-

Posts

438 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Q A's Revenge

-

Proxon micro Shaper

Q A's Revenge replied to mikeaidanh's topic in Modeling tools and Workshop Equipment

Have a look at this Mike. http://miniatures.about.com/od/cuttingtools/f/Where-To-Find-Router-Bits-Or-Cutters-For-Scale-Mouldings-And-Dolls-House-Trims.htm There also seems to be a limited range of 3.2 mm shank cutters so make sure you can get the profiles you need. Must say I was unaware that you could get miniature moulding cutters with 1/4" shank. Found this as well. http://www.wealdentool.com/acatalog/miniature.pdf http://www.wealdentool.eu/press/WWP_50th_issue.pdf -

Proxon micro Shaper

Q A's Revenge replied to mikeaidanh's topic in Modeling tools and Workshop Equipment

No problem Mike, I'm sure you know what you need. Just thought one of those linked might do the job. -

Proxon micro Shaper

Q A's Revenge replied to mikeaidanh's topic in Modeling tools and Workshop Equipment

This looks nice as well. All you need is a cheap router for it. Screwfix have one on offer for £30 at the moment. http://www.axminster.co.uk/axminster-axminster-premier-benchtop-router-table-prod833056/?src=froogle&gclid=cn_v8llwu7ocfqrjtaod-yiaaw -

Proxon micro Shaper

Q A's Revenge replied to mikeaidanh's topic in Modeling tools and Workshop Equipment

What about this? http://www.rutlands.co.uk/sp+woodworking-whats-hot-best-sellers-best-sellers-in-woodworking-powered-router-table-with-height-adjustment-dakota+dk2080 Bit bigger but probably more durable if you can find the space for it? The Proxxon is only 100W, the Rutlands machine is 1500W. -

Thanks for that Sarge. If you want some more blocks these are pretty good and have Metric threads instead of those funny UNC things or whatever they used to use ... :-) I have both the 10-20-40 and 20-40-80 blocks (in addition to some Moore & Wright 1,2,3's. http://www.arceurotrade.co.uk/Catalogue/Workholding/Vee-Blocks-Angle-Plates

-

" Deck Color"

Q A's Revenge replied to riverboat's topic in Painting, finishing and weathering products and techniques

So, what's the best way of getting a grey finish on pale woods like basswood? -

I think I already know the answer to this question but it doesn't hurt to ask! Are there any shops in the UK that import Model Shipways kits apart from Cornall Model Boats? They only import two kits and don't seem interested in any others. :-(

-

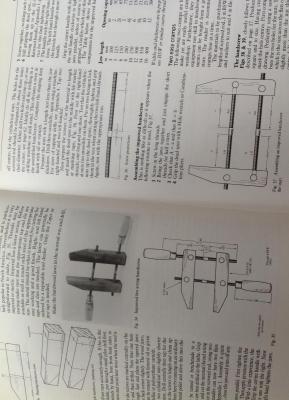

Make your own clamps

Q A's Revenge replied to Q A's Revenge's topic in Modeling tools and Workshop Equipment

All the other clamps in the book use conventional threads so are straightforward to make. The author even explains how to make them without a thread Tap. -

I'm guessing what John is saying is that he temporarily fits the margin (your term, Edging) plank first without cutting the inner edge. He then runs the conventional planks forward having cut the ends to shape, joggling as he calls it. He then traces round the "joggled" end onto the margin plank for cutting. That's the way I read it anyway and it seems to make sense!

-

Make your own clamps

Q A's Revenge replied to Q A's Revenge's topic in Modeling tools and Workshop Equipment

I've also discovered this book, which has clear instructions on making many types of clamps including the Jorgensen type. Lots of other useful stuff in the book as well. http://www.amazon.co.uk/The-Resourceful-Woodworker-Techniques-Tricks/dp/0713464852/ref=sr_1_1?ie=UTF8&qid=1382864241&sr=8-1&keywords=The+resourceful+woodworker I bought a very good used copy for 1p, plus postage of course! -

Miniature Spindle Sander

Q A's Revenge replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

A drill press is many folks first machine tool as it is so useful. -

Miniature Spindle Sander

Q A's Revenge replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

If you have a drill press you could also fit a sanding drum in lieu of a spindle sander. I've even seen a sanding drum in a drill press used for thickness sanding. Just a thought. -

Sanding Block

Q A's Revenge replied to Hexomega's topic in Building, Framing, Planking and plating a ships hull and deck

I don't think X-acto make them any more. -

Sanding Block

Q A's Revenge replied to Hexomega's topic in Building, Framing, Planking and plating a ships hull and deck

Forgot to mention, I bought a box of mixed 1" abrasive rolls a while back so made this. It's a copy of an old X-acto type. -

I bought this Mic checking set very cheap a while back. Can't say it gets much use though! :-)

-

For most jobs Digital calipers are pretty good and easy to read but if you want accuracy a Micrometer is hard to beat. Bear in mind though Mic's only have a small measuring range.

-

I bought a pair of 4" calipers to use in tight spaces, particularly on my milling machine. For normal use though 6" ones are much easier to handle IMO.

-

These seem reasonably priced, anyone got a set? Interested to know how good they are! http://www.xacto.com/products/cutting-solutions/knife-sets/knife-sets/Carving-Tool-Set.aspx

-

It really is a shame we don't celebrate this as a nation here in England. Bit late as I'm retired now but it would would make a good excuse for an additional bank holiday! :-)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.