westwood

Members-

Posts

278 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by westwood

-

yes I agree, looks amazing Ben!

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

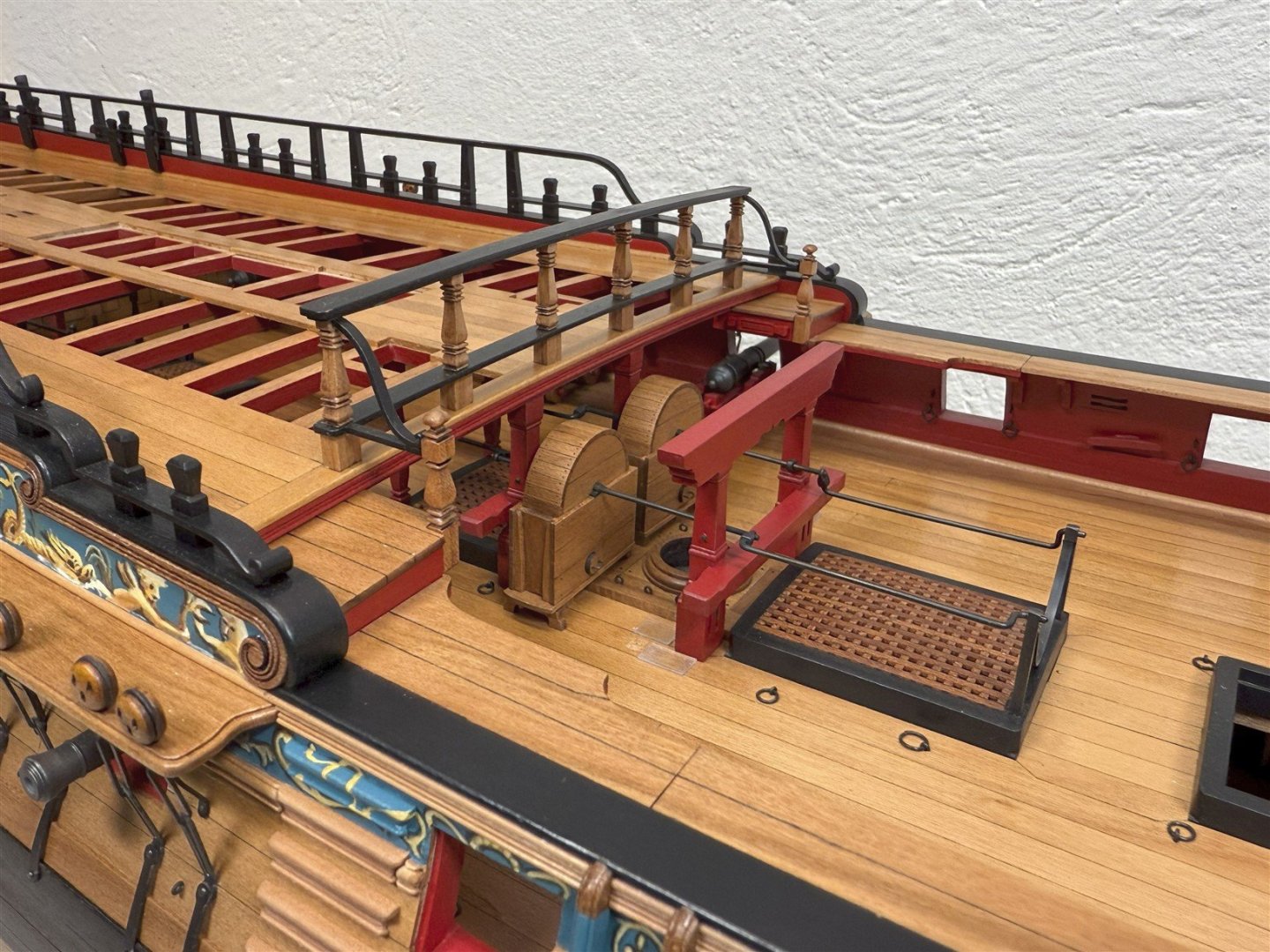

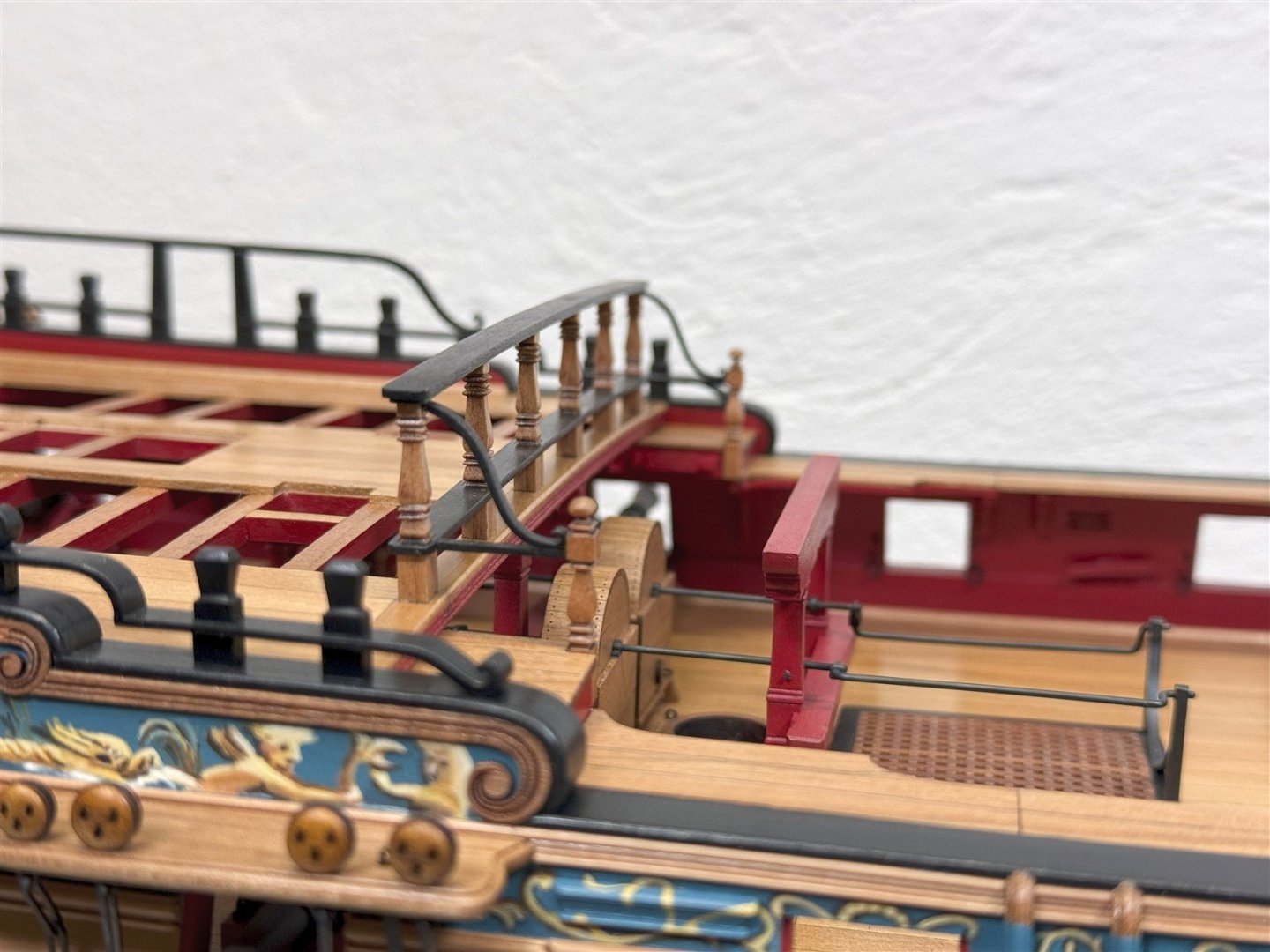

Hey guys, Thanks for your kind words and likes. I'm slowly making progress, finishing things I've been putting off. I cleaned up the carvings and since I couldn't get the Old Masters Gel Stain I had to find another solution with Vallejo Wash. I also had to paint the friezes on the binnacle... It didn't turn out as I wanted, but I can live with it. The belfry, belfry rail and other details and the forecastle are almost finished. The breastrail.... is finished and I just have to install the rest of the parts and finish the quarterdeck.

-

Hey Glenn, I've been following your blog since the beginning, I always enjoyed it when you posted new photos and comments, insights from the build. It was a great motivation for me. Thank you for that. You have built a really beautiful and admirable model. Congratulations and I can't wait to see what you will do next time.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

It was definitely one of the more difficult parts of the build. But you did a wonderful job with it, Glenn!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

such a quick progress and beautiful as well

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Beautiful work Ben. I like it a lot also like this when you left a lot of parts without red paint.

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

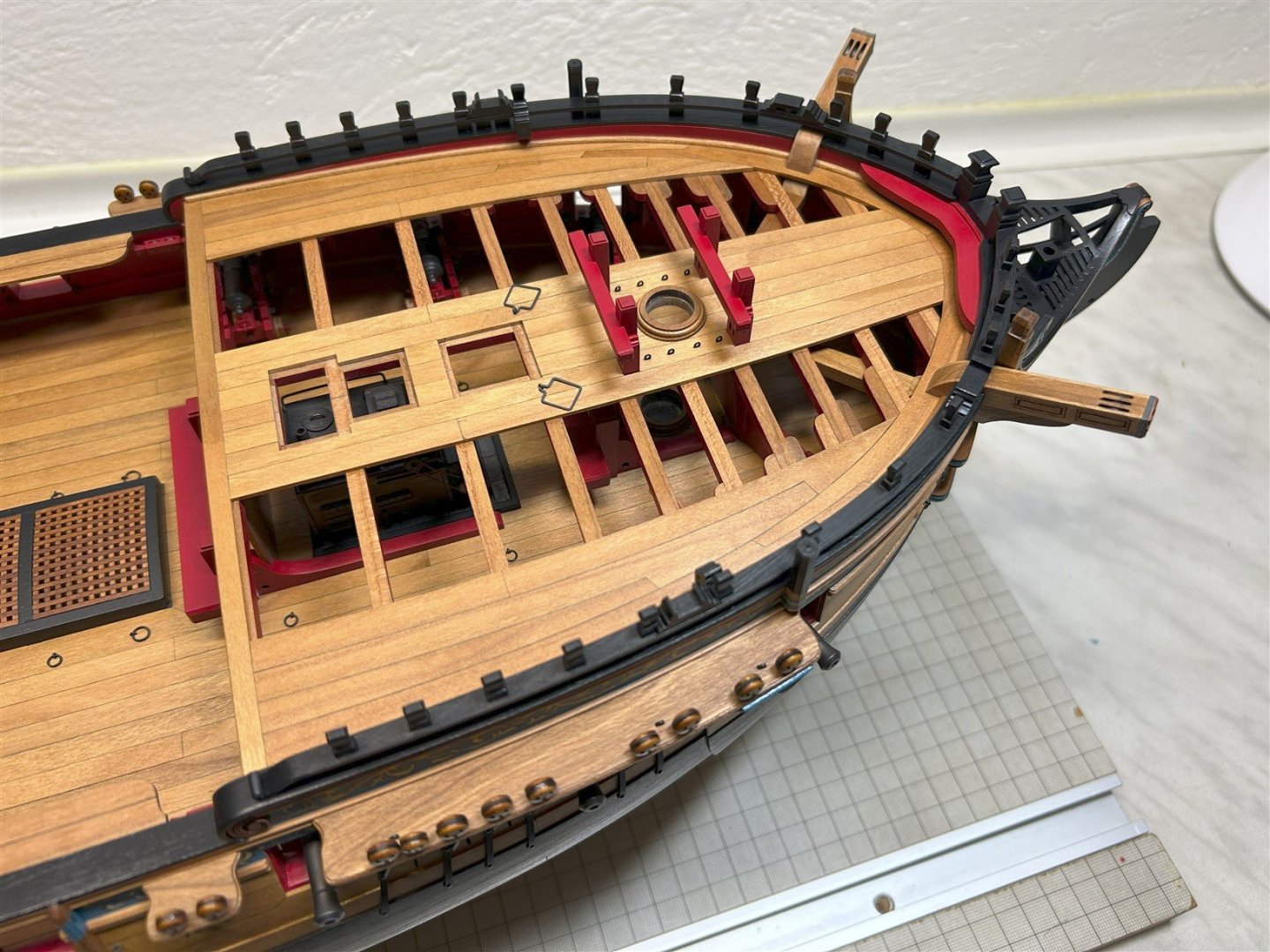

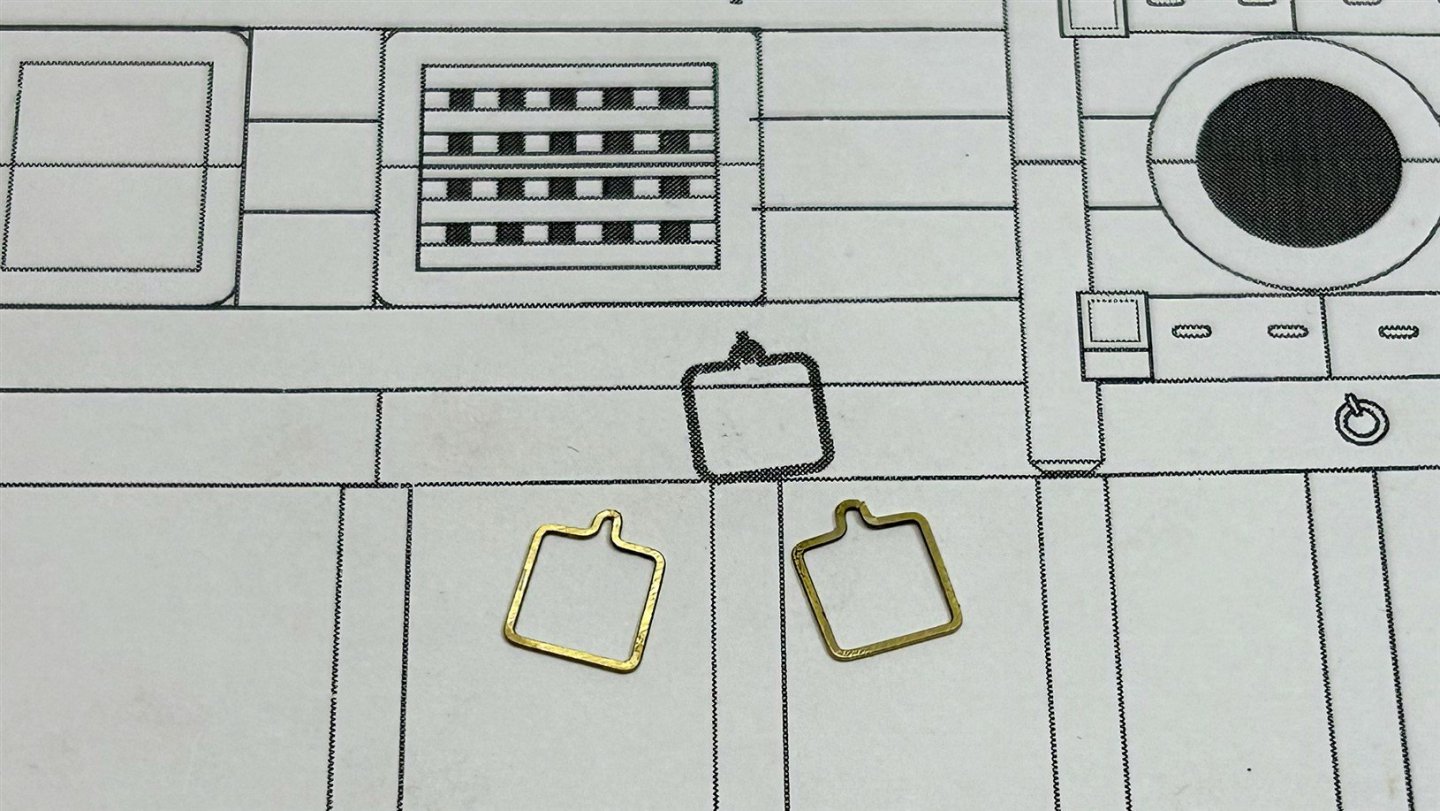

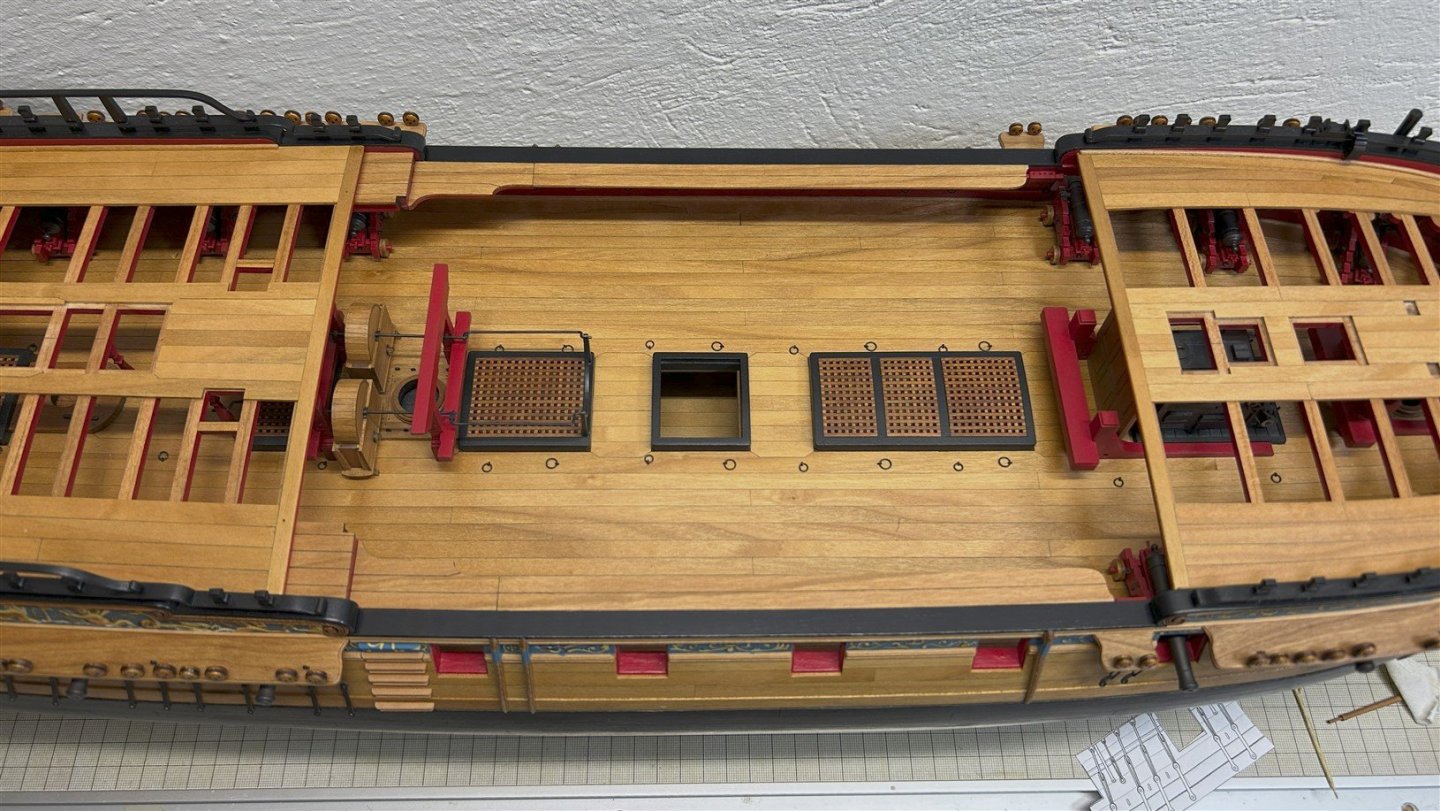

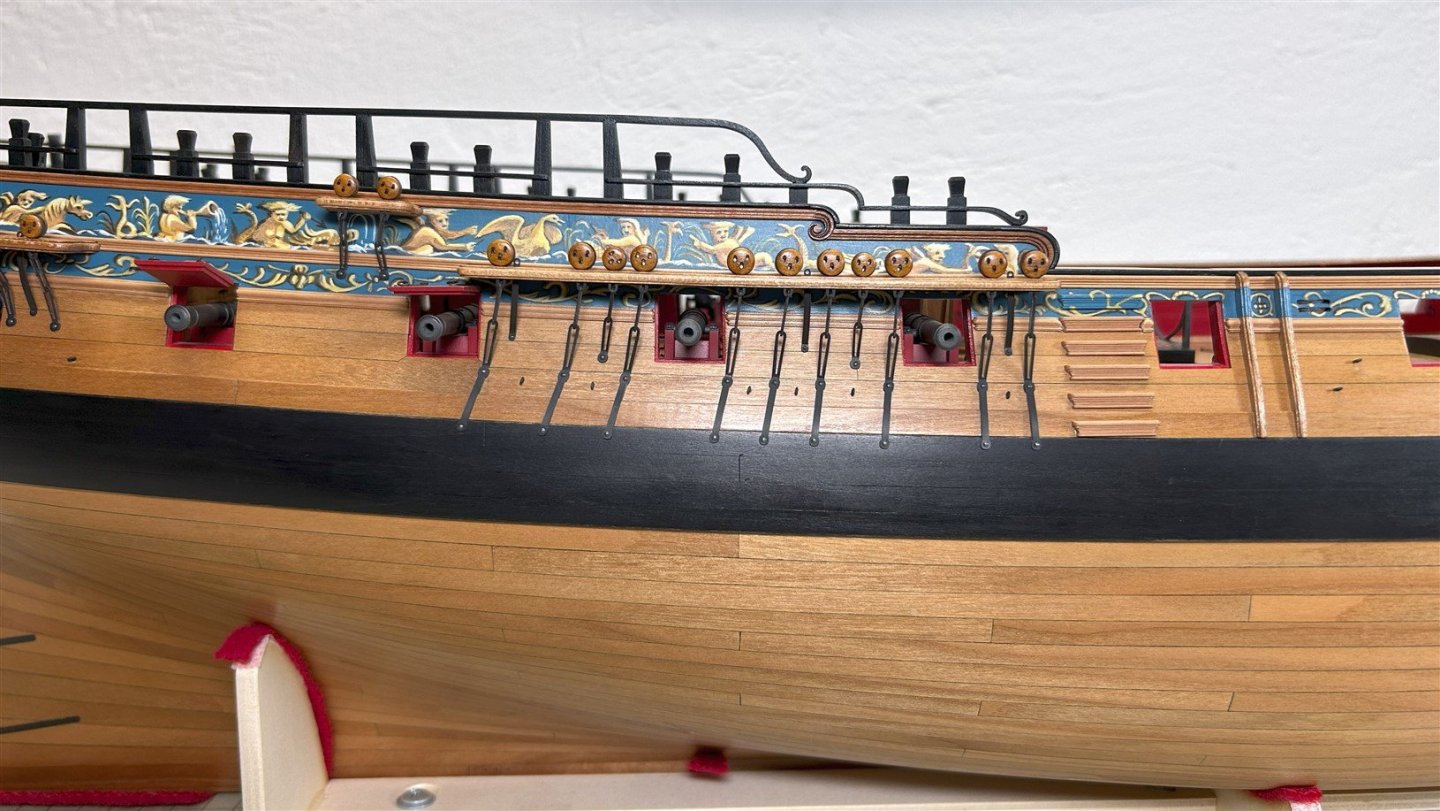

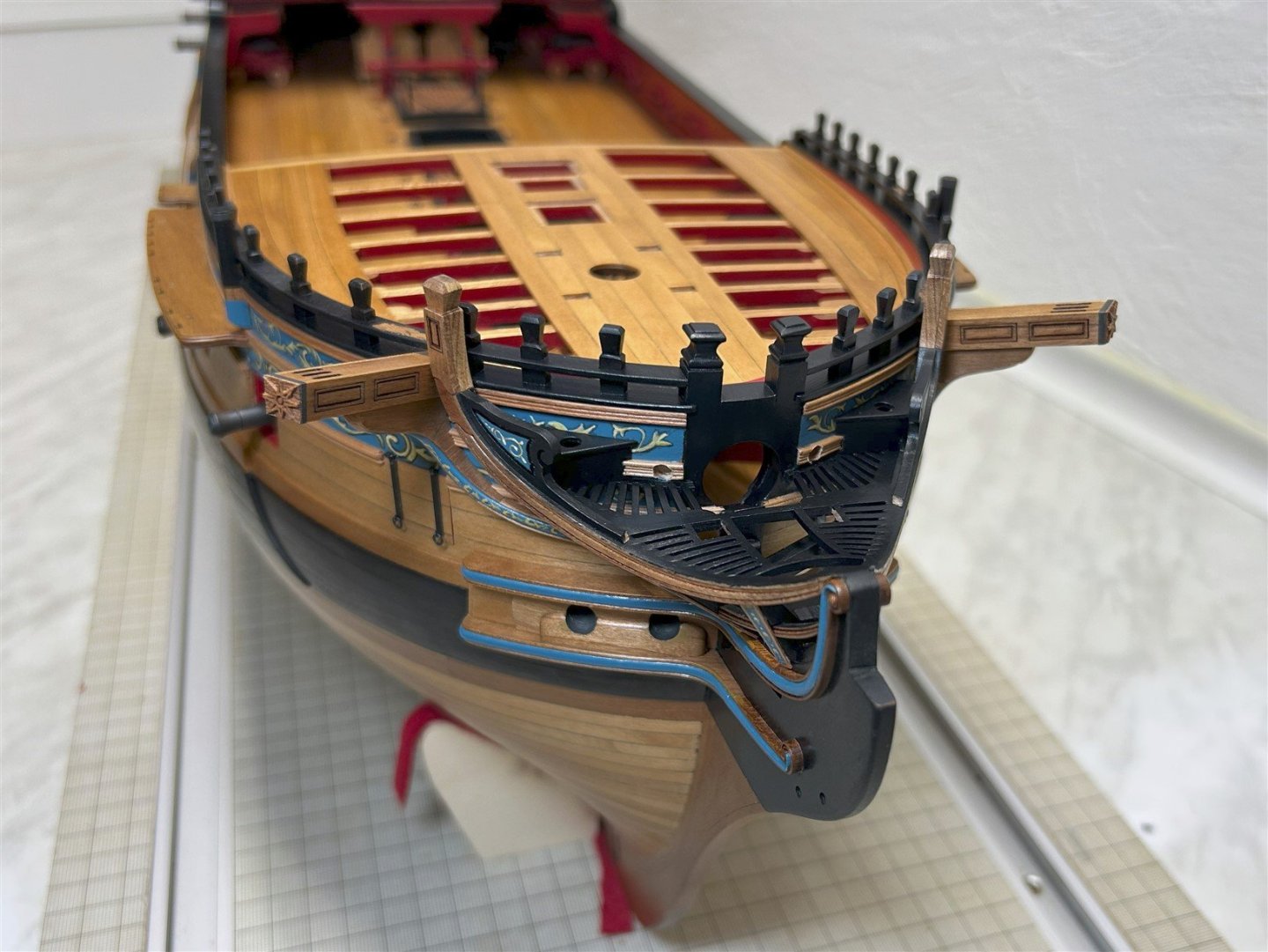

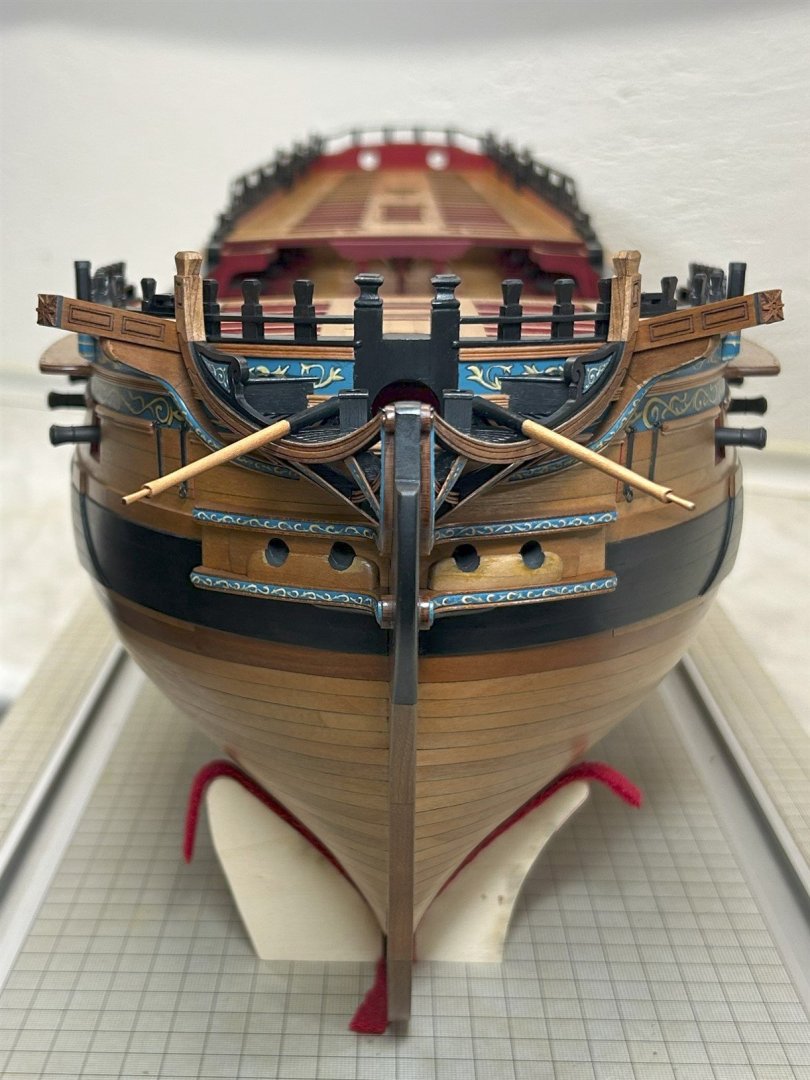

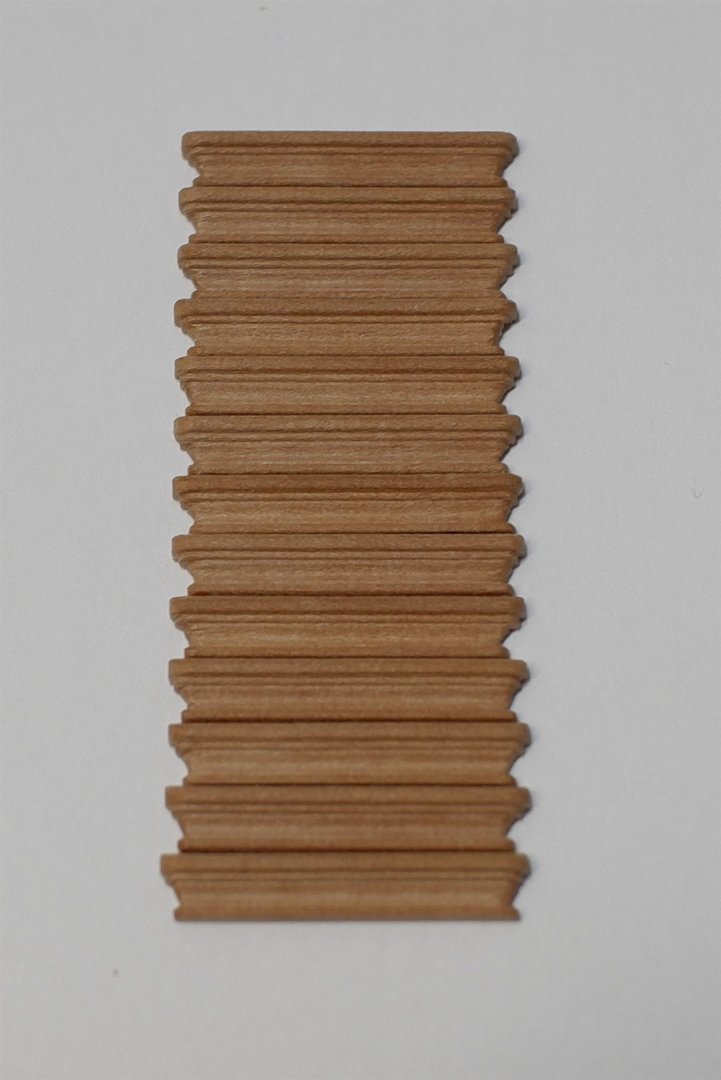

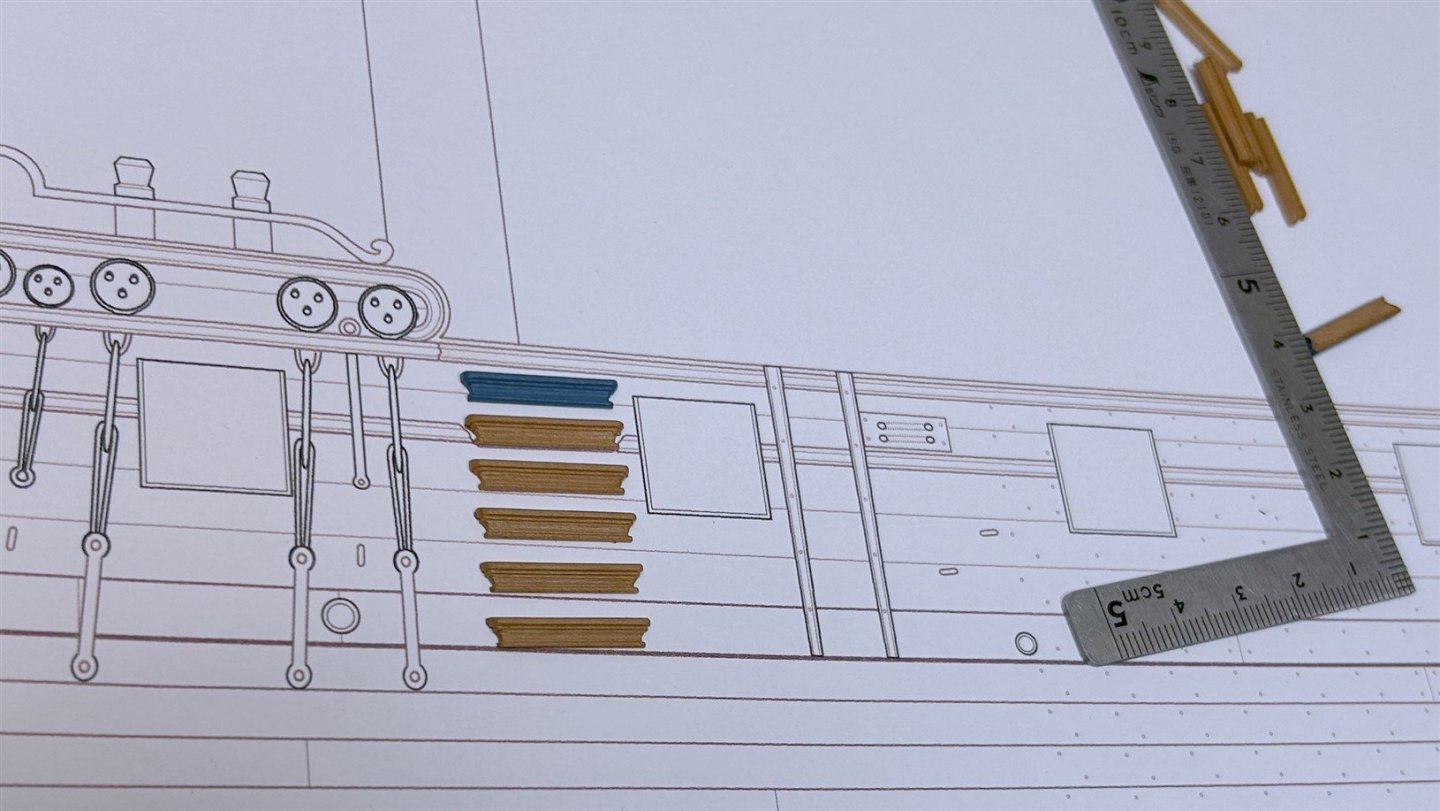

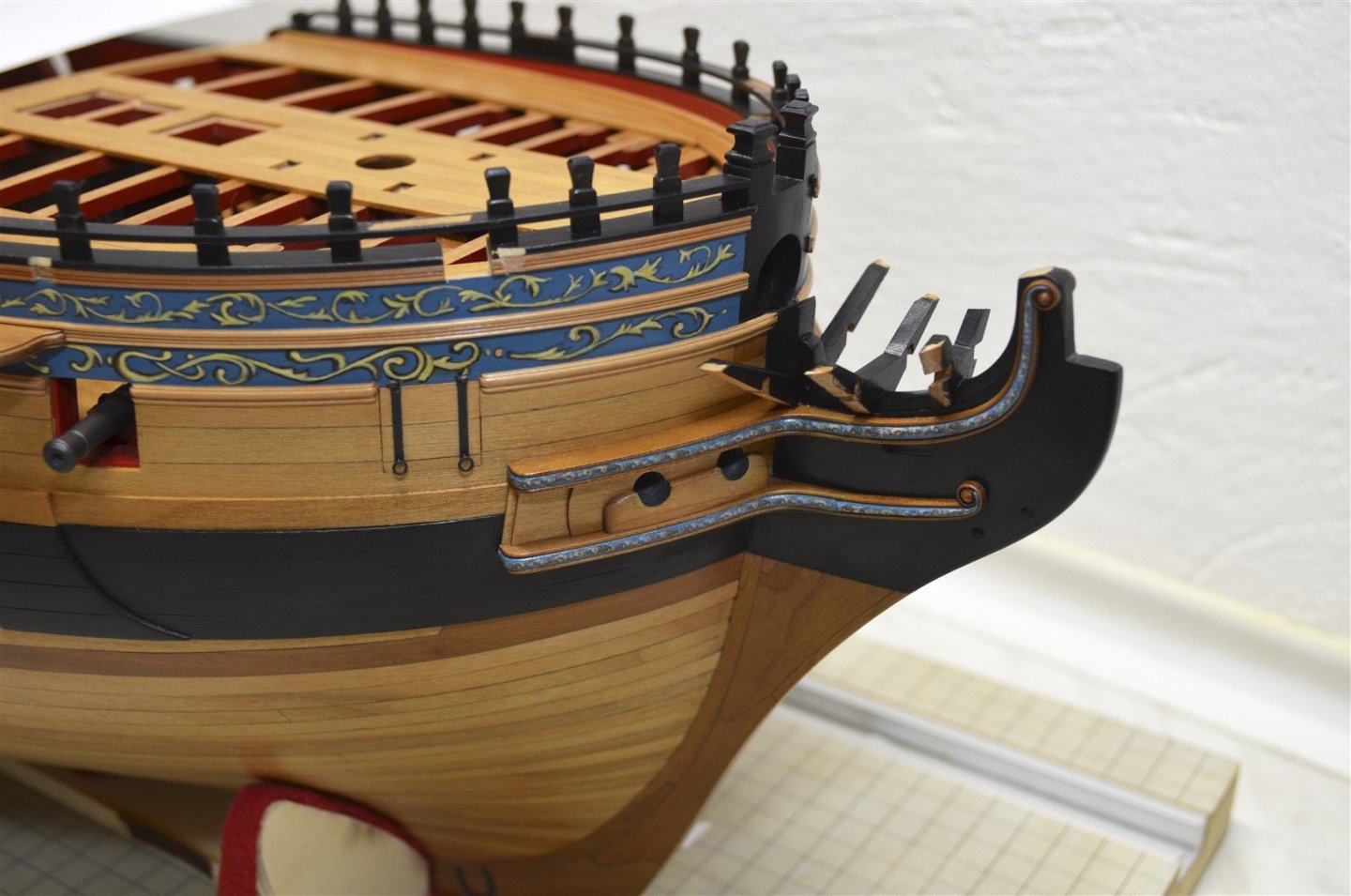

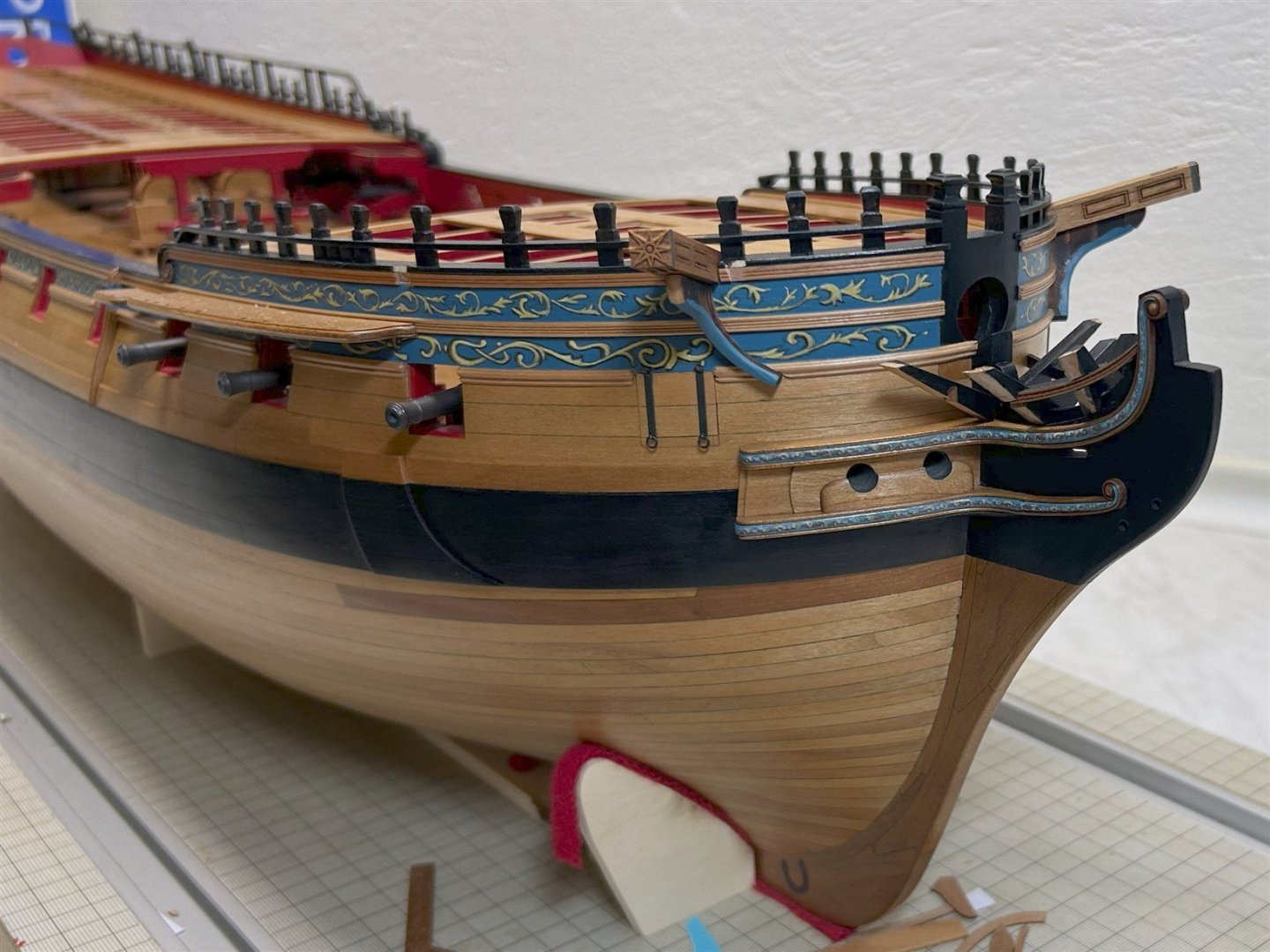

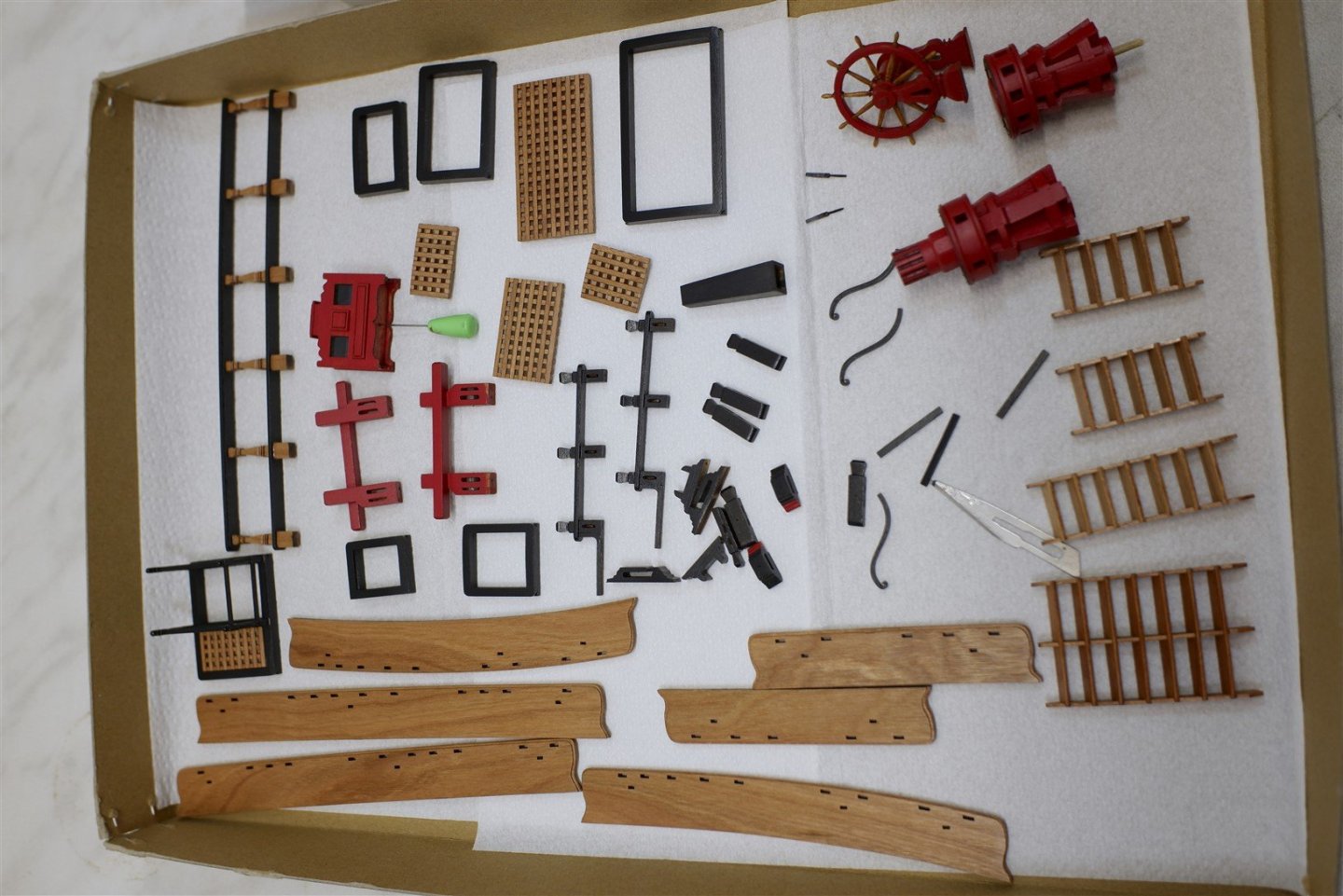

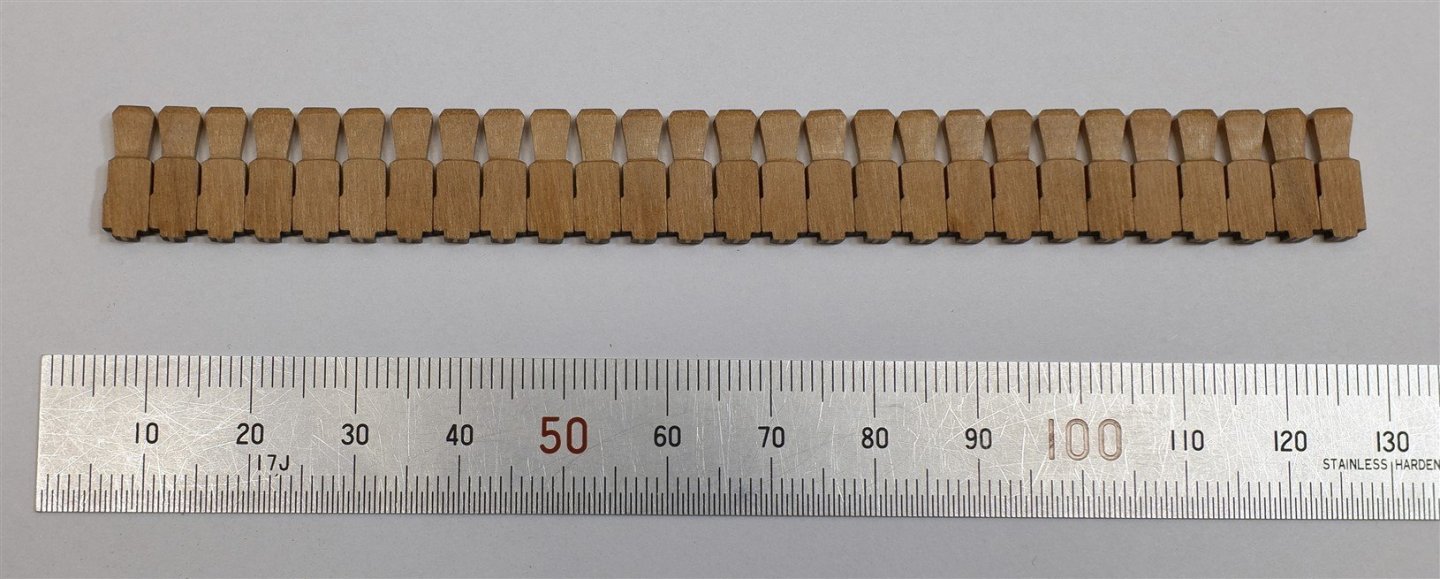

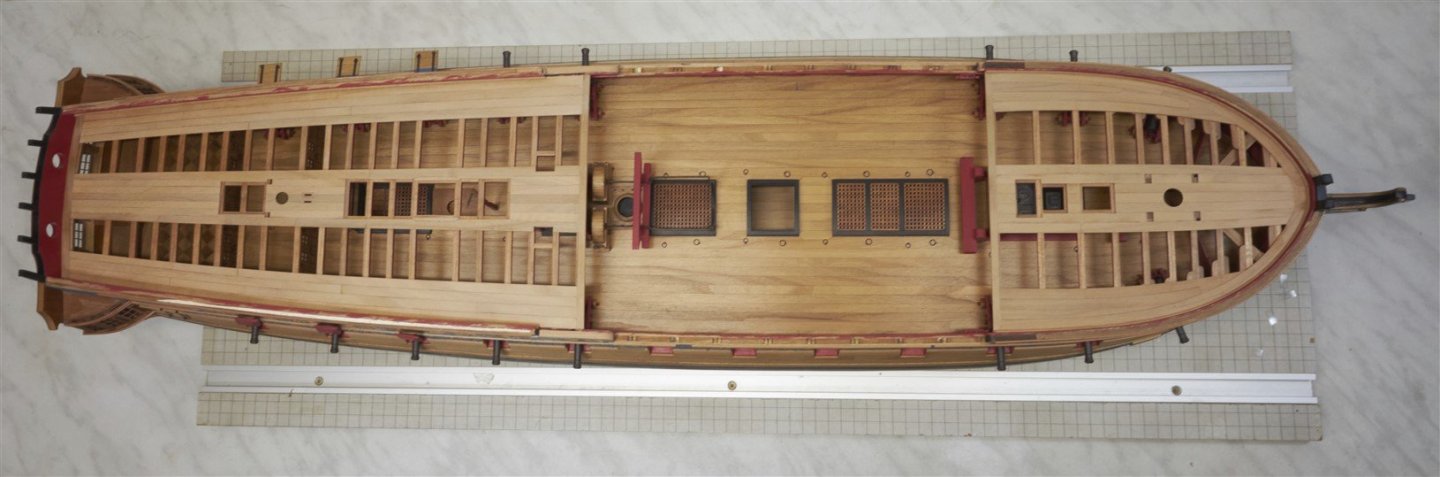

Thanks for the kind words and likes, guys. I can't wait to get all these little things in their place on qdeck and fcastle, but for now I'm keeping them safely stored away. It's both to keep the dust off while I work on the final chapter and to keep them from getting damaged. I'll add them at the very end. But something is there... I made the deadeyes (they will be added to the model at the end as well) The ladder - I have to paint the frieze and then glue the main channel. The other channels are already glued on, as well as the fenders and the chesstrees and the swivel stocks. Partly also the gangways. And now the main thing, I'm working on the last chapter. The headtimbers are in place. The headrails are ready but not glued yet. But I've finally permanently glued Catheads. And right now I'm currently preparing the Catheads support. And here is some photo

-

You did a great job on it, Glenn.👍

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.