-

Posts

3,158 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Glenn-UK

-

Foremast Shroud Work Continues I tied off the lanyards on the lefthand side this morning and then added a temporary thread which will be used to indicate the lower edge of the first shroud sizing. This also means I have left a bit of room to add the lowest ratline. Once the lower shroud seizing's were completed the lowest ratline was added. As can be seen in the photo below I also tied a thread around the first shroud to indicate the position of the lower edge for the next shroud sizing. You will also note that the first two shroud deadeyes (left hand side) have rotated anti clockwise and are now slightly misaligned. I will try to rotate them back to the correct position without removing the lanyards, but I suspect I will have to remove the lanyards to rotate the deadeyes. Of course I could just leave them as is.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Foremast Lower Shrouds I have continued with my work adding the lower fore shrouds and the deadeyes have now been added. The seizing still needs to be completed. I have done my best to get the shroud deadeyes to the same level and for the most part I am happy with how the shrouds are looking in that respect. There is a bit of room for adjusting the deadeye positions by adjusting the lanyards. My progress has been slow as I have been taking my time with positioning each of the shroud deadeyes. The method I have been using has yielded much better results compared with some of my previous builds.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I have not try fitting them as yet, but will have a look once I've finished with the initial fitting of the foremast lower shrouds.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Loving your work and attention to detail, beautiful work, as always.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Always good to reach this milestone, excellent work.

- 233 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Foremast Lower Shrouds - Take 2 Following on my last post, where I had an issue aligning the shroud deadeyes, I did some experimentation this morning. Using the method I had previously outlined I did find it difficult to ensure the loop seizing was added to the same point. With previous builds, once the deadeye has been seized in the loop, the shroud deadeye height could always be adjusted by moving the loop seizing. This is not an ideal method but it did seem to work reasonable well. This method did not seem to work to well with the Indy, possibly due to using larger threads for the shrouds. I thought there must be a better /easier method. After a little bit of thought I devised a modified jig, as shown in the picture below. By adding an additional pin (blue arrow) above the shroud deadeye the shroud line can be fed into the jig. A bit of tension is applied to the line by clipping on a pair of my reverse action tweezers. I have a vague recollection that another member MSW passed a loop seizing through the shroud line. I thought this would be worth a try. Using a sewing needle I was able to feed the seizing thread through the shroud line, thus ensuring the seizing point was fixed in place. It was then a simple task to complete the seizing. Once I had added the deadeyes to the first shroud pair I did an alignment test with some lanyards. I am much happier with the end result compared with yesterday effort. Tomorrow I will continue to add the deadeyes and, fingers crossed, the new method will yield a more consistent end product.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Starting work on the fore shrouds After due consideration I decided to start with rigging the lower fore shrouds. Based on a bit of research I thought a spacing of 25mm would be an acceptable distance between the deadeyes. As a rule of thumb it seems this distance is normally 3 to 5 times the diameter of the deadeye. I made a simple jig to set the required distance between the deadeyes. With the jig in place a shroud line is wrapped around the deadeye. The loop was then seized. With the seizing completed the deadeye was correctly positioned in the shroud loop and the loop was tightened around the deadeye, using the jig to double check the spacing was correct. The following is another photo showing the jig in position. With the loop in place I added a temporary thread to hold the shroud end in place. These will be properly seized once all the shrouds have been added as I have a plan to ensure all the seizing's are level with each other. With the first shroud pair in place I added the lanyards, noting these will be redone as I plan to get rid of the fluffy edges. Once the lanyards were properly adjusted the phrase "Houston we have a problem" seemed appropriate. Thankfully It is not a major issue as I can easily redo the right-hand shroud, as the left-hand side lanyard spacing is set to the required distance.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Many thanks for your advice @chris watton. I am currently tending toward adding the shrouds before the foreyard. The deck area, after looking at the belying requirements, seems to have a bit more room compared to the smaller models I've built. The one aspect I am not totally clear on is where the jeer line is belayed after it passed through the bitt hole (blue arrow). Either it should be wrapped around the bitt (top yellow arrow) or around the bitt rack (lower yellow arrow). The position of the belaying pins on the rack makes either option awkward. The photo I took last year (HMS Trincomalee) does not really help me.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Decision Time My initial thought process was to add the foreyard to the foremast before the shrouds are rigged. The reasoning for this was for easy of access with regards to the foreyard central rigging (truss pendants, sling, jeers and lifts). With that in mind, after constructing the foremast, I built the foreyard which is now ready for installation. I am now reconsidering my strategy as this requires the end cap to be in place so the foreyard sling and lifts can be added and rigged. However I prefer to make the shrouds off boat and then drop them in place before the mast cap is added. This can be done as I can keep the shrouds out of the way whilst I add the foreyard and rig the truss pendants, sling, jeers and lifts. My concern is will the foreyard make adding the ratlines, futtock shrouds and catharpins more difficult. I decided that I should set the two jeer blocks located on the foremast to the required height and then seized to the figure of 8 lashing. With this done I then decided I should also add the burton pendants. I then decided that I should made the shrouds. The large loops allows the shrouds to be dropped oved the foremast. When the shrouds are correctly positioned the loop seizing can be adjusted to tighten the loop. The shrouds were then added to the foreyard, but kept them out of the way as can be seen in the photos below. Please note the shroud loops have not been tightened as the shrouds are not in their required positions. I am now going to study the rigging plans (again) to see where the truss pendants, jeers and lifts are belayed at deck level before deciding on weather to rig the shrouds or to add the foreyard next.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Foreyard It took quite a bit of time to add the various blocks to the foreyard. It is important to ensure the block holes are correctly positioned and orientated on the foreyard, in readiness for the rigging stage later on in the build process, as they are added. After the all the blocks had been secured to the foreyard I turned my attention to the truss pendant rigging. I started the process by creating a thimble to one end of each truss pendant. The truss pendants were then secured to the foreyard. The final task was to add the footropes. Thankfully this turned out to be a relatively straight forward task. I started by creating the loops either side of the foreyard mid point. The footropes were then passed through the footrope stirrups. I then made a loop each end which were placed over the end of the foreyard and positioned just before the end cleats. The two end loops were then slowly tighten up until I was happy with how they footropes looked. I have added a selection of photos of the completed foreyard. Before securing the foreyard to the foreyard I will add the lower fore shrouds to the foremast.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Seizing Blocks With Alternate Half Hitch Knots

Glenn-UK posted a topic in Masting, rigging and sails

Seizing a Block I have often described in my build log posts the method I use to seize a block using a series of alternate half hitch knots. Today I thought I would make a video showing how I do this in real time. In this video a 4mm single block is wrapped with 0.25mm black thread and then seized with 0.1mm black thread. With the block held in place using my quadhands the video starts after a length of 0.25mm black thread had been wrapped around the block. Sometimes the seizing can slide away from the block during the seizing process therefore you will note after I added the first pair of half hitch knots a touch a ca glue was used to prevent the slide from happening. This video also shows that once I had completed the seizing a micro drill was used to check the block hole and the required rigging line was then test threaded. This method works really well for me, but I know modellers will have other methods which suits them better, -

Seizing a Block I have often described in my build log posts the method I use to seize a block using a series of alternate half hitch knots. Today I thought I would make a video showing how I do this in real time. In this video a 4mm single block is wrapped with 0.25mm black thread and then seized with 0.1mm black thread. With the block held in place using my quadhands the video starts after a length of 0.25mm black thread had been wrapped around the block. Sometimes the seizing can slide away from the block during the seizing process therefore you will note after I added the first pair of half hitch knots a touch a ca glue was used to prevent the slide from happening. This video also shows that once I had completed the seizing a micro drill was used to check the block hole and the required rigging line was then test threaded.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Foreyard Stunsail Boom I had been pondering where to fit the stunsail boom in relation to the foreyard. I had an inking should not be positioned directly above the foreyard but was not 100% sure. With many thanks to @allanyed who confirmed that the stunsail boom should be rotated forward by approx 45 degrees for ships built after 1773. I used Allan's information to set the position of the yard irons, as can be seen below. Block Fitted to Foreyard Before moving on to adding the various blocks to the foreyard I decided to do a bit of research to try to understand their purposes and to check the required rigging lines from Chris’s excellent rigging plans. There are quite a few blocks to seize and fit, as detailed in the ensuing text. Sling Thimble A loop is wrapped around the central point of the foreyard with a thimble positioned on top. This is used to hold the foreyard in place once it has been hoisted into position using the jeer block and tackle. This thimble is linked to a second thimble which is wrapped around the foremast end cap. To create the sling a length of 0.25mm black thread was double wrapped around the thimble and seized (10 upper and lower half hitch knots) with 0.1mm black thread. The excess thread ends were trimmed to leave the required sling which is ready to be secured to the foreyard. Jeers Two double blocks are located on the foreyard, each situated either side of the foremast. These will be linked to triple blocks which are wrapped around the mast (above the platform) and hang down below the platform. These blocks are used to hoist the foreyard into position. A length of 0.25mm black thread was wrapped around each jeer block and was seized with 0.1mm black thread. According to Longridge’s book, reference Plan No.8 (page 213) two loops are added to each jeer block which are then tied together to secure these blocks to the foreyard. I will secure the jeer blocks to the yard either using a simple clove hitch knot or a reef (square) knot. Fore Topsail Sheet and Yard Lifts Blocks and tackles are used to hoist the sail up from the deck using the clewlines which are attached to the outer corners (clews) of the sail. Once the sails have been hoisted up from the deck they can be tied to the yards. A double block arrangement is fitted to each end of the foreyard. The inner larger block is used for the topsail yard clewlines and the outer block is used for the yard lifts. Clewlines, taken from the fore topsail yard, are fed through the inner end blocks, and are then fed from through additional blocks on the foreyard situated beneath the jeer blocks and are then belayed to the bitts. Yard lifts are used to adjust the foreyard position in the vertical axis, in conjunction with blocks fitted around the mast cap. The outer blocks are used for the yard lifts. To create the double block arrangement a length of 0.25mm black thread is wrapped around the outer smaller block and seized with 0.1mm black thread (4 lower and 4 upper half hitch knots). The two free ends are then wrapped around the second larger block and seized with 0.1mm black thread (10 lower and 10 upper half hitch knots). The correct method for securing these double blocks to the foreyard should be via linked loops (as per the jeer blocks) but I will use a simple clove hitch or reef knot. Seizing the outer block. The second block held in position, using my guadhands, as is ready be seized. The completed double block arrangement. Foreyard Tackle The yard tackles are used to allow the yards to be used as cranes. They can be stowed, when not in use and they hang down from the foreyard when in use. They are located at either end of the foreyard and each tackle comprises a double block arrangement. Chris’s plan sheets shows both rigging options so it will be left to the builder to configure either way. The double block will be created as per the topsail / yard lift double blocks with the addition of a thimble. These will be attached to the foreyard with a flying lead with either clove hitch or reef knots. The flying leads will be secured to the blocks via the thimble. This is a photo of how the double block should look which I did replicate. The block arrangement, complete with the flying lead seized. Foreyard Braces The braces operate as a pair of lines used to rotate the foreyard around the mast, either to port or starboard, to allow the ship to sail at different angles to the wind. They are located at each end of a foreyard. Once seized the blocks will be secured to the foreyard via clove hitch or reef knots. Bunt and Leech Blocks There are two blocks per side for the bunt lines. There is one block side for the leech lines. The bunt and leech lines are used to lift the middle and outer edge sections from the deck. These are simple blocks to seize and will be secured to the foreyard with clove hitch or reef knots. Each block will be wrapped with 0.1mm black thread and seized using black fly tying thread. In the photo below the blue arrow shows the bunt lines and the yellow arrow indicated the leech line, which could be secured to the mid point or bottom corner (orange arrows). Fore Sail Tack The clue line starts on the foreyard and is taken down to the fore sail tack block arrangement and then feeds through the clew line blocks located on the foreyard before being taken down to the deck level. The clew line blocks will be wrapped with 0.25mm black thread and seized with 0.1mm black thread and then secured to the foreyard with clove hitch or reef knots. Blocks ready to be added After a fun day seizing all the blocks are now ready to be added to the foreyard. I have stopped work for the day as the light is starting to fade.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

They are tricky cleats to fit, you've done well to get them all in place.

- 233 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

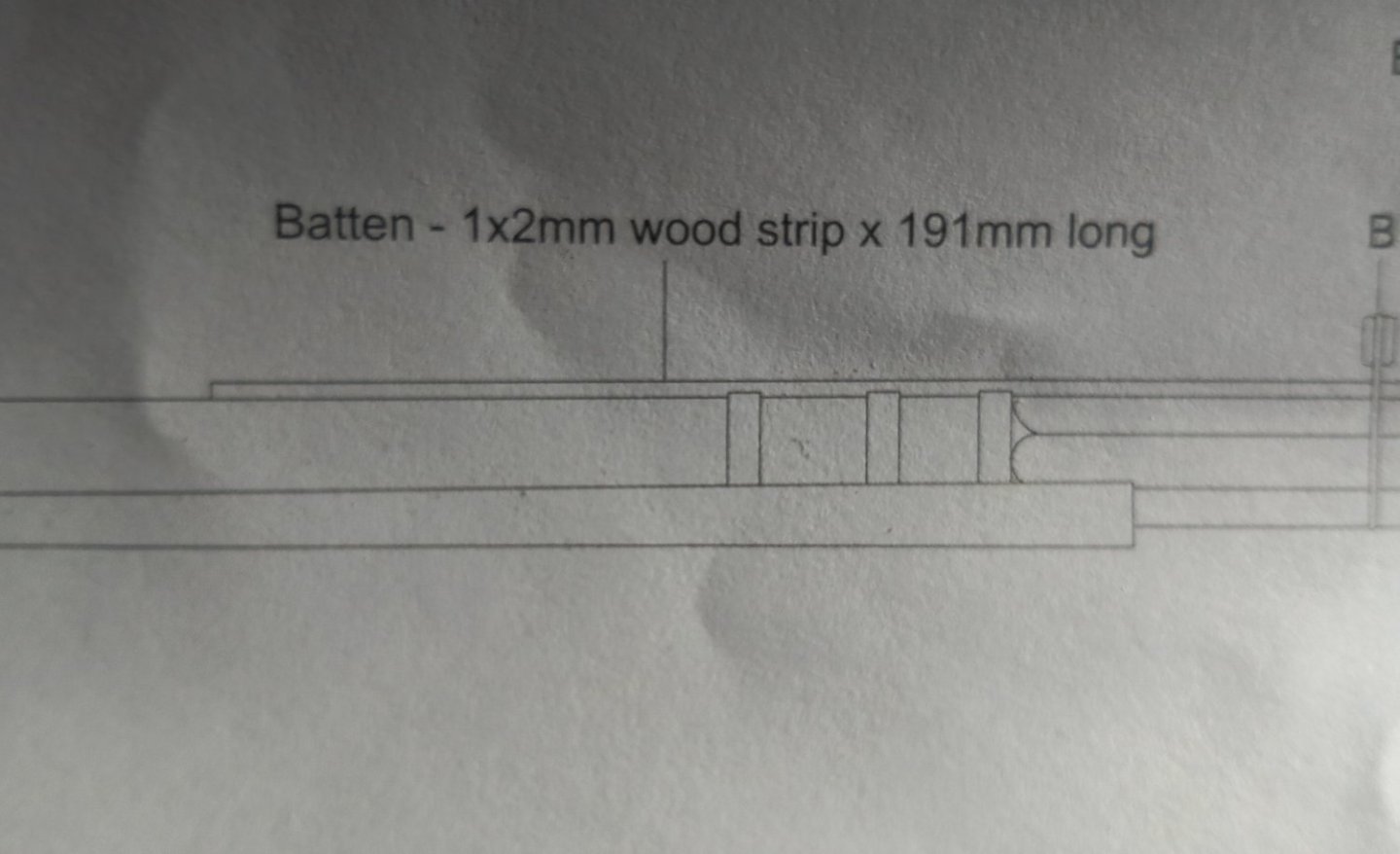

Foremast Work Slow Progress Due to more grandparent duties work on completing the foreyard has been very slow this week. After making the basic foreyard from the 8mm dowel, as detailed in my last post, I looked in Longridge's book. I noted that it is common to add an outer set of batten's to the octagonal central section. This is something I feel is worth adding. I had noted an additional batten is fitted along one edge, as shown in Longridge's book and this is also shown on Chris's plan sheet. I did have some suitable 3mm wide x 0.5mm thick planks which I was able to use to add the required battens to the central octagonal section (yellow arrow). It is not clear in the following photo but I did taper the octagonal batten ends, as shown in the Longridge picture. I used some 2mmW tape to simulate the iron banding, which will look OK when painted black. The two central cleats and 2mm batten (blue arrow) were then added. The foreyard is now ready to be painted black. I did make a school boy error by adding the 4 off end cleats. With these cleats in place it will be impossible to fit the inner stunsail boom irons. I will have to remove them carefully and refit them at a later stage.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

The lathe is a great addition to have for making the yards.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thoughts and Start of Making The Lower Foreyard Today I started work on making the lower foreyard. The foreyard is 380mm long and is manufactured from a length of 8mm diameter dowel. The central section is octagonal (7mmW) and either side is circular tapering from diameter 7mm down to 4.5mm. There are a few PE parts, cleats and blocks to add to the foreyard, once the foreyard has been made. After looking over the plan sheet I made a few notes for easy reference. I have been considering different options with regards to making the central octagonal section. My first thought was to use a length of square material which will assist greatly with making a nice looking octagonal section. I could then round off and taper either end in my proxxon lathe. I decided to put this method on the back burner for the time being. I also tested a method of making the required shape using my table circular saw. As can be seen in the next two photo's it did work to a degree. However when I tried the same method on a longer piece of dowel I realised this method was not going to be that successful. I decided it might be easier if I could make a simple jig. I added two 4mm high parts to a base plate. These were parts were positioned so the dowel was a snug fit and clamps can be used to stop any unwanted movement. I then used a needle file and a sanding block to add the flat edges. With the brackets being 4mmH meant I could draw lines along the midpoint of the dowel. I start the shaping process by making a 7mm x 7mm square shape. The drawn lines ensures it is easy to accurately rotate the dowel through 90 degrees. It is also easy to add a line so the holes can be drilled for the yard footrope stirrup. I find it easier and more accurate to add these holes prior to tapering the dowel. Once the octangle shaping was complete I added the first taper, using my proxoon lathe. I started by reducing the overall diameter from 8mm down to 7mm along the whole length. I then created the required taper checking the diameters for both the inner lower stunsail boom iron and lower stunsail boom end cap. As can be be seen in the final three photo's everything seems to be a good fit, noting they are only dry fitted. Inner Lower Stunsail Boom Iron and a Yard Footrope Stirrup Outer Lower Stunsail Boom Iron and Lower Stunsail Boom Iron Cap

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks, I think I need to remove and reshape it a bit to match the picture provided in Longridge's book

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thoughts On Adding Foreyard to Foremast As mentioned in a previous post I think it might be easier to secure the foreyard to the foremast before the stays and shrouds are rigged. The reasoning behind this is for ease of access and I know @ECK has done this with his Indy build. I plan to add the threads for the burton pendant, shrouds and stays to the mast before I add the mast cap but I will not rig the other ends so they can be kept out of the way whilst I rig the yard jeers, sling, truss pendants and nave lines. To help me fully understand the yard rigging process I have made the following notes. It has very interesting to work out the function of the various aspects of hoisting and securing a yard to the mast. Jeers The yards are hoisted up into position using the jeer block and tackles. Two double blocks are located on the yards, each situated either side of the mast. Two more triple blocks are seized to the figure of 8 wrapping around the mast (above the platform) and they hang down, so they are positioned below the platform but above the yards position. The rigging between these blocks then allows the yard to be lifted up in position. Once in position the free end(s) are belayed. Slings Once the yards have been raised to the required height, using the jeers, they are then supported by a sling arrangement. A loop is wrapped around the central point of the yard with a thimble. A second longer loop is wrapped around the mast cap with a thimble on the end. The two loops are then linked together with thread, via their respective thimbles. Truss Pendants Once the yard has been hoisted, using the jeer block and tackles, and held in place with the sling, truss pendant are used to keep the yard in place with the mast. The truss pendant comprises two parts, with each part located either side of the mast. Each pendant is a loop tied around the yard with a thimble on one end. With the yard in position the other end of each pendant is placed behind the mast and is then feed through the other pendants thimble before they are belayed to the deck via a block and tackle arrangement. Nave Line The nave line is used to hold the truss pendants in place. The nave block is located on the underside of the platform, centrally on the rear crosstree. The thread that passes through the nave block has a thimble on one end and the other end is belayed to the deck. A length of thread is passed through the thimble and each end is then secured to the truss pendants. More Thoughts And Progress on Rigging I have been doing a little bit more on some rigging and testing bits and pieces on the foremast and I thought I would this section of this post with some information regarding the seizing threads I like to use. Seizing Blocks When seizing blocks I use different threads, depending on the block and / or rigging thread size. For most 3mm and 4mm blocks I normally use Semperfli 18/0 spyder thread (black, white or beige). For larger rigging thread and / or blocks I normally use Gutterman thread CA02776 (COL722 and COL000), which is akin to 0.1mm thread. Foremast Top Section When looking at the following photo in Longridge’s book I noted there is a curved section added to the top of the mast cap. I decided to add this feature to my Indy build. I also noted the figure of 8 wrapping required which the jeer blocks are seized to. I simply cut a slice from a dowel and then added the groves for the lifts and sling rigging. The curved block top does need to be painted black. I then made the slings and lifts rigging which were then very loosely test fitted in the slots. Sorry the photo is out of focus. The lift blocks will be secured to the cap using the lashing method as shown in Fig 174 (Longridge). I tested this method in the following photo (blue arrow). The yellow arrow in the photo shows the sling test test fitted. The free end of the sling thread has been fed through the eyelet on the other end of the thread but I will seized once the yard has been fitted so the sling's thimble can be set to the required height above the yard. I have also added the figure of 8 wrapping around the top of the foremast (orange arrow). I then threaded the two triple jeer block threads in place. I have not seized the jeer blocks threads to the wrapping as this will be done once the foreyard has been added so I can ensure they set to the right height above the yard. I am about to start the manufacturing process of the lower foreyard which should keep me busy for a few days, noting my wife and I will looking after our 2 year grandson this weekend so I'm not expecting to spend any time in the shipyard.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I agree it is better to do that than sand away.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Foremast Channel Chainplates I have now added the various deadeyes, strops and chain plates to both foremast channels. I am reasonably happy with how these have turned out. I did use a diluted mixture comprising 50% wood filler / 50% titebond to fill some of the small gaps between the channel and hull.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.