-

Posts

59 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Roman

-

-

-

-

Daniel, il tuo Sciabecco è magnifico e molto bello. Grazie per aver condiviso la tua arte. Bravo

Daniel, your Xebec is magnificent and beautiful. Thank you for sharing your art.

- druxey, Forlani daniel and mtaylor

-

3

3

-

I have a copy of this book and it is detailed to a degree that leaves very little to the imagination. The compilation of photographs that illustrate it speak for themselves. Beautifully segmented and illustrated to help the modeler navigate through the complexities involved in understandIng the process of building an Arsenal model. It is a how to step by step; it’s all there to see. This book is a classic reference manual of incomparable content. Congratulations.

Roman

-

-

Mahonesa was undoubtedly one of the most beautiful frigates of the time. The hull lines attest to the advancements made by the Spanish throughout the 18th century which of course made them desirable prizes for the British. Much is known about French and British ship building practices in the English speaking world and thanks to individuals such as Boudriot, Lavery, Dodds & Moore who have recognized the importance of Spanish technology and design we can see and appreciate its significance in architecture. Following Mr. Sorolla and his masterful rendition of the Mahonesa has been a treat.

Adrian Sorolla is the author of a very valuable book titled “ Introducción al Medelismo de Arsenal” or Introduction to Arsenal Ship Modeling I believe it is available in English and published by ANCRE. No doubt of the value of his work. Masterful skills indeed. I look forward to seeing more. -

-

Hmm, it seems that I've created a challenge for myself. Well ok, but right now I'm installing new arbor bearings in a 1956 Yates American table saw - a battleship-quality instrument

But what I'll tell you about what I've noticed, is that although a tablesaw is wonderful, but other times it's a waste of time to set up and it blows dust everywhere. I'd guess that for many modelers, that they have limited space to pursue the craft, and maybe they'd like to enjoy the craft with other persons in the room, who might not be enthusiastic or comfortable in a big shop environment.

Bob those are beautiful castings on that table and simply elegant. These saws were ahead of their time. It reminds me of Inca saws, nothing overdone but wonderfully engineered.

Roman

-

Richard, I think your opinion is very much in line with most of us. The Byrnes tilt table is a relatively new thing compared to the saw itself. When I first purchased mine it was not available but I did get the micrometer and the fence extension. The taper attachment and a handful of blades came later. I cannot imagine most owners of the Byrnes saw did any different. It is fair to say; grow the machine as your needs grow! Yet it is a good thing if you have the means to get the whole kit in one shot.

Roman

- flying_dutchman2 and GLakie

-

2

2

-

So I have decided that a Byrnes is in order.

For those of you that have them, did everyone purchase the "deluxe" saw? Meaning with the tilting table, micrometer stop, extended fences? Basically a saw with all the works? Or is the best bet just getting the saw?

Also where are you purchasing blades?

Let me know.

Thanks

Shawn

Shawn, get as much saw as you can afford. Considering that Byrnes makes such a fine tool, look at it as an investment. I have all but the tilt table and it is in my short wanted list. What you think you will not use today, who knows you may end up using it or not in the future; however you will have a complete Byrnes machine that is truly unique. I do not think you will ever lose your money on these and to someone else, it will only make it more desirable that you have the complete Byrnes table saw; in case you decide to sell it or will it to your children. As Mark said the blades are made by Thurston but you can get them from Byrnes.

Roman

- flying_dutchman2 and GLakie

-

2

2

-

I must say that ship model building is after all a fastidious but enjoyable past time. We all have our own way of approaching and solving similar problems. I am quite sure that model makers of the 18th century were using tools that were state of the art then and along the way came another modeler who preferred to use 16th century tools. I guess that is normal in us humans. I would assume that we could all scratch build with less specialized tools but it sure is nice to be able to look in the tool box and have at your disposal a Stanley #6 or a scroll saw or the Byrnes saw or anything else that can make our life's easier. I am willing to bet that those great model builders of the 18th century would have used electric power tools had they been available at the time; but knowing what I know now from reading the comments, I must accept the reality of it all. After all, Beavers scratch build their Dams with a single tool, teeth. Thank god we are not Beavers.

Respectfully

Roman

-

Again, Thank you for this explanation. You are very knowledgeable on this subject. I know I will post more questions on this thread.

Last paragraph. I have used a Scroll saw for about 4 years and I have done so much with it. I improvised on creating fences to get a straight cut. It works but have bin thinking and looking at band saws. I also need to research a milling machine. Need to understand all it can do.

Marc

Marc, you used a word that is key to using all tools. Understand! while participating in this blog I realize that there are many modelers out there who do not have full size tools nor are they required to do the job, many are not even interested in them. Understanding the capabilities and the limitations of all tools is essential, be it powered or hand. I do not know any more than the next guy about tools but since I owned a shop with two dozen plus employees I had to be on a constant vigil so no one got hurt, and no one ever did. I am certainly not going to feed 3mm x 1.5mm strips thru a jointer of any kind even the little Proxxon, but I am in the interest of time going to feed 2"x6"x24" thru my Jointer once all the safety precautions have been taken. This is one of the reasons that make Byrnes tools so good. They are scaled for scale down work. Make no mistakes, all tools are dangerous including hand tools. They should be understood and respected but not feared. Have fun with them. After all most of the fun of ship modeling is the journey.

Roman

- gjdale, GLakie, flying_dutchman2 and 1 other

-

4

4

-

Now you guys really have me confused , Can i do the same on a good band saw as i can on a table saw plus a bit more ????? Is a table saw the best for ripping fine strips or can this also be done easily on a band saw ,fine meaning 0.5mm ???

Don't be confused, all of this is food for thought. If all you want to do is cut strips from s4s (surfaced four sides) stock the table saw is the easiest to do that task with. If you are buying rough lumber, then you will need a tool to surface the stock. Please don't let any of this make you think that you need a warehouse full of tools to do ship modeling. As Dave mentioned before a well fettled hand plane and patience will take you there.

As an example, in my situation I like working with Loquat (Japanese Plum). This wood is very common in Tampa where I live but not commercially available so I have to keep an eye out for fallen limbs or cut trees to harvest. In other words I am working with trunk or limbs 4" to 12" diameter initially. These will have to be cut into manageable 2"x6"x24" from a log once dry. This task is not suitable for a table saw but easily handled by a bandsaw or a handsaw if you so desire; from this point you still have to plane two surfaces one to lay flat on the table saw and the other to run along the saw fence in order to get somewhat accurate strips.

Roman

- mtaylor, flying_dutchman2 and shihawk

-

3

3

-

I can't help but wonder if Byrnes has other machines in the works....

Obviously I can't speak for the man but I visited Jim at his shop a few months ago and he is very busy producing the four machines he offers along with the many accessories not to mention the myriad of projects he has at hand, so you never know. For those that are not familiar with him he is as you would expect an excellent ship model maker if he does not mind me saying so. In my book he is a renaissance man. Every time I have come out to see him, he has always been very gracious and accommodating. I don't know but when I visit his shop, it is a pilgrimage for me. God knows send him your requests.

Roman

- mtaylor, GLakie and flying_dutchman2

-

3

3

-

I think someone earlier addressed this but I'll chime in. The planer is good for getting stock down close to the desired thickness and the thickness sander will bring it down the rest of the way and at the same time put a sanded smoother finish on it. Also the planer will flatten out slightly warped wood.

George, you are correct and I did not notice the previous reply to this question given by Clark.... I must clarify a misunderstanding about planers. Despite its name the sole purpose of a planer (not a hand plane) to clarify, is to make two surfaces parallel to each other while cleaning up the 2nd face of the stock. If the bottom surface is warped or slightly warped the upper surface although surface planed, will conform to the bottom surface warp after the feed & out feed rollers release their pinch. The tool that has the ability to true up the surface and remove the warp is the Jointer. On the jointer you would normally flatten or true one face and one edge, once that is done you can run the stock thru the Planer and both surfaces or faces will be theoretically flat and parallel. That is the reason I posted earlier the pictures of the Jointer and the Bandsaw. The thickness sander Byrnes or any other behaves the same as the Planer. At least one surface must be true and flat for the lumber to be sanded to the desired dimension. To me, the Byrnes sander picks up where the planer reaches its limitations; that is stock thickness and finish quality. I am sure you have heard the comment from machinists and engineers: "with a Milling Machine you can do anything"! Similar holds true for the Bandsaw and the Jointer combined.

Respectfully

Roman

-

How do the Proxxon Planer and the Byrnes Thickness Sander compliment each other. ( thought they did the same thing but with different approach, blade vs sandpaper??)

Richard

The question is still out there!

-

Question: Are the blades for the band-saw, especially the 1/8th pretty rigid. Sometimes with the scroll saw the blade is on a slight angle if I push too hard so the edge is on an angle.

I would like to research table top band-saws. Are they sturdy enough that they don't vibrate of the table or work bench?

What other suggestions do you have if I invest in a bench-top band-saw?

Any advice is appreciated.

Thanks, Marc

Marc, there could be several issues that cause the scroll saw and bandsaw blades to wander off track. One of them is force feeding the wood into the blade and not allowing it to cut at its natural pace. This causes the blade to dull up prematurely and it forces you to add more pressure to feed and correct the trajectory of the cut. The second has to do with the blade itself. Scroll saw and Bandsaw blades are fabricated by a stamping process that leaves one side of the blade or the exit side of the stamp sharper; when installed on the saw this sharp edge will want to push the blade to one side. This of course has to do with the quality of the blade. When ever possible try to use double skip tooth blades, this has a positive effect on the cut and will reduce the amount of sanding you will need to do as they cut faster and cleaner. The gap between the double tooth format allows the blade to remove the wood dust more efficiently from the kerf and keeps the blade cutting cooler without burnishing the wood; furthermore if you use a reverse skip tooth or double skip tooth the tear-out at the bottom of the cut will be reduced. Scroll saw blades are hardened along the cutting edge but not at the grip points( top & bottom )where they are malleable, this is to allow you to twist the tips and mount the blade sideways on your scroll saw. This action increases the length of the rip cut beyond the throat capacity of the machine. The Olson sheet provided as a pdf shows how to round off the back of the blade to improve its performance and prevent wander. This does not need be anything complicated you can use an emery board, a file or even sandpaper for metal. Give it a try.

Best regards

Roman

- fletch944t, WackoWolf, GLakie and 1 other

-

4

4

-

Is it possible to "rip" thick lumber, 1 to 2 inches thick, without a band saw or other full size tools?

Thanks all,

Richard

Richard if I am permitted to chime in on your question, the answer is yes but. Let me begin by saying that table saws are inefficient and dangerous beasts that occupy much real estate. I speak from experience as I have owned a number of them including a monstrous Altendorf F-45 capable of ripping 6 7/8" thick material (six and seven eight inches). It was not cheap and lets leave it at that. Someone else mentioned a Japanese saw and I agree with him. It will take practice and patience, but a Japanese Kataba saw with rip teeth will do a good job. They are not cheap but if you have the desire to spend the time they cut on the draw and have a finer blade than western saws. They are in my opinion easier to use. A some what decent Kataba will set you back $45 to $60 U.S. There is also another Japanese tool called a "Kebiki Dai", it is a slitting gauge and can be used to make strips of wood. It looks like a western marking gauge.

You should consider a Bandsaw and a 6" Jointer and they do not have to be big. In fact if I could only choose one saw for my work the chosen one would be a Bandsaw. There is no tool in a shop that is more versatile and capable it takes very little room, quiet and has good cutting capacity far greater than a table saw even for a small machine. You need the jointer or a hand plane to true up or level the wood blank and the Bandsaw to rip, crosscut, miter, contour cut; put a sanding belt on the thing and sand. These two tools are easy to use and store as they are relatively small. I think Grizzly has a 6" Jointer that is even cheaper than the Porter Cable. I think the Rikon is $289 at Woodcraft less 10% and the Jointer at Lowe's around $269. Don't forget the tax.

Regards

Roman

- flying_dutchman2 and Archi

-

2

2

-

As Frank Lloyd Wright used to say... "Take care of the luxuries the necessities will take care of themselves". You may or may not agree with him, buy it while you can.

-

Anything Byrnes you purchase is a joy. During my last visit to Jim's shop I purchased the Ropewalk and as customary...... Superior. The thickness sander could not be simpler and more elegant in its design. I is designed to work accurately and last for a lifetime. You cannot go wrong with it.

Regards

Roman

-

Joss, I do not know if you are aware of the twist and turns of the October 5th, 1804 battle to this day. When this attack took place the British people criticized it because it took place in time of peace. There is a company here in Tampa that some may not be aware of, but well known in Spain and particularly in Gibraltar; some of its people were arrested leaving the latter. The company, Odyssey Marine Exploration Inc. a salvage company was in the news until late 2012 because of its discovery and recovery of the treasure from the silver fleet of 1804. Said wreck is claimed by the Spanish government to be that of the frigate "Nuestra Señora de las Mercedes", the Mercedes of your story. Odyssey Marine has lost its court battle in the US Supreme Court and the treasure recovered that includes thousands of coins and other relics had to be returned to Spain. Due to the many souls lost the ship is considered by many to be hallowed ground. For those that think it is there for the taking, there is an International Treaty that protects warships sunk in battle from treasure seekers. The treasure recovered is said to be worth some $500 million US.

This is one more reason to model the Amphion. The history behind these events of 1804 reaches us today.

-

I have the NMM draughts of Medea, as fitted out as Cochrane's HMS Imperieuse. She is very beautiful. Her carvings (presumably her new British carvings) are drawn separately in half inch scale. They are IMHO too intricate, with all their fine, swirling 'vine-ery' and 'rope-ery', to have been drawn in 1/4 inch scale. I suspect this is why the carvings had vanished from the plans at around this time.

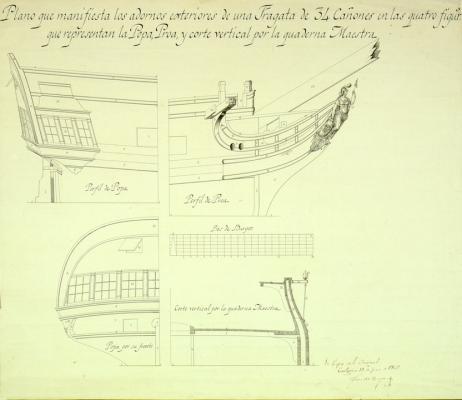

Here is a bit of detail by Thomas Bryant who was stationed in Cartagena during those years. This one is dated June 13, 1802; title reads: Plan that manifests the external decorations of a Frigate of 34 Guns in the four figures............. etc.

Should be nice to contrast this sort of detail with that of Amphion and Medea's transformation to HMS Imperieuse.

Roman

-

Joss I am looking forward to your work. These vessels were so dynamic in the evolution of ship design that the Amphion is definitely worth the attention you are giving it. I think this holds for all the nations involved in the maritime trade that designed and built their own frigates; of course as usual much of the fun is in the research.

-

Are there any paintings of her sister frigates, Medusa or Aeolus? Did not Medusa also fight the Spanish Treasure Frigates in 1804 with Lively, etc? Are there realistic depictions of that action?

Medusa and Donegal did fight the Spanish Treasure Frigates of 1804. The Spanish frigates taken in action of 1804 were: Fama 34, Medea 40, the Mercedes was destroyed; a little later Santa Matilde 34 and Anfitriti 40. Spanish frigates of this period were very similar although some hull design differences existed. Fama 1795, Medea 1797 and Anfitriti 1797 were of improved designs compared to Matilde which had been launched in 1778.

The following three paintings of the battle are in the National Maritime Museum collection: BHC0535 by Francis Sartoris, PU5684 by John Gore and PU5685 by Nicholas Pocock. All three depict Mercedes at the time of its magazine explosion. Here is an image of Sartoris's painting.

Mahonesa 1789 by a.sorolla - 1:32 - 34-gun frigate - monography by Adrián Sorolla, plans by F. Urtizberea

in - Build logs for subjects built 1751 - 1800

Posted

Congratulations Adrian, looking forward to a copy.