-

Posts

154 -

Joined

-

Last visited

-

GrandpaPhil reacted to a post in a topic:

Bluenose by jre8655 - FINISHED - Model Shipways - Scale 1:100

GrandpaPhil reacted to a post in a topic:

Bluenose by jre8655 - FINISHED - Model Shipways - Scale 1:100

-

GrandpaPhil reacted to a post in a topic:

Bluenose by jre8655 - FINISHED - Model Shipways - Scale 1:100

GrandpaPhil reacted to a post in a topic:

Bluenose by jre8655 - FINISHED - Model Shipways - Scale 1:100

-

GrandpaPhil reacted to a post in a topic:

Bluenose by jre8655 - FINISHED - Model Shipways - Scale 1:100

GrandpaPhil reacted to a post in a topic:

Bluenose by jre8655 - FINISHED - Model Shipways - Scale 1:100

-

GrandpaPhil reacted to a post in a topic:

Bluenose by jre8655 - FINISHED - Model Shipways - Scale 1:100

GrandpaPhil reacted to a post in a topic:

Bluenose by jre8655 - FINISHED - Model Shipways - Scale 1:100

-

cristikc reacted to a post in a topic:

Proxxon Mini Lathe DB-250 - Opinions/assessments/recommendations?

cristikc reacted to a post in a topic:

Proxxon Mini Lathe DB-250 - Opinions/assessments/recommendations?

-

tasmanian reacted to a post in a topic:

Proxxon Mini Lathe DB-250 - Opinions/assessments/recommendations?

tasmanian reacted to a post in a topic:

Proxxon Mini Lathe DB-250 - Opinions/assessments/recommendations?

-

Popeye, I wish I'd seen this build when you started it. I purchased the Thermopylae kit quite some time ago and when I found that the instructions were in Italian I contacted the manufacturer and was sent an English version of the build sequence. I've attached them for you. Jack Thermopylae Assembly Instructions.doc

- 452 replies

-

- thermopylae

- sergal

-

(and 1 more)

Tagged with:

-

Tom, I'm not so sure I would try using the drill press/x-y table to cut out the bulkheads. Here's why: it's very easy to turn the adjustment knob the wrong way, thereby risking cutting in a direction you don't want to go. Now there is another way to do this...use the x-y table to move the cutting tool to a precise location then drill a hole. Repeat this all the way around the section you want to cut out, drilling a series of holes then just cut between the holes to remove the section. It wouldn't be much of a chore to file and sand the bulkhead after that. I've done this with some difficult pieces in the past and had very nice results.

-

Tom, I'm not sure if a Coping Saw is route to go. The spiral blades are hard to control and as mentioned are very course. The Jewelers Saw Blades are somewhat expensive and I have found Scroll Saw Blades that are finer. Several suggestions: Try using automotive masking tape on the back side of the plywood. It has a very fine grained adhesive and should not harm the wood. I've used scroll saw blades from Woodcraft that are up to 46 tpi and found they cut very cleanly with a minimal splintering on the back. Here is the URL: http://www.woodcraft.com/category/PA115-08-01/scroll-saw-blades.aspx?gclid=CKqOz5GY9coCFQoNaQodwj4PiA And one question. What kind (brand) of a Scroll Saw are you using?

-

I like it! I can't tell you how much time I spent tying knots on Ratlines and these were on 1:100, or less, scale. At those scales the knots look too large. I will have to try this.

-

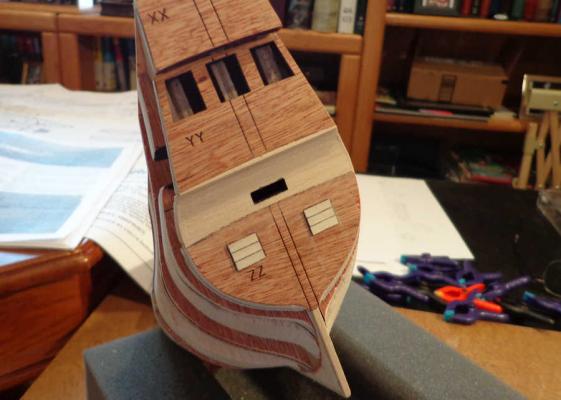

I used the first set of planks that I prepped with the plank jig for the stern and counter. The instructions called for a layer of 1/16” x 1/8” planks to be applied to the counter. When I finished this set of planks I noted that there was a 1/16” drop from the stern piece ZZ to the counter. I found that I had to apply a second layer of 1/16” x 1/8” planks in order to achieve a smooth transition from stern piece ZZ into the counter. I’m thinking that maybe the planks should have been laid flat instead of upright; however, the plans show them laid upright. Once these two layers of planks were sanded to shape and blended together I began the second layer of 1/32” x 1/8” planks. Per the instructions, the gun port lids are placed first. With the gun port lids in place I transferred the angle of the planks from the plan sheet to an adjustable protractor (37°). The planks were then cut and applied to the stern piece ZZ and finally to the counter. < I realize that most of the stern planks will be covered with white paint so all this lovely caulking will be lost. I therefore considered this an opportunity for me to practice coloring the plank edges and laying the planks in preparation for the deck planking job that lies ahead.

-

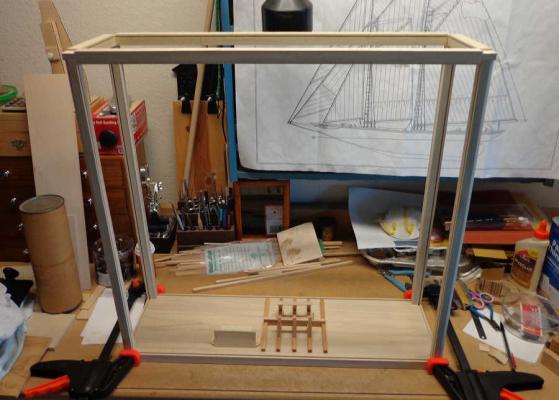

Previously I made a comment that I was going to construct a jig to help prepare planks for this build. I wasn’t sure if the time spent designing and building such a jig would ultimately save future effort with the planks. Well here is the jig I came up with. The center section of the jig is movable slides to clamp the planks between the two pieces of pine. These pieces were cut to a 3/32” thickness to accommodate 1/8” wide planks. This would allow for sanding the planks to the same thickness. I spent one morning at our community woodshop and cut all the pieces from ¼” Masonite. The two lighter colored pieces are pine. The idea was to have a clamp that would hold a number of planks so they could be gang sanded to the same width and length then edge colored to simulate the caulking. To test the jig I cut 25, 1/32” x 1/8” planks and stacked them in my jig then closed it. There is enough friction between the pieces of Masonite to hold the plank stack, but if needed I can wrap a rubber band around the slides to add pressure. Once in place it was a very quick operation to sand all the planks to the same dimensions. After sanding, I colored the edges with a Prismacolor black pencil. Now it’s on to applying the planks to the model.

-

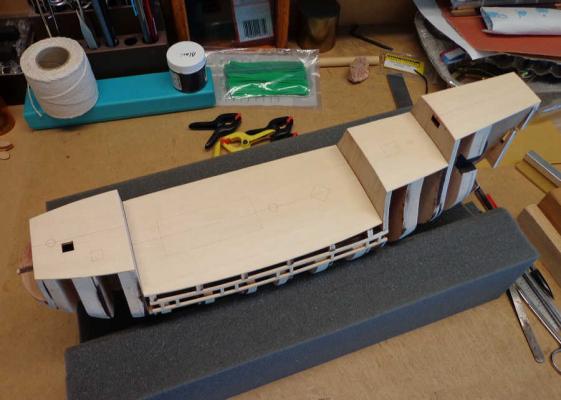

All the decks are now glued in place and the upper sections of the bulkheads and decks are faired. I’ve been reading over the instruction manual and delving into some of the other Mayflower build logs for information on planking the decks. Looking at the plans and the photos in the manual it looks as though the deck planks are laid down in very long sections. I’m not sure what length these planks should be, but I’m thinking of making them about 1.5 to 2 inches in length. There is an illustration in the manual showing the deck planks much shorter than depicted in the photos. Any thoughts on this?

-

How to build a wood case ?

jre8655 replied to alexmd's topic in Painting, finishing and weathering products and techniques

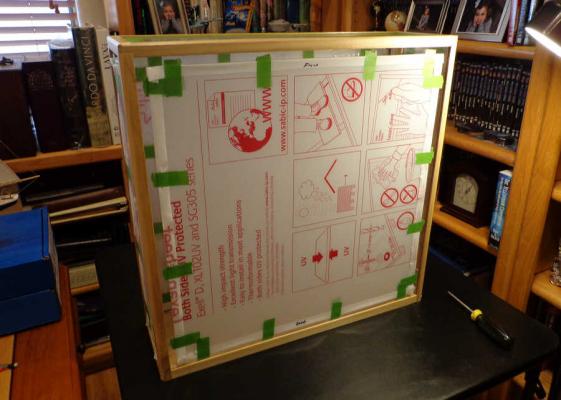

All the 1/8" grooves, base and frame pieces, were cut with the MicroLux Table Saw. I used a Dado disk with the blade for the 1/8" cut. The Lexan acrylic was cut to order when I purchased it. I had the dimensions figured out when I got it. -

Once I began fairing the bulkheads I realized that there were several places where it would be necessary to add some filler material to achieve a nice roundness to all the bulkheads. I decided to add filler blocks to most of the bulkheads to get the roundness I wanted and provide a wider gluing surface for the planking. I used some scrap balsa for the fillers. I have a fair amount of experience with balsa from my days building model airplanes. Now it’s time to get on with the planking.

-

How to build a wood case ?

jre8655 replied to alexmd's topic in Painting, finishing and weathering products and techniques

Using the dimensions you posted, your case should be about the same size as the one I made for my Bluenose. I made that case using Poplar. The base is 24" x 7.5" x 3/4". All the pieces for the frame are of 3/4" square Poplar. The case is 23" high. Here are some photos of the case construction: All the acrylic is Lexan and the pieces slide into 1/8" grooves I cut using a MicroLux miniature table saw. The wood frame certainly provides strength and you don't have to worry about trying glue the acrylic itself. I believe that at some point you will have to use a table saw to cut the parts. If you know someone that has one, you could ask to use it for the amount of time it would take to cut and groove all the parts. -

How to build a wood case ?

jre8655 replied to alexmd's topic in Painting, finishing and weathering products and techniques

Realistically, the only way to cut a groove in the wood is with a table saw. You can set up the rip fence on the saw to cut the groove whatever distance you want from the edge and adjust the saw blade to the depth you want the groove. Once the rip fence is set up, say to allow a 1/8" space from the edge of the piece to the groove, you can then cut the groove in all the pieces. -

Many years ago, around 1973, I purchased a Unimat SL. That thing was a variable (belt driven) combination lathe (metal and wood), drill press, verticle milling, table saw, jig saw, disc sander, flexible shaft handpiece, all around whatever you needed machine. There were so many accessories available that it was an entire workshop rolled up in one. Wish I still had it!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.