westwood

Members-

Posts

275 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by westwood

-

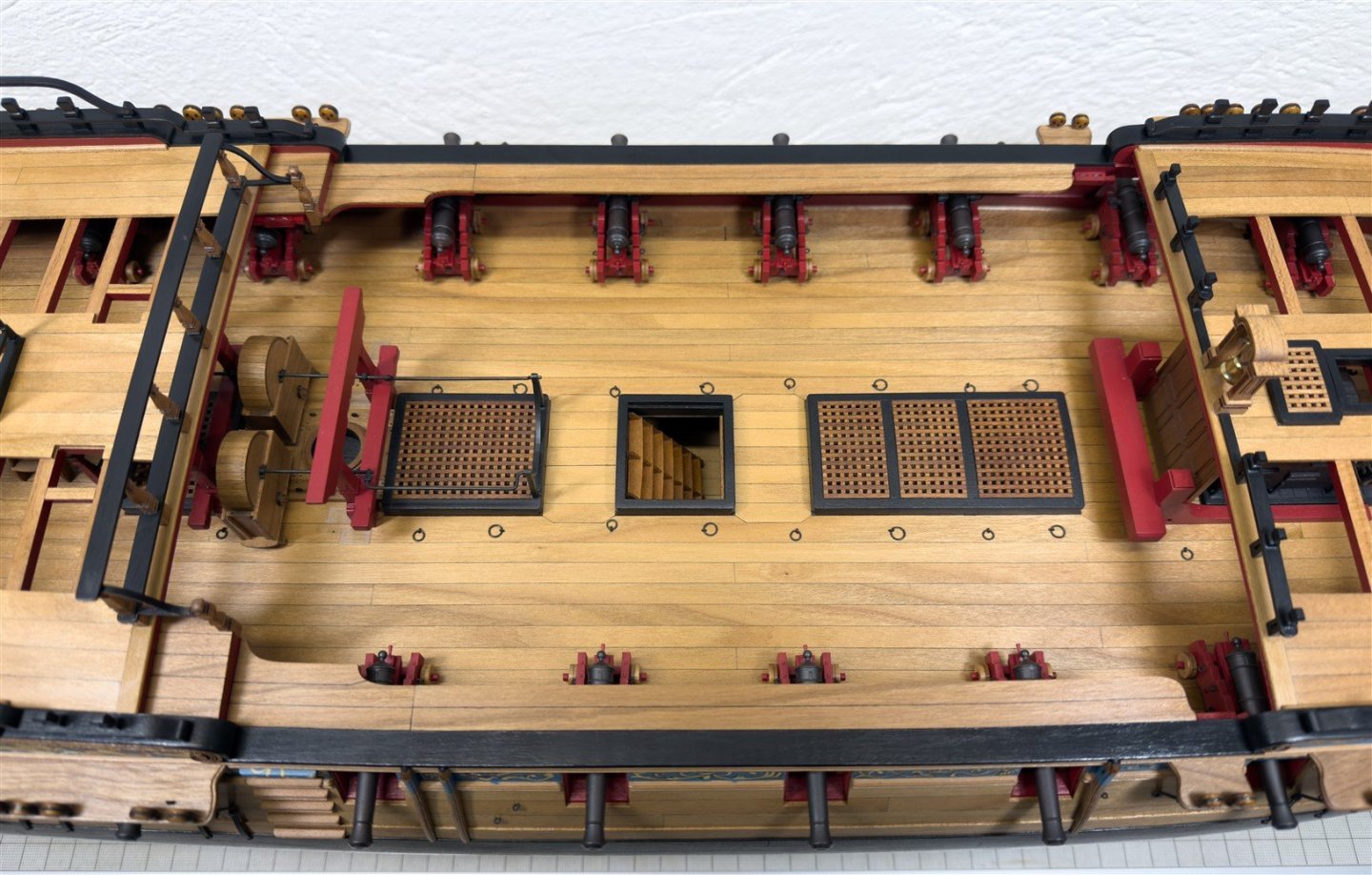

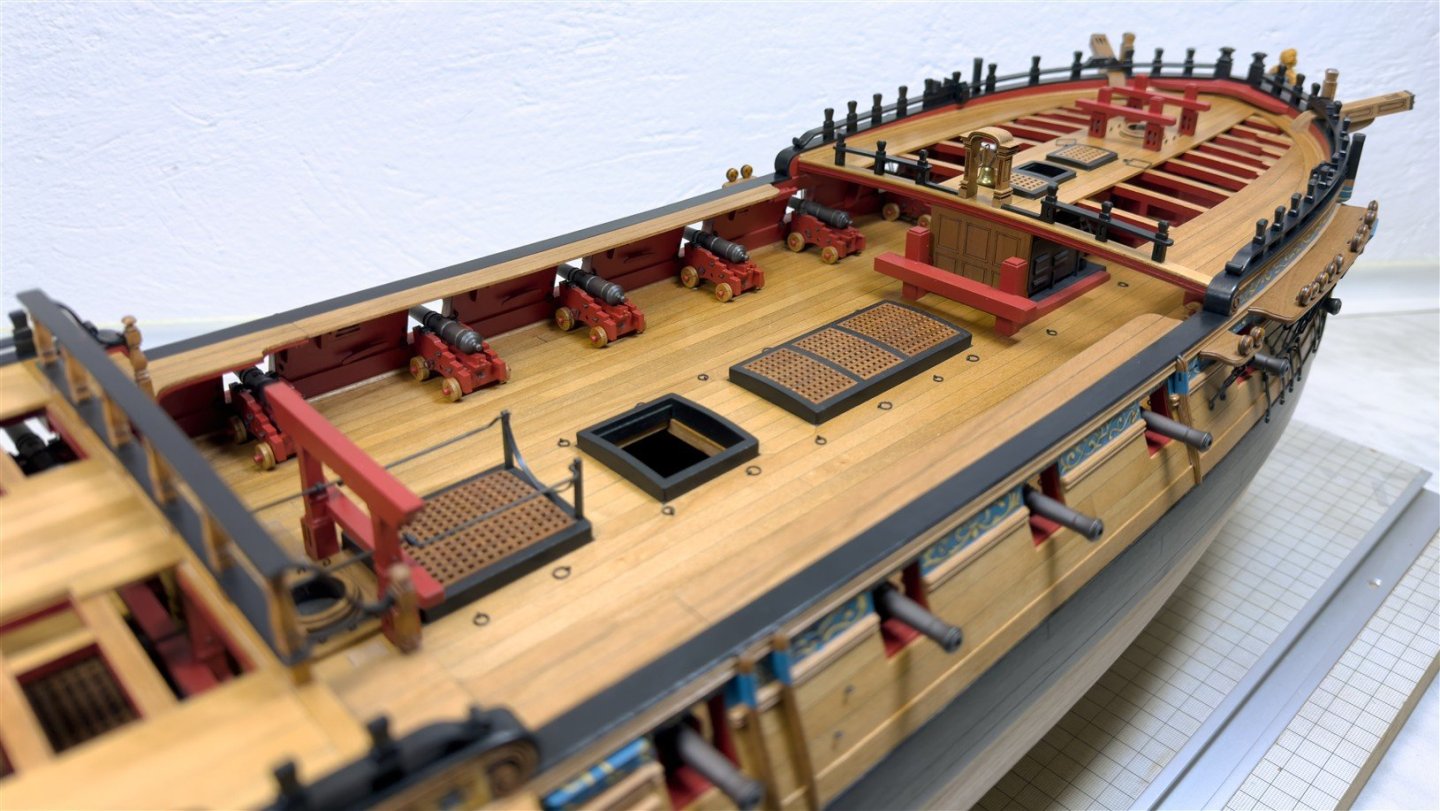

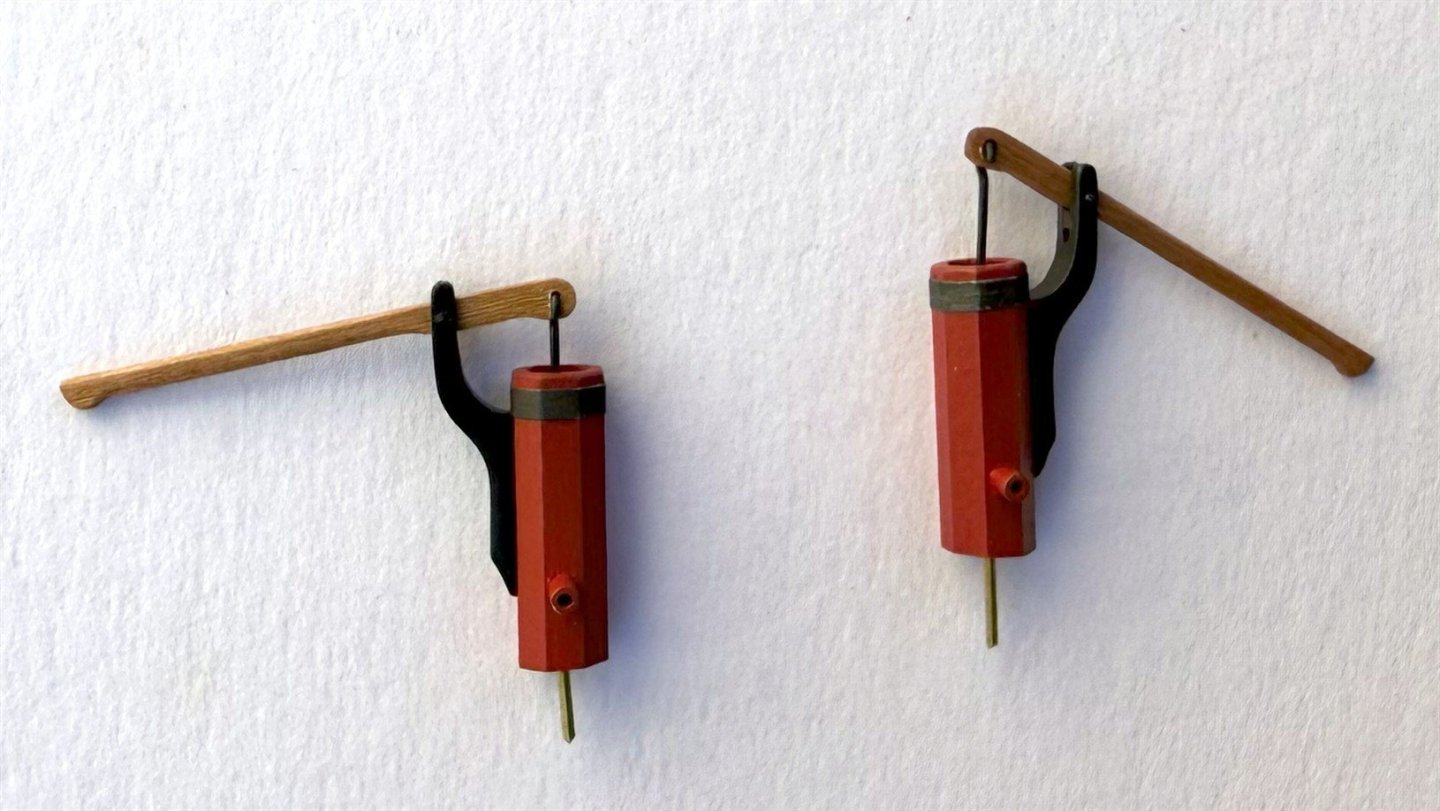

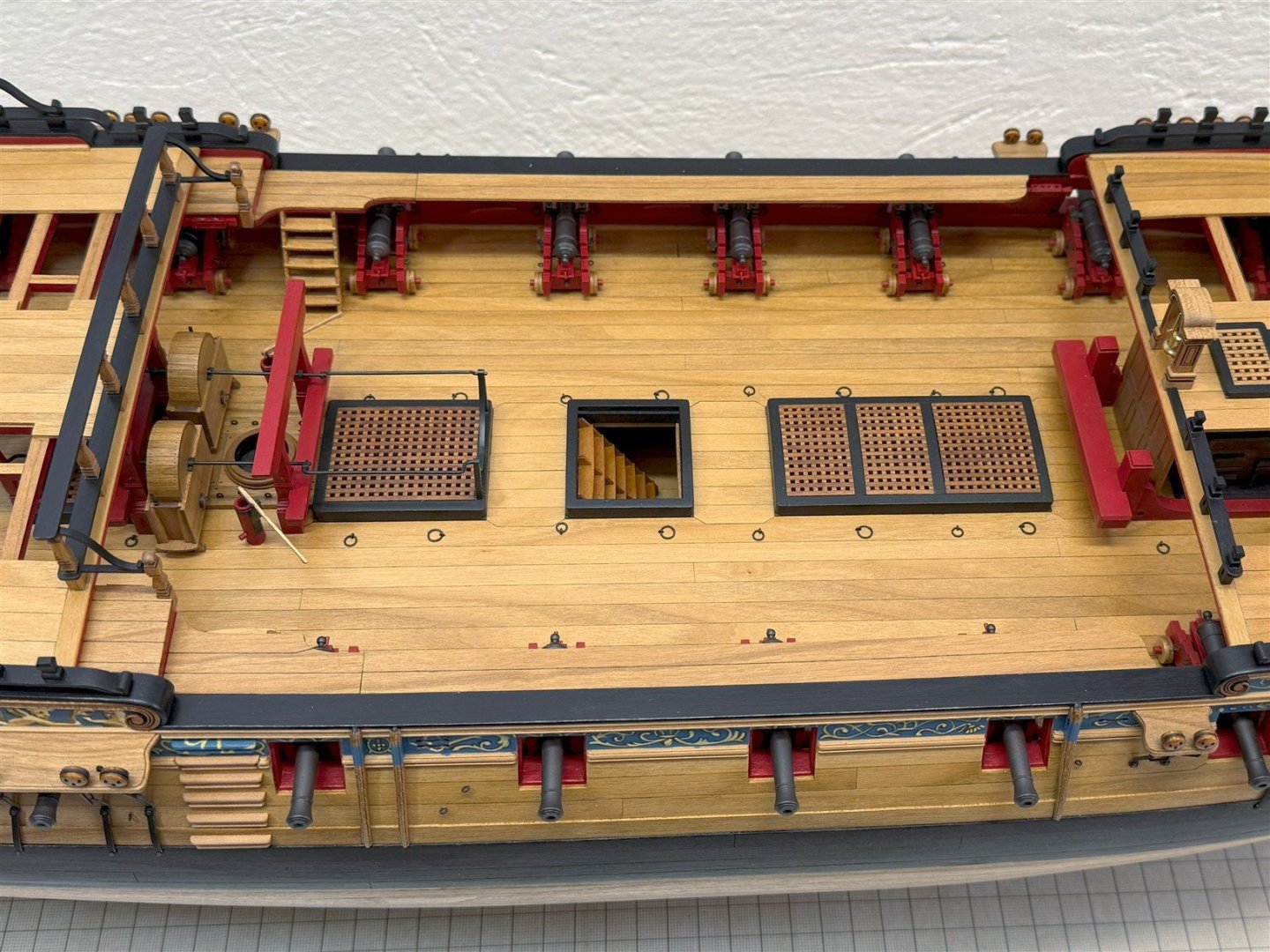

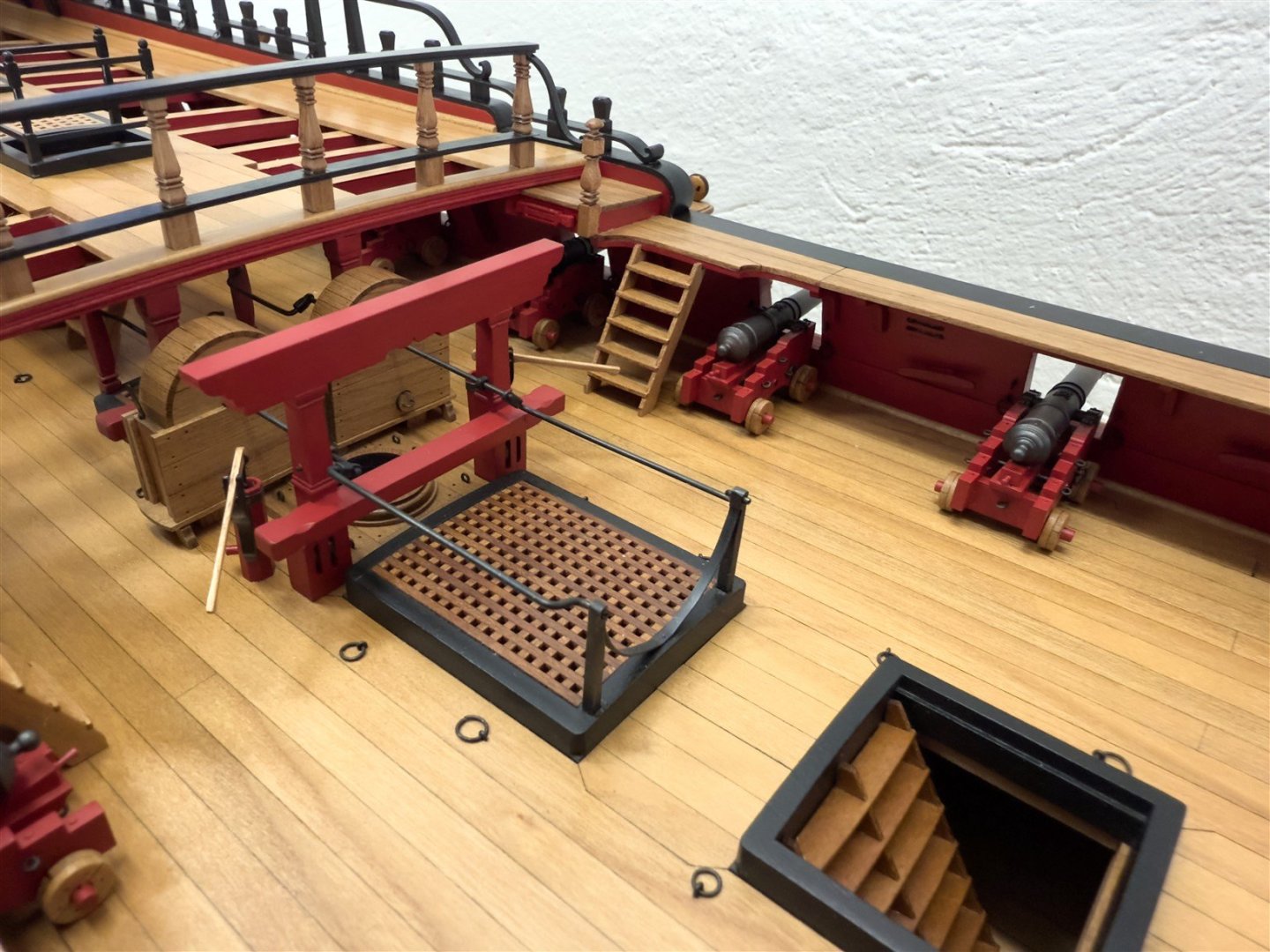

Hi Yves, Thank you! As I mentioned earlier, the model was designed by a longtime member of this great forum scrubbyj427 HMS Portland 1770 Prototype 1:48 - 4th rate 50 gun ship This is the first model he has designed himself, and he is doing everything in his spare time. In addition to designing the entire model, he is also working on prototypes, a build manual, and a website. The model will be released in chapters, as Chuck did with Winchelsea. The model's overall length is 43 inches (109 cm), so it's quite a beast. Ben and I are building prototypes to verify the design elements. Stay tuned, and keep your fingers crossed!

-

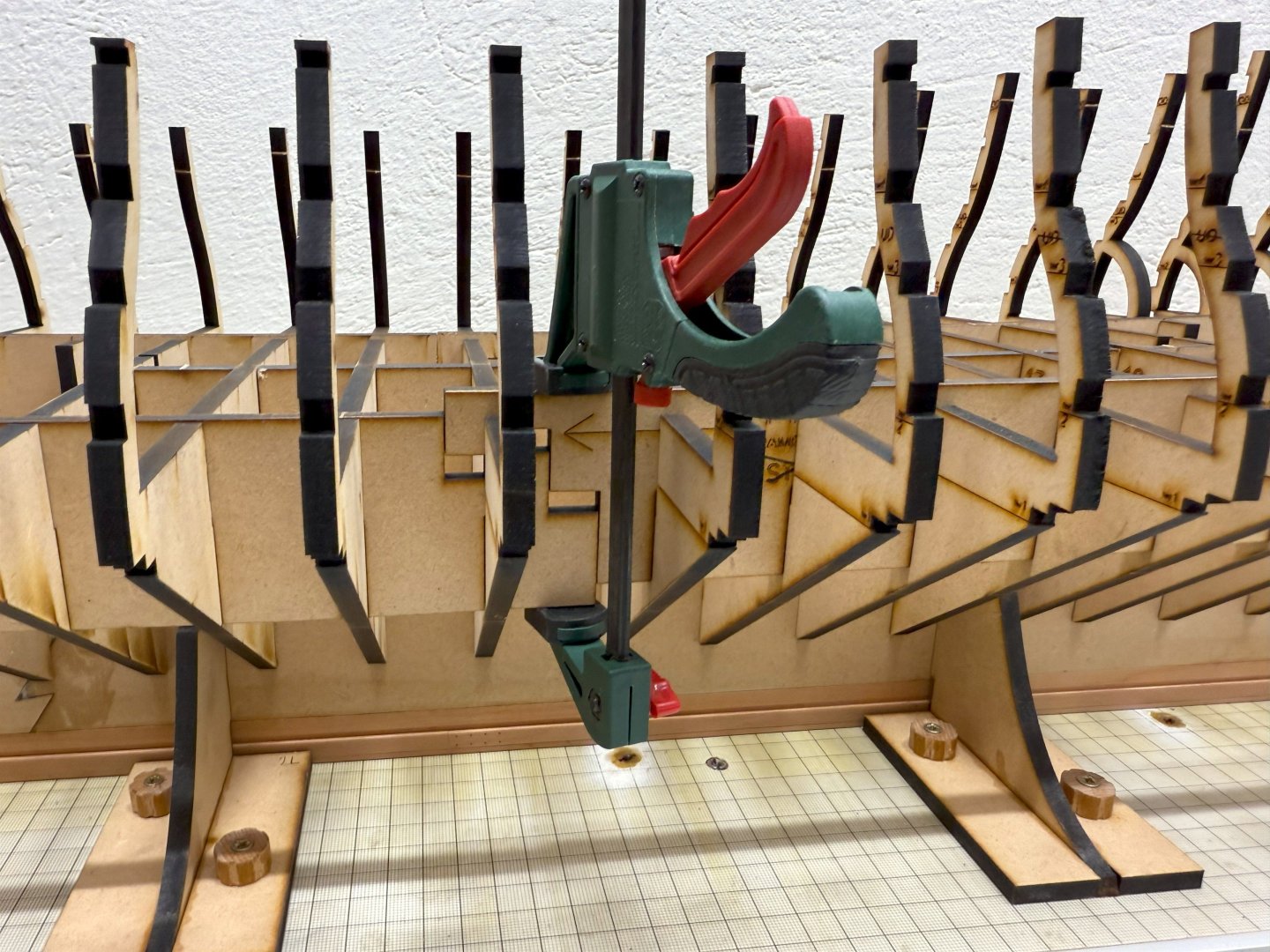

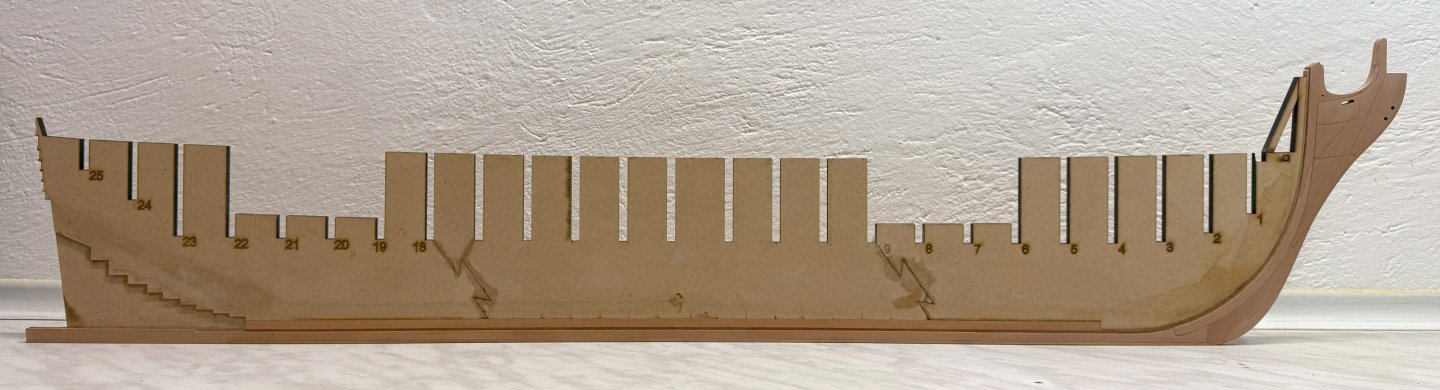

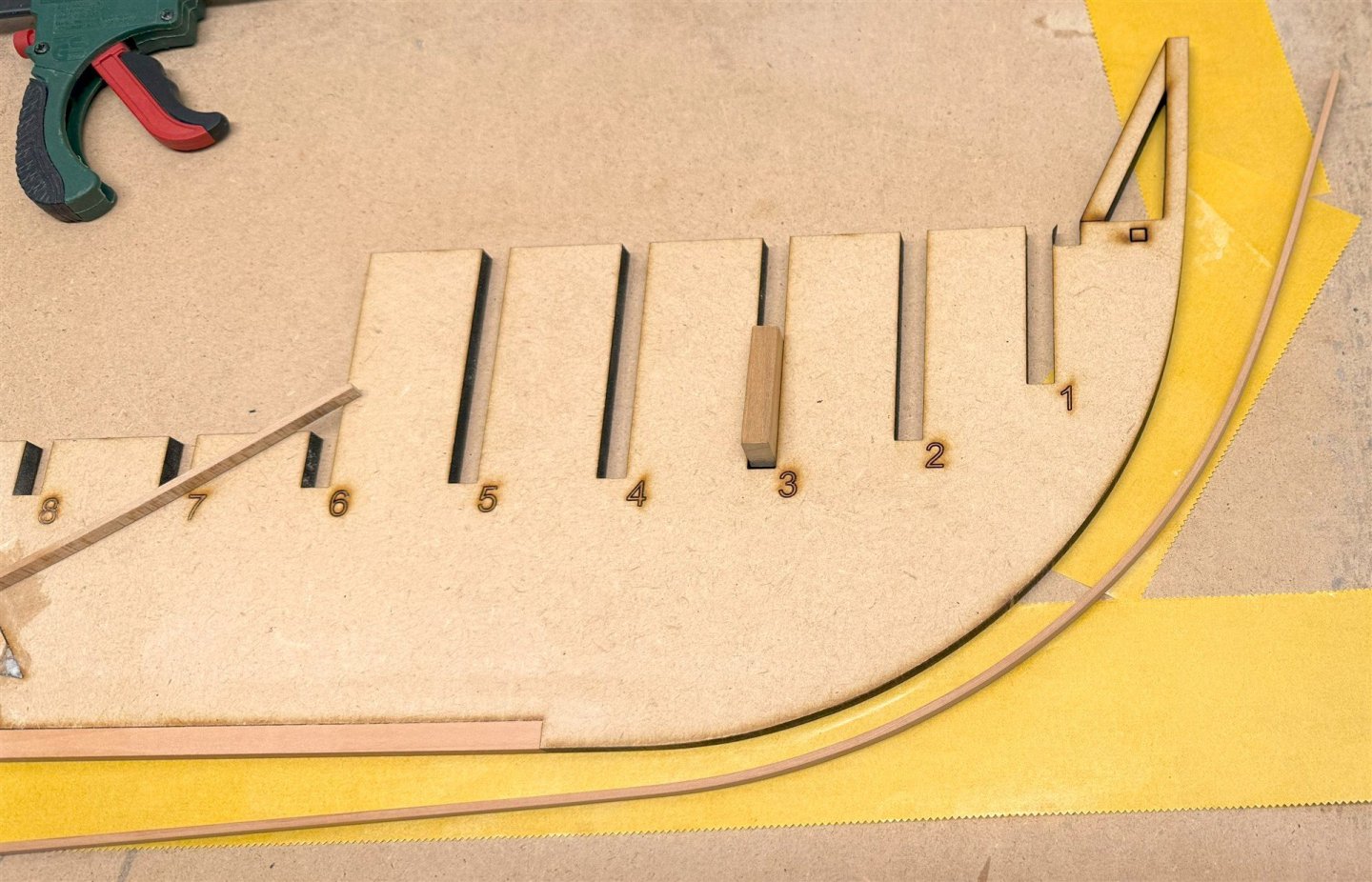

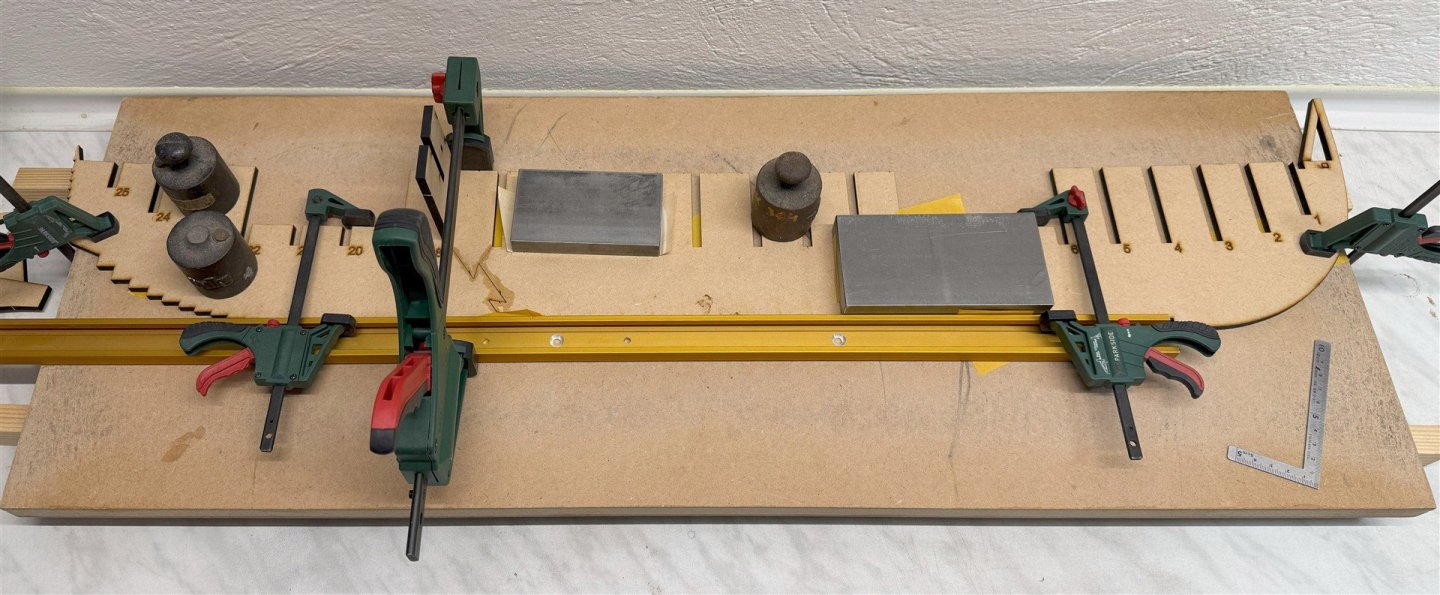

Thank you, guys! Yes, I'm excited to start building, but I'm taking it slowly. Today, I glued the fake rising wood to the bottom of the bulkhead former and bent the rabbet strip over with hot steam. I've only clamped it for now to dry and shape it by tomorrow. Alongside that, I'm slowly assembling the knee head parts...

-

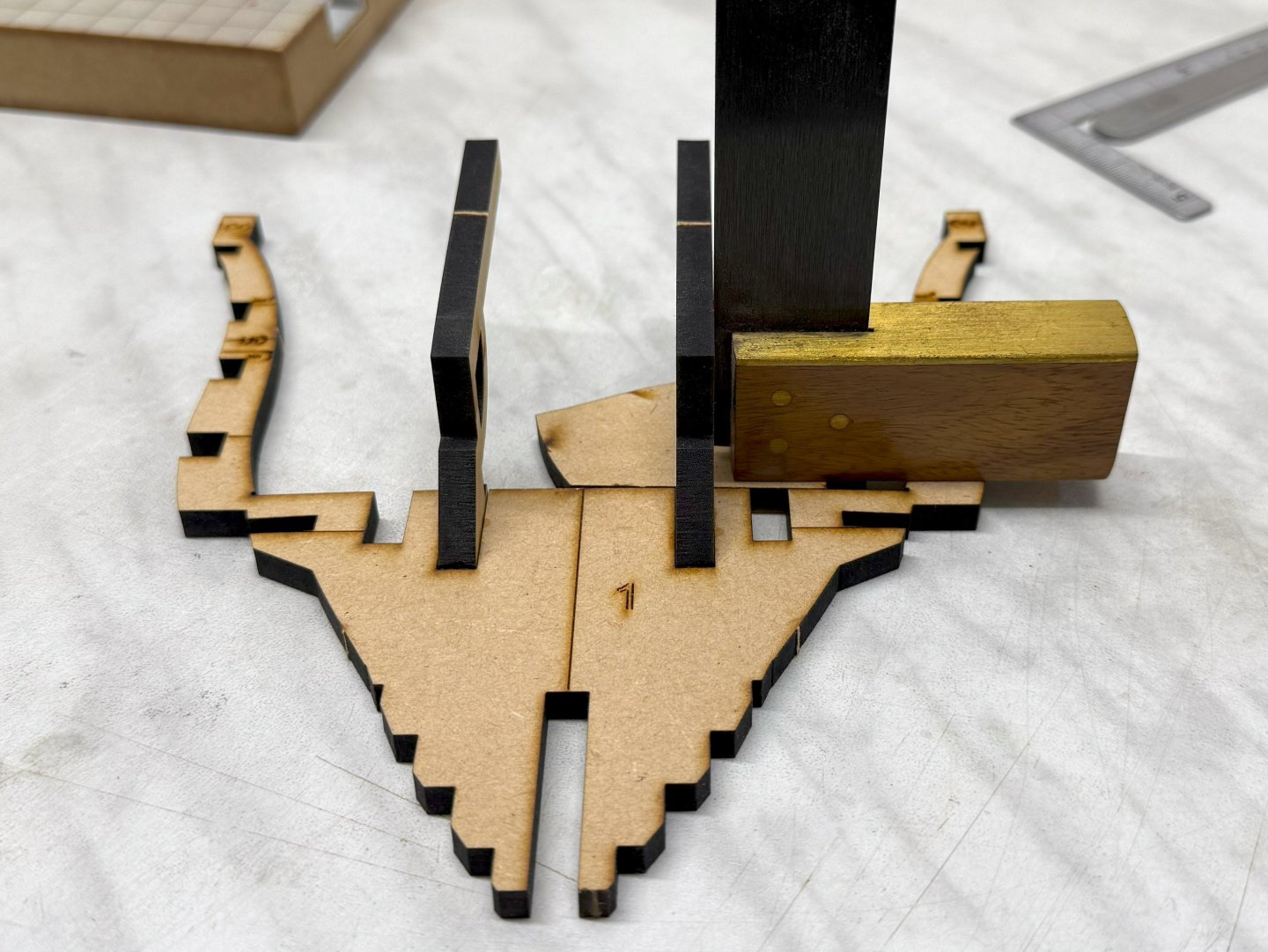

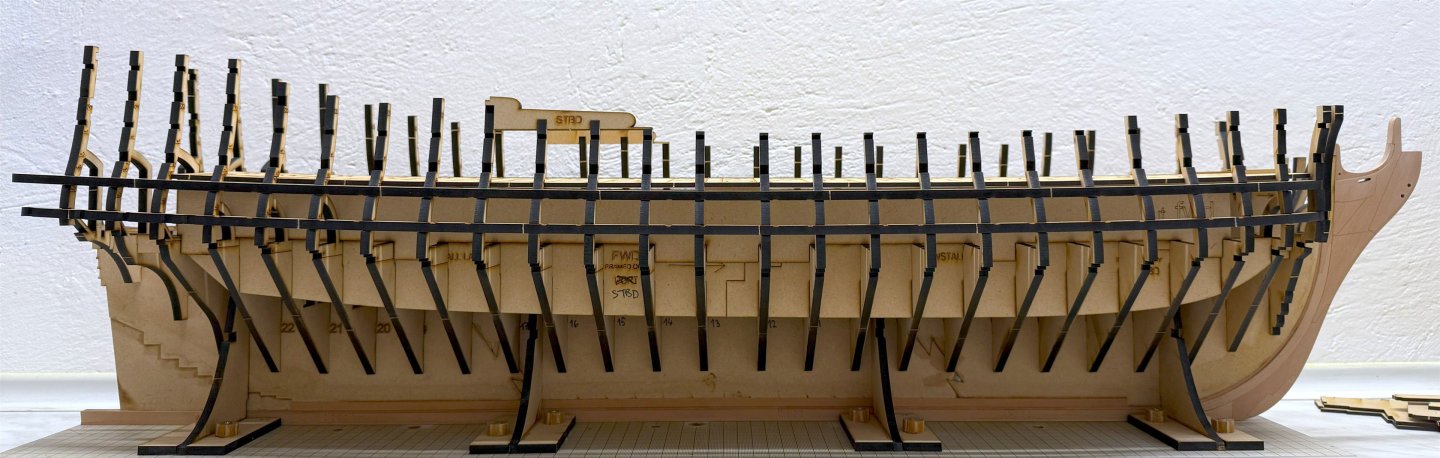

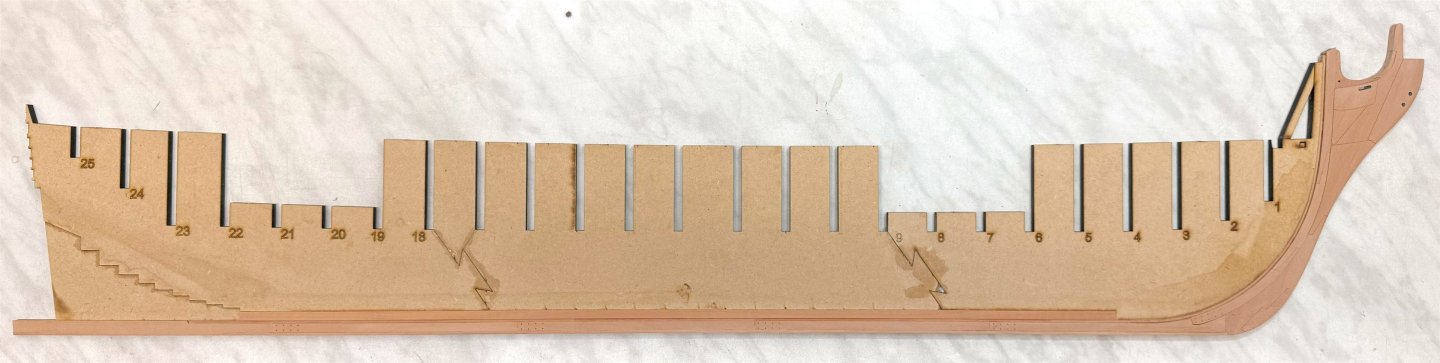

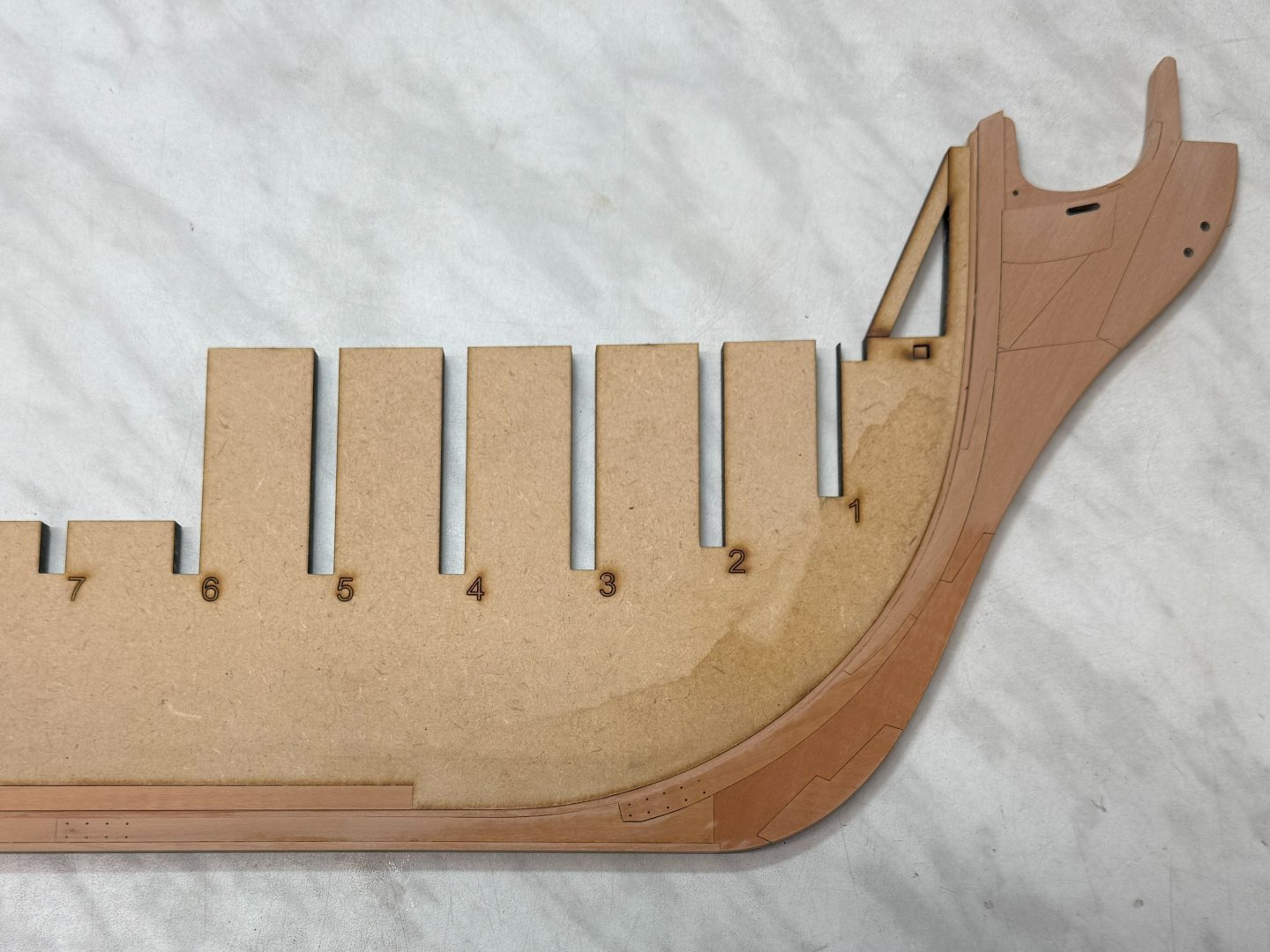

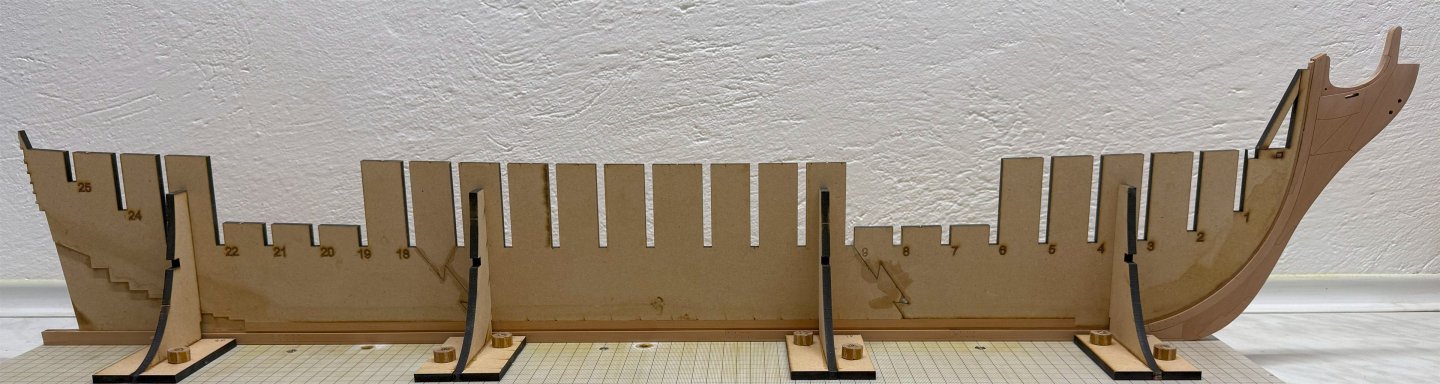

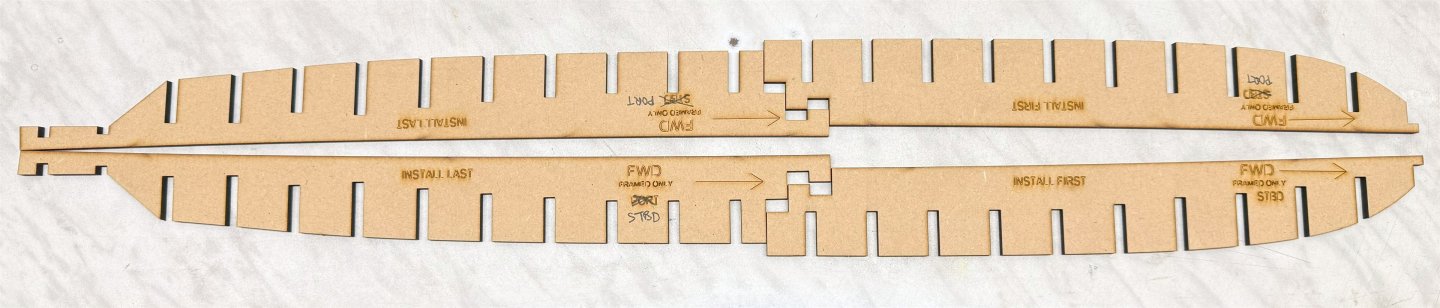

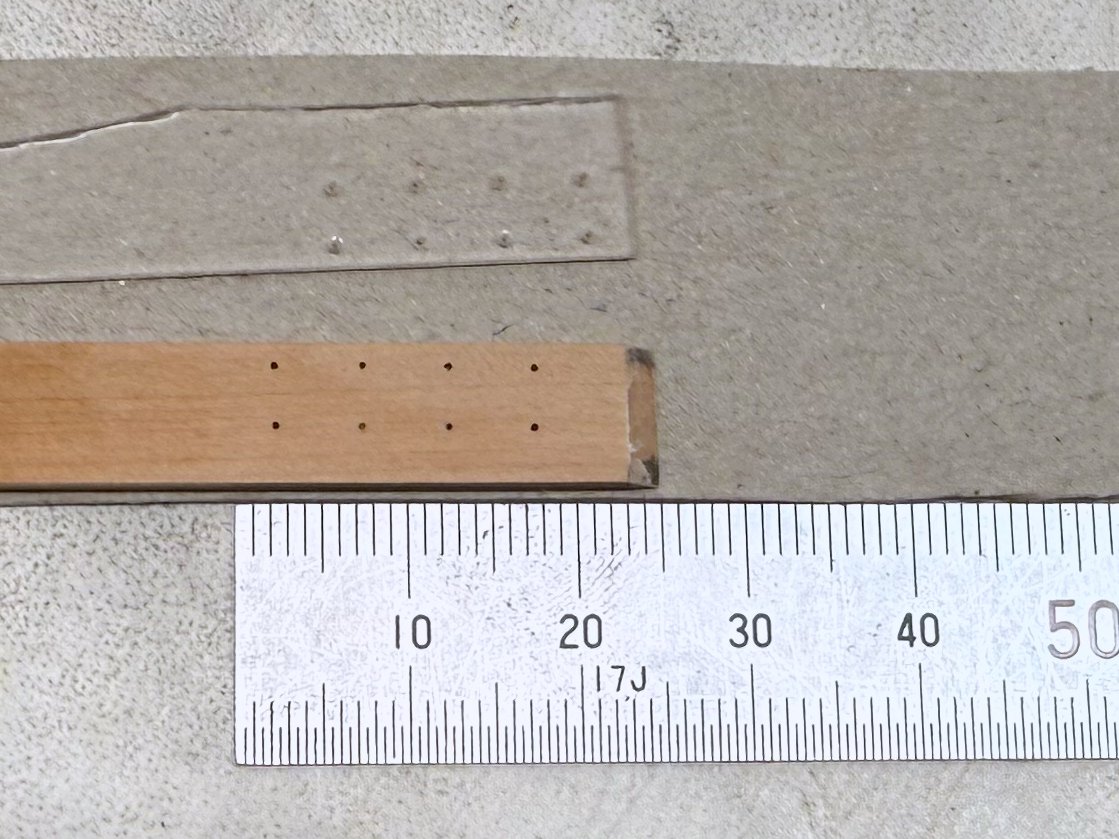

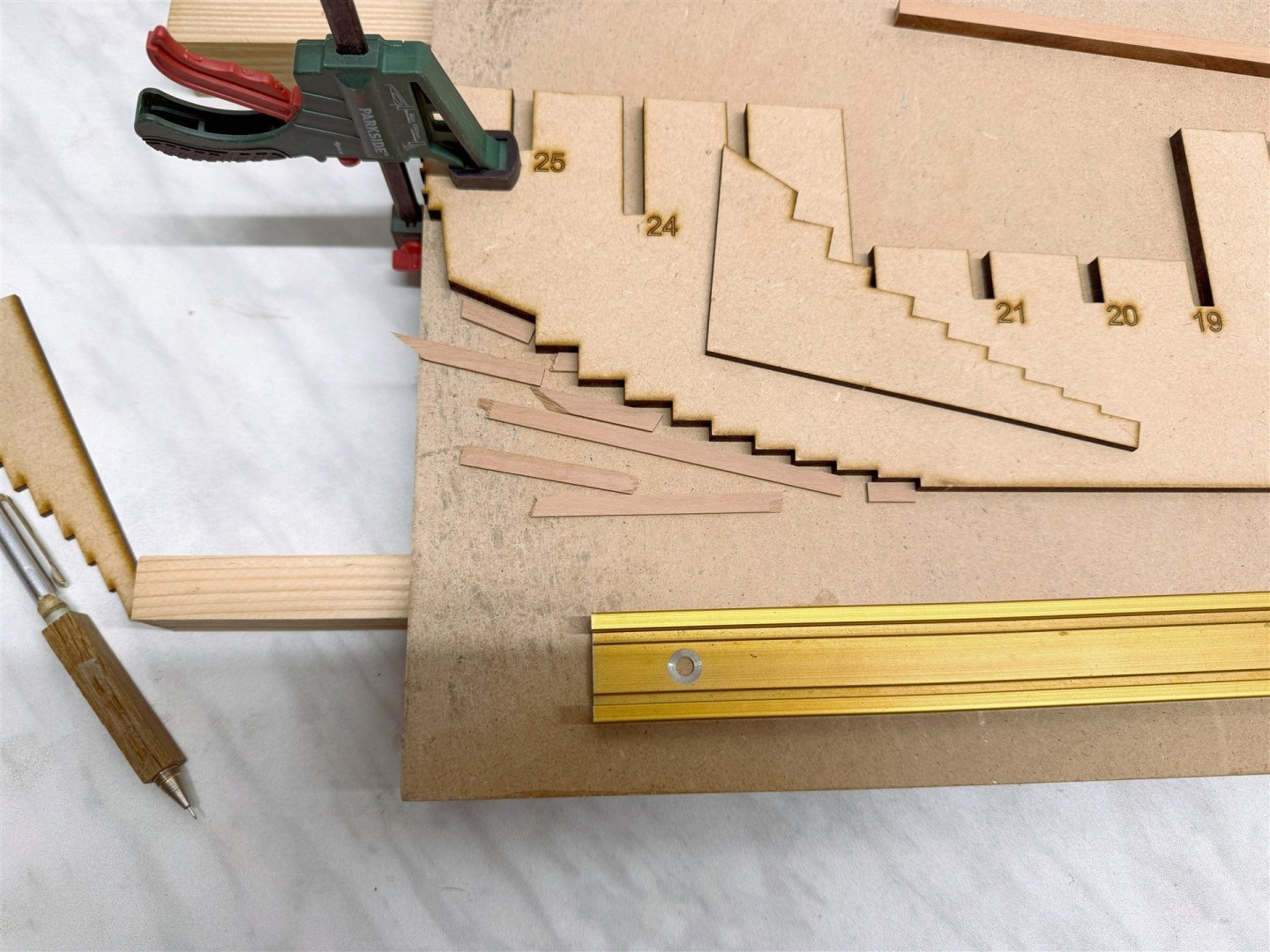

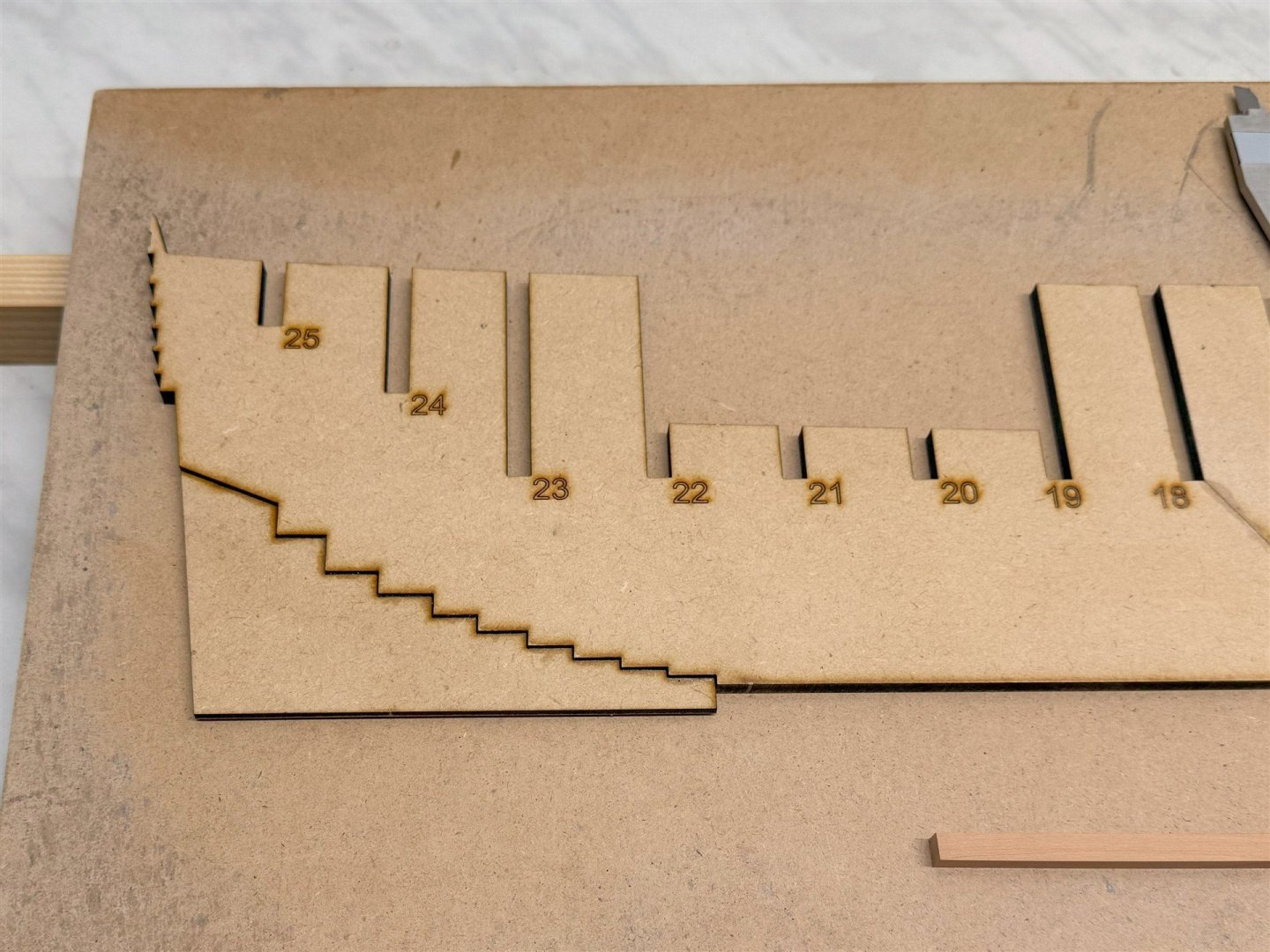

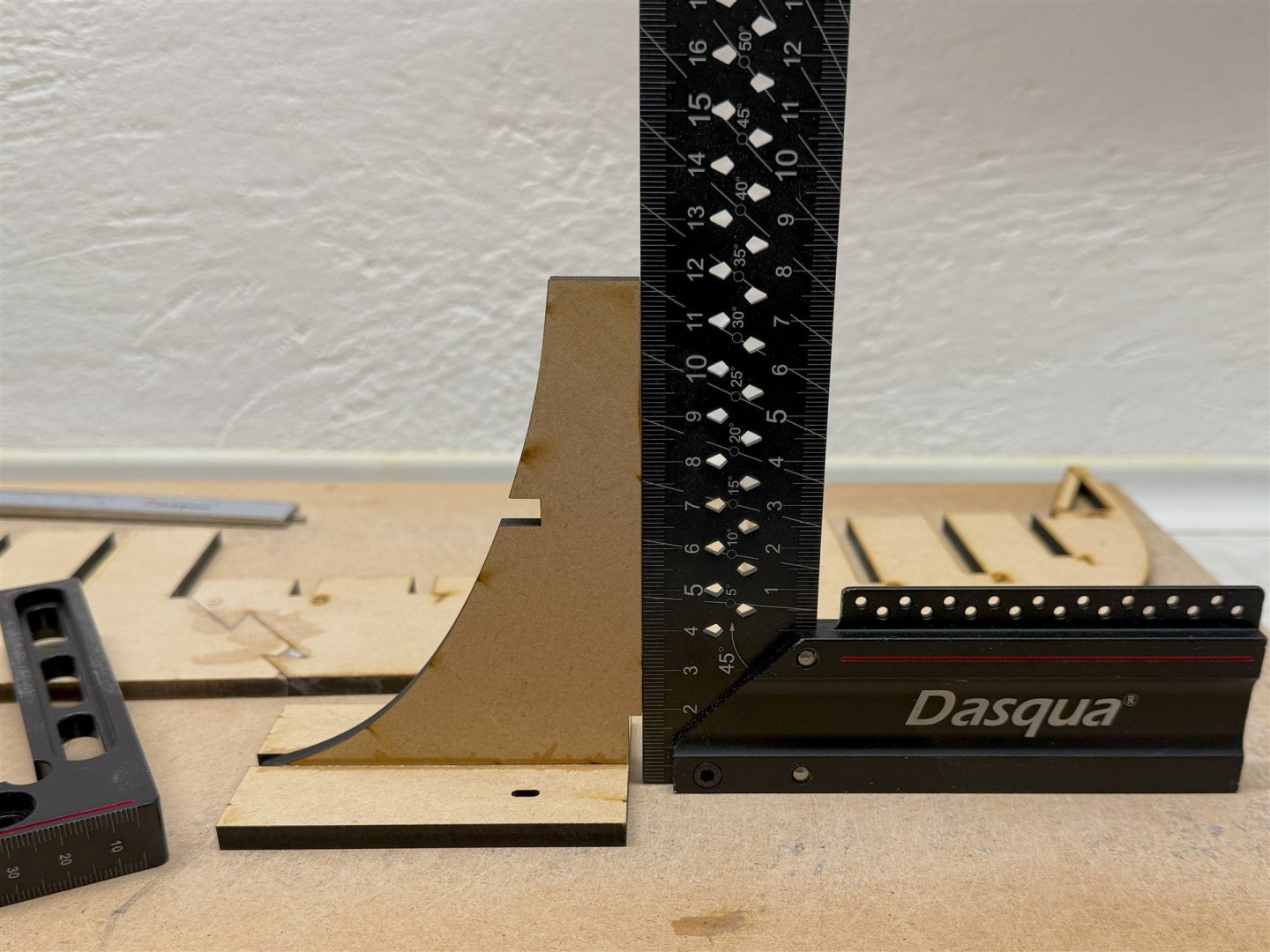

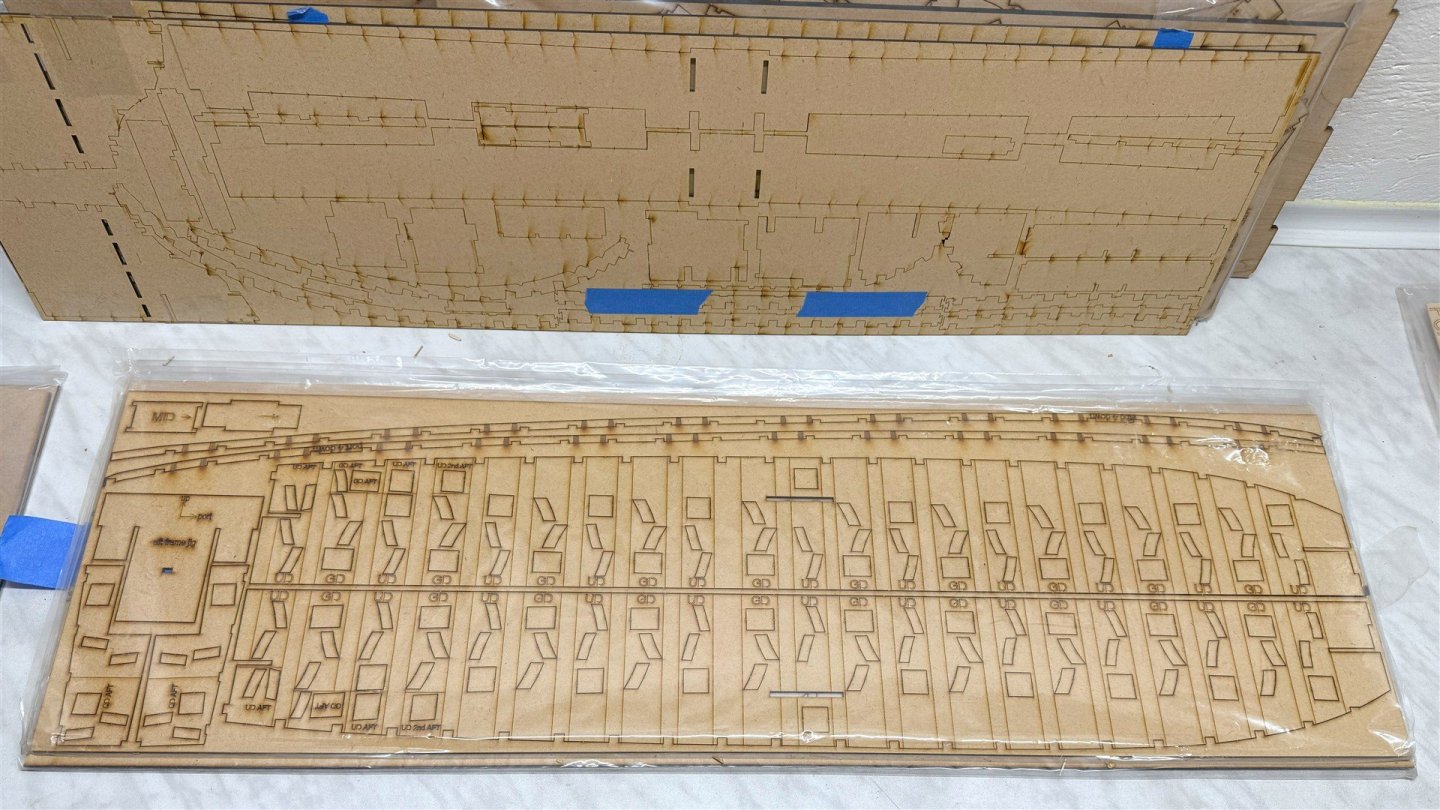

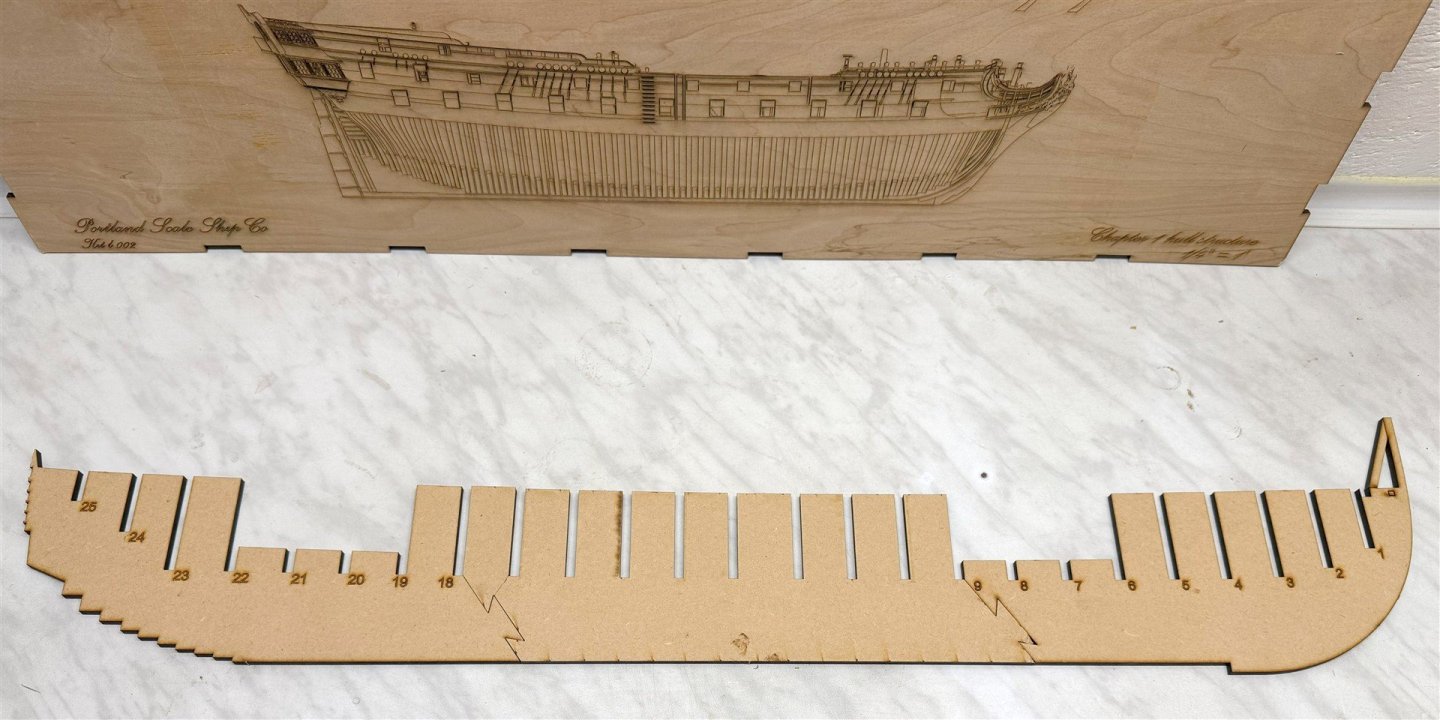

First steps of construction, I glued the three pieces of MDF bulkhead former together on a flat board. From the bottom, I attached an aluminum rail to keep all three parts flush. I let it cure well overnight. Then MDF deadwood - 3mm thick so I used 1.5mm strips to centre it Bulkhead former is 6mm thick. I also glued the hull stands together. I use a very thin CA glue to glue the MDF together, which I let flow into the joints Next tuning The knee of the head parts so far dry

-

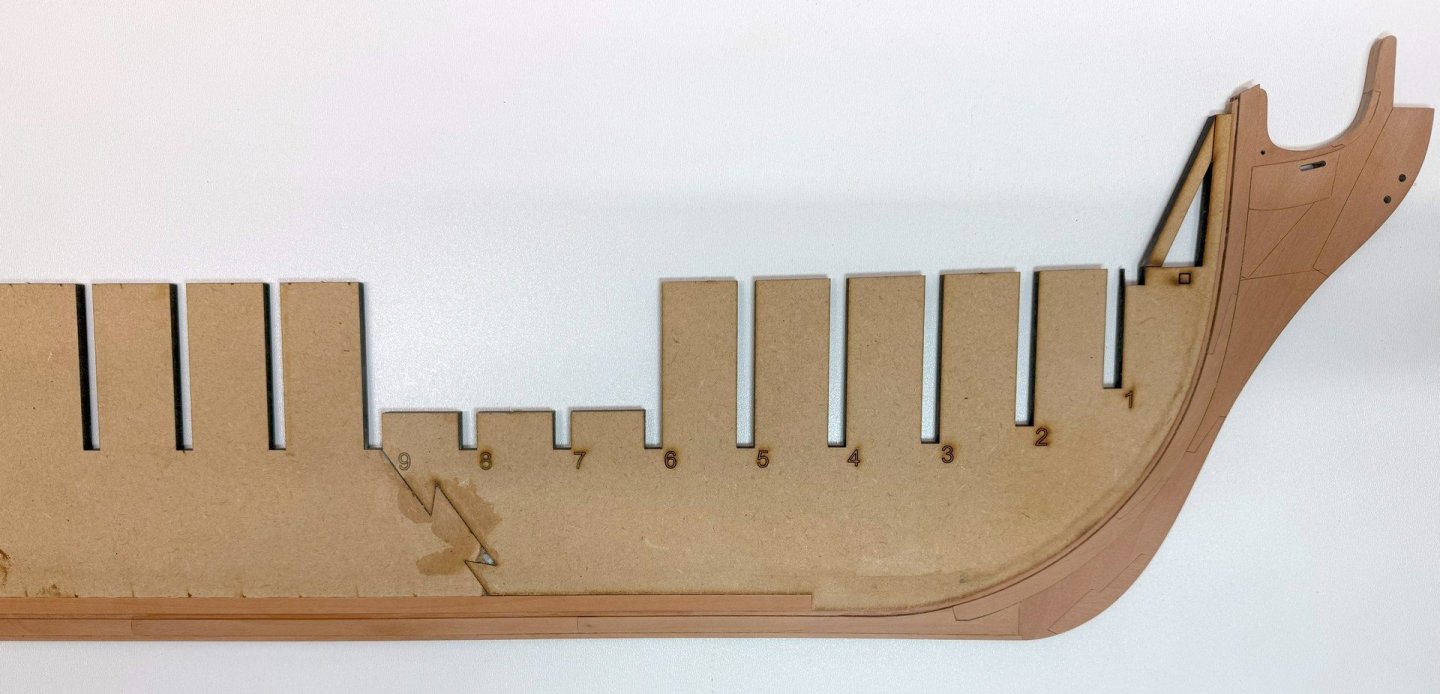

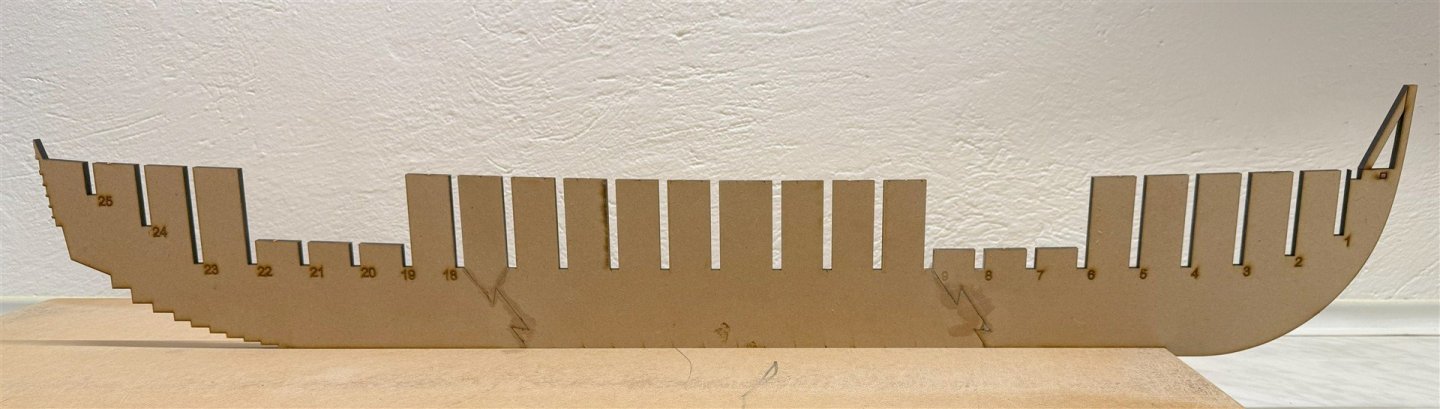

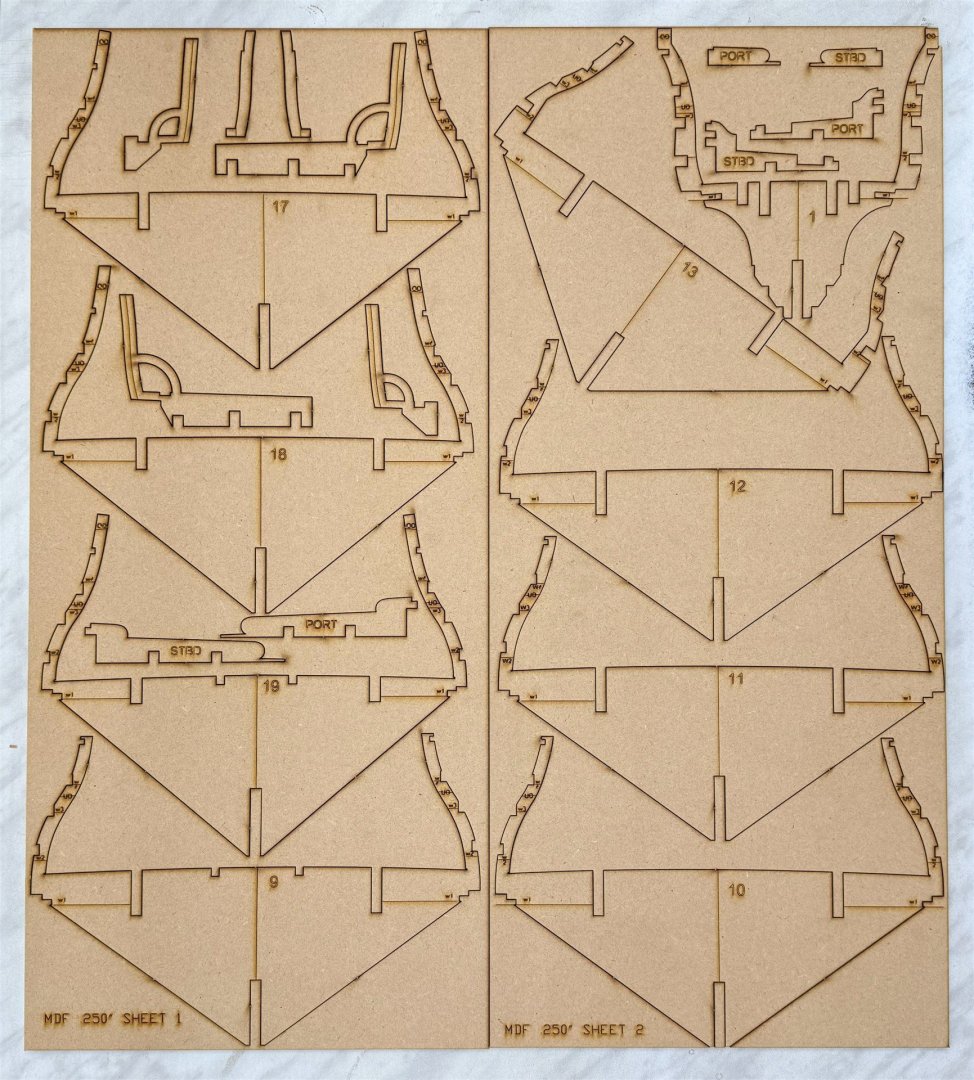

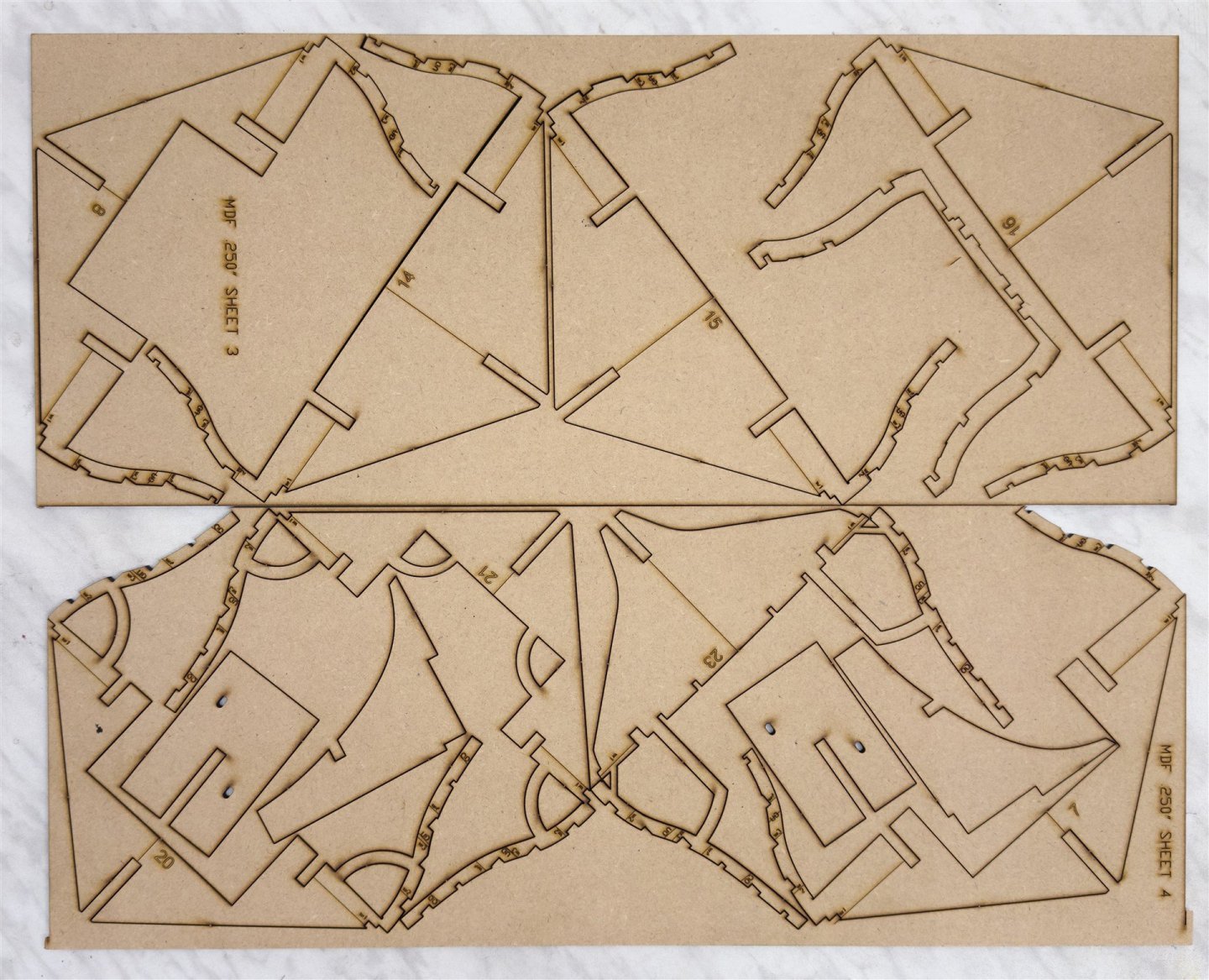

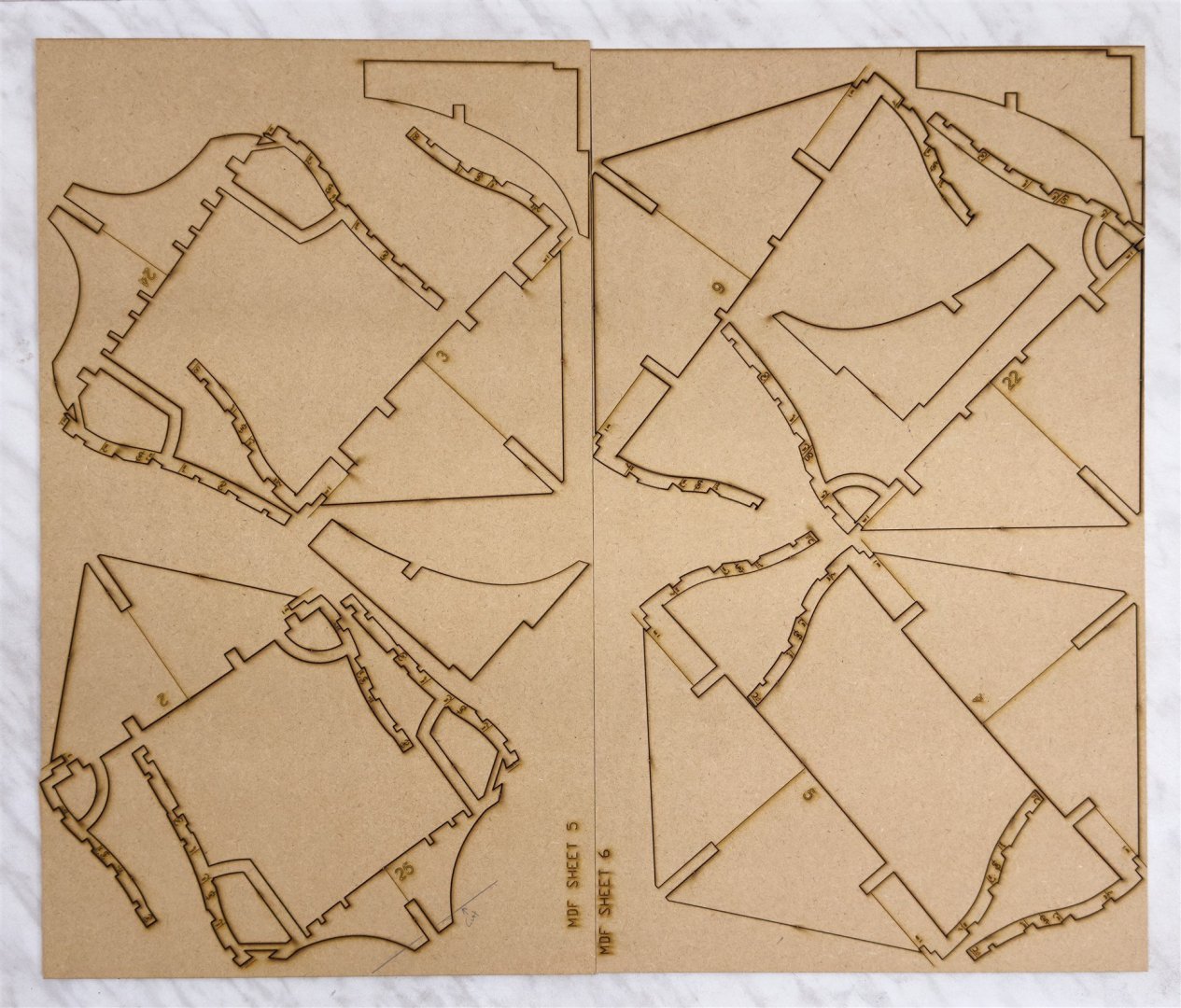

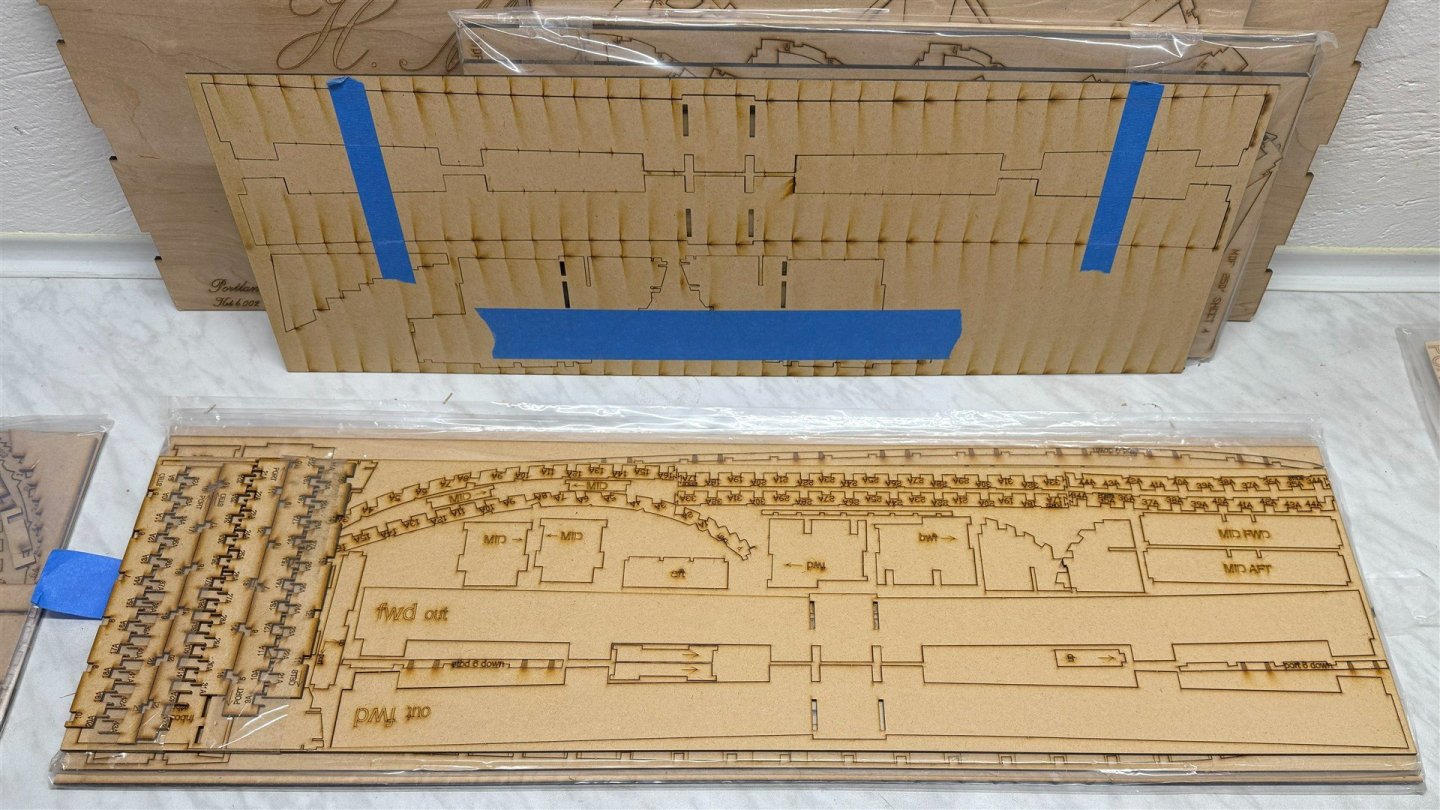

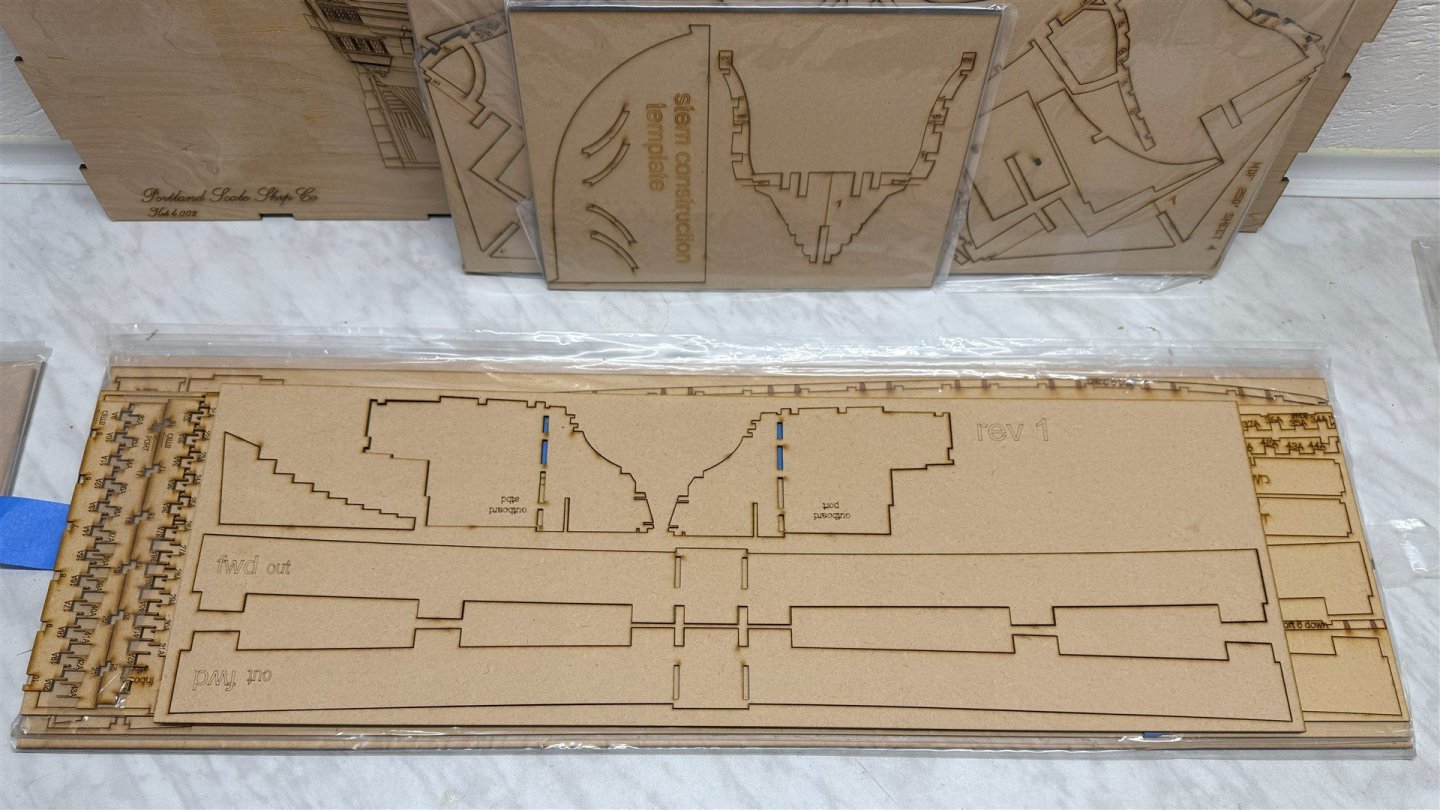

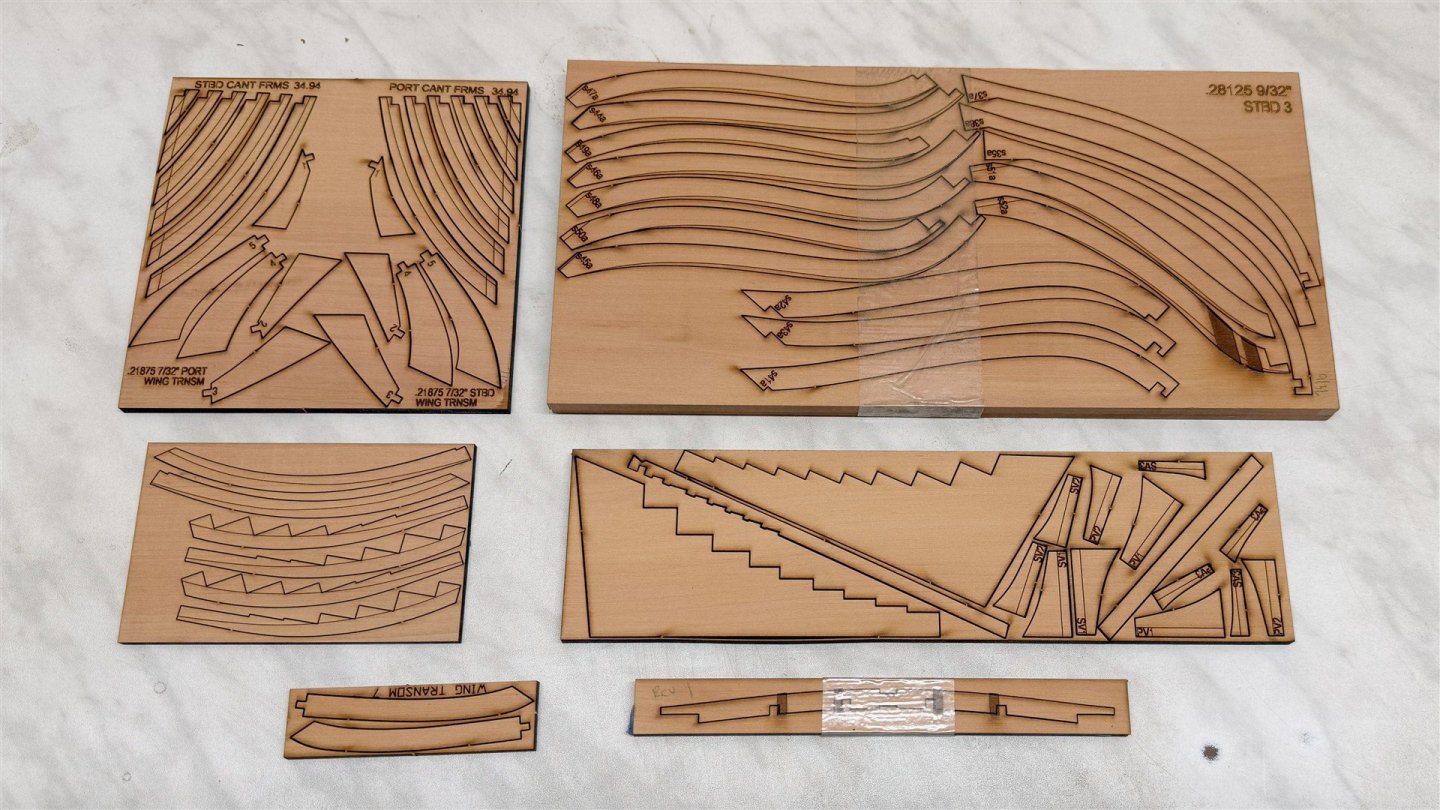

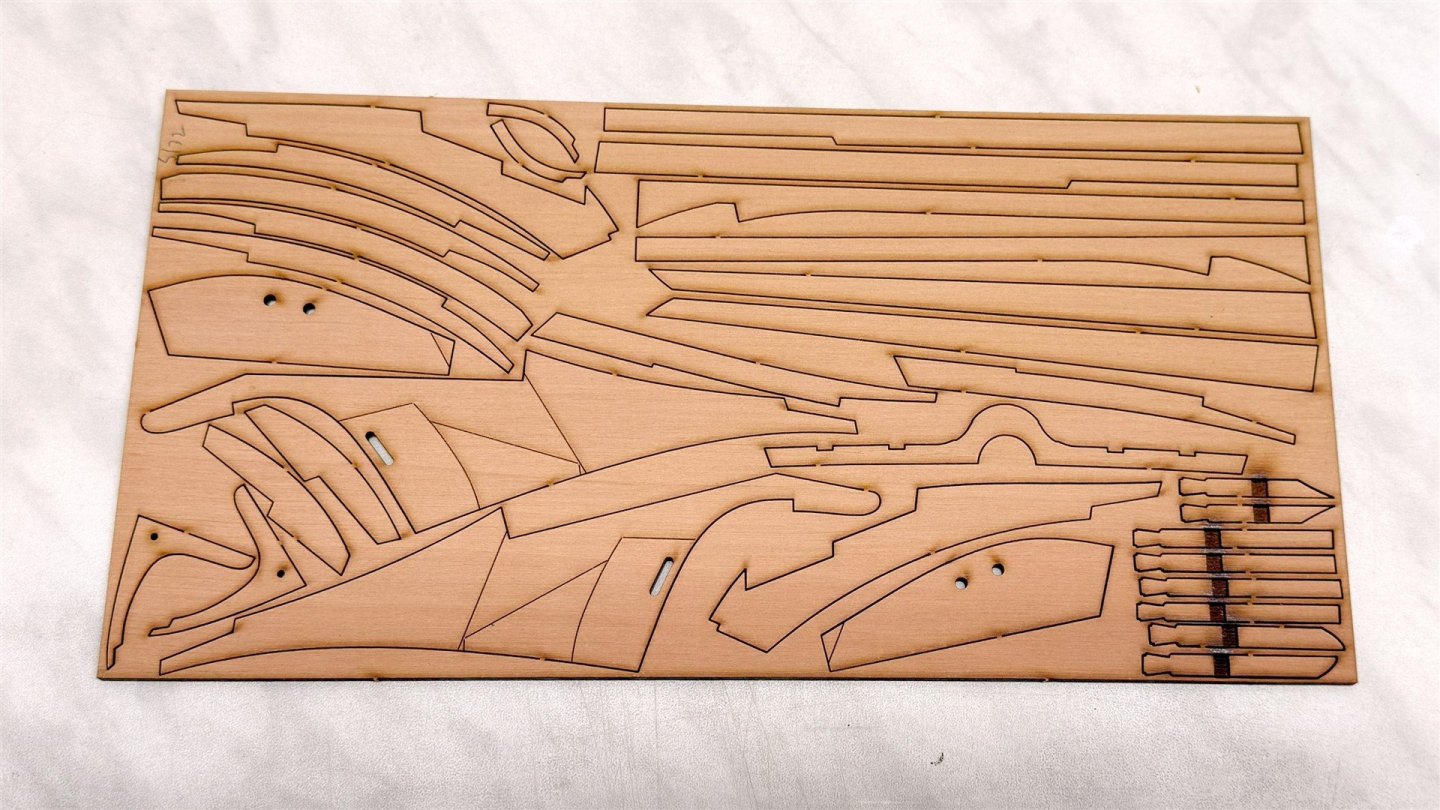

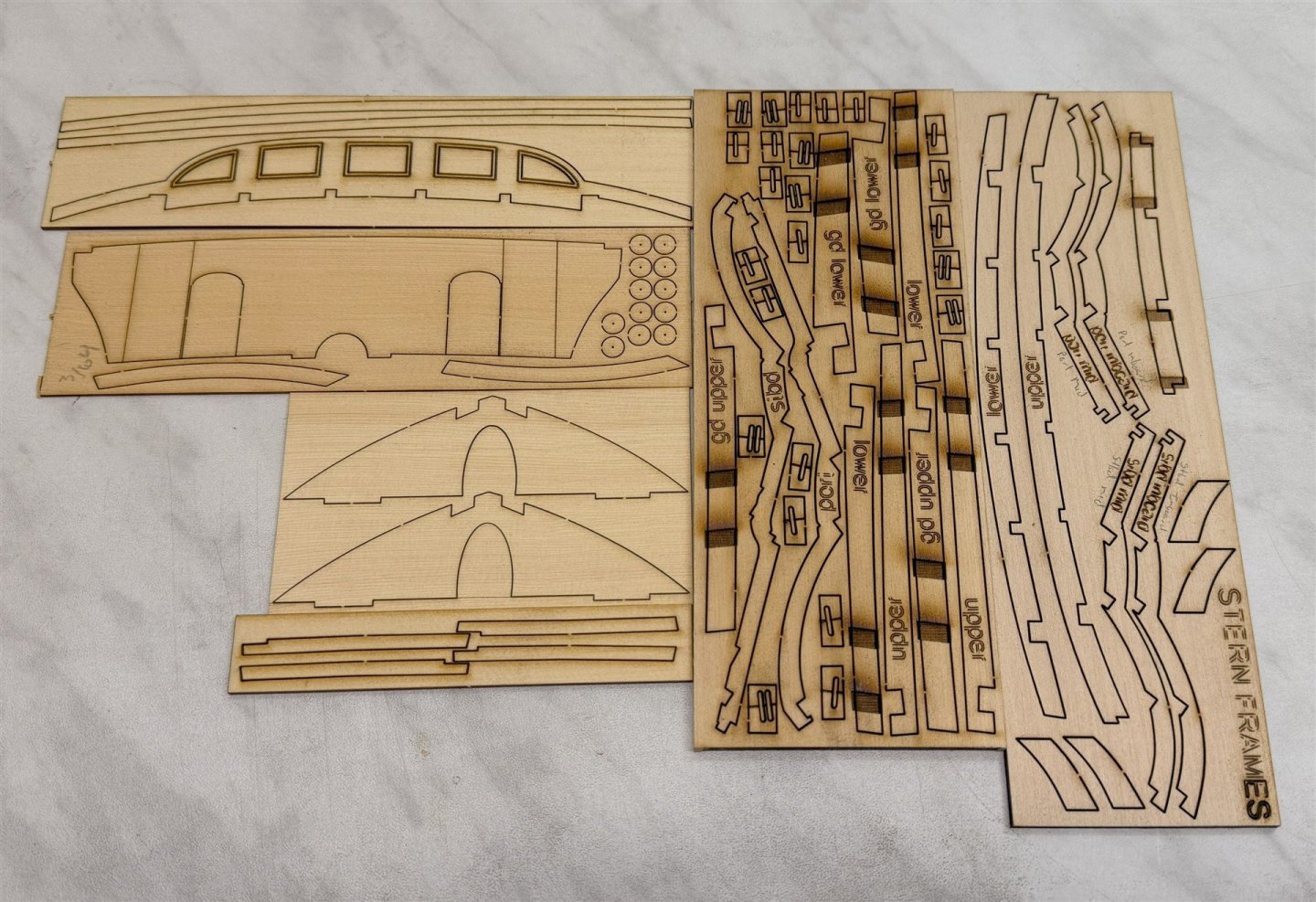

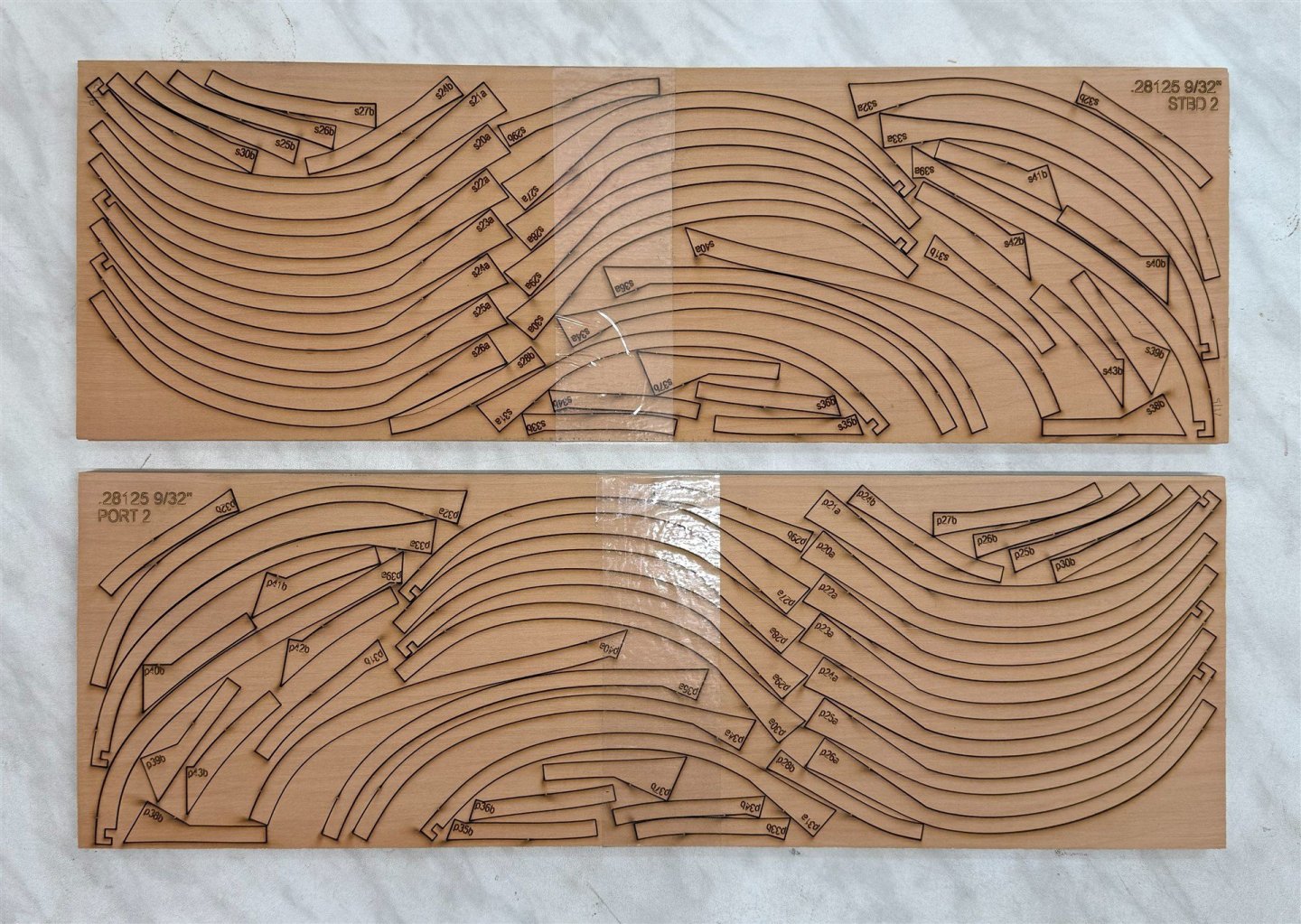

Hello, friends! It's been a few months since I finished Winchelsea. Even before its completion, however, I have been following the development of the new HMS Portland 1770 kit with great interest. I really like contemporary models of this class, especially when they have such wonderful carvings and painted friezes! I also very much like Joseph Marshall's painting, which serves as a visual template. scrubbyj427 elaborate design, as well as the idea of a hybrid frame construction, really appeals to me. I impatiently awaited updates on the development until finally, word got around! So here is my new build log. HMS Portland 1770 1:48 - 4th rate 50-gun ship Ben and I had the opportunity to start building the prototype together. Unpacking first. The box and weight is huge and yet it's not a complete model yet. It's chapter one - the basic hull structure. All the parts were well packed even though the first unpacking was done by customs officials 🙃 Many parts, such as the bulkhead former, bulkheads, jigs, and stands, other supporting parts are made of MDF of different thicknesses. The frames, keel, and knee of the head are made of beautiful pear. Here are some photos.

-

Hi Rick thank you so much for the compliments. You are right I only used the leather dye on the wales and everything else was well painted with Vallejo Mecha Color - Pure Black 69.042. And also thanks for all the comments and likes guys. Winie is currently waiting for the cover and base and then I will take the final pics.

-

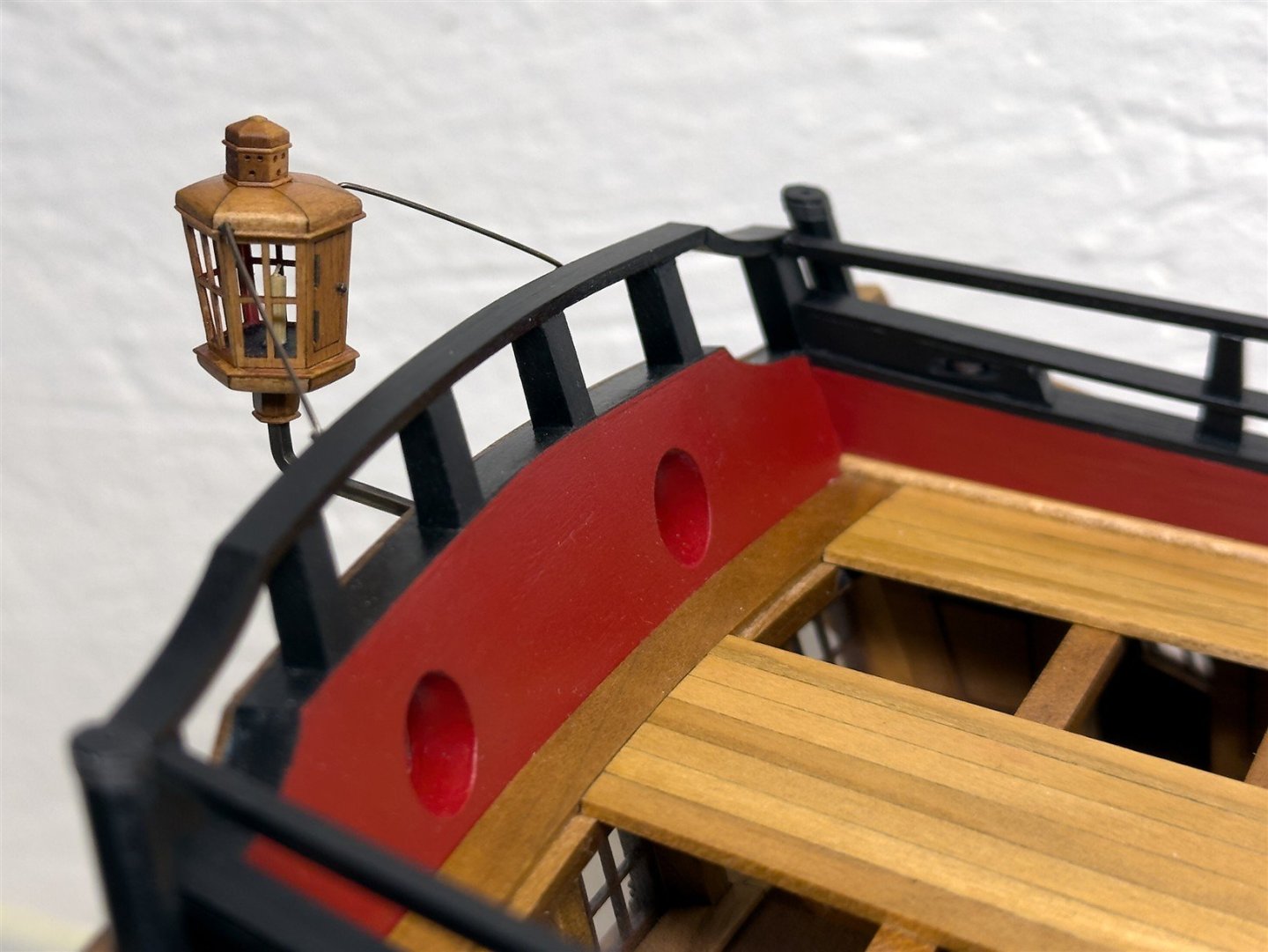

Thank you guys and I wish you all the best in the new year. Test fitting of the lantern on the model. Compromise solution - I didn't drill the badge on the transom. The square brass rod is just a support The lantern is only hanged on two auxiliary rods. Tomorrow I'll probably order an acrylic cover and just make the base and it's done 🙂

-

Thanks Chuck, Yeah, I'm glad I chose the cherry version. Although I was a little worried at first about how it would turn out in that size. I had a cherry on the Revenge from a different source, and I didn't like the "tigering" there so much. That's why I used a different source for the Winie and cut the strips slightly different so that the grain wasn't so visible. I'm trying to build a Stern lantern. I tried, but it didn't work as well as I imagined. Hopefully I will finish it and then decide if it will be on the models . I have already made a request to local companies to make me a plexiglass case And I'm already thinking about what to do next...

-

Hi Ben, the case looks great. Do you have any older acrylic cases on other models? How do they look after all these years? Is there any yellowing? Don't they scratch when you dust them? I like them because at this size the glass is heavier and definitely more expensive I think. Here in Slovakia, or at least in the EU, I haven't found a manufacturer yet...

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Wow, a beautiful and unique model Ben. I loved following your diary. Congratulations on the finishing

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

yes I agree, looks amazing Ben!

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.