Charley54

Members-

Posts

83 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Charley54

-

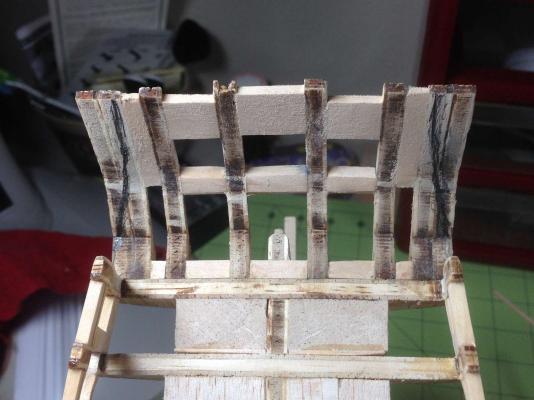

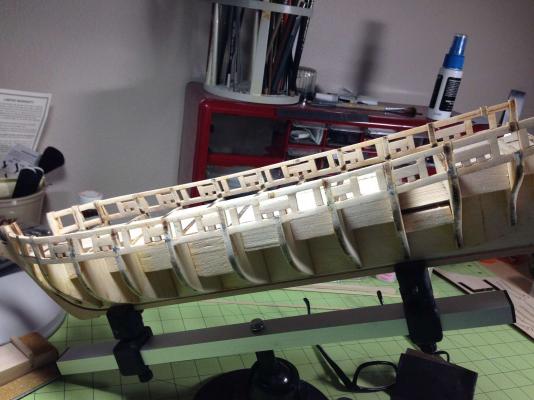

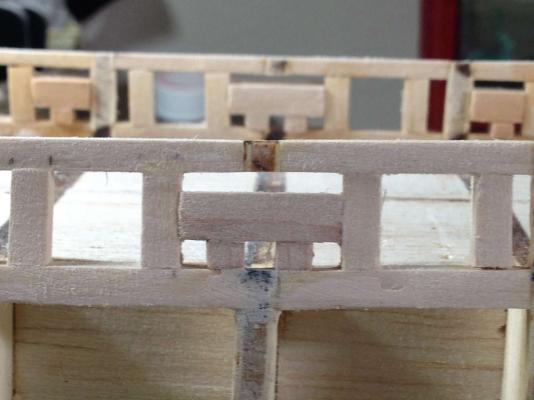

Ok, here we go - Chapter 4 - Stern framing. Just following Chuck's great directions. I, like everyone else, have discovered how absolutely fragile these parts are. Do not even look at them very hard- they will crumble. Other than that just A, B, C ........... Now just let the glue dry- Sills and lintels are next

-

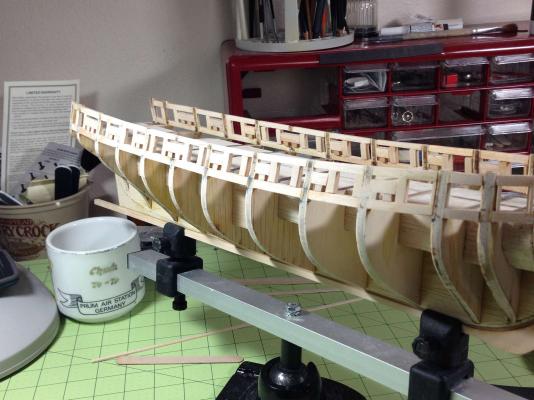

Finally, an update. Real life seems to keep interfering with important things, like working on my Syren, but I have made some progress over the last few weeks. First, a picture of my MicroLux pen sander which has become indispensable to me. I love this tool. It has really taken away much of the drudgery of sanding for me. Just my opinion of course. And a few more pictures of my more completed framing. I can not seem to stop tweaking, here and there, but I am almost satisfied. Now it is on to stern framing. Actually it is already complete. I just have to catch the log up to current state. More pictures in a few minutes

-

Todd- Checked my kit for you and I see what you mean. I have 5 pieces total for the boat and in the picture it looks like there should be 5 lifts plus a bottom. Hmmm.... inquiring minds want to know........ As for the variation in the vertical framing.. I just made sure that the framing plan was lined up on the last bulkhead and then made small adjustments as I installed all the remaining frames. I think it came out ok for me. Ive been working to much the last couple weeks so I havent been around as much as I like but your Syren is looking good! Charley

-

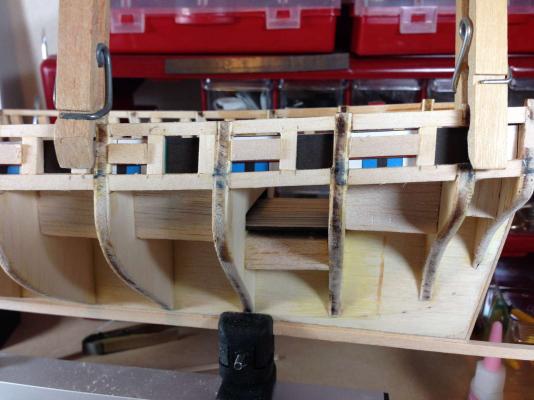

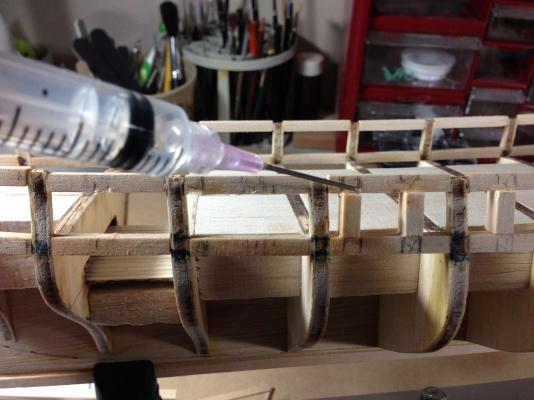

Dont worry Robbyn I stole the idea for the spacer from someone else , Dirk- I believe. I was using the syringe that day for alcohol because I had to redo those frames. It didnt work very well, too big of a syringe and needle, I think. I subsequently switched to insulin syringes with 31 guage needles and am able to control flow much better and get the alcohol right where I want it. If nothing else, I am getting really good at taking things apart after gluing them together Floyd- I am going to check out that Chopper thing

-

Augie-you gonna set up a planking class anytime soon ? Looks sweet. Charley

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

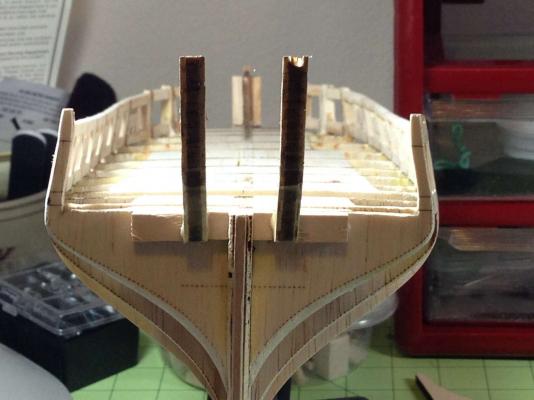

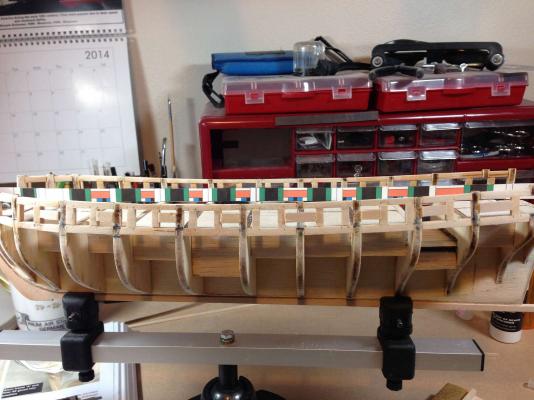

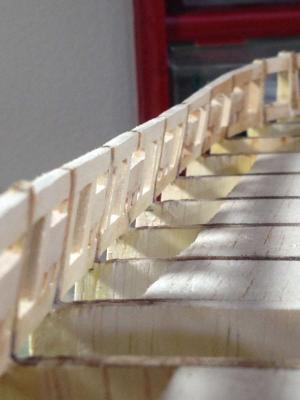

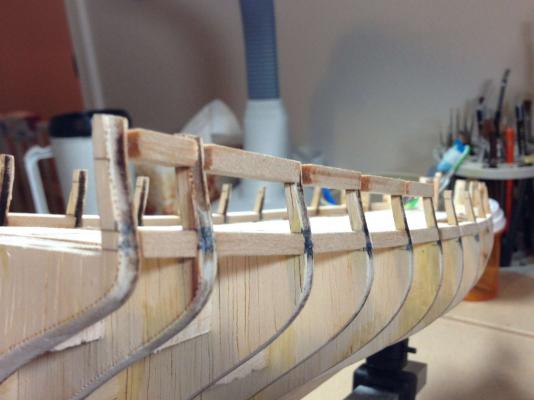

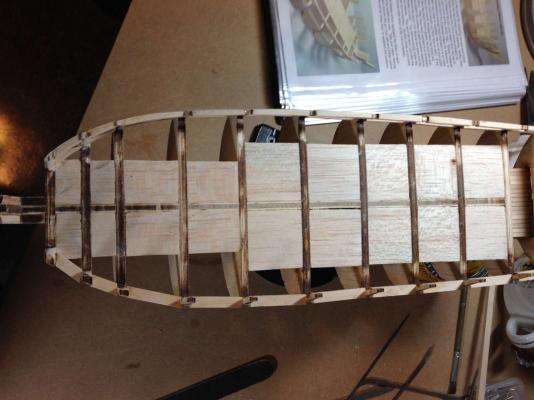

I finally finished the rough framing. All of the green, red and blue frames are done. I still have some sanding to do just to get her cleaned up like the lady she is . I have found I definitley need to work on my cutting skills. I struggle to cut a clean straight edge and angles are an exercise in frustration. I am using an Xacto miter box and razor saw but even so I find a lot of play in the slots. It may be time to put together some kind of jig. Here are a few pictures of progress to date. Happy New Year !!

-

Thanks for the support guys. I still have plenty of sanding to do. Im not sure how far down I should go on the grit size of the sand paper at this point, since this is all sub-structure that will be covered up. I am pretty sure that Santa is bringing me one of those microlux mini sanders so I am hoping that will help me in that regards. Thanks for stopping by Charley

-

Ahhhhhhh..... there it is. I love those last two side views. The deck is beautiful. It fires my imagination. It had to have been a time tested design based on function and the will of the men who used this ship so succesfully. I can already see the masts in my minds eye. Great work John. Happy holidays to you and your family Charley

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Hey Richard- I checked through my kit and I see what you mean.I dont see any specifically supplied wood. I looked at Dirk's build log and see that he cut his out of some after-market pear wood. I wish I could shed some light on this. I havent made it nearly this far yet but I will be very interested in the pending solution. Charley

-

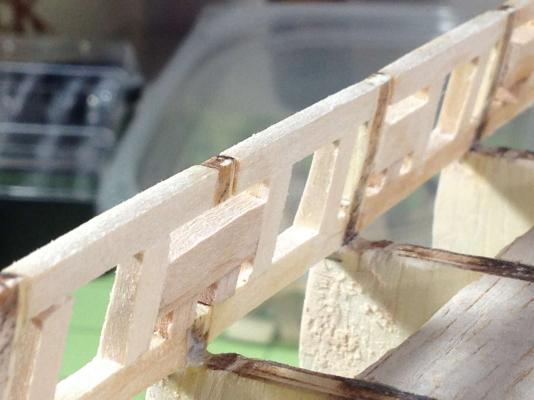

Green frames ( gunport sides) are also done. Pretty straight forward. Measure, cut, sand to perfect size with excruciating care, glue, wait to dry, come back and decide I dont like it, take out then repeat till I finally decide- enough is enough . I can't lie though. I am enjoying every minute of it. I have never found anything that takes my mind off "stuff" better than shipbuilding. Cheap therapy Anyway gunport sides are all in and sanded and I am on to the frames that define the sweep ports. I also wanted to say happy holidays to everyone here on MSW. I hope it is a good time- each in your own way. Thanks for being here.

-

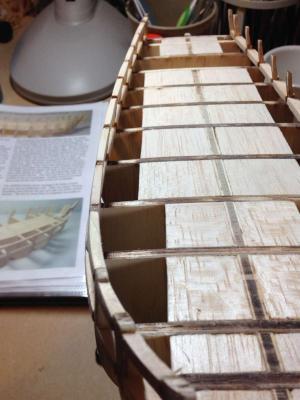

Ok finally a small update. Sills and lintels are all completed. Had to re-do a few. Seems like every time I walk away then come back they move Yessss...I have taken my medication today but I swear every time I stop working then come back after awhile I see some small error in a spot that looked perfectly fine previously. Anyway I have mastered the art of using isopropyl and debonder. I think you guys are rubbing off on me. A few of the tools I use and a few pictures of my progress

-

John.. all I've got to say is " I have got to get me one of these!".. Your work is ingenious. I love this ship more and more. I think the C.W. just went to the top of my short list for my next build. Of course I do need to find some time to wotk on my Syren first. Charley

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Hey John- The more I see - the more I like. Keep it up and keep the pictures coming. Charley

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

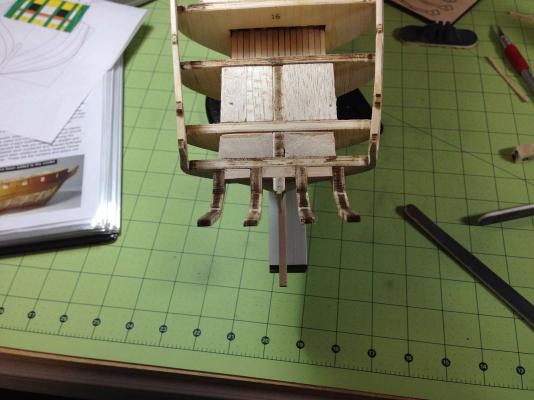

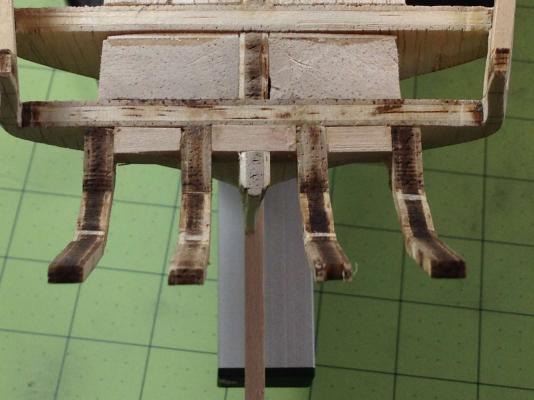

Augie- I just re-worked the idea for the spacer from several other builds I have seen on MSW. Someone always comes up with some little way to deal with most challenges. So many great ideas. As for the covering- I have my iron right here along with my heat gun on the shelf---sigh....but I think it would not be the same . Thanks for checkin in Larry- I am so used to trying to make everything look old and beat up. I am just not happy if I am not trying to weather something

-

Their are a couple things I may have done differently on the framing that I have done so far First - I would have faired each set of frames sills, then Lintels after I completed each run, starboard then port, as Chuck suggested. Instead, I completed sills and lintels on the starboard side then sanded the whole thing. I think this made it more difficult. Second - I would not have glued the frames in place with so much inboard exposure ( if that makes sense). I have found it veryy difficult to sand inboard as opposed to outboard. ....duh . If anyone knows any tricks, let me know. I almost done with the starboard side ( it has taken me forever) but I still have to do the port side.

-

Its been a very busy week.....but....back to framing I made a 15/32 plug to help with lintel spacing. I am trying to make the change to PVA glue but it is hard. I have become so used to CA. I like to make things fit then run a little thin CA in a tight joint- then its done. I have built to many wings I guess. So, I have used PVA on some of these and CA on others. Of course the CA will be a problem when trying to stain but the frames will all be covered anyway so I am using this as a learning experience. Unless? I wonder if they make a wood grained Monokote? I could do one quick planking job

-

Really nice work though John. What you did looked really outstanding. Heck to me the one in the real ship picture looks almost to large, although I am certainly no expert. I guess its just a reaally big skylight. You know, maybe its the picture, but to me the bottom looks closer than the top. I admire your dedication. My skills are a long way from accomplishing anything like this.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Hey John, I finally got caught up on your build. Looking good ! Looks like I got here at a good time. I am interested to see how you tackle the skylight. Great detail. Charley

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.