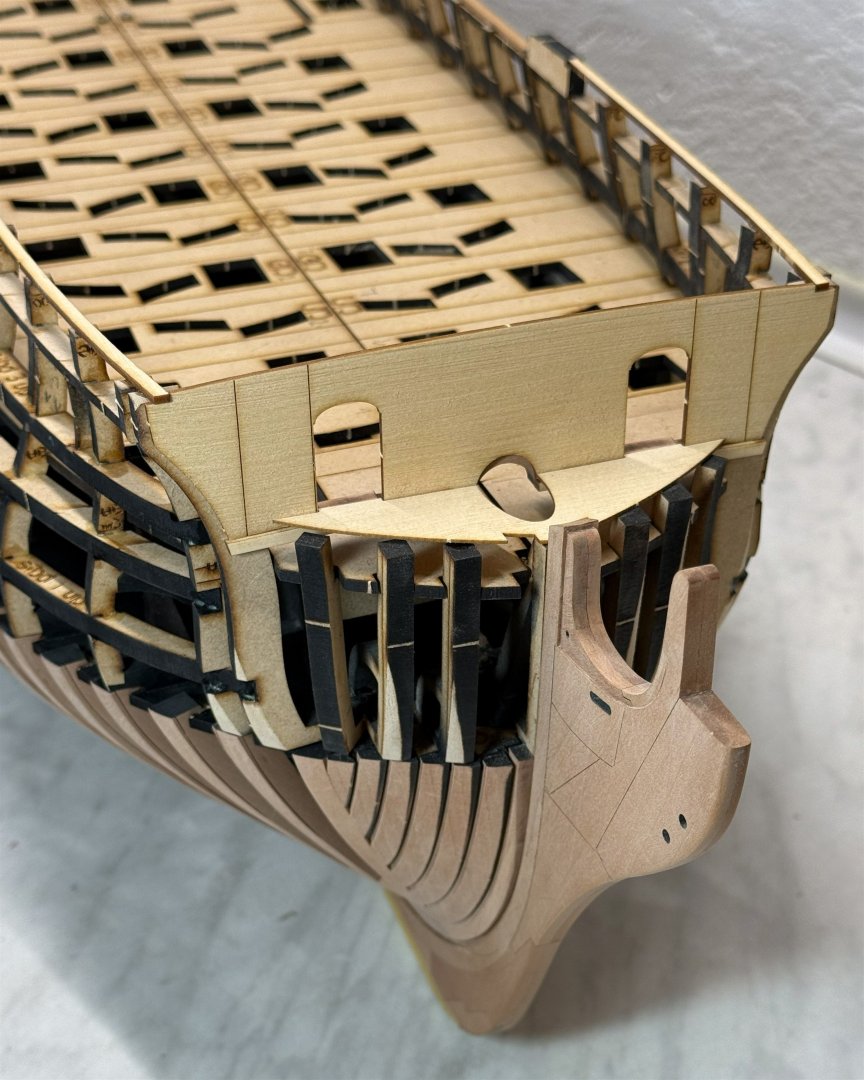

Hi guys, I'm sorry I'm not posting more updates, but there's no end to the housework before winter. But here's a small preview of what I've done so far. I took a slightly different approach and did the vertical filler first. The inner and outer posts is glued together, but don't yet glued to the bulkhead former. Then, I laminated the wing transom. Now, I'm fine-tuning the other transoms...

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.