-

Posts

1,915 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by cdrusn89

-

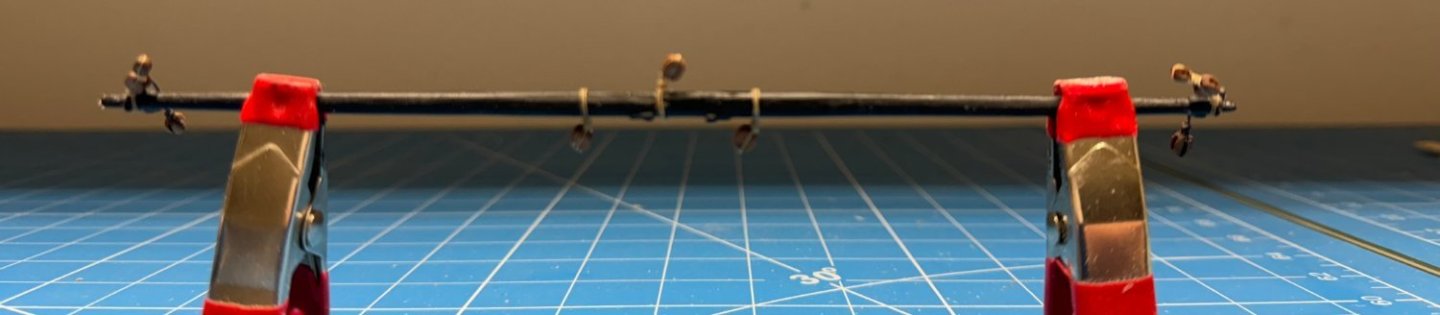

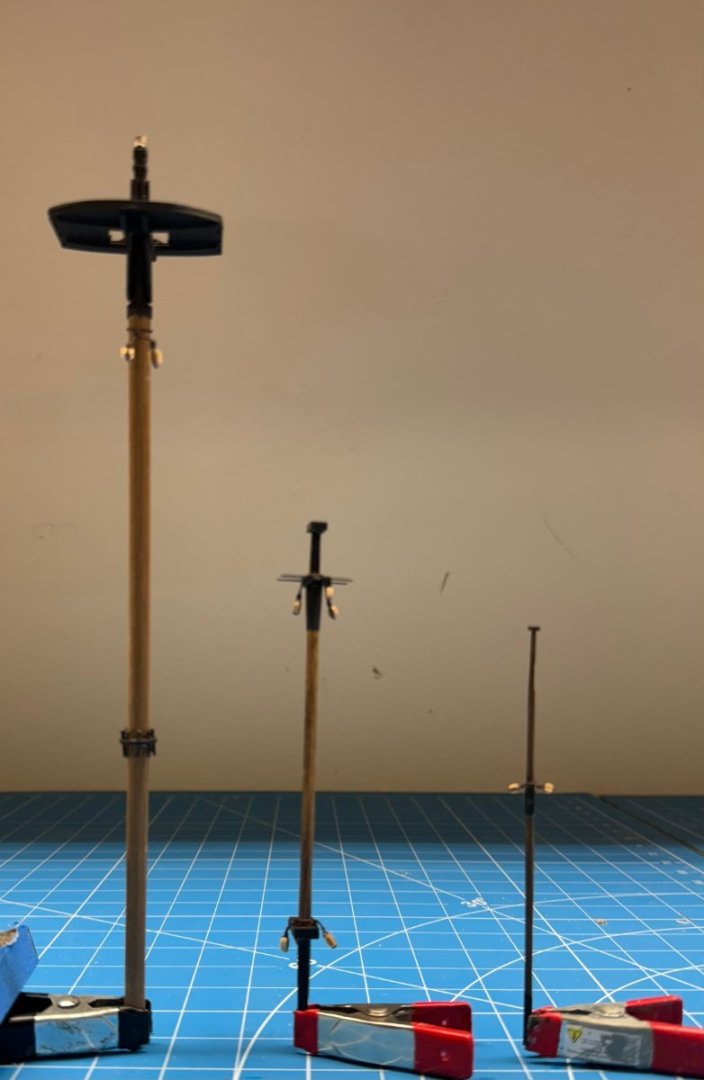

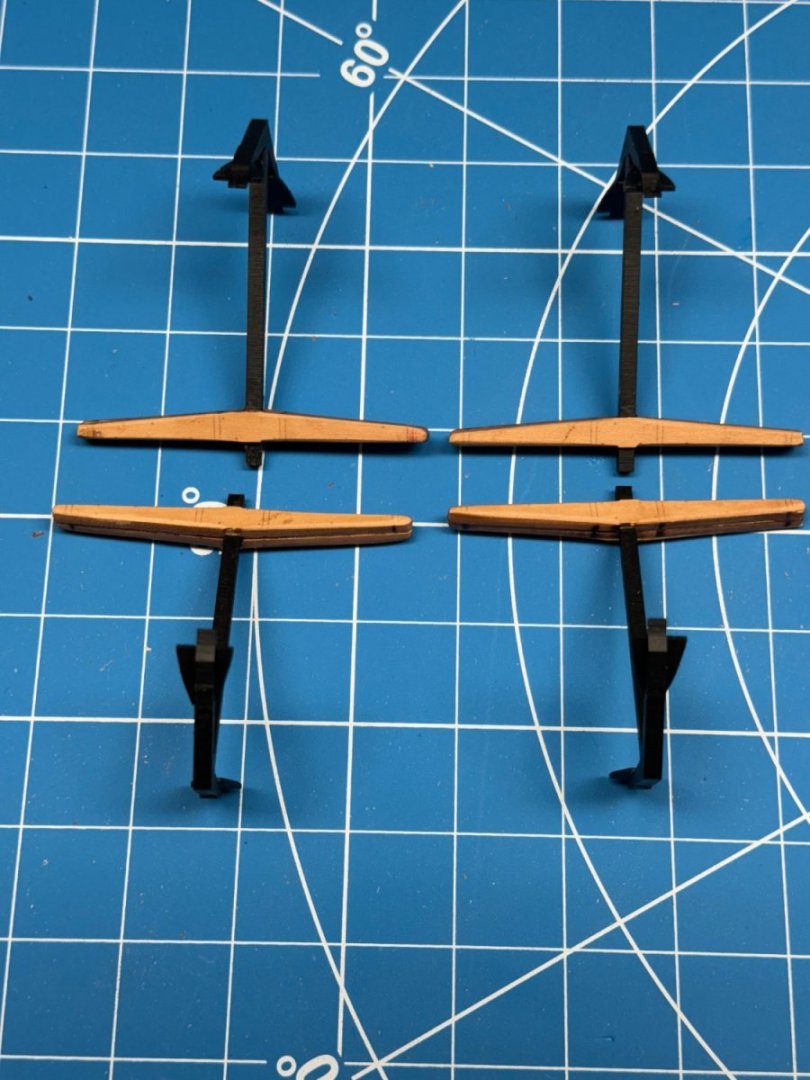

As a test of my material and technique I went and completed the Crossjack yard arm. On the mizzen mast I used Syren blocks but I do ot have enough of them (and according to Chuck it will be months until he replenishes his inventory) to do all the masts and yard arms so I switched to Model Expo "premium" pear wood blocks for the yard arms. So here is the Crossjack yard with the nine blocks attached and the hole (.039") and wire to pin it to the mast. The wire is not glued in yet - I plan to do all the yards at once using 30 minute epoxy glue so I am reasonably sure the pins will not come out.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

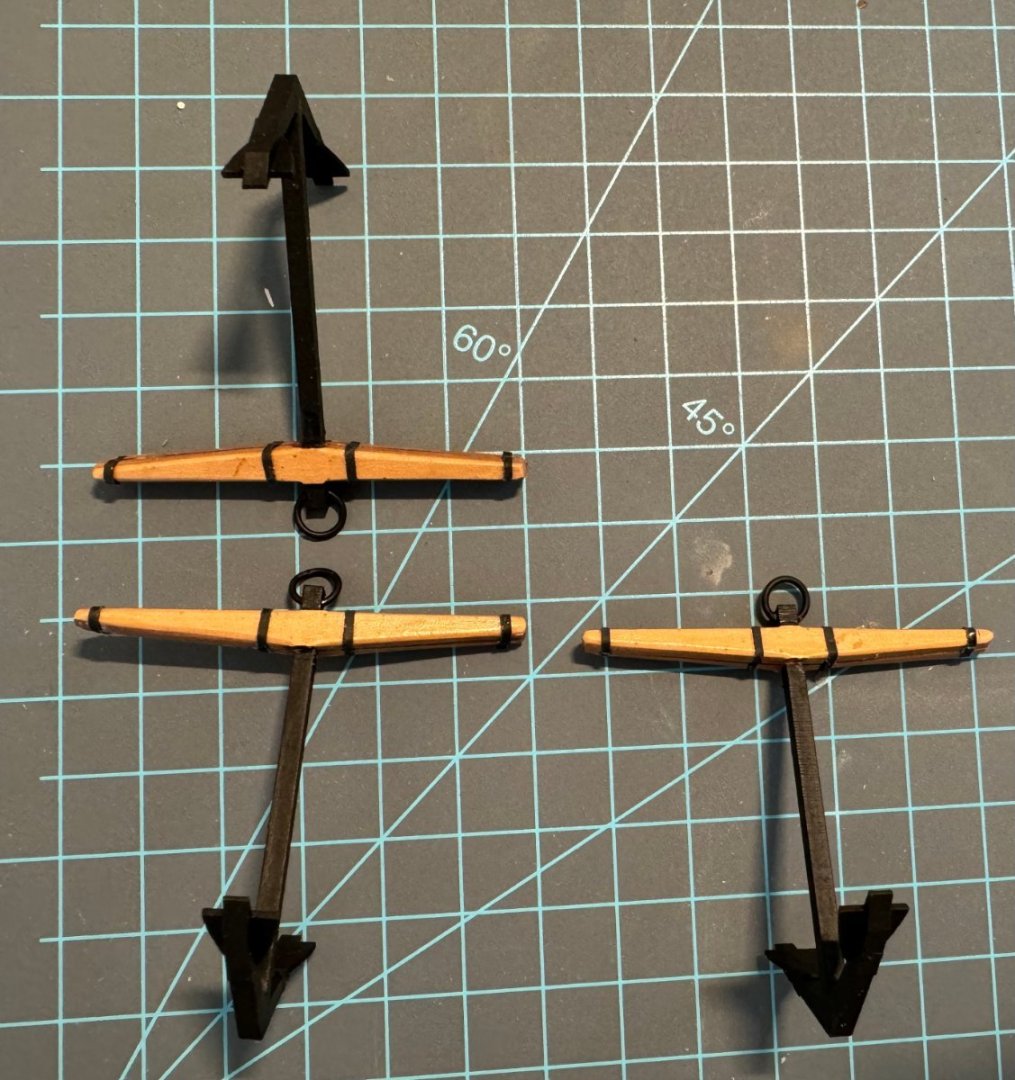

The anchors are finished but not without some drama. There are no rings supplied for the anchors, the instructions say to use brass wire to form the anchor rings. I had 5/32 split rings which seemed easier than making new ones. however, the hole in the supplied anchor shank is too small for the 5/16 split ring to fit. It took a #56 drill bit to get the ring in and then the curve of the ring was too sharp to make it out the other side without some effort. Don't ask me how I know but the MFD material that the anchor shank is made of does not take kindly to being twisted. I believe the issue all started with my making up the anchors. The stock is made of four pieces, two inner that enclose the shank, and two outer finish pieces. As delivered the "slots" in the inner stock pieces are too shallow to allow the two stock pieces to completely enclose the shank without a gap showing near the shank. To get around this I deepened the slot in the inner stocks and narrowed the shank where it fits through the stock. Probably should have just worked on the inner stock pieces and left the shank alone. Anyway, the fourth anchor is having its upper shank (above the stock) replaced with a custom manufactured piece and will join these in storage shortly.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

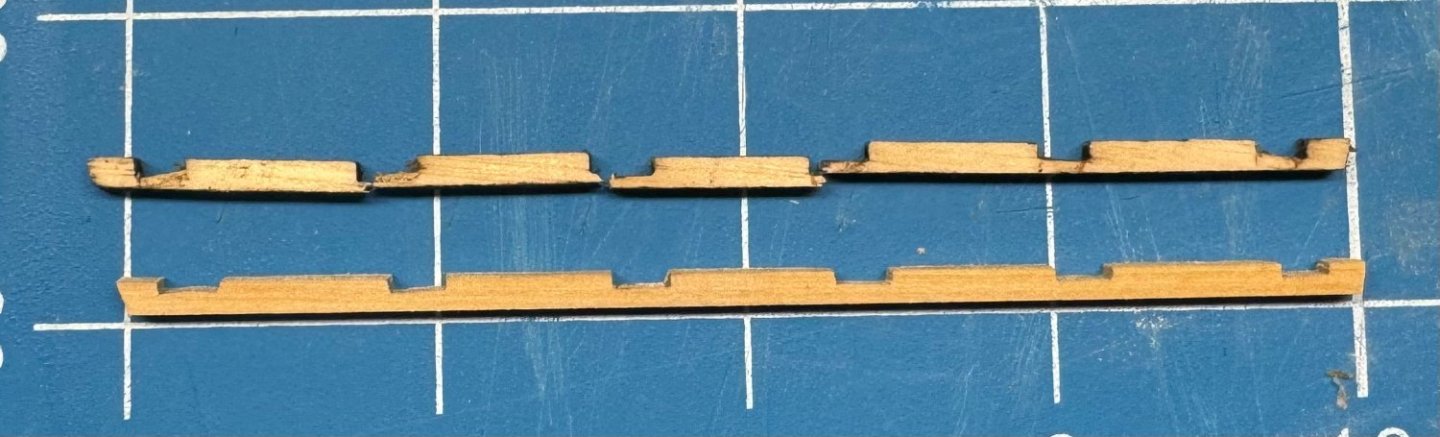

As I mentioned there was considerable difference in the thickness of the material provided - for the record here are two that turned up as I was shaping two more planks at the stern.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

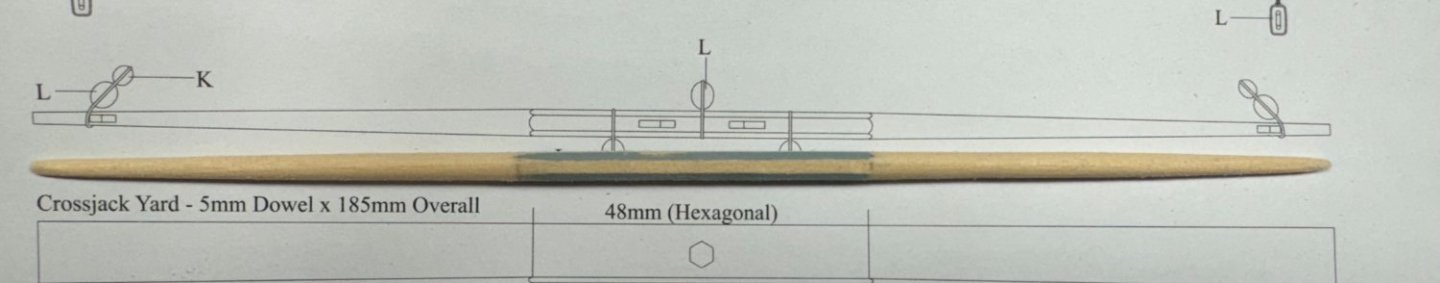

Thanks Schooner To complete the cross jack yard story Here is the piece after one side has been rounded and tapered. I used a 120 grit sanding stick to do most of the tapering then switched to 220 for the final. I plan on putting some sanding sealer on before painting. The basswood grain can go crazy if painted bare. I should have left some "extra" on both ends as I find it hard to not excessively round off the end of the taper if it it also the end of the piece. And here is the completed yard against the drawing Probably needs some meat off in the middle of the taper but getting a "straight line taper (which is what the drawing shows) takes practice and patience.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

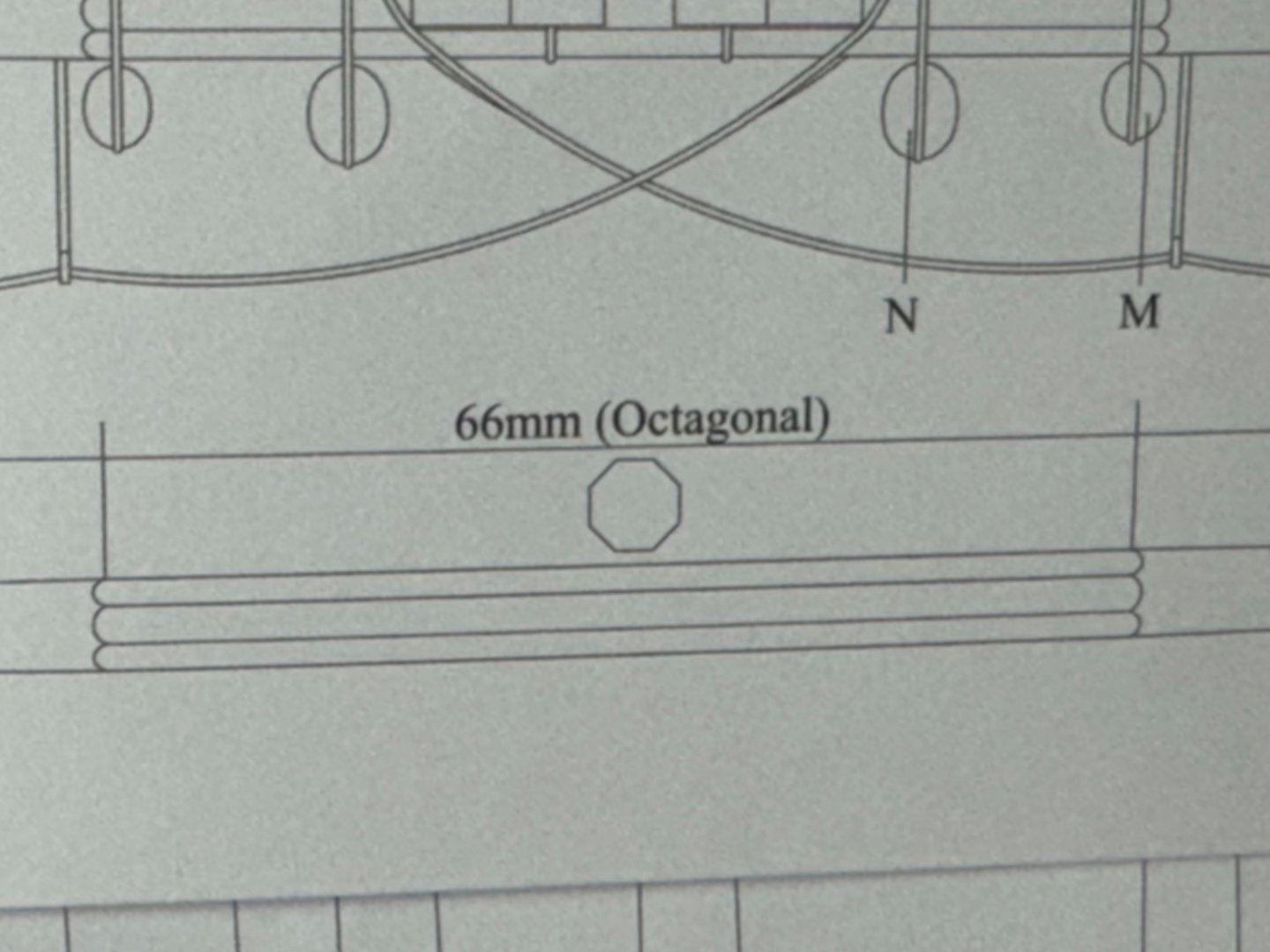

More on the yard arms. Here is the 4.2mm square "billet in the holder to make it octagonal. After one pass - the gray helps to know when "enough is enough" and whether the width is consistent from end to end. I make the billet long enough so I can leave a couple of inches at each end untouched. It helps keep the billet in the holder especially when three sides have been done. And all four sides done. I cut the end off to show that the billet is now pretty c;lose to octagonal. Hopefully it is this way from end to end. Now I will mask off the center part that will remain octagonal and round and taper the two ends per the drawing.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

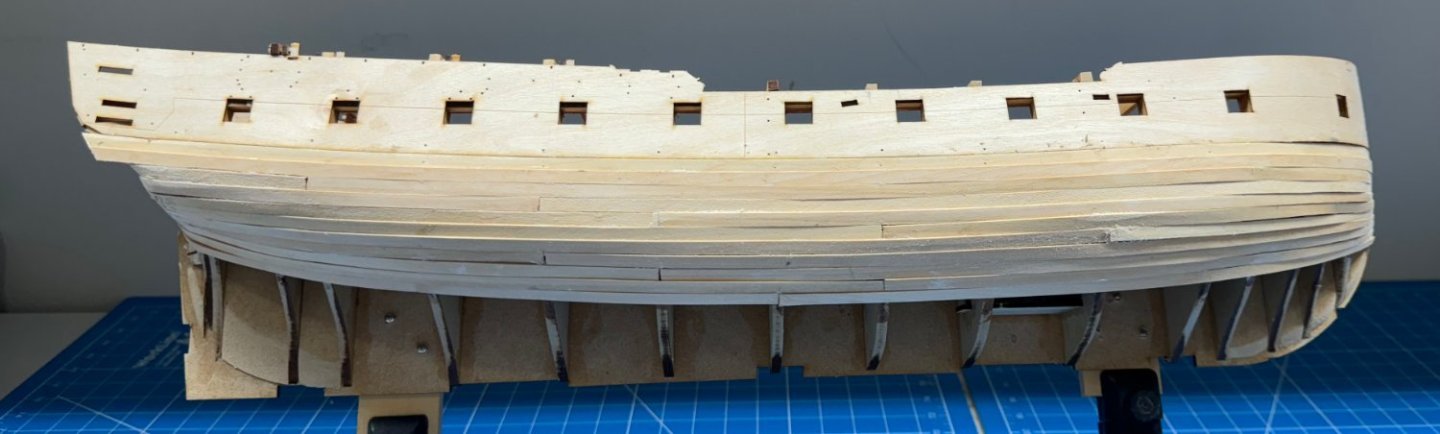

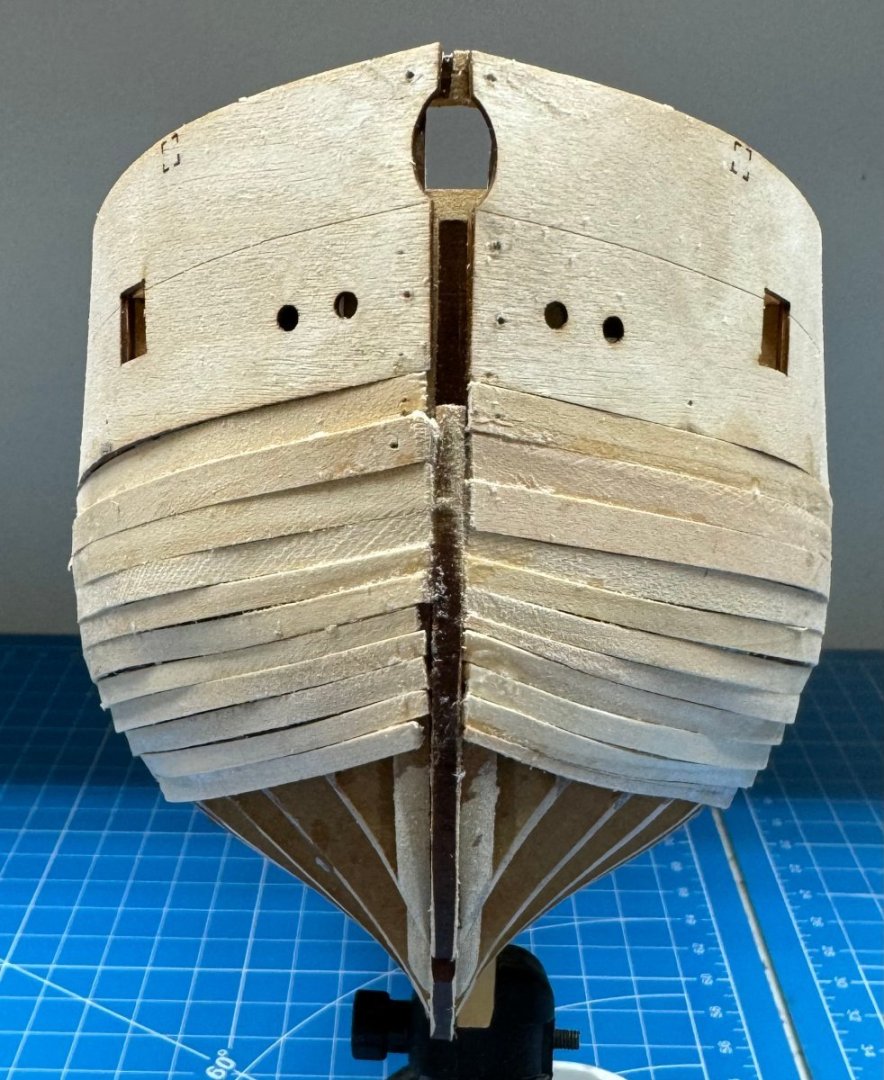

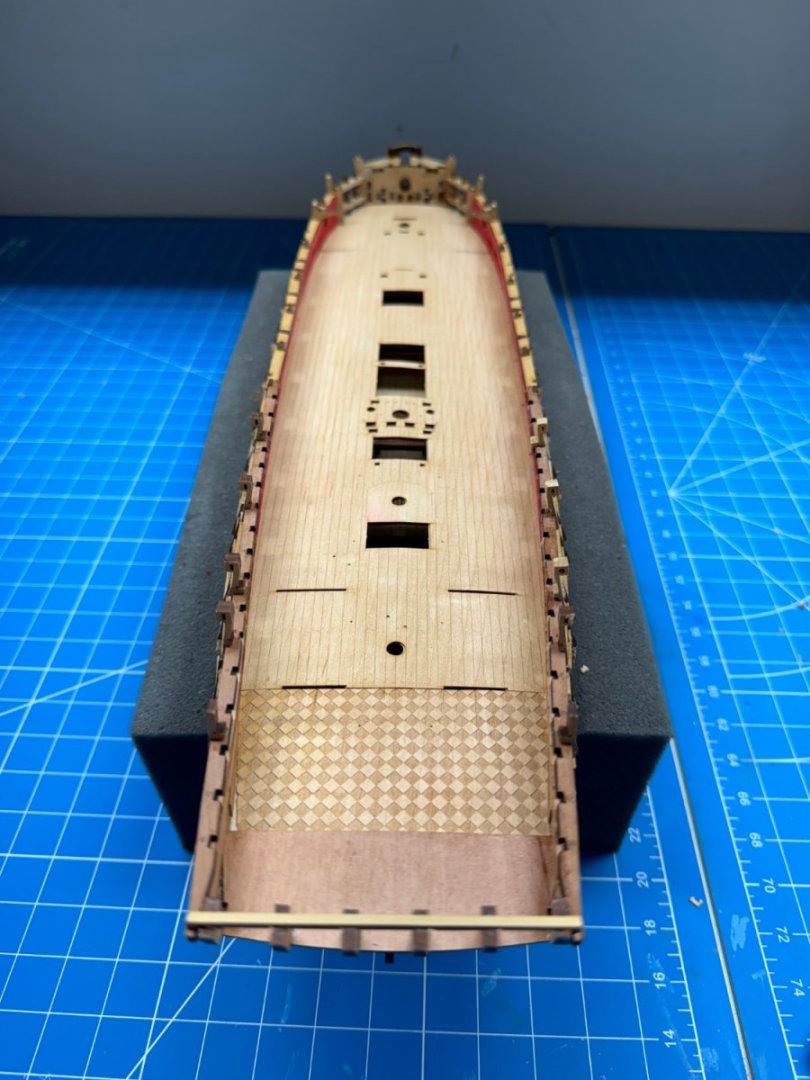

I have not been idle these last few days just not a lot of progress beyond adding more planks. I have 11 on each side now but I think there are at least that many more to go. Here is how it looks - not the best planking job ever but as the instructions note more than once this does not have to be "pretty" just cover the surface without lumps and bumps, or more correctly in my case no lumps and bumps that can't be sanded out or filled over. I would note that there is considerable variation in the thickness of the provided material. not that is going to be a problem (I hope) but it does make the job look worse that it might have been with more consistent material thickness. Any way new subject - yard arms Since I have the Mizzen Mast almost completed I decided to look at the yard arms to have a new project to work while I continue planking for the foreseeable future. For some reason known only to the shipwrights of that era, the main and fore yards are octagonal in the center while the mizzen are hexagonal. On this model they will all be octagonal - I do not have a methodology for making something hexagonal. Here the main yard as an example. The starting point, per the instructions is an 8mm dowel. This is to be reduced to an 6.6mm (an obvious mistake on the drawing) octagon. I am not sure I am capable of creating an octagon 1.4mm smaller than the starting dowel and keep all eight sides approximately the same size. I am sure some people can do this but I am pretty sure I am not one of them. So my solution is to make the yard arms starting with square section basswood (the dowels are pretty hard to boot) thickness sanded to just over the desired octagonal measurement - 6.7mm (or there abouts in this case). I chose basswood because I have it in the "surplus stuff cabinet" and since all the yards are painted black there does not appear to be any advantage dealing with harder woods. I paint the square section material with gray primer to help show the width of the section being worked better than just the bare wood. More on this is i get tired of planking.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

So I decided to use the tried and true water soaking to get the planks "around the curve" at the stern. Here are planks 3 - 7 on each side wrapping around the stern drying. One by one after they are dry, they are glued (medium CA and dilute PVA) onto the hull and when one stern plank is done I move on to the corresponding plank for the bow. No soaking needed at the bow, at least so far. Looks like two more planks on each side and then I will be at the stern post where I think the bending gets easier. To while away the soaking/drying time I worked on the mizzen mast. It is now completed, including the blocks but not the railing or stanchions (too easily damaged). I will leave the three pieces unassembled for now as together they make it hard to find a place safe enough to store.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Three rows on each side. I noticed that in spite of my best effort I did not get the two upper patterns on exactly lined up vertically. hopefully this is not a big deal since this is only the first layer but it will bear careful watching as the next layer is added. I switched to 60/40 dilute white glue (easier to apply) on the edges and medium CA at the bulkheads for attaching the planks. It is really easy and reduces (almost eliminates) the use of pins. I have been working the anchors in parallel with the planking. The instructions say to use black cartridge paper (not sure what that is in "US -speak") but I have some 1/32" (.8mm) black striping tape due for delivery tomorrow which I will at least try to use for the metal bands, here and on the masts and elsewhere the cartridge paper is called for in the instructions.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

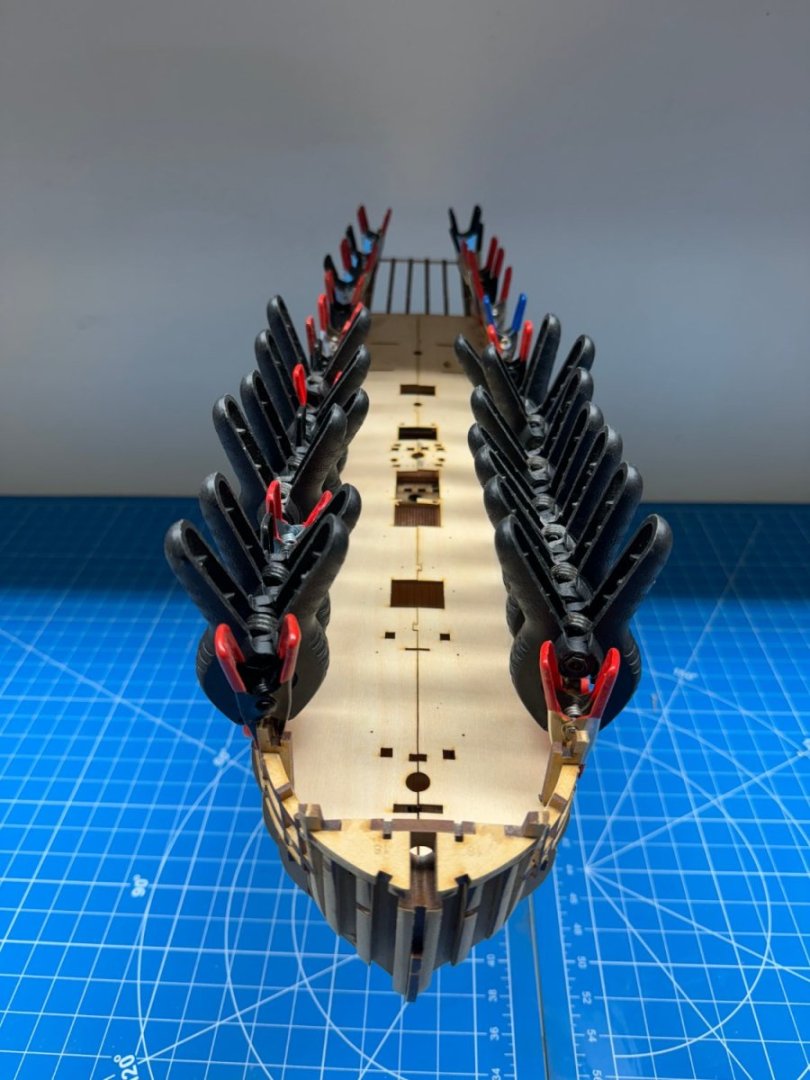

One row of planks on each side. Using PVA , nails and clamps to keep the planks in place. Am considering goes to medium CA on the bulkheads and PVA on the seams as I did on Winnie. Plan to do three rows untappered unless something goes awry. Then taper as required. Will do full length planks for these rows then go to half lengths (staggered butts) for the rest.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Thanks Don - I opted for the "natural" cabin although the color combo you suggest sounds very interesting for the next project (whatever that might be). While on the subject of cabins I was thinking about redoing the floor using a TBD design printed on some thin but still opaque paper (don't want the kit provided design showing through) and gluing that down like was done with the friezes on Winchelsea. I heard/read somewhere that the real cabin floors (at least on the 6th rates) were painted sail cloth rather than inlaid wood.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

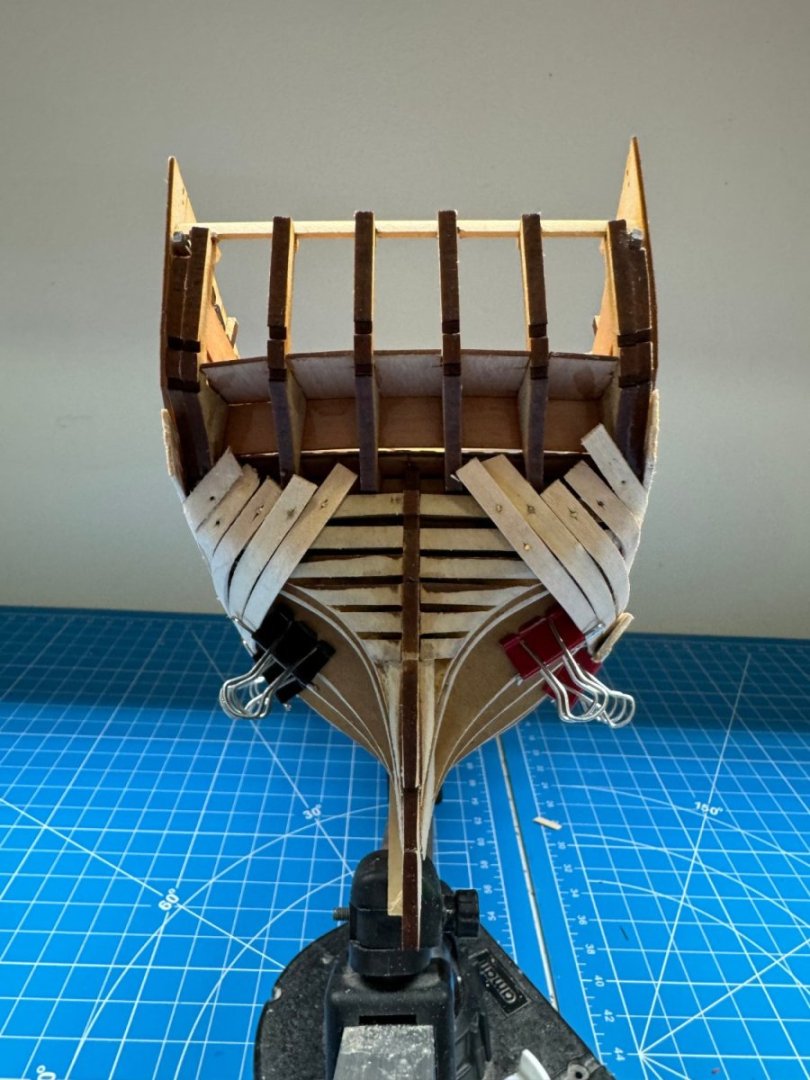

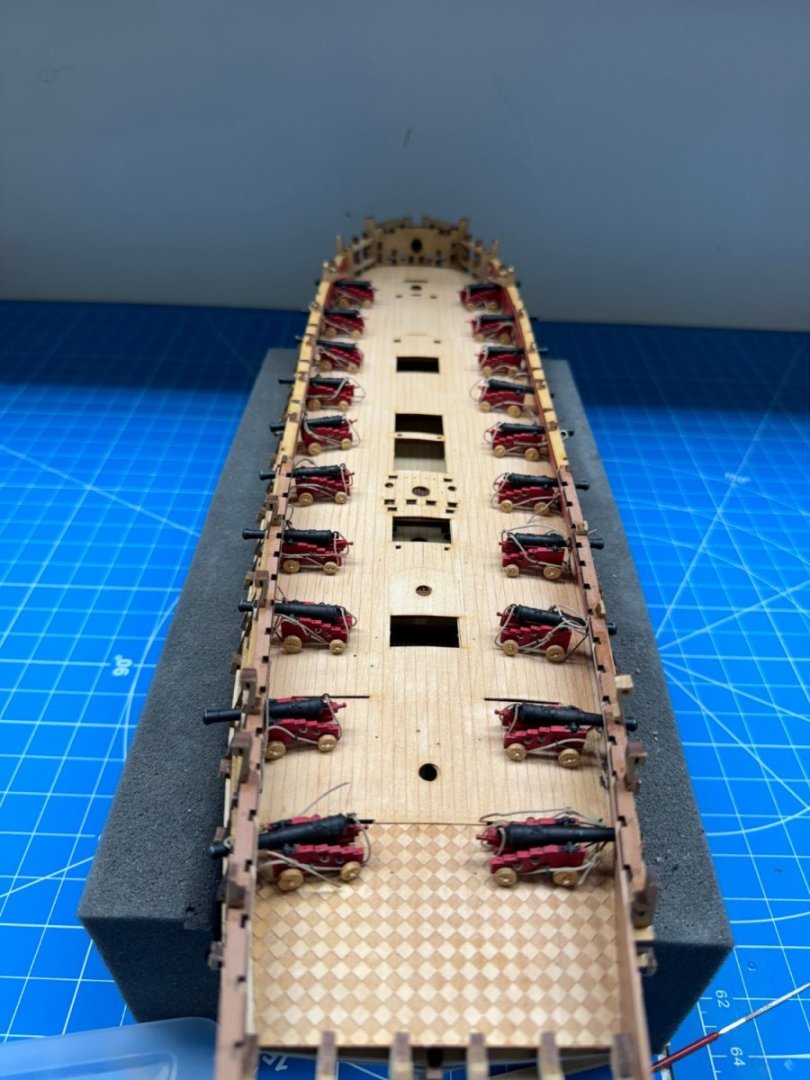

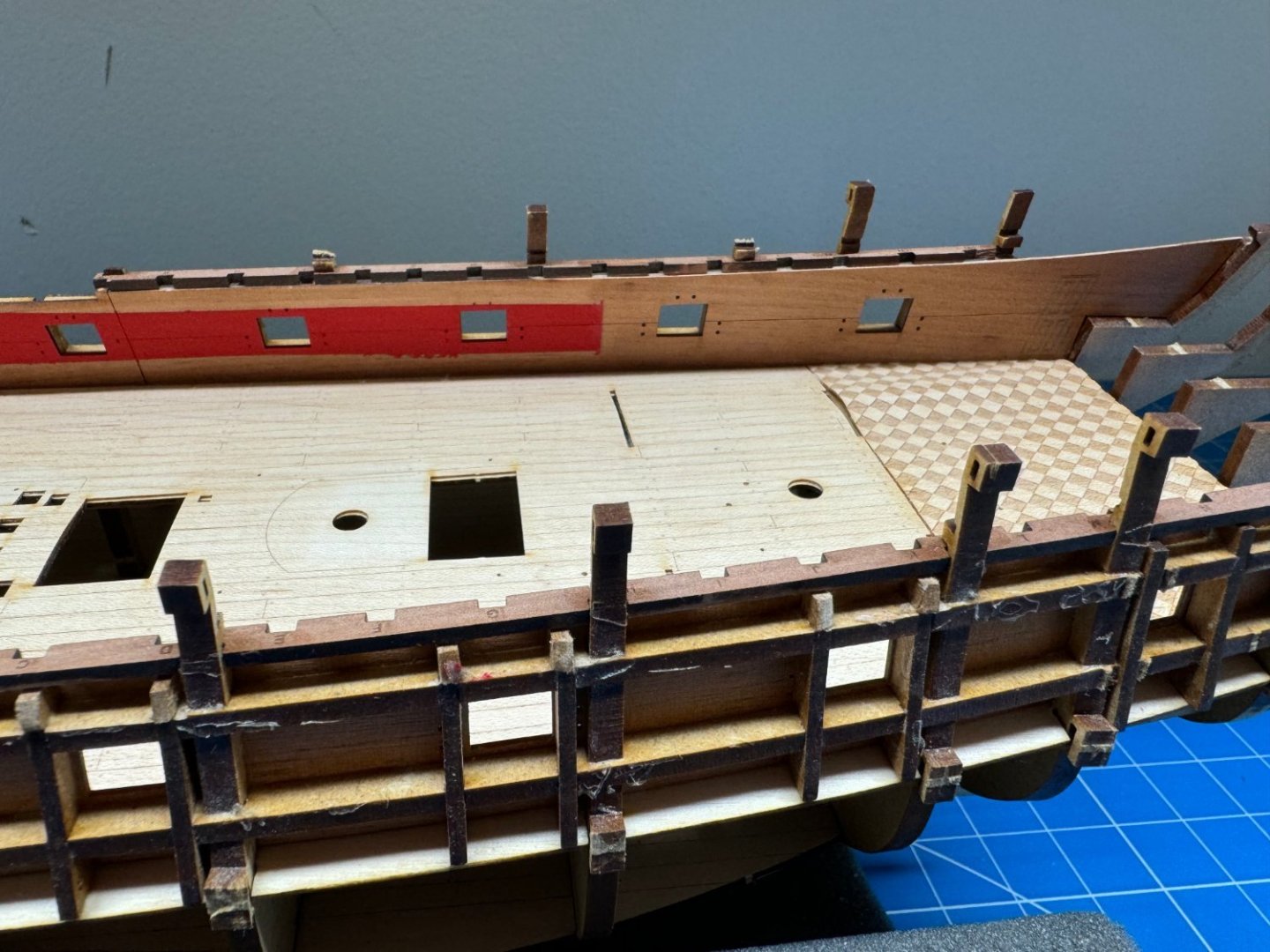

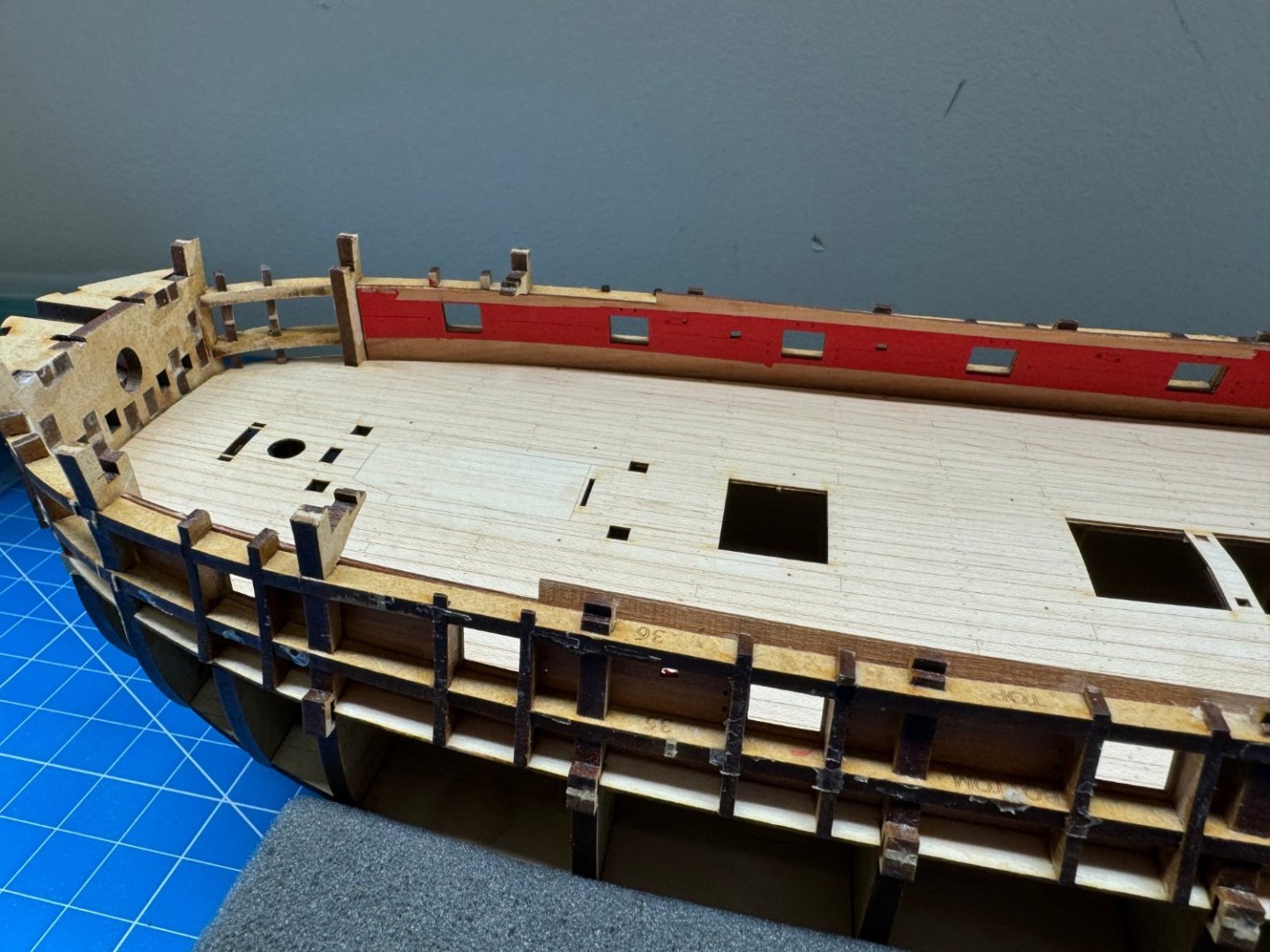

Time to make dust according to the instructions. All the jigs for supporting for maintaining the hull spacing are ready and all the interior features have been added. The sharp eyed may notice that there is no spirketting pattern in the great cabin. I got mixed up and painted the rear lower pieces entirely red. Given they are only .6mm thick sanding them would make them paper thin and probably still not get all the red out of the spirketting groves; I decided to make new pieces out of some thin cherry I had. I morn the lose of detail but have no one to blame but myself.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

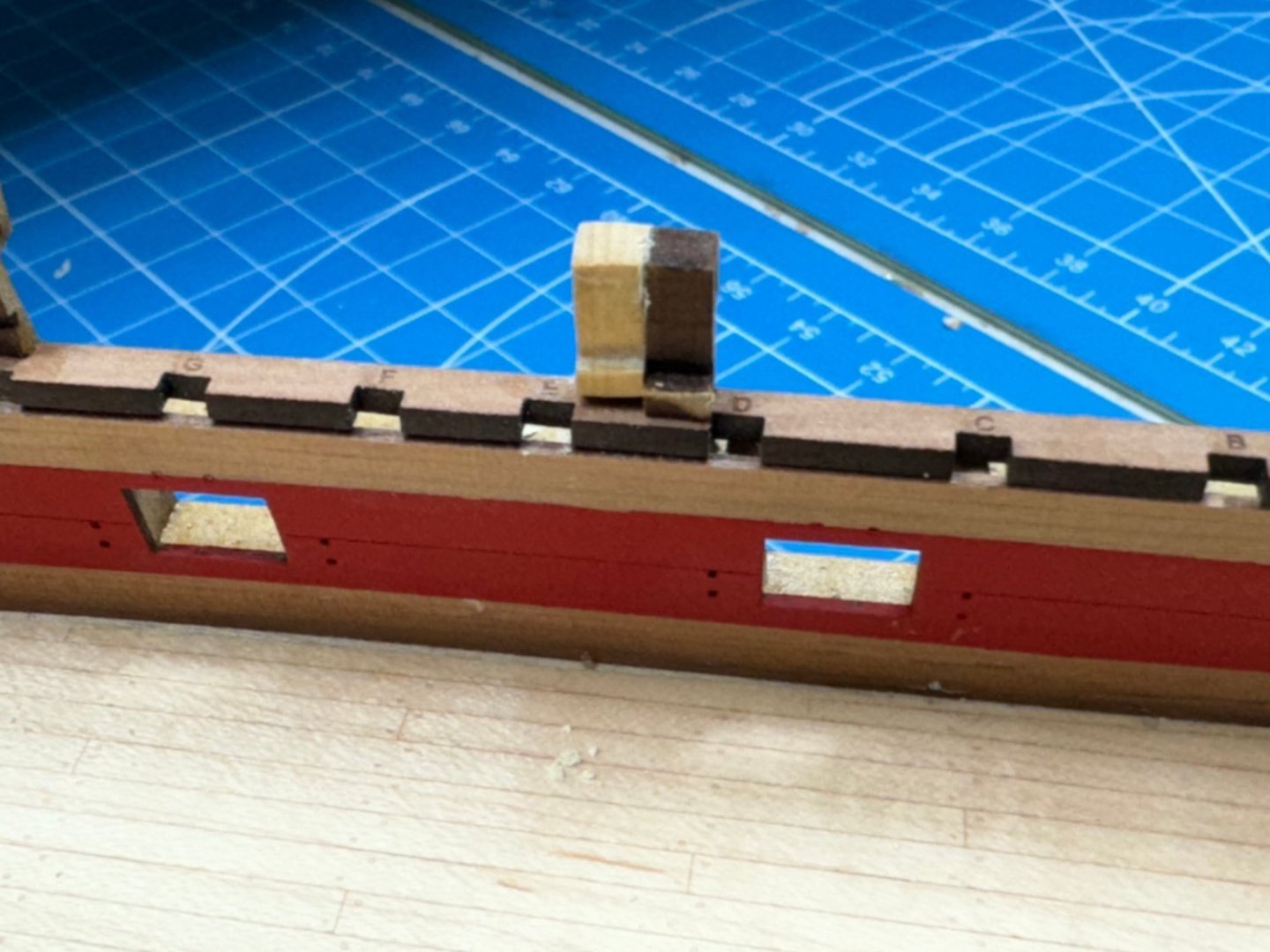

Sometimes it takes (me) several attempts to finally arrive at a modest;y successful approach. I had to replace three (not two as previously stated - I flunked kindergarten math) of the bulkhead ears on the starboard side. The first two times I started at the "ear" and worked my way down - this does work, eventually m- I think it took five attempts to get something that could be construed as being "close" to what it replaced. For the third attempt I started at the bottom, where the bulkhead meets the upper gun port frame and worked up. Turns out this is the way I should have done it from the beginning. I used the port side bulkhead 9 ear as the template and first cut the slot where the "ear" fits onto the QD beam spacing pattern. Then I traced the outline of the existing ear onto the new piece and shaped it to match. It took more fitting and sanding and fitting and sanding than I care to remember but in the end it came very close to replicating what was on the port side. Here is the piece I fashioned along side the port side BH 9 ear. On the inboard side I tried to replicate the "ledge" that sticks out from the ear but did not get it placed correctly and in trying to fix that managed to cut the entire protrusion off. I decided that rather than start all over I would fashion a separate piece to become this ledge and then glue it on separately. Here are the two pieces - the "ear" and the "ledge" glued on to the starboard side BH 9 above the upper gun port frame.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

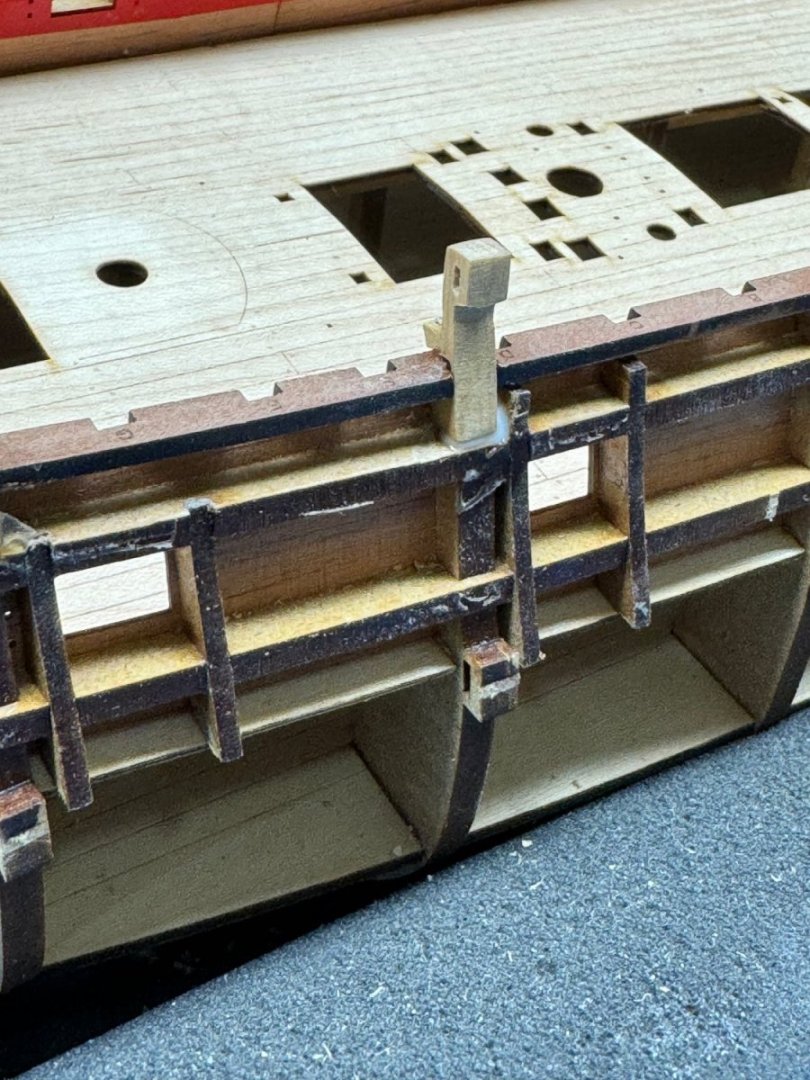

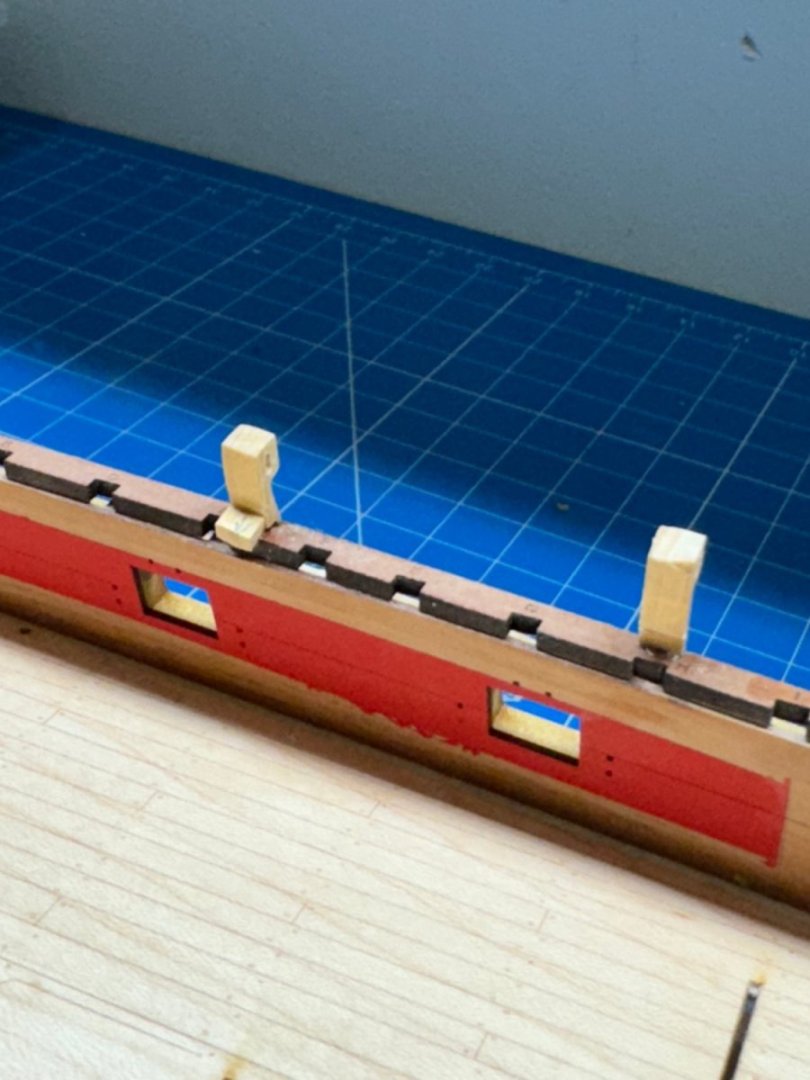

So to "fix" the two bulkhead "ears" that were broken I decided to try and make an entire new "ear" from the top of the upper gun port frame rather than try a glue the missing piece onto what remained. As you would expect it broke at the narrowest point thus making getting any kind of glue to "hold" a challenge. As with the stern timber spacer I used boxwood which I sanded down from 7/16 X 5/16 to about 5/16 square although I used the dimensions of the remaining piece as the "benchmark". Here it is glued into the gun port framing and the bulwark. maybe not as straight as I would like but I think it serviceable. I clamped a ruler on top of the two "ears" fore and aft of this one to set the height. Here is the view from forward. I drilled out the center rather than trying to get to the rectangle because I was beginning to get nervous about stressing the piece. If I had been smart(er) I would have created the opening before forming the rest of the piece. I will do that on the next one which is two bulkheads forward of this one. I do not know what purpose that opening serves but will find out eventually. On the good news front now that the gun deck is in place I pulled out my already made (although slightly taller and longer than the vanguard versions) of the cannons and they will fit through the gun ports, without any wheel sanding. Back in the box they go along side the ships boats for use somewhere in the distance future.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

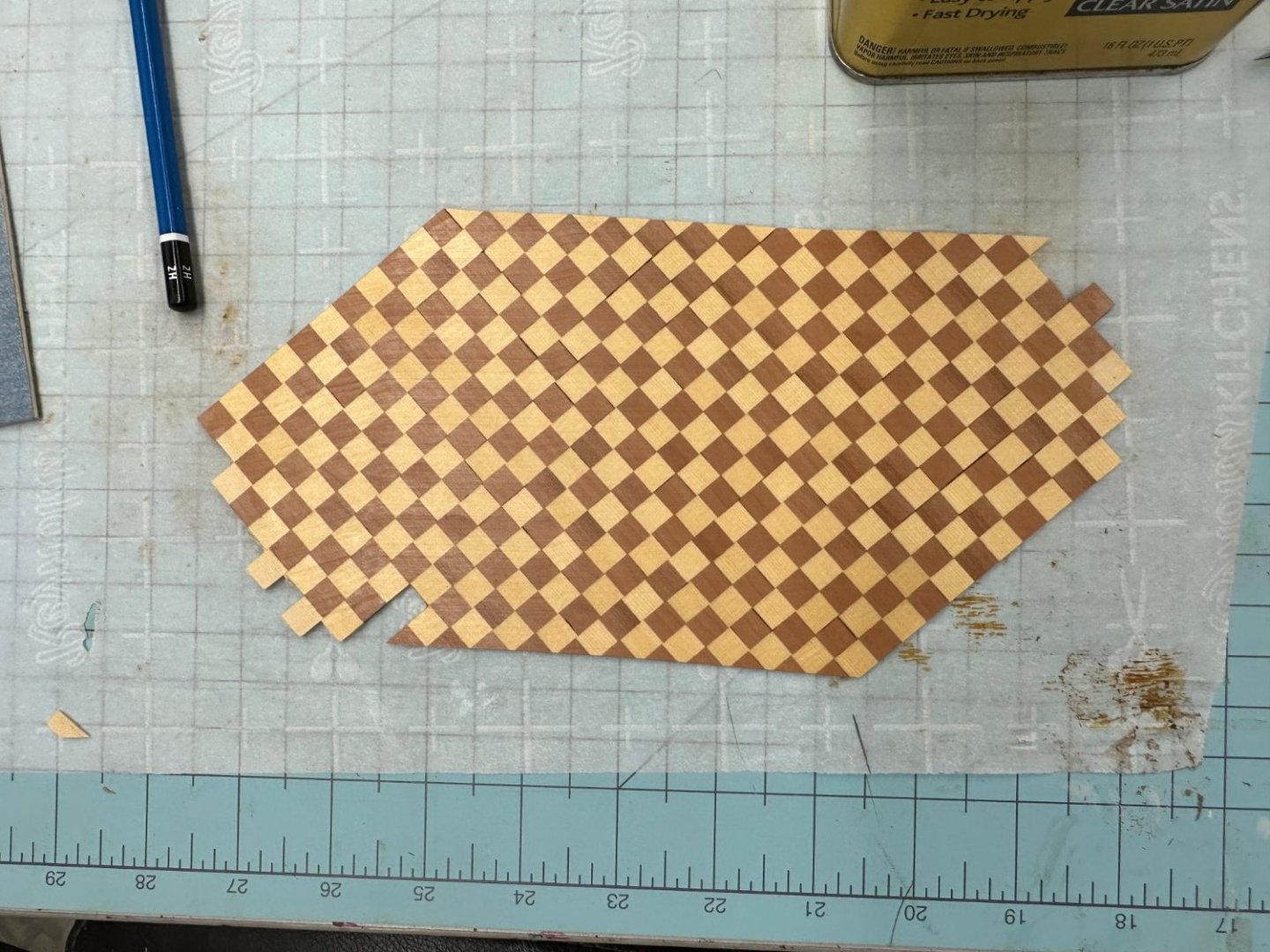

Deck completed although I did have to re-glue both outside edges. I guess my glue painting party was not all that successful. After I painted the bulwarks I added the checkered floor and then put a coat of Polycrylic Clear Matte (PCCM) on. I am going to add another coat of PCCM and then install the new stern timber connector and the missing piece of the QD Beam Spacing Pattern. And then on to the spriketting and deck clamps; which have also been painted.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

I did not mention it at the time but the switch back to the foam cradle was the result of the Amati clamp actually falling over as the mechanism the provides the swivel feature was not designed to handle the load of four machinist blocks if they are not very carefully balanced. The fall was not very far but it was not without damage. Principal among those was it broke the connector that runs across the top of the stern timbers (part #41 for those following along). I assume based on my experience with Winchelsea that this is an important piece keeping the stern timbers properly spaced and proceeding without it is probably not a good idea. I measured one of the pieces and took a piece of boxwood and sanded it down to the same dimensions. Then I carefully filed the slots into the boxwood using the surviving pieces as the template. Luckily one of the fragments had two slots in it so I used that to get the spacing. Here is the finished product and the "template". I am waiting until I get the bulwarks masked and painted before I install the new piece and proceed with the other repairs that are necessary (several inches of the QD Beam Spacing Pattern broke off as well as the "ears" on bulkheads 9 and 11). Gluing back the QD Beam Spacing pattern piece is no problem but the ears I do not have a solution in hand. Luckily they do not come into play for a good bit yet.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Thanks Greg - I think that is a wonderful looking piece you made there but I will stick with the provided floor - Maybe if I do Speedwell after Sphinx I will try that method for the floor.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

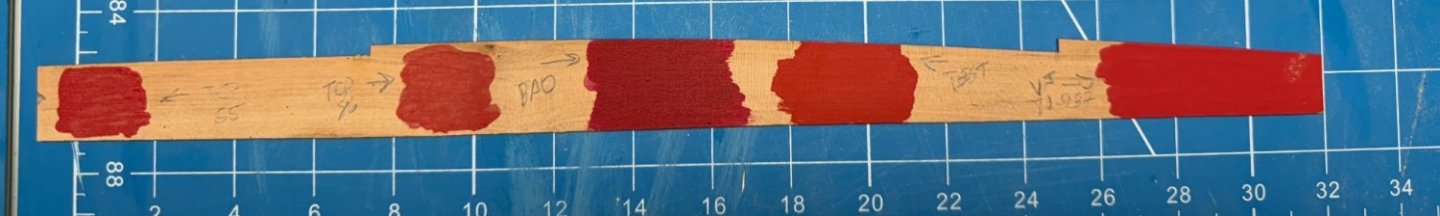

With the deck it ism getting time to paint the bulwarks. I am generally a "Badger Paint Guy" but of late have been know to use other brands/types. So I took a piece of carrier sheet similar to what the bulwarks came on and ran a test with the barious "reds" that I have "on the shelf". Below from left to right: Tru-color Burlington Red; Tru-color Soo Line Red; Badger Windjammer Red; Testors 11500 Red; Vallejo 70.957 Red To my eye it is a tie between the Burlington Red and the Vallejo. I am going to go with the Vallejo since it is water based and the Tru-color is not.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Thanks guys - really appreciate all the comments. And of course no lobster boat in history coiled lines down like that. On to HMS Sphinx which has a double planked hull, a first for me. Get to cover all the first time mistakes😄

- 88 replies

-

- Muscongus Bay Lobster Smack

- Finished

-

(and 1 more)

Tagged with:

-

Lobster Smack is finished and ready for display. I think it si going in the family room. somewhere. Hopefully out of the way of dogs, children, etc.

- 88 replies

-

- Muscongus Bay Lobster Smack

- Finished

-

(and 1 more)

Tagged with:

-

So after the glue set on the aft bulwarks "planking" I started on the gun deck decking. First try the decking was too wide. After several rounds of sanding I got it to fit satisfactorily and used the "paint the glue" method to cover the under deck with dilute PVA and then clamped and weighted down the deck in hopes of it coming out attached at every point. The machinist blocks all have a layer of masking tape on the bottom so there will be no rust stains on the deck (I hope). I also switched back to the foam carrier becasue the Amati had a hard time holding the weight of the machinist blocks.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Greg, Thanks for the suggestion. Yes, I actually have two Byrnes (may he rest in peace) table saws and your proposal would work fine up to the limits of the saw which would be a strip about 3/4" "tall" (aka wide). Then I could glue the deck up in strips to whatever width was required. Not sure to what "thinness" the saw will cut but I doubt .025" so some thickness sanding would still be necessary. I would have to be very careful gluing up the square stock as any void in the glue coverage would likely lead to so parts coming off the "sheet. Same problem with gluing up strips but probably easier to manage with square stock.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

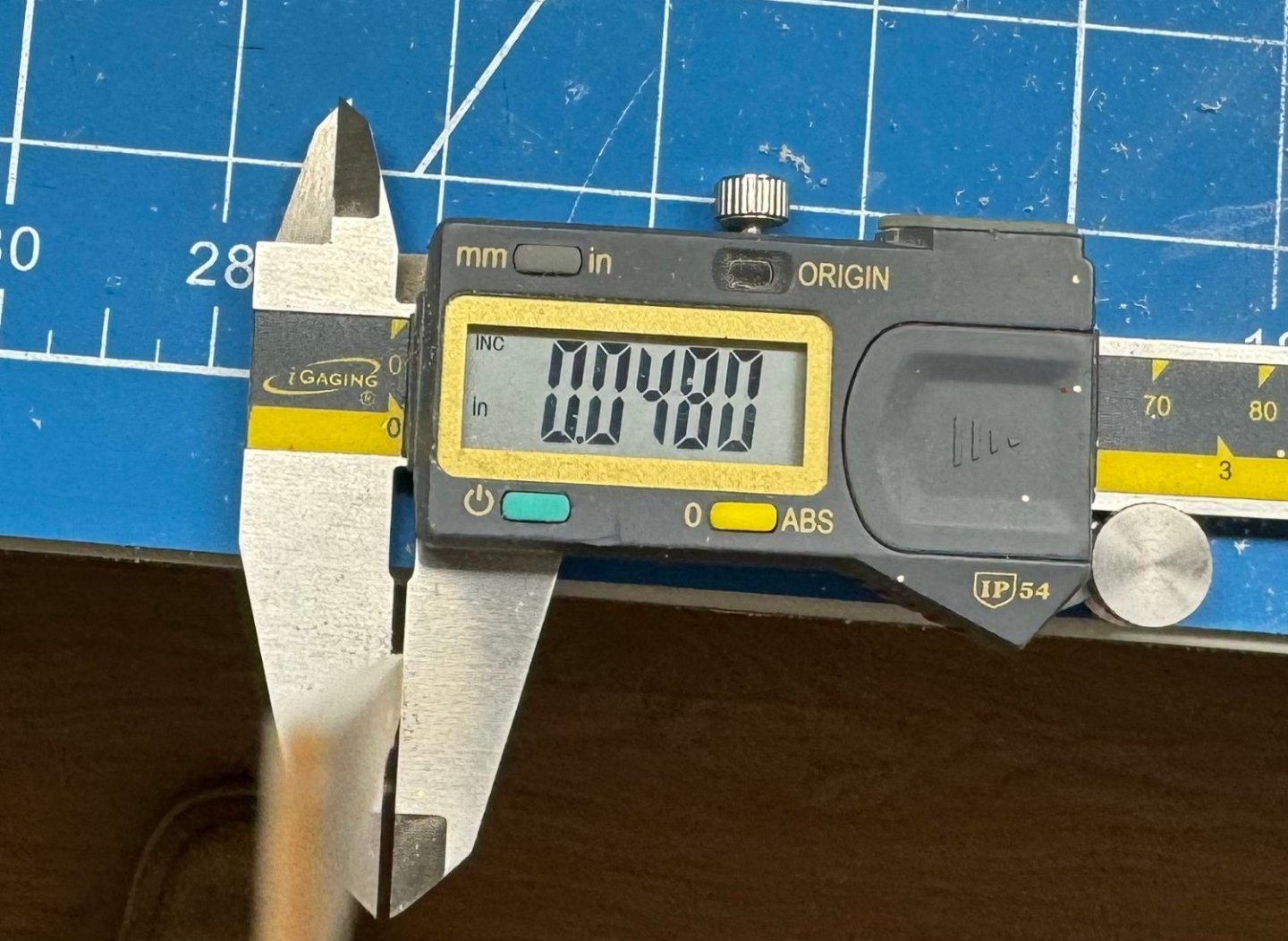

Since am now at the stage of adding the gun deck and great cabin floor I need to decide whether to use the provided checkerboard or make my own. On Winchelsea I made the floor using Boxwood and Swiss Pear and it came out pretty well (IMHO) but that was at 1/4" = 1'. Here the strips would have to be narrower; about 1/4" using the supplied floor as a template. with that many strips (about 22 or so) it is not hard (for me) to imagine a glue joint failing and some part or parts coming apart. You can see where that happened on the left side above. As it turned out I made this piece big enough that was not a problem but the more strips the more likelihood of problems. The other issue is thickness. On Winchelsea the floor was 3/64" (.047); where here it s is about half that (.0244). In order to get sufficient area for the glue to hold the floor has to be built thicker; typically 1/16" or so and then use a thickness sander to get the desired thickness. That is another time when the glue joints can fail, even if using fine paper in the thickness sander. I think I will stick with the kit flooring but I will wait until the bulwarks are painted to install it - no sense risking getting red paint on the floor and having no choice but to fabricate my own.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Thanks Mugje - yes, I am not sure I want to go back to cutting upper and lower sills and sides for every gun port - especially not on something with more than 22 ports. The stern bulwark "planking" needed more "fashioning" since I presume it needs to fit under the QD Beam Spacing Patterns. That was not a problem for the first two gun ports back but from there aft the bulwark "planks" were progressively over the QD Beam Spacing Pattern. It took several tries with 220 grit paper to get the bulwark trimmed down enough to fit as well as being slightly too long as mentioned in the instructions. Everything finally fit into place and another glue painting party ensued.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

So I got the forward bulwark bulkheads "planked" and the QD Beam Spacing Pattern on the hull, held a glue painting party and am ready to call it quits for the night. Stern bulwark bulkheads tomorrow. Did I mention you cannot have too many clamps.

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

No good deed goes unpunished. Despite of my precautions mentioned above I still managed to "remove" 8 of the gun port frames sides pieces above the upper longitudinal frame. And rather then try and figure out which little piece came from where I cut a new piece from the carrier sheet scrap with the correct cross section and made new ones. Luckily the ones I broke off were all the same height so I only had to make one source piece. I also cleaned up the top of the longitudinal frame and glued them down with undiluted PVA. I can say that sanding down the fiberboard is considerably more difficult than the other materials used for bulwark frames and longitudinals. I broke my own rule about nothing more aggressive than 220 grit sandpaper and used 120 grit to get most of the laser char off the inter bulwarks. I can also say that I managed NOT to break off the pieces at bulkhead 3 that sticks out over the deck. So here we are with the bulwarks faired ready to start installation of the bulwark "planking".

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.