-

Posts

538 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SGraham

-

Jesse, I just read through your log. Your patience is inspiring. The hull looks very nice; I think your fix worked well. Also, I really enjoyed seeing your kids involved. Steve

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Hi Jesse, Thanks for the response. I'm probably going to do the same thing to the false keel of my next build, but I'm going to cut the rabbet differently. I dug in too deeply with the chisel and now I've got a see-through rabbet all along the stem. Seriously, you can look right through it. Even so, when the planks are glued in there, I'm thinking it'll be strong enough. The only sailing it's going to do is on a shelf. On my next build I'll go at it with a lighter hand. That must have been disappointing to find the framework was bent in your build. Was it in the frames or in the keel? How did you find out it was crooked? I'm curious about how you are going to fix it. I put the first 2 planks on last night and will pull them off and redo them today. My learning curve remains as steep as it ever was. I searched for the same information on the Shenandoah and got the same results. I think they could just as well have sold the kit as a generic mid-19th-century American cutter. I may leave the swivel guns and flag off. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Today I thinned some of the maple planks and glued them to the inside of the transom. I'm thinking of painting the inside of the transom and bulwarks, so I beveled the edges of the planks to give them some definition. Hopefully it will be enough to see the lines between the planks after I paint them--if I don't lay it on too thick. The planks are pretty wide and may end up looking a little silly, but I'll do better (hopefully) on my next build. I also sanded off the little tabs on either side of the transom. They are for connecting the plywood bulwarks. Since I don't plan to use them, there was no need for the tabs. Oh yes, please notice the custom-made crystal running light on the bottom-left of the last photo. Thanks for reading! Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

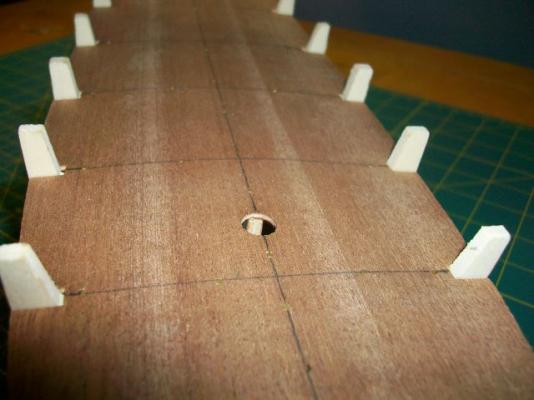

I'm getting ready to begin planking. I don't know what I'm doing, but I've been reading the tutorials. The basswood planking supplied with the kit is very narrow. I think I want to go with something wider and maybe a little harder since I put some pretty good fingernail marks in the basswood just by holding it up to the model. That stuff is seriously soft. I guess I could try trimming my fingernails. I have some more of the maple strip cutoffs from which I cut the stem, keel, and sternpost. So, this morning I tried resawing some planking from one of them. I resawed it on the band saw and then ran it through the drum sander. It's the same thickness as the basswood, but it's harder and seems flexible enough. I'm not sure if the grain is too textured. The last photo shows the grain. Cool screw hole too--fortunately, it's in the middle of the piece, right where It'll be cut in half anyway. Thanks for reading. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

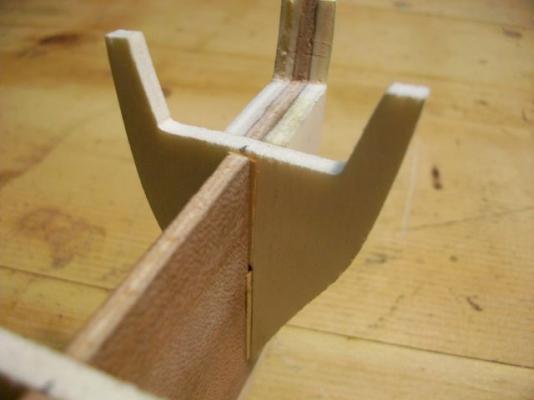

Well, last night I finished excavating the rabbet. It looks pretty rough to me, but I hope it's going to work all right. The false keel is really thin and soft. Right where stem meets the keel, the wood is shaved so thin that you can see light through it. I'm hoping that when I glue planking in there on either side it'll be strong enough. Here are some pics. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks, J. Keep up the good work on that Half Moon. I need the inspiration. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

HALF MOON by jct - FINISHED - Corel

SGraham replied to jct's topic in - Kit build logs for subjects built from 1501 - 1750

Hi J, I'm really enjoying watching your progress. I'm got a Half Moon kit burning up a space on my shelf. I think it's going to be my next build. Steve -

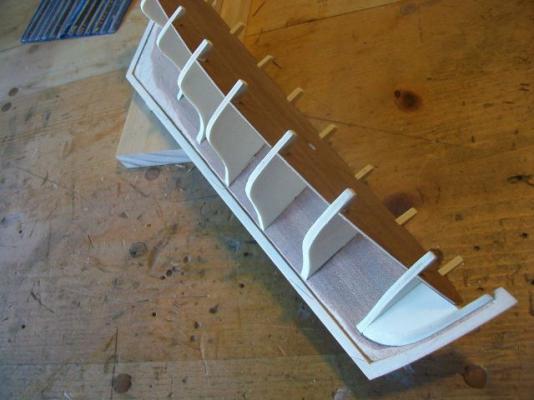

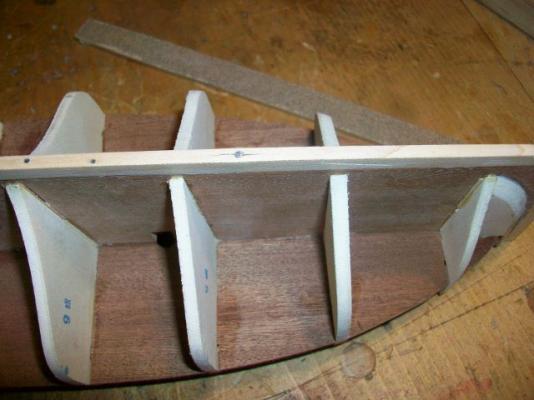

As Mark suggested, I made a batten and glued sandpaper to it (100 grade). This did a really quick job of fairing the frames. I was trying to bend the batten while sanding to cover 3 frames at a time. I succeeded part of the time. I haven't pinned longitudinal battens to the frames to seriously check for fairness yet. I'm going to do that after I finish cutting the rabbet. Still after holding one plank across the frames with my fingers, it's looking pretty fair. Next, I sharpened up a chisel and began on the rabbet. I've done a small bit of the section where the stem joins the keel on the starboard bow. How does this look? It's a little hard to tell from the photos, but the sides gradually bevel into the cut. I think a problem I might have is cutting the rabbet too deep. This false keel is really skinny and soft. It's easy to take what seems like too much material off. If that is the case, I can plank that side first and then cut the other rabbet on the port side. That's what I'm thinking, anyway. Comments?

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks Mark. I'm glad for the tip. I'll do the rest of the frames with a batten. Hopefully, I haven't done too much damage to the one I beveled already. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks for the kind comment, Curtis. I get pretty jazzed about old tools. Most of my power tools (band saws, drill press, table saws, planer, jointer, 6x48 belt sander) date from at least the 50's--some as far back as the 20's. They are incredibly heavy and smooth to operate. But to me the real advantage is that people will get rid of them for next to nothing. My drill press (Delta 17") and jointer (Craftsman 6") were both free. Seriously, folks would say, "Come and take this old junk off my hands. So I can buy something new" (made of sheet metal and plastic). Bearings are a couple of bucks. The others tools were in the $50 - $100 range. Hand planes, spokeshaves, and scrapers are even cheaper. I picked the stuff up over the years with an eye toward being able to scrounge free wood and turn it into musical instruments. I wasn't thinking about ship modeling at all. I think, though, that there will be considerable cross-over of applications, since I want to mill some of my own planking. Thanks, Mark, for the tip. I take it that the batten isn't too flexible? Do you glue the sandpaper to the batten? Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

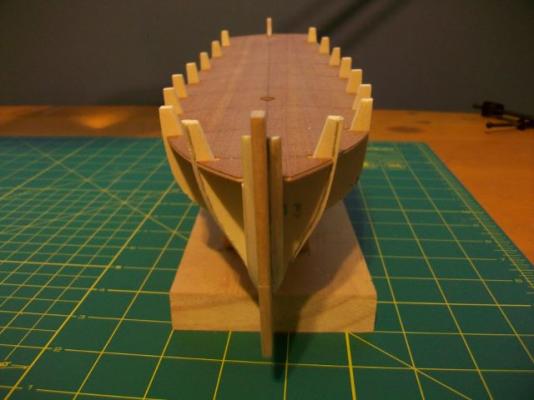

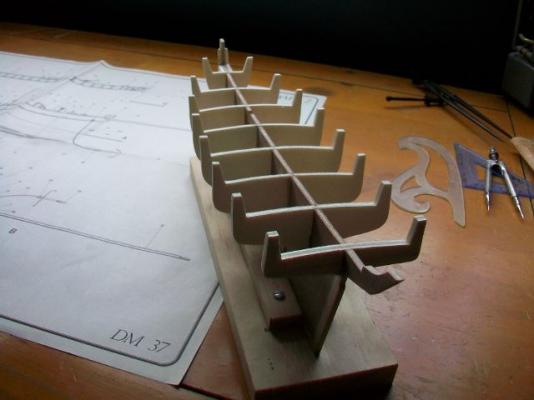

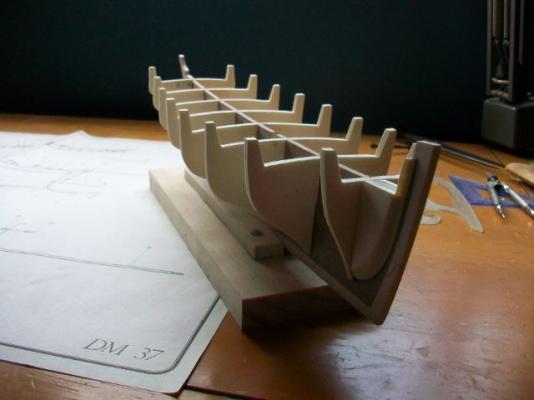

I got a little more done on the cutter last night. First, I glued and nailed the sub-decking on. I like how the frame tops are radiused to represent deck beams. It's going to give the deck a nice camber. I'm sure most if not all POB kits do this, but I, being rather new at this, noticed it with appreciation. Next, I beveled the first frame on the starboard bow. It was surprisingly easy to bevel with an X-acto knife. It's visible in the second-to-last photo. Does it look right? I hope to do the rest later tonight. I also got the stern filler pieces made and fitted. Finally, I reinforced the joint between the keel and false keel with long thin nails. This was after I inadvertently broke the keel off while nailing on the deck. It should be stronger now. Please bear with me. Later, on my 3rd or 4th build log I probably won't post so many pictures of the same thing from so many different angles. Is it clear that I'm having a great time building this little boat? Thanks for reading! Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Hi Pat, What a clean job you're doing. Any comments on the quality of the kit? Steve

- 7 replies

-

- small

- chesapeake bay flattie

-

(and 1 more)

Tagged with:

-

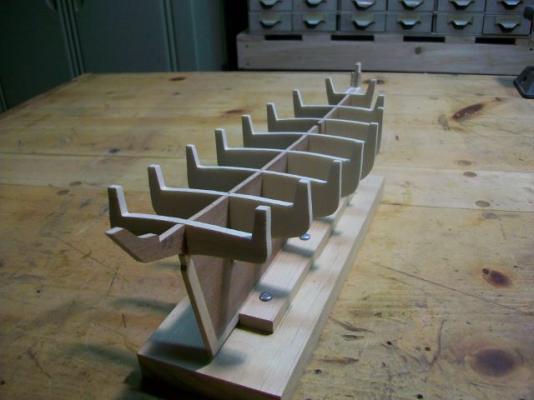

I guess the technique for tightening up loose frames is pretty intuitive and obvious. I glued some thin strips into strategic places and now have the frames glued in. When they are dry, I'll install the deck and then see about that pesky rabbet. Below is a my super cheap Central Machinery 1" belt sander. It did a great job of shaping the bow filler blocks. It'll do a nice job of beveling your knuckles too. The next pic shows the gaps between the frame and keel. The rest are of the glued-up framework. This model shipbuilding is pretty fun--so far... Thanks for reading. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks for the encouraging words, everyone. I think the thing I like the most about looking through the build logs is seeing how people solve problems. There is so much evidence of critical thinking on this site. MSW is an amazing place. It's interesting too how this hobby nudges you into historical research. Arjan, thanks for the thoughts on single-planking. I'm no perfectionist, but I certainly admire the work of people who are. I don't think the Shenandoah kit is a representation of a single actual ship. I think it would be more accurate to say it is a general representation of a type of craft. So, I feel free to take certain liberties. My single-planked model will be a little bit on the skinny side...Shenandoah light. My next step is to get the frames to fit. Only two of them fit the keel right out of the box. The rest are so loose that they fall immediately down to bottom of their slots. Since they won't sit in place correctly yet, and since I'll need them in place to cut the rabbet, I'm going to put off the rabbet and focus on the frames right now. Any thoughts on how to tighten up loose frames would be very welcome. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

I tried the bending iron on the warped keel and it straightened out nicely. Below are some pics of the iron and the keel.

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks Arjan. I'm thinking of making some of my own planking. I want to learn to spile planks. I'd like to do the garboards correctly. I was reading Charles Davis' The Built-up Ship Model, and from what I understand, the garboards will need to be wider than the planks supplied with the kit. So, I'm thinking of picking up a piece of basswood and resawing it. I have a question. Does a kit have to be double-planked? Has anyone here ever single-planked a kit that was sold to be double-planked?

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

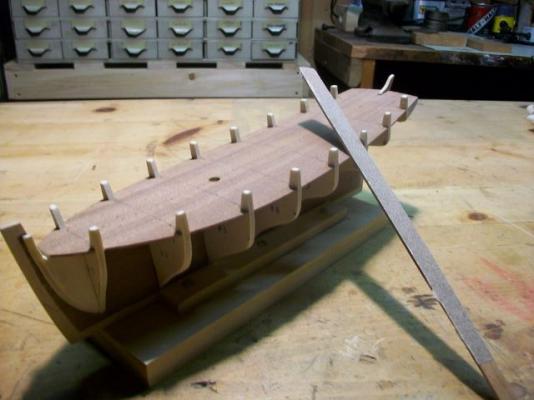

I found some nice clear maple strips that I scrounged somewhere. I thicknessed one of these on a drum sander (I've got an old Ryobi that I used to use in dulcimer building). I traced the stem, keel, and stern post onto it and cut them out on the scroll saw. I cut the scarf joint where the keel and stem meet. The other scarfs I'm planning on just marking in with a knife. I did one on the front of the stem, but I noticed that the horizontal legs of it look a little droopy. Oh well. The stern post I cut out wasn't long enough, so I'll make another. I'm thinking I should add the keel shoe after I've got the hull planked. Before I glue up these pieces, I've got to take care of the warped false keel. Thanks for reading!

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

I don't know if I'm running this build log correctly; if not, please let me know. Next, I had to clean up the cut on the bottom of the false keel so my new piece would form a strong joint. Even taking my time on the scroll saw, I can't cut a perfectly straight line. I used a Stanley 118 low-angle block plane to even out the surface. Just a couple of passes is all it took. The 118 is only 6 1/4" long, but it has some heft to it and works with little effort. Also, the low angle of the blade helps keep things from splitting. Is this too much detail? The thumbnails below show the bottom of the false keel prior to and after jointing with the plane.

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

I also noticed that there was no separate piece of wood for either the stem, the keel, or the stern post. All three were simply included in the area of the false keel. This concerned me for a few reasons. First, I didn't like the idea of the wood grain running horizontally on the stem and the stern post. Also, I wasn't happy with the thought of looking at my ship from the bow on and seeing the plywood edge exposed. I suppose I could cap it, but then I'd have a seam showing on the side. I also wanted to fit the planks at the bow and stern into a rabbet, and since I've never cut a rabbet (the kind on a ship, anyway) I thought it might be easier if just removed the parts of the false keel that represent the stem, keel, and stern post. This was easy enough to do on a scroll saw. Then I could make the parts out of some hard wood. You might notice also that the bottom of the false keel is not straight at all; it's missing some material in the middle of the bottom edge--like the machine Corel ran it through gave it a good snipe before letting it go.

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Well, here goes. My name's Steve and I'm new here at MSW. This is my first kit build log on the first wooden ship kit I've built since 1983. My earlier attempts on wooden ship models weren't very impressive. I've got an older version of Corel's La Sirene on the shelf, but thought that this little cutter might be a better way of getting my feet wet. I also thought that the sharp bow of this boat might be easier to plank than the bluff bow of an 18th-century French frigate. The first thing I noticed on checking through the parts was that the false keel has a kink in it. It's not big, but it's there. I've got a device for bending guitar sides, and I thought a few moments on that might cure the kink...unless someone has a better idea? I haven't tried it yet but will soon. In the thumbnails below, you can see the bend in the false keel viewed from the top. I'm adding a shot of Shenandoah's sail plan as well.

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.