westwood

Members-

Posts

279 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by westwood

-

Congratulations for completing a beautiful model Don. It has been a pleasure to follow your posts as you build this model.

- 144 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Excellent Glenn, congratulations, you've made good progress. And thank you for the detailed description and photo documentation. I will be inspired.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I've really enjoyed following your work Rusty. And indeed I will be looking for inspiration in your log for a long time to come because my Winie is far from finished. So, congratulations on the completion of a beautiful model. Now I wish you a nice vacation and I look forward to your new building diary.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

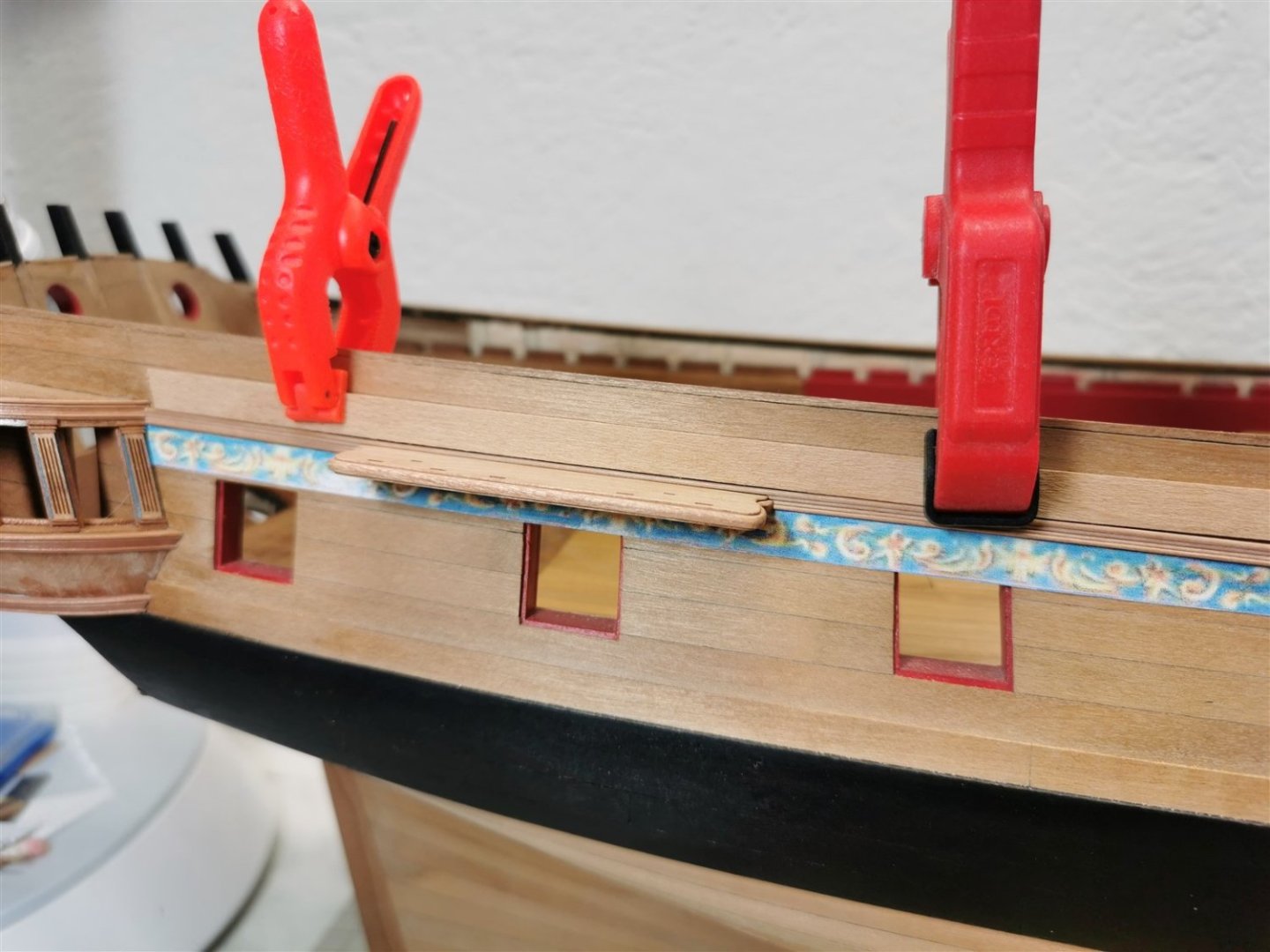

Thanks for the comments and likes guys, Especially now that I wasn't doing so well and progress was minimal. I kept toying with the idea of doing something with the friezes. I thought about editing in PC, but I'm not a graphic designer and I couldn't do it. It would take experience with graphics and a graphics tablet would probably be useful. Then I thought what about getting some waterslide decals made. Expensive and uncertain result. Today I tried hand painting but I'm not a cartoonist either, and my magnifying glass isn't strong enough. And I also don't have such micro brushes yet How the hell did they do it at the time? So I guess I gave up, and today I put the first friezes in place. What do you think?

-

You're doing great, Rusty, Fingers crossed for the final and looking forward to the gallery.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I'm speechless Glenn, beautiful work. Also starting to shape all those eyelet and ring bolts...

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Wow beautiful photos Glenn. Thank you for showing them to us

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Jim, I'm building a cherry version too. I would also like a wax or Tung oil finish. It really is not only a beautiful finish but I like the smell of it too. But from a practical aspect, I finally used the classic WOP. I was thinking that it would be difficult to glue other parts to an oiled surface. I just applied the first coat yesterday and it looks nice. After application, the color of the wood became quite rich. One or two more coats and then I'll take pics. Also, it depends what version of cherry wood you use. My laser cut parts from Chuck are darker colored and for planking I used a lighter cherry . You'll see it better when you make a few planks to use for the planking. But I'm just a beginner at this...

-

Hi my friends, I can finally show a little - big progress. Before gluing the moldings I moved away from the plans and assembled the channels to prepare them for later fitting on the model. And then I glued the middle moulding first and then the bottom one. I chose this method and the friezes I'll try to glue in the end. But before that happens, I've done what I've been looking forward to for many months.

-

Congratulations on finishing Winie Mike. Beautiful and clean work, a level hard to match for me. So thank you for the whole "building log" which will serve as an inspiration for me for a long time to come. And I also keep my fingers crossed in the next project which I will like to follow as well.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Superb deck Glenn, congratulations and I look forward to the next chapter in your work

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

It's a pleasure to watch your build Siggi, looks amazing. Awesome detail, you are a perfect craftsman.

-

great photo of perfect work. just super Mike

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.