-

Posts

629 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by kruginmi

-

Thanks Eamonn and Floyd for the motivation from your own builds. That's what is great about a site like this. Not sure what I am doing next, but it will be something! Mark

- 128 replies

-

- artesania latina

- Finished

-

(and 2 more)

Tagged with:

-

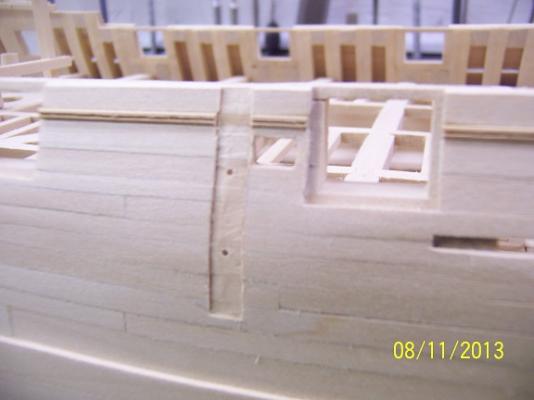

Floyd, no magic here on my frankenbuild! I have attached some pics of what I think you are looking for: For the light planks, they are sanded at a 45 degree angle at their join to make the joint between the stern and side hull only a line. Why did I apply the stern planks angling upwards? I saw this done somewhere and always liked it. Seemed like a good time to apply it. For the dark planks, I first applied a plank across the bottom of the stern and sanded the edges to make it match the hull (with only the first planking on). Then as each plank on the bottom of the hull was applied, it was sanded flush with the stern (leaving the end of the board exposed). It seemed the way to go and I am happy with the result. The Crothers book is only the hull (focusing on the internal structure). For rigging I have opted to go for something that I can try to understand and find answers to my questions: the Pride of Baltimore rigging scheme. I picked up the PoBII Model Shipway Plans during a sale at the Expo and have spent many an hour studying the plans and figuring out how to translate to my hull. As for the naming, keeping the commander in chief happy (and actually having some interest) makes everyone a winner! Cheers, Mark

- 128 replies

-

- artesania latina

- Finished

-

(and 2 more)

Tagged with:

-

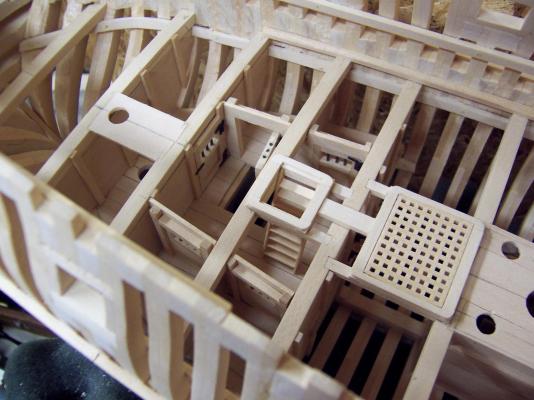

Okay, some quick responses: Mark I am most interested in your plans for the Cabin. First off what year are you aiming for? So the cabin doesn't fit the scale or the design from that period. Also I haven't found any ship from that time with brass bars on the skylights. Krug- Unknown yet. The Crothers book shows weather deck arrangements for every clipper built during this time frame. I will figure something out from these. We both know that there was no such thing as a Baltimore Clipper in 1847. Much more likely would have been 1790s thru the end of the war of 1812. Krug - The book by Crothers is entitled 'The American-Built Clipper Ship 1850-1856.' So that is the general time frame of my ship. I particularly like the design of your hatches. Can you give me the dimensions of your hatches? Did you use the gratings from the kit? Krug - I will measure when I get back downstairs. Yes I used the gratings from the kit but a lot was damaged and thrown out. Instead of making undersized ones, I decided to to compartmentalize the grates by outlining in basswood and adding the straight planks. Everything surrounded by walnut. What do you plan for the shot garlands? Krug - Since this is a cargo ship and not a warship, I wasn't going to include them. The size of the cannon seems to reflect keeping longboats and such at a distance and not for any big fight. I am actually thinking I will 'stow' the midship cannon below decks (leaving just 4) and maybe fashion a cover for these port holes. I also wonder about that forward Hatch in front of the foremast. Is it really useful? Where do you plan for the anchor lines to go? Krug - You have answered your own question. This hatch is strictly to allow the anchor lines to be stowed. I need to remember where I saw this, but a real example showed the hatch opening aft like I did. Can you give me a close up picture of your final planking at a rear corner. I am trying to get that to look better. Krug - Can you elaborate? External / internal and which corner? Happy to oblige.

- 128 replies

-

- artesania latina

- Finished

-

(and 2 more)

Tagged with:

-

Thanks for all the tips. Thinking on it, probably the biggest thing I could do is enlarge the hole a tad to leave a gap for more glue to remain. I am probably removing a majority of it. Also, to be more precise, this is primarily aimed for the kit deck. So you have (at max) an 1/8" thickness of wood (half false deck, half planking) and for real grabbing power, probably only the 1/16" thick plywood false deck. Mark

-

Floyd, I would blame MSW - lots of things always swirling around here to totally upend your plans and make you rethink your whole build! I checked out your build and it looks great (surprised at the call out at the beginning). Eamonn: FIrst of all, Happy Birthday. Hope you get a big box wrapped up nice that contains the ship model of your dreams. To all: Looking for more ideas! (Okay, now I guess I need to make some progress.....)

- 128 replies

-

- artesania latina

- Finished

-

(and 2 more)

Tagged with:

-

Definitely a rake to those masts! Looks like it is going over 10 knots standing still..... I also really like the look this provides. Mark

- 128 replies

-

- artesania latina

- Finished

-

(and 2 more)

Tagged with:

-

Question: What is a good way to secure eyebolts so they don't pull out later? (other than CY glue) Setup: I have an enclosed POB hull that requires MANY eyebolts to be installed. History: On other builds this had been an easy practice of drilling in a hole equal to the diameter of the eyebolt stem (hopefully at an angle separate from the rigging pull) and apply CY glue to the stem before pushing through the hole. Since i do not have access to the lower part, this was all I could do. Drawbacks: You usually end up with a little puddle of CY glue around the bolt that even with the best wiping will not take a finish like the rest of the surrounding deck. BIGGEST ISSUE: I have had a couple pull out when rigging. I try not to put too much tension on the lines, but there is some. Idea: I am pondering creating a much larger hole than the eyebolt diameter (but still pretty small). Offship I will create a matching plug. The plug would be drilled out for the eyebolt and the eyebolt pushed through WITH NO GLUE. Now the plug would be flipped over, the eyebolt bent to prohibit it going back through the hull and CY glue applied at this end. Once complete the plug would be glued into the hull. This would provide a much larger gluing area and shouldn't pull out (the plug or eyebolt). Is there a simpler idea out there that I am overlooking? I will try a prototype for pics if my words have confused. Thanks for any help, Mark

-

That I can do (I am actually home this AM watching the kids). I do want to stress that this is a kit hull, supposedly of a representative clipper from 1847. I have done little in the way of verifying and definitely no modification. It was a fun hull to plank - very smooth lines that minimized any need for extreme bends or crazy clamping (much easier than say the Swift). The hull isn't finalized: some planks at the stern need some adjusting and the bowsprit will be radically changed, but hey, it is what it is. I did include one picture of the ship with masts. Yes, that is a 12" ruler in the photo. This ship is pretty big. My wife has inquired where I intend to display it and frankly, I have no idea. This is a relax the rules and enjoy the build. Besides, given my output rate the display issue won't be realized until the kids are gone (and I have a 3 year old!). Mark

- 128 replies

-

- artesania latina

- Finished

-

(and 2 more)

Tagged with:

-

I think I might have a winner. I should have checked the paint section of this forum for potential hints, but after a trip to the local Woodcraft and asking the grizzled veterans there General FInishes Gel Urethane came highly recommended. Now, the label says wipe on and that is a potential issue, but the gel was very viscous and a paint brush worked very well. If you paint it on consistently in one direction, any excess is essentially removed negating the need for wiping. It does need to dry overnight but I am okay with that. I took some surplus steps to verify it can handle small fiddly bits and there was no issue. Definitely no shine like the the other two finishes I tried. No fuzzies or crazy grain rising either. It recommends 2-3 coats but visually there wasn't much difference so.....one coat for the hard to reach internal surfaces and two coats for everything else. There is a slight change in color and the potential to darken some with age but again I have no issues with that. Once I start I think it should take about a week of steady work to get it covered. Then I can incrementally do the internal sections as they are completed and ready. Mark

-

Thanks Eamonn, When i decided to work 'outside the box' one of my requirements was for it be visually appealing. I change things on the fly if they don't quite seem complete. The deck reinforcing was one such item. It seemed right but definitely wasn't planned for originally. The result surpassed my expectation. The warning is, once you start bashing you want to bash more and more! Cheers, Mark

- 128 replies

-

- artesania latina

- Finished

-

(and 2 more)

Tagged with:

-

Since this was a working boat it spent a good chunk of time moored to a dock while it loaded or unloaded, so……it needed a robust way to tie up, usually to docks below the height of its bulwarks. I had noticed the use of cavels on some wooden period ships I have visited and thought this the perfect solution. A quick check of the Pride of Baltimore II reinforced this by seeing she had them. These were pretty straight forward but I believe really added some pop to the hull. I decided to use a block of walnut for the hull pass through and basswood (my go to wood) for the interior tie up post. Since the bulwark was veneer overlaid on the inner sub-layer the walnut really provided a consistent clean look that I liked. For location, I drilled through the inner bulwark at the center point between frames for accuracy. A little wood removal with a sharp knife / files and lots of test fittings and this part was good to go. The inner cavel post was pretty straight forward (don’t forget the matching center hole to the hull) and glued on. All in all, this was less than an hour of work. A total of four were put on the Lady Anne (two each side).

- 128 replies

-

- artesania latina

- Finished

-

(and 2 more)

Tagged with:

-

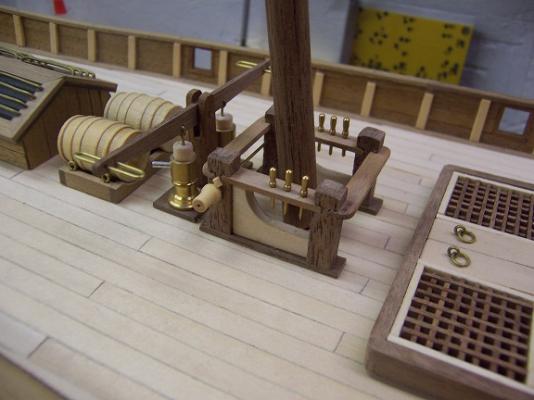

This is my build of the Lady Anne (named after the wife – bonus points). If you squint real hard and tilt your head you may recognize the hull as the AL Harvey. Other than that it has been a whole lot of kit bashing. This model was given to me by someone who had just glued the bulkheads on and decided this just wasn’t the thing for him. Over time (as a break from the Druid) I have done a little bit here and a little there. I planked the hull as a standard model hull to demonstrate to someone else it wasn’t that hard, so there are planks that taper to points and no real attempt to mimic real practice. I had ‘assumed’ it would be built out of the box and continued in that direction. Then things started to get fuzzy. I knew that Harvey was a fictitious ship and things really started to bug me about how realistic it was. The deck furnishings especially just seemed haphazard and in some cases wrong. This is where I stepped out of the box and this fast build took a hard right into kit bashing. Over the years I had made a point of keeping pictures of ideas on real ships and models of things I really liked and I started to look at what I could add / substitute in this build. I started perusing books about clippers, especially ‘The American-Built Clipper Ship, 1850-1856’ by Crothers to look at deck arrangements used by Clippers (and believe it or not, I did find those outhouses shown on the Harvey. I don’t like them, but I found them). I cleared the decks (literally), made paper cutouts of potential deck furniture, and spent a lot of time pondering the imponderables. A big decision was to rig her as the Pride of Baltimore II was rigged, a true Baltimore Clipper. This defined the needed pinrails and deck tie downs required (as well as block counts which were a LOT more than the kit supplied). I moved the pumps aft to where they could actually do some good. The forward windlass was replaced with a windlass actually capable of bringing in an anchor. The capstan was moved to a position where it could actually be used, a below deck access was added and on, and on, and on. The last addition I added are cavels to allow easier docking. To retain its original heritage I created a 1:48th scale workman that I named sailor Harvey to verify heights as I proceeded. The deck currently has a configuration that I am happy with. The last original piece is the aft deckhouse and it just seems out of proportion for sailor Harvey to navigate through so that will probably be scrapped and an alternate built in its place. Oh, I retained the cannons since my son insists that cannons are cool and I couldn’t possibly take them off. I did, however, modify their locations, retain only six (continental breeched) and will probably have two of those stowed parallel to the bulkhead. As time allows I will post past pictures of the process I used to build various pieces and the rationale used for including them (which may just be I liked the look). I am really trying to focus on the Druid and get’r done, but this ship will be warming up. As usual, any comments are welcome. Mark

- 128 replies

-

- artesania latina

- Finished

-

(and 2 more)

Tagged with:

-

Greg, Believe it or not this is a trip down memory lane for both of us. This is the same Druid from back in the Warrior website days. You supplied me with some stern shots of your model that were very helpful in formulating a plan of attack. I finally say that this will be done in the first quarter 2014. I do have the Swan books and even when not building because of life have continued to read and learn from everything I could. Love the hobby even if my production rate is so slow! Mark

-

Let's see. Banging headache (hoping it didn't go into a migraine). I did something to my heel and it hurt to walk. Too many things to do around the house. So....best just go to the workshop. It was the right cure because a couple of hours later and I am feeling better (head wise) and I am reflecting on completing the entry steps (starboard side at least). Those items had been a little intimidating - why? I don't know. I stumbled across some 1/32nd inch cutoff discs for my dremel (so much easier than the 1/16th inch), drew up a simple molding pattern and had it quickly cut out. I actually found a previously cut piece of boxwood that matched the dimensions required. Some quick scraping and cutting to equal lengths and I was ready to glue. I laid down some paint tape to get a straight line and cut out a spacer to insure they match. The big question was whether the eighth step would rest on the wales as the plans show....and yes it did. This almost was too easy. What did I forget or mess up? Still haven't figured it out yet (hah, hah). Pics are posted. I do laugh to see how the camera really seems to magnify all the issues, dents and everything wrong that are invisible otherwise. One almost oops moment was when I as verifying the distance from the steps to the end of the waist railing - it was too short. A couple of anxious moments before I realized (so many years ago) that I had intentionally left the upper railing long to allow cutting down in the future. So, no issues. Tonight I hope to get the port side done. This will officially end the external hull work (sans the eking rail which waits until the cathead is affixed). The rudder metal work awaits. Mark

-

zilsner shellac and sealer had relatively the same result as the polycrylic - though slightly better. Application wise the plycrylic is much easier to clean up (water based) so if I really needed to, I would probably opt for this. The question is do I really need to. As is usual when you hit a roadblock, I will put it aside and think before jumping in. Mark

-

After (finally) getting the college girl out of the house and moved into her apartment I found some time and got the port chesstree and pass through hull blocks roughed in. These will be finalized after the rail is installed in the future. Pondering all this talk about putting a finish on the hull, I created a little test piece and tried some Minwax Polycrylic. Because basswood so porous nothing works fantastic, but after three coats (sanding between) I wasn't very happy with the result. At certain angles it looks fine, but at others a shiny splotchy residue is evident. The following picture gives a hint of this. I did try some paste wax and that didn't look too bad but has to be applied with a rag and then buffed out. Not so good for between the frames and anything internal. I am pondering to pick up some clear sealer / shellac and see what that will do. I still have pretty good access - only the berth deck floor is attached. Everything else is currently held by friction and removable trunnels. If that doesn't work I will probably go back to the original plan - a good case. Mark

-

Let's see, full on POF Druid in work (trying to finish by 1st quarter 2014), kit bash Lady Anne (previously Harvey), Billings Boats Regina (now known as Queen Anne) framed up oh so many years ago and plastic large Constitution from my Dad's estate that he had started. Not to mention normal day activities plus #6 - the three year old. Begin something else? Why not..... I will bring one of my son's into this one though! Mark

-

I actually have this 'kit' stuck on my shelf. I had originally thought it would be something to do with my kids but seemed a little of a stretch and got put out of the way. Maybe pull it out for a dual build! I have used balsa only once before for a ship (three masted schooner Marion Sprague by Ideal Models) and it dented when I even looked at it wrong. I will be using basswood as a replacement. Other than that I probably won't go too crazy in the scratch department. I have never seen a built up model with vertical slices. Mark

-

It is surprising how few waterline models are built. Kudos to you! Is the intent for a diorama or a shelf? I really like clippers and will watch your build with interest. Mark

- 89 replies

-

- scottish maid

- clipper

-

(and 2 more)

Tagged with:

-

On to the chesstrees. There is definitely a few hours here as will be explained below. My first gut was to jump right in, make a cardboard template to match the hull shape, transfer to a wooden piece and get'r done. Well, I never really like butt joints that show and in this case I was unable to get a real tight fit all around the chesstree. Pause to think..... Well, the easiest way is to inset the chesstree into the planking. So, I carefully trace around the chesstree and chisel half a plank depth away. The result is much more satisfying. As a bonus, the joint will be a whole lot stronger. Now here came the biggest problem to overcome, creating the sheave hole. At first I jumped in and carefully drilled a hole at both ends of the sheave hole and tried to remove any remaining wood in between. I didn't even take a picture as the result was totally unacceptable no matter how much I carefully filed, scraped and poked. I ended up walking away for the night. Later on the solution came to me and involved keeping it as simple as possible. I would cut into the chesstree to the sheave from the bottom. Once everything was cleaned up (now that the entire hole was accessible this was easy), a small section of wood would be replaced. Very quick and the result I liked very much. The actual block you see is one fashioned quickly and will be replaced. So overall the process was probably 3.5 hours. The next one for the port side will probably be done in less than half the time but I am okay with that. I ended up with something that looks good and methodically worked through the issues as they came up. Cheers, Mark

-

RIght now I have no plans to. This hull has been around for 8 years (assembled) and been very stable so far. Also, there are already regions I am unable to adequately reach. With basswood really need some sort of sealer. This whole ship has been a learning experience for me. Most items (where possible) are doweled or positioned with clamps as opposed to glue to allow some movement. I attach an internal pic of the orlop deck which has survived with no ill effects so far. Loving the hobby, Mark

-

Thanks, Brian. The wood is natural. This being my first such build, the complications of applying a finish really got my head spinning. You need to apply as you go and be real sure you don't need to glue something onto that surface later on. So...I opted for no finish. The flexibility it gives me provides no regrets. I am still pondering whether I will do this the same way for the next build - but first I need to get this one done! I am almost done with the external hull fixtures. Chesstrees and steps are up next. After the rudder is affixed I want to keep the hull handling to a minimum. The Orlop is complete and I am waiting on the rudder arm to be able to button up the berth deck. Mark

-

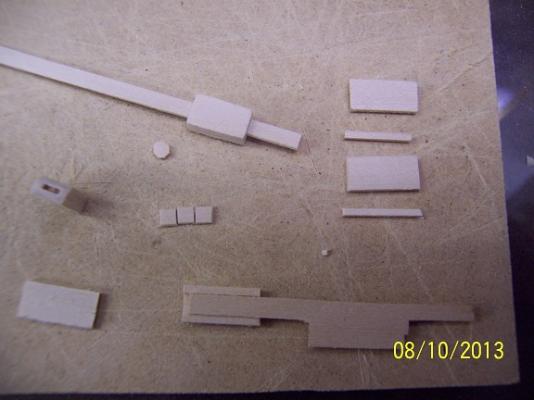

Today the object was to rough in the pass through blocks, two each side. They will not be installed until the internal planking is complete (for ease of planking). Their construction was pretty straight forward. I used 1/32" sheet basswood and cut out the box shape pieces. A basic jig was cut out to insure the inner opening was consistent both all the way through the piece, but also all four constructions. These pieces are built considerably over sized to allow for shaping and final fit later. A small circular piece is inserted to mimic the internal block. After construction the pieces are sanded to thin out the dimensions even further. Once the position on the hull is identified and marked, the hull was drilled through at the four corners and the rest cut out. To cover any gaps upon final install, basswood is great for just injecting a little glue into the gaps and then sanding and pushing the sawdust into filling the gaps. The inside will have additional supports glued in to insure the pieces go in and out exactly the same. A little time well spent in the shipyard. Mark

-

Primarily basswood. Only the details (rails, cheeks and moldings) are boxwood. I can acquire the basswood locally as I need it (amortize the cost) and by using sharp tools I really don't have too many complaints. It is a good chance my next build will be the same. Mark

-

Greetings (again). Returning to MSW after a bit of off time (eg I just completed my 5th sprint triathlon). I have not been idle and have lately been kicking it into high gear with my version of the HMS Druid. Believe it or not, started in 2003 (two kids and a couple of homes ago) but looking to finish in the first quarter, 2014. I have loved every minute I have spent - probably a little over 300 hours so far. I just finished with the bow assembly (sans the eking rail which will wait until the cathead is affixed). Previous to that was the stern caprail. I believe I am on the downhill of this build. Next up is finishing the rudder metal work and then working up from the berthdeck finishing all the details. Additionally I have made progress on my Lady Anne and finished the DaVinci wing (currently on display at the Michigan Aviation Academy), but that will be a subject for another day. Mark

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.