Supplies of the Ship Modeler's Handbook are running out. Get your copy NOW before they are gone! Click on photo to order.

×

-

Posts

213 -

Joined

-

Last visited

Reputation Activity

-

FreekS got a reaction from ccoyle in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from ccoyle in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

Progress on the lifeboat continues. The electromagnets are installed under the decks - they can unfortunately not be covered with thin veneer as this reduces their force dramatically.

I did add some hardwood along the sides and used veneer on the decks. Cracks were finished with epoxy containing some hardwood sawdust.

inside the boat I used some lighter hardwood for the floor “racks” and the benches. Navigation lights from some brass tubing and these are always on while the white top light can be switched.

the magnets are rated for 2,5kg each (under ideal conditions) at 6V. I’m however driving them via a relais at 10v (3S LiFePo). They do get warm and I need to ensure they are not on too long. So I installed a blue LED in the dashboard to signify when the magnets are powered and the boat can be lifted by the davit. Here the boat is connected to the davit in its case.

and the magnets release when they are switched off.

boat is ready for first test tonight - then some more details can be added and I can start to think how to control the davit raising and lowering the boat from the transmitter - without losing sight of the fact that this davit design was manually operated and not powered.

-

FreekS got a reaction from Haliburton in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Haliburton in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

Progress on the lifeboat continues. The electromagnets are installed under the decks - they can unfortunately not be covered with thin veneer as this reduces their force dramatically.

I did add some hardwood along the sides and used veneer on the decks. Cracks were finished with epoxy containing some hardwood sawdust.

inside the boat I used some lighter hardwood for the floor “racks” and the benches. Navigation lights from some brass tubing and these are always on while the white top light can be switched.

the magnets are rated for 2,5kg each (under ideal conditions) at 6V. I’m however driving them via a relais at 10v (3S LiFePo). They do get warm and I need to ensure they are not on too long. So I installed a blue LED in the dashboard to signify when the magnets are powered and the boat can be lifted by the davit. Here the boat is connected to the davit in its case.

and the magnets release when they are switched off.

boat is ready for first test tonight - then some more details can be added and I can start to think how to control the davit raising and lowering the boat from the transmitter - without losing sight of the fact that this davit design was manually operated and not powered.

-

FreekS got a reaction from Mirabell61 in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Mirabell61 in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

I’ve filled some of the gaps with small pieces of wood and a bit of “liquid wood”.

then applied an epoxy layer with a layer of 80g/m2 glass fabric. This was followed by another two layers of epoxy and one inside

the wood filled did discolour a bit with the epoxy, but I think I will leave the hull as it is instead of painting it.

I installed a small brushless motor, a couplet and the axle connected to a 40 mm diameter brass prop.

rudder is made from two sheets of hardwood glued together and shaped with file and sandpaper.

I’ll need to make two small holes in the hull to drive the rudder from a small servo.

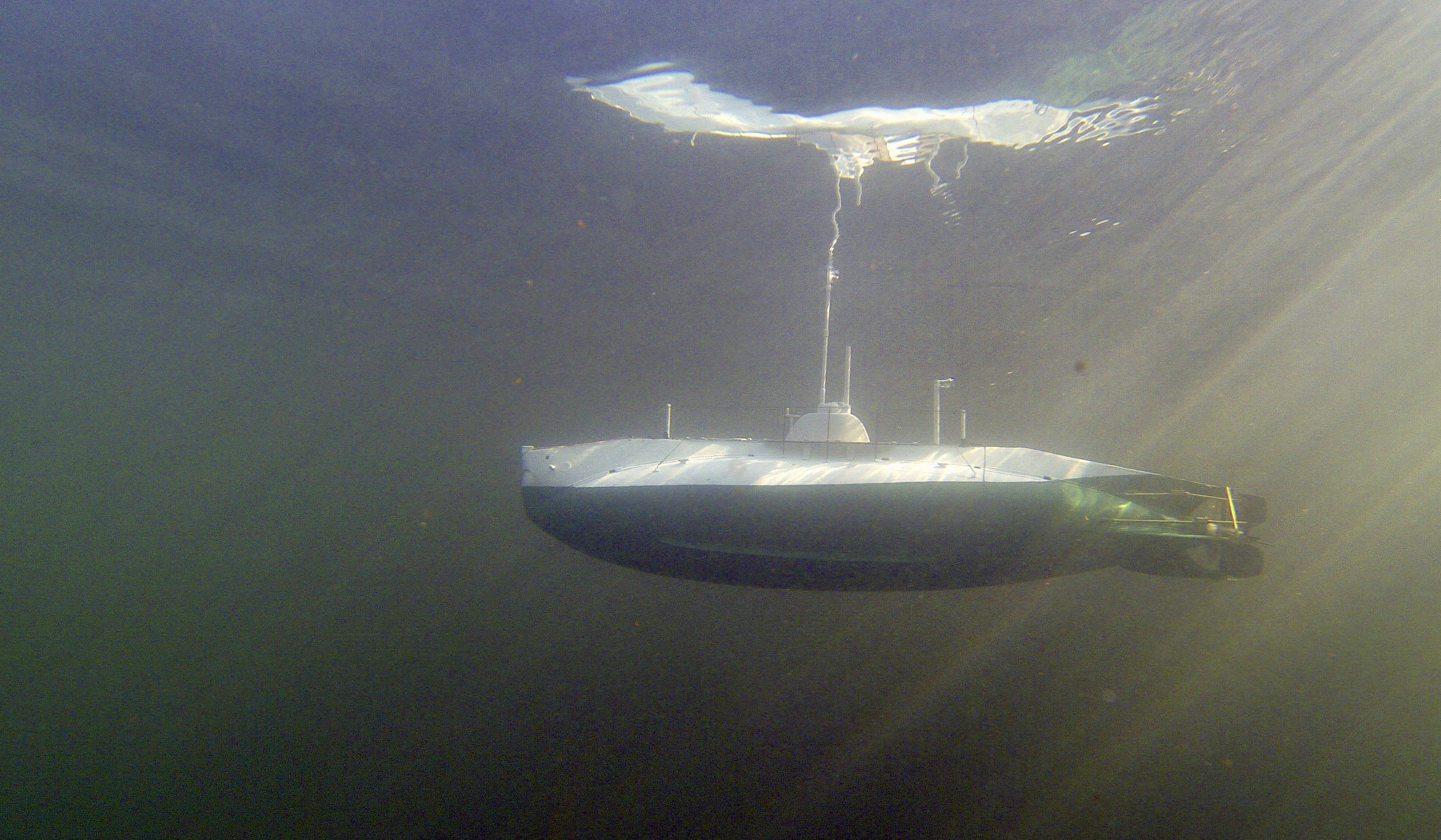

that will be the time for a wet test to see how much current the motor draws, how much ballast to add and if the boat is watertight…

-

FreekS got a reaction from Haliburton in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Haliburton in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

After first sanding of the outside I’ve cut the boat off it’s build plank to sand the inside. Surprised to weigh in at only 200 grams! The planks are only 2 mm thick (before sanding!) and the sun shows how thin it is!!

I connected the tops of all frames with two more sets of planks - looks OK and strong.

Plan is to use filler, epoxy and glasfabric for strengthening - not sure yet of the order!

-

FreekS got a reaction from Haliburton in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Haliburton in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

Here is the frames on the build plank, and the start and finish of the planking.

Lots of sanding is next, and coating with epoxy

-

FreekS got a reaction from Haliburton in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Haliburton in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

This winter I’m working on a “grandfather” repair and renewal project.

My grandfather was shipbuilding engineer, and was drafted in WW1, spending the war in neutral Netherlands on one of the fortresses of the defence of Amsterdam. That’s where my last project came from.

From the 1920s until the end of WW2 he worked in Dutch East Indies (Indonesia) for a shipping company. In 1947 after repatriation to Netherlands he filed a patent on a method to launch a lifeboat from a davit through a clever use of a pivot. Two crewmembers each rotated a handle over 180 degrees, which swings out the lifeboat, descending slightly under its own weight. Then lines are slipped to defend it to the sea.

To help him sell the patent, he had a demo model built, published an article in a trade journal, and even made a “cartoon movie” from a set of cards to show the operation. I think about a dozen ships were equipped with the system.

The demo model survived the past 75 years or so, but was in somewhat of a state when I received it from a cousin before Xmas. The boat is solid. Just needed a paintjob but is unsuitable for radio control.

My plan has three phases

- repair the model

- build a RC controlled new lifeboat to be launched from it

- possibly make the Davit RC as well

the repair was fairly straight forward, involved re-soldering the brass and copper past, new paint job and polishing up the blocks and brass parts.

in the last photo, the solid wood boat is half painted, I decided to make a new boat using “plank on frames”. The new boat will be slightly shorter with room for a rudder, and will have a prop obviously.

To obtain a plan of the frames, I marked out frames on the keel of the boat model, and used a home made measuring device to measure out the shape of each frame.

from that I drew the frames on a 7mm pine plank, and the keel on another one (slightly shorter and with opening for the prop).

also the planks themselves were sawed from pinewood, and I’ve just started mounting the frames and keel on a build plank for planking. TBC…

-

FreekS got a reaction from Mirabell61 in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Mirabell61 in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

Progress on the lifeboat continues. The electromagnets are installed under the decks - they can unfortunately not be covered with thin veneer as this reduces their force dramatically.

I did add some hardwood along the sides and used veneer on the decks. Cracks were finished with epoxy containing some hardwood sawdust.

inside the boat I used some lighter hardwood for the floor “racks” and the benches. Navigation lights from some brass tubing and these are always on while the white top light can be switched.

the magnets are rated for 2,5kg each (under ideal conditions) at 6V. I’m however driving them via a relais at 10v (3S LiFePo). They do get warm and I need to ensure they are not on too long. So I installed a blue LED in the dashboard to signify when the magnets are powered and the boat can be lifted by the davit. Here the boat is connected to the davit in its case.

and the magnets release when they are switched off.

boat is ready for first test tonight - then some more details can be added and I can start to think how to control the davit raising and lowering the boat from the transmitter - without losing sight of the fact that this davit design was manually operated and not powered.

-

FreekS got a reaction from KeithAug in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from KeithAug in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

Progress on the lifeboat continues. The electromagnets are installed under the decks - they can unfortunately not be covered with thin veneer as this reduces their force dramatically.

I did add some hardwood along the sides and used veneer on the decks. Cracks were finished with epoxy containing some hardwood sawdust.

inside the boat I used some lighter hardwood for the floor “racks” and the benches. Navigation lights from some brass tubing and these are always on while the white top light can be switched.

the magnets are rated for 2,5kg each (under ideal conditions) at 6V. I’m however driving them via a relais at 10v (3S LiFePo). They do get warm and I need to ensure they are not on too long. So I installed a blue LED in the dashboard to signify when the magnets are powered and the boat can be lifted by the davit. Here the boat is connected to the davit in its case.

and the magnets release when they are switched off.

boat is ready for first test tonight - then some more details can be added and I can start to think how to control the davit raising and lowering the boat from the transmitter - without losing sight of the fact that this davit design was manually operated and not powered.

-

FreekS got a reaction from modeller_masa in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from modeller_masa in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

Progress on the lifeboat continues. The electromagnets are installed under the decks - they can unfortunately not be covered with thin veneer as this reduces their force dramatically.

I did add some hardwood along the sides and used veneer on the decks. Cracks were finished with epoxy containing some hardwood sawdust.

inside the boat I used some lighter hardwood for the floor “racks” and the benches. Navigation lights from some brass tubing and these are always on while the white top light can be switched.

the magnets are rated for 2,5kg each (under ideal conditions) at 6V. I’m however driving them via a relais at 10v (3S LiFePo). They do get warm and I need to ensure they are not on too long. So I installed a blue LED in the dashboard to signify when the magnets are powered and the boat can be lifted by the davit. Here the boat is connected to the davit in its case.

and the magnets release when they are switched off.

boat is ready for first test tonight - then some more details can be added and I can start to think how to control the davit raising and lowering the boat from the transmitter - without losing sight of the fact that this davit design was manually operated and not powered.

-

FreekS reacted to Valeriy V in Cyclone-Class Destroyer 1902 by Valeriy V - scale 1:45 - Russian Imperial Navy

FreekS reacted to Valeriy V in Cyclone-Class Destroyer 1902 by Valeriy V - scale 1:45 - Russian Imperial Navy

Thanks Ras!

My process is slowly moving forward, while the epoxy resin on the hull dries, I am making the propeller group of the destroyer.

-

FreekS got a reaction from Mirabell61 in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Mirabell61 in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

Boat has been ballasted with about 1 kg lead plates - glued with epoxy. Motor mount and rudder are functional.

I made the boat 3cm smaller than it’s static predecessor - to allow some room for the rudder.

after planking the foredeck and aft deck I could test where to put the mounts to hang it in the Davit. The not has 5mm rim in either side but swings out nicely.

In place of the hooks in the decks will come two electromagnets that can each lift 2.5kg and consume 250mV at 6V (visible in foreground).

-

FreekS got a reaction from mtaylor in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from mtaylor in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

Boat has been ballasted with about 1 kg lead plates - glued with epoxy. Motor mount and rudder are functional.

I made the boat 3cm smaller than it’s static predecessor - to allow some room for the rudder.

after planking the foredeck and aft deck I could test where to put the mounts to hang it in the Davit. The not has 5mm rim in either side but swings out nicely.

In place of the hooks in the decks will come two electromagnets that can each lift 2.5kg and consume 250mV at 6V (visible in foreground).

-

FreekS got a reaction from Valeriy V in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Valeriy V in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

Boat has been ballasted with about 1 kg lead plates - glued with epoxy. Motor mount and rudder are functional.

I made the boat 3cm smaller than it’s static predecessor - to allow some room for the rudder.

after planking the foredeck and aft deck I could test where to put the mounts to hang it in the Davit. The not has 5mm rim in either side but swings out nicely.

In place of the hooks in the decks will come two electromagnets that can each lift 2.5kg and consume 250mV at 6V (visible in foreground).

-

FreekS got a reaction from Roger Pellett in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Roger Pellett in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

Boat has been ballasted with about 1 kg lead plates - glued with epoxy. Motor mount and rudder are functional.

I made the boat 3cm smaller than it’s static predecessor - to allow some room for the rudder.

after planking the foredeck and aft deck I could test where to put the mounts to hang it in the Davit. The not has 5mm rim in either side but swings out nicely.

In place of the hooks in the decks will come two electromagnets that can each lift 2.5kg and consume 250mV at 6V (visible in foreground).

-

FreekS reacted to Valeriy V in SMS Karlsruhe by Wreck1919 - 1/100

FreekS reacted to Valeriy V in SMS Karlsruhe by Wreck1919 - 1/100

Sasha, now I am calm for the safety of your corps.

-

FreekS got a reaction from Ian_Grant in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Ian_Grant in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

I’ve filled some of the gaps with small pieces of wood and a bit of “liquid wood”.

then applied an epoxy layer with a layer of 80g/m2 glass fabric. This was followed by another two layers of epoxy and one inside

the wood filled did discolour a bit with the epoxy, but I think I will leave the hull as it is instead of painting it.

I installed a small brushless motor, a couplet and the axle connected to a 40 mm diameter brass prop.

rudder is made from two sheets of hardwood glued together and shaped with file and sandpaper.

I’ll need to make two small holes in the hull to drive the rudder from a small servo.

that will be the time for a wet test to see how much current the motor draws, how much ballast to add and if the boat is watertight…

-

FreekS got a reaction from Prowler901 in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Prowler901 in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

I’ve filled some of the gaps with small pieces of wood and a bit of “liquid wood”.

then applied an epoxy layer with a layer of 80g/m2 glass fabric. This was followed by another two layers of epoxy and one inside

the wood filled did discolour a bit with the epoxy, but I think I will leave the hull as it is instead of painting it.

I installed a small brushless motor, a couplet and the axle connected to a 40 mm diameter brass prop.

rudder is made from two sheets of hardwood glued together and shaped with file and sandpaper.

I’ll need to make two small holes in the hull to drive the rudder from a small servo.

that will be the time for a wet test to see how much current the motor draws, how much ballast to add and if the boat is watertight…

-

FreekS got a reaction from Harvey Golden in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Harvey Golden in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

I’ve filled some of the gaps with small pieces of wood and a bit of “liquid wood”.

then applied an epoxy layer with a layer of 80g/m2 glass fabric. This was followed by another two layers of epoxy and one inside

the wood filled did discolour a bit with the epoxy, but I think I will leave the hull as it is instead of painting it.

I installed a small brushless motor, a couplet and the axle connected to a 40 mm diameter brass prop.

rudder is made from two sheets of hardwood glued together and shaped with file and sandpaper.

I’ll need to make two small holes in the hull to drive the rudder from a small servo.

that will be the time for a wet test to see how much current the motor draws, how much ballast to add and if the boat is watertight…

-

FreekS got a reaction from KeithAug in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from KeithAug in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

I’ve filled some of the gaps with small pieces of wood and a bit of “liquid wood”.

then applied an epoxy layer with a layer of 80g/m2 glass fabric. This was followed by another two layers of epoxy and one inside

the wood filled did discolour a bit with the epoxy, but I think I will leave the hull as it is instead of painting it.

I installed a small brushless motor, a couplet and the axle connected to a 40 mm diameter brass prop.

rudder is made from two sheets of hardwood glued together and shaped with file and sandpaper.

I’ll need to make two small holes in the hull to drive the rudder from a small servo.

that will be the time for a wet test to see how much current the motor draws, how much ballast to add and if the boat is watertight…

-

FreekS got a reaction from Roger Pellett in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Roger Pellett in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

I’ve filled some of the gaps with small pieces of wood and a bit of “liquid wood”.

then applied an epoxy layer with a layer of 80g/m2 glass fabric. This was followed by another two layers of epoxy and one inside

the wood filled did discolour a bit with the epoxy, but I think I will leave the hull as it is instead of painting it.

I installed a small brushless motor, a couplet and the axle connected to a 40 mm diameter brass prop.

rudder is made from two sheets of hardwood glued together and shaped with file and sandpaper.

I’ll need to make two small holes in the hull to drive the rudder from a small servo.

that will be the time for a wet test to see how much current the motor draws, how much ballast to add and if the boat is watertight…

-

FreekS got a reaction from mtaylor in LARA 1969 by Elder_dumpster - RADIO - Trident 24 centerboard sloop - first scratch POF model of a yacht I used to own

FreekS got a reaction from mtaylor in LARA 1969 by Elder_dumpster - RADIO - Trident 24 centerboard sloop - first scratch POF model of a yacht I used to own

Hi great looking boat. Note the ballast scales to the power 3! So your 940kg ballast becomes 1,5kg at scale 1:8!

you need to get that weight as low as possible in, or even below the keel with a “false keel”. See my Corsaro 2 build log for example. You also need to build the whole boat and especially the rigging as light as possible!!

ill definitely follow this!

-

FreekS reacted to Javelin in Sea Installer by Javelin - FINISHED - 1/2000 - BOTTLE

FreekS reacted to Javelin in Sea Installer by Javelin - FINISHED - 1/2000 - BOTTLE

Hi Glen,

I was saying somewhat the opposite, that the nacelle idea would be difficult due to the blades, but given your comment, I actuall thought about it again. A small tower on the bottom would indeed be a nice stand for the bottle, while the tip could actually be a nacelle without the blades. This vessel builds the towers, puts the nacelles on top and then inserts the blades into the nacelle, so an unfinished windmill is a possibility. If I'd leave the blades out and leave 3 large holes, it would allow more light to enter the front of the bottle and give some visibility to the bottleneck, which would otherwise be nearly invisible... I'll have to draw it out.

It would take a long time to build that hub though, not sure if I want to invest this much time in it. I don't really have much of a connection to the vessel and I'm having trouble considering it a real project. It remains a prototype in my mind for the time being.

Now on to the vessel itself. I continued the hull, losing quite some time with a nasty seam in the middle. Again I was in doubt whether to give it a better finish or leave it as it was, about 0.5mm in between the hull halves. I decided to try to fill it and give it a better fit.

It'll always be visible of course, but I'll try to hide it with deck equipment and a lot of it is already covered by the accommodation block as well.

As you can see in these pictures, the hinges, which will be retracted into the hull, are made invisible by these blocks around the legs (where I assume the jacking mechanism is located).

She has a very unusual triple Voight Schneider propulsion, which is something normally used by tugboats. This propulsion is basically a modern paddle wheel, with the blades standing upright and rotating. The angle of the blades varies during the rotation, creating a forward motion. I made the base for this propulsion in form of 3 circular plates at the bottom, but decided to wait with the tiny blades until the last moment before bottling, since they will be too fragile to handle during the build.

In the back you see the three propulsion circles, the central one was also the reason for splitting this hull this way. The bow seam I solved (after several attempts) by covering one half of the bow with vaseline, while applying Milliput epoxy filler to the other half. This way I got a good fit and the filler would stick only to one half of the hull. The back was eventually done in the same way. You will also see that on the top deck, the split is straight in the back. This allows me to align the hulls easier inside the bottle.

-

FreekS got a reaction from Mirabell61 in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Mirabell61 in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

After first sanding of the outside I’ve cut the boat off it’s build plank to sand the inside. Surprised to weigh in at only 200 grams! The planks are only 2 mm thick (before sanding!) and the sun shows how thin it is!!

I connected the tops of all frames with two more sets of planks - looks OK and strong.

Plan is to use filler, epoxy and glasfabric for strengthening - not sure yet of the order!

-

FreekS got a reaction from Mirabell61 in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Mirabell61 in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

This winter I’m working on a “grandfather” repair and renewal project.

My grandfather was shipbuilding engineer, and was drafted in WW1, spending the war in neutral Netherlands on one of the fortresses of the defence of Amsterdam. That’s where my last project came from.

From the 1920s until the end of WW2 he worked in Dutch East Indies (Indonesia) for a shipping company. In 1947 after repatriation to Netherlands he filed a patent on a method to launch a lifeboat from a davit through a clever use of a pivot. Two crewmembers each rotated a handle over 180 degrees, which swings out the lifeboat, descending slightly under its own weight. Then lines are slipped to defend it to the sea.

To help him sell the patent, he had a demo model built, published an article in a trade journal, and even made a “cartoon movie” from a set of cards to show the operation. I think about a dozen ships were equipped with the system.

The demo model survived the past 75 years or so, but was in somewhat of a state when I received it from a cousin before Xmas. The boat is solid. Just needed a paintjob but is unsuitable for radio control.

My plan has three phases

- repair the model

- build a RC controlled new lifeboat to be launched from it

- possibly make the Davit RC as well

the repair was fairly straight forward, involved re-soldering the brass and copper past, new paint job and polishing up the blocks and brass parts.

in the last photo, the solid wood boat is half painted, I decided to make a new boat using “plank on frames”. The new boat will be slightly shorter with room for a rudder, and will have a prop obviously.

To obtain a plan of the frames, I marked out frames on the keel of the boat model, and used a home made measuring device to measure out the shape of each frame.

from that I drew the frames on a 7mm pine plank, and the keel on another one (slightly shorter and with opening for the prop).

also the planks themselves were sawed from pinewood, and I’ve just started mounting the frames and keel on a build plank for planking. TBC…

-

FreekS got a reaction from Ian_Grant in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Ian_Grant in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

After first sanding of the outside I’ve cut the boat off it’s build plank to sand the inside. Surprised to weigh in at only 200 grams! The planks are only 2 mm thick (before sanding!) and the sun shows how thin it is!!

I connected the tops of all frames with two more sets of planks - looks OK and strong.

Plan is to use filler, epoxy and glasfabric for strengthening - not sure yet of the order!