-

Posts

3,169 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Glenn-UK

-

I have just ordered the HM Alert (V2) from Vanguard Models and I am looking forward to receiving the kit next week (UPS delivery scheduled for Tuesday 6th April). I am currently rigging the Duchess of Kingston (Vanguard Models) which should be completed in a few weeks time. I choose the Alert for my next build as I think it will fit the gap between the completion of the DOK build and the release of the Sphinx kit from Vanguard Models release in few months time.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

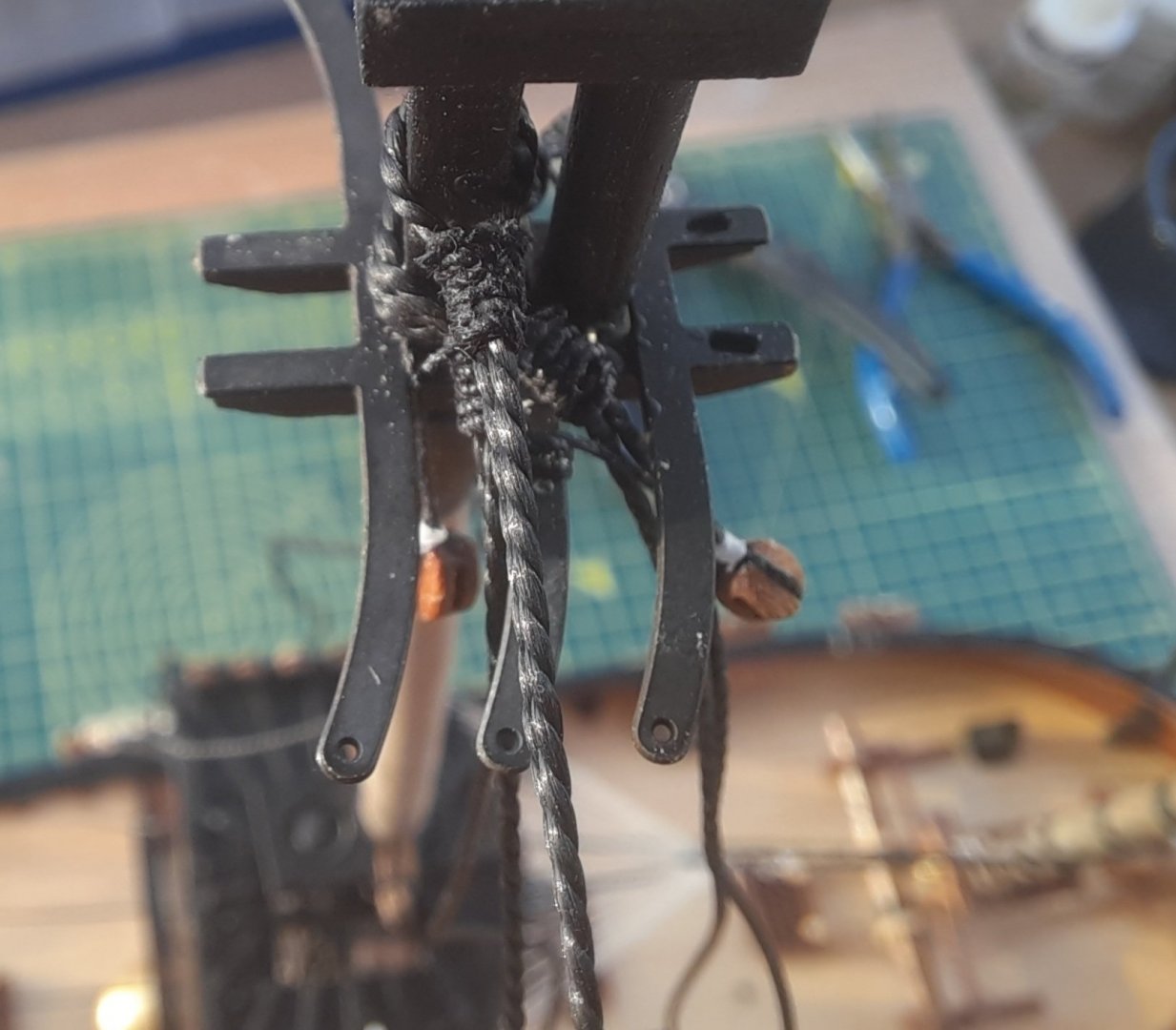

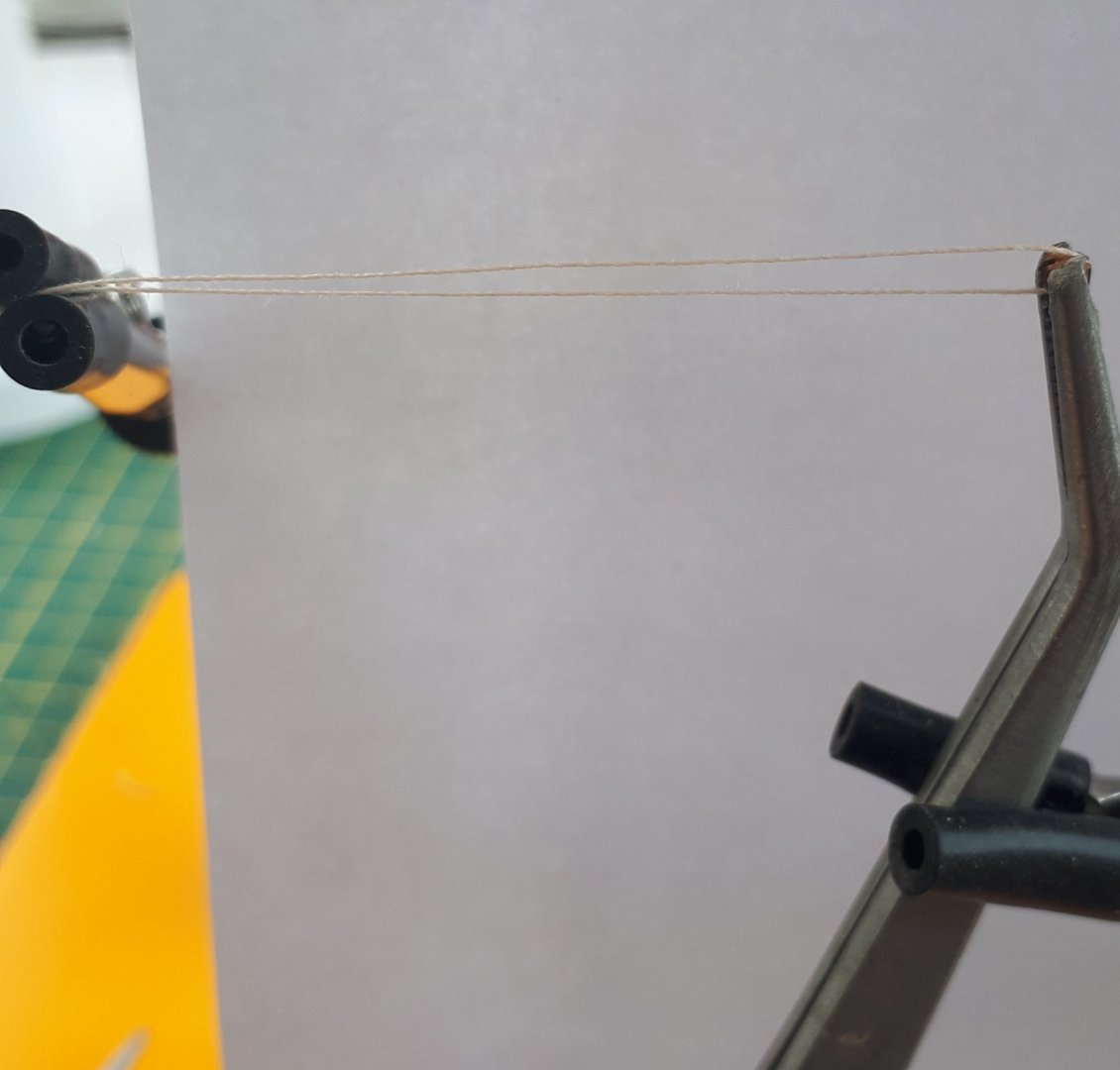

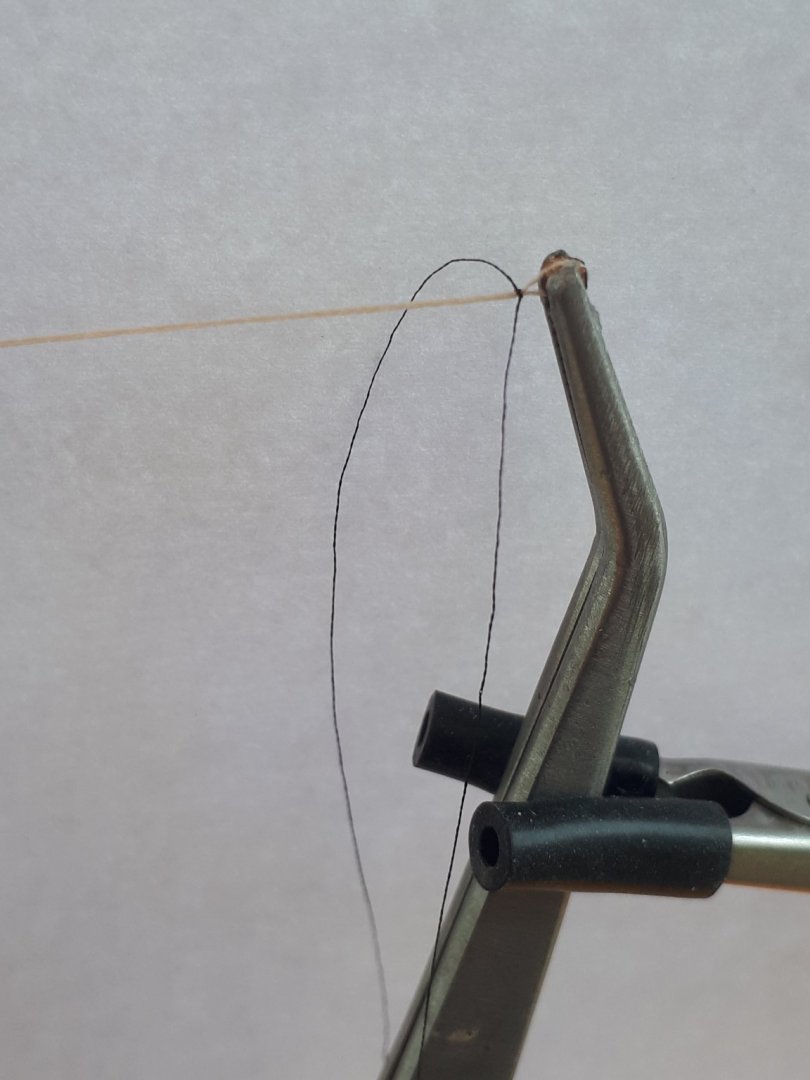

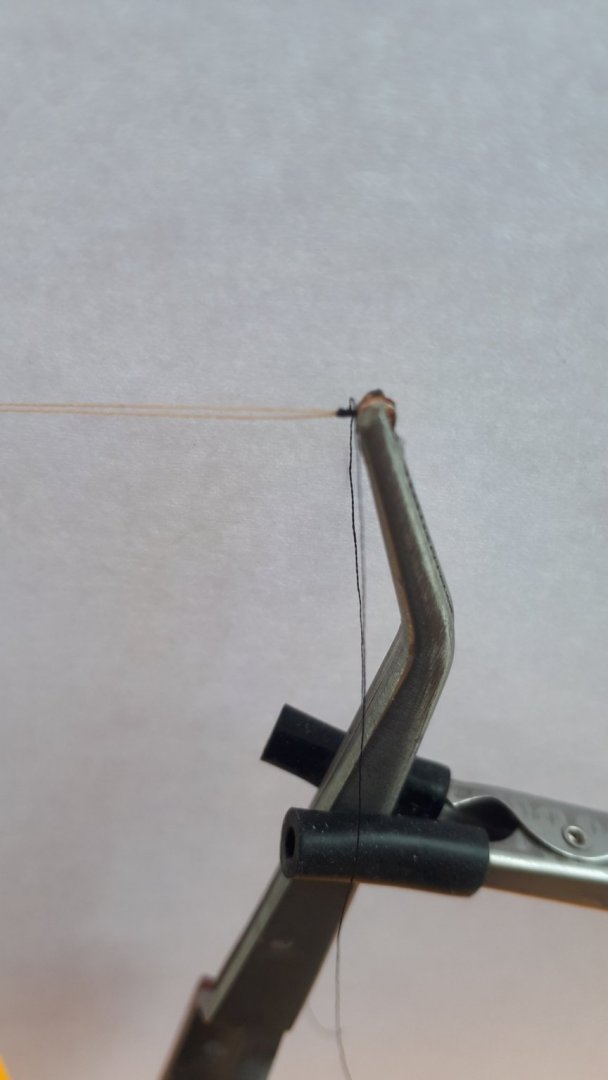

As work progresses on adding the main top mast shrouds I thought I would share my methods. I started by cutting a 40cm length of black 0.75mm thread. This was wrapped around the top of the main mast to create the first two shroud lines. The quad hands were used to tension the shroud, as shown in the photo below. The photo also provide a nice vista of the view from my ship yard. Using the top and bottom half hitch method with 0.25mm black thread I applied the seizing to secure the shroud. I opted for 6 top and 5 bottom half hitches. The end result of the seizing is shown in the next photo. It took approx. 30 minutes to add the 4 shroud line pairs. Next it was time to add the 3mm deadeyes. The first task is to form a hole for the deadeye. To do this I used my deadeye jig, as described in an earlier post. In the photo below the jig has been position and the first shroud line wrapped around it. To keep the tension in the shroud line I have used a pair of reverse action tweezers attached to the end of the shroud line. Using the black fly tying thread I was able to form the hole in the shroud. It was then then a simple task to fit the deadeye in said hole. It is a nice snug fit. The next task was to add whipping to the shroud line. I held the deadeye in the quad hands and adjusted the position to ensure the line was tensioned. I then cut a length of 0.1mm natural thread and started the process of adding top and bottom half hitch knots. I added 5 top and 5 bottom knots and in next to no time the task was complete. A 15cm length of 0.1mm natural thread was cut for the lanyard which was then threaded through both deadeyes. The shroud line was tensioned as the lanyards were adjusted. The thread was then passed through a small gap between the top of the deadeye. The shroud line and will tied off later on once the final tensioning process has been completed. The above process is now to be repeated for the 7 remaining shroud lines.

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

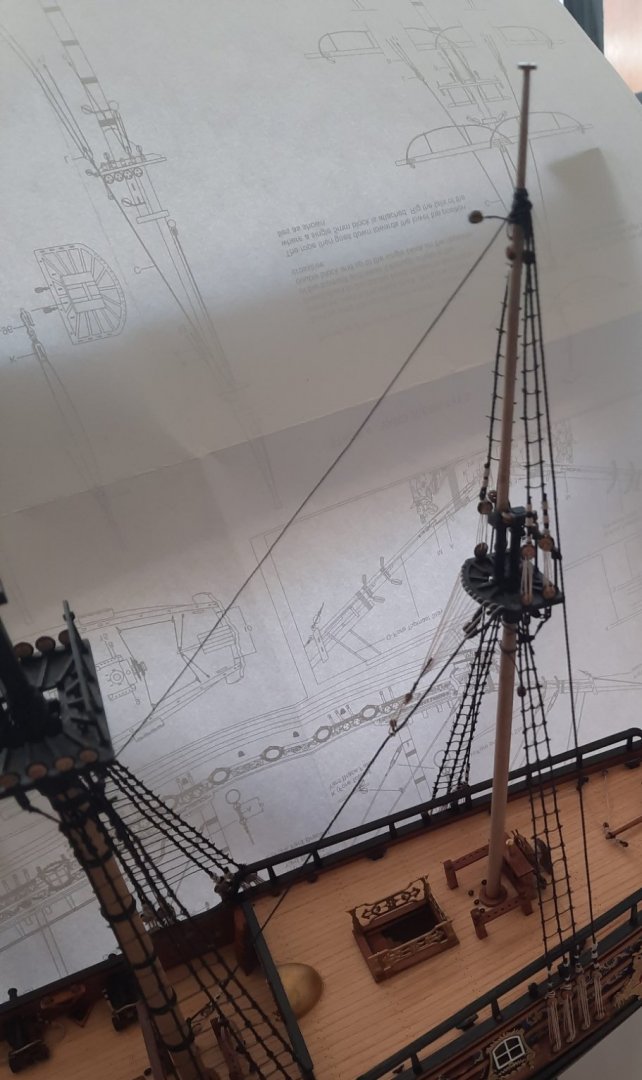

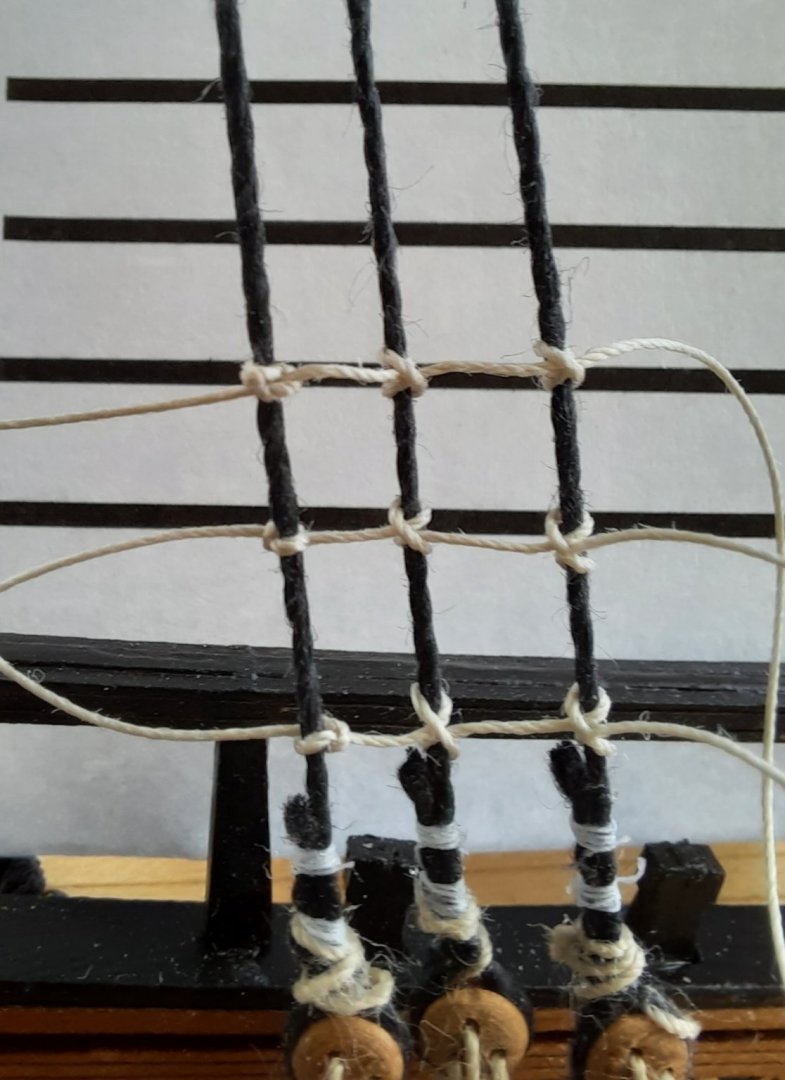

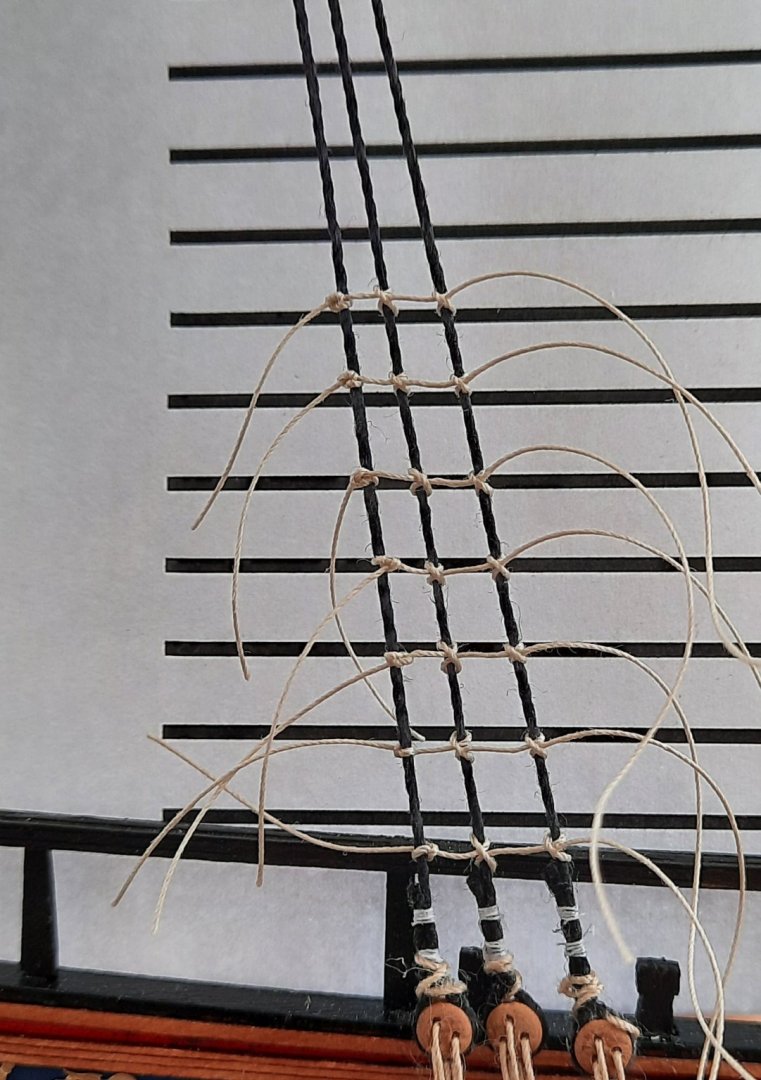

I have now completed adding all the shrouds, ratlines and stays to the mizzen mast and mizzen top mast. The mizzen is now ready for the yards. Before fitting the yards I will have to complete adding the shrouds, ratlines and stays to the main and fore masts. Tomorrow I will start work on adding the shrouds and ratlines to the main topmast, followed by the main top gallant mast. This is a picture taken as I was adding the mizzen top mast ratlines. I quite like adding ratlines. I start with the bottom ratline, then I add the middle one and then I add the top one. I then fill in the gaps in stages. Once I am happy with the position I coat the ratlines and shrouds with a 50/50 diluted pva solution. After all the ratlines have been added I dyed the lines black. Picture showing the shrouds, ratlines and stays. Another picture showing the shrouds, ratlines and stays.

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

Great to see the progress, you are doing a great job. This looks to be a brilliant kit.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Following on from yesterdays post I have now completed adding the main mast crows feet rigging. I started by taking a 3m length of 0.1mm natural thread. There are 18 holes in the main mast platform. To ensure I finished with the thread running through the last platform hole nearest to me I started the rigging up through the 10th hole, then I passed the thread through the euproe back towards me then I fed it down platform hole 9 then back up platform hole 8 back and then back through the next hole in the euproe etc. Picture of the start of the rigging As the rigging progressed the more observant will see I made a error with the threading pattern which meant I had to unthread it all and start again. I did not waste much time thankfully. 2nd time around and everything is looking better, no mistakes so far! After a few more minutes the rigging was finally completed. I will start to add the shrouds to the mizzen top mast next.

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

Today I thought I would detail my work on the main mast Euproe assembly. I will follow this up with the rigging of the main mast crows feet in a separate post. The assembly consists of 2 x 2mm blocks and 1 x euproe photo etched part which I blacken using a burnishing product. I ran a 0.5mm micro drill through both the 2mm blocks to help with the threading the rigging thread. Using 0.1mm natural thread this was seized this to the 2 2mm blocks using black fly tying thread. Stage 1 - Setting up the 1st 2mm block in the quad hands. Stage 2 - Starting the seizing. I used an alternate top and bottom half hitch method to add the seizing. I found it better to work toward the block when adding the seizing. Stage 3 Adding the euproe I ran the 0.1mm natural thread thread through the euproe hole and then seized it with black fly tying thread using an alternate top and bottom half hitch method. It produces quite a nice end result as can been seen below. Stage 4 - Rigging the blocks Once the 2 x 2mm blocks and 1 x euproe part were seized it was a simple case of running the 0.1mm rigging thread through both blocks. The assembly is now ready to be added to the Main Stay. After viewing the attached photo I did tidy up the seizing and badly cut ends on the right hand block.

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

The 1mm black thread I ordered has still not arrived from CMB so I am unable to progress with adding the fore mast shrouds. I therefore decided to add the main stay and the main preventer stay. I had just enough 1mm black thread left for the main stay and I used the kit supplied 1.3mm black thread for the main preventer stay. I added a little bit of serving to each stay line hold the mouse in place. Once the stays were fitted I coated the lines with a diluted solution of pva which has stiffen them up nicely. I plan to add the main mast crows feet next. Main Stay and Preventer Stay Deadeyes. I am really pleased with how they have turned out. Much improved compared with the main mast shrouds. I am starting to get the hang of this rigging malarkey.

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

I am currently waiting for a delivery of some additional thread from CMB (it has now been dispatched) before I can continue with the Fore Mast shrouds. I had managed to use all the kit supplied thread because I had to redo the main mast shrouds. Over the last couple of days I have added the mizzen stay and mizzen crows feet. I decided to manually serve a bit of the mizzen stay to hold the mouse in place. I have quite pleased with the end result. Mizzen Mast Crows Feet with a nice reflected shadow. Very fluffy lines (no beeswax!!!!!) They do not look fluffy to the naked eye however, Mizzen Mast Stay (again with a shadow).

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

A great weekend of work, very impressive looking even at this very early stage. What is the sanding tool you are using?

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Work progressing slowly at the moment. Adding shrouds, futtock staves, catharpins and futtock shrouds to the main mast has proven to be a very time consuming task. It has also a really test of patience at times but as I progressed with this aspect I found my skill levels were improving. When adding the futtock stave I found the use of the quads hands to be of great benefit. I used the quad hands to hold the futtock stave in positions as whilst I seized the copper bar to the shroud lines. The attached picture shows a long length of copper held which enabled me to cut the copper bar to the required length. The following picture show the futtock stave after it has been seized and painted black. As can be seen there was still a little bit more trimming of excess thread required. The main mast is now ready and waiting for the ratlines to be added.

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

I also use quad hands. Has made many rigging tasks much easier

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

It looks very good, and thanks for the shout out.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

Great to see you have started on this build, it is going to be once of my next projects after the DOK

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

I am happy to report that take two of the main mast shroud and lanyards work is much better. The jig used is simply a thin strip of wood fitted with two copper wire lengths set for the channel deadeye and a dowel (approx 4.8mm diameter) to represent the shroud deadeye. With the jig in place the shroud line can be wrapped around the dowel. Using some black fly tying thread I seized the shroud to make a loop for the deadeye. Picture of jig in place and shroud being siezed Completed shroud with deadeye fitted With deadeyes fitted to the first starboard shroud pair I added the lanyards, using 0.25mm natural thread. I will continue to add the deadeyes and lanyards to the other shroud lines.

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

It has been a few days since my last post. I had completed adding all the shrouds and lanyards to the main mast. However I was not totally happy with how the deadeyes were sitting in the shrouds. The jig I had made, similar to the one I used on the mizzen mast, allowed the deadeye to fit, but they very loose. I carried on thinking it would be OK but common sense prevailed so I took the decision to remove the lanyards and shrouds and to start again. I started by modifying the jig, so the shrouds when wrapped around the jig and seized would form a smaller hole for the deadeye. I did a test after I had modified the jig and it produced a much better result with a nice tight fitting deadeye. I then cut 4 x 50cm lengths of 1mm black thread for each shroud pair (2 pairs per side) and 2 x 30cm lengths for the single shrouds (1 per side). The first shroud line was then positioned around the mast. I used the the quad hands to hold the shroud line in place, as shown below. I also used a croc clip to bring the lines together near the point of seizing I used 0.25mm black thread to seize the shroud line around the mast. I will now continue to add all the shroud lines this morning which should not take too long to complete. My next post will (hopefully) so the progress of adding the deadeyes and lanyards to the shrouds which will take me a few days to complete.

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

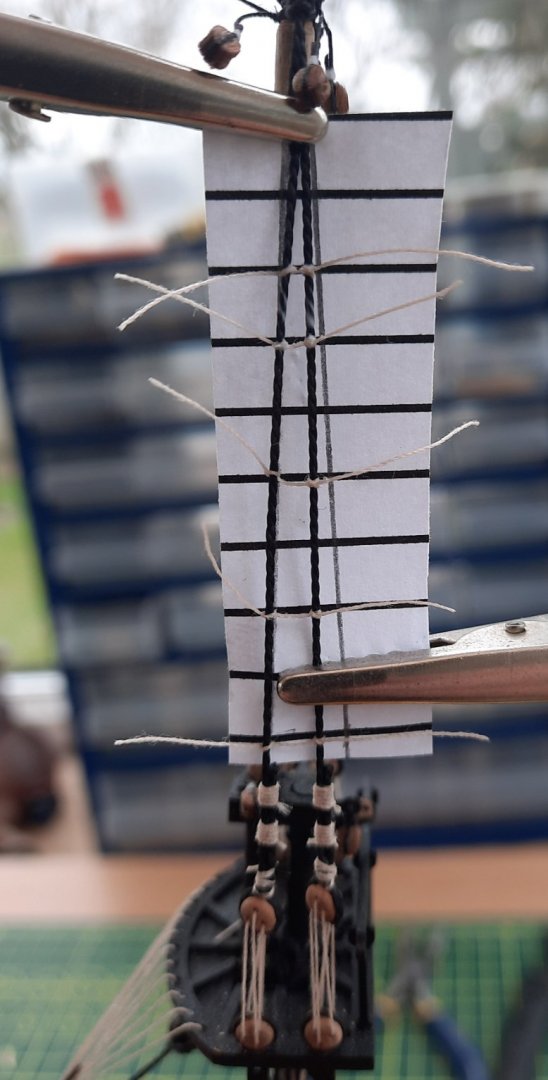

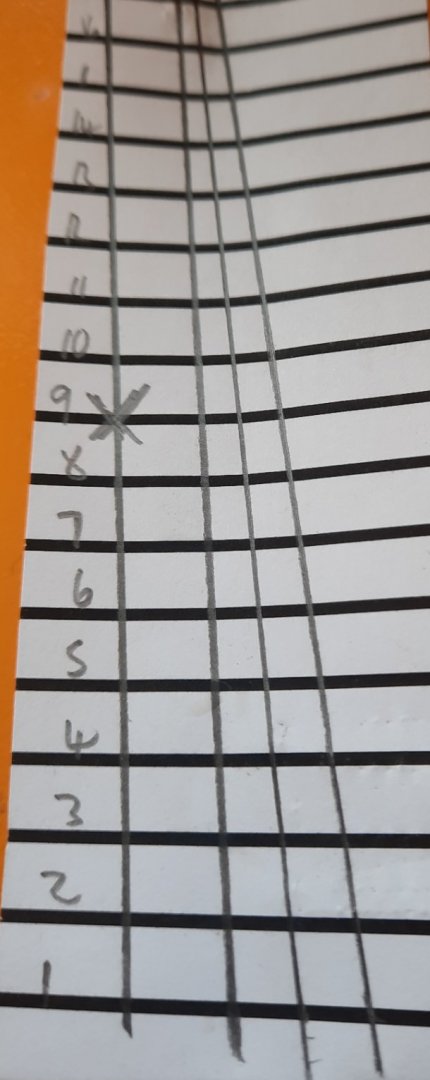

As I progressed with the mizzen mast ratlines I noticed the central shroud line was not properly centred. As I had only done half the ratlines and it was taking me around 10 minutes to add each ratline I decided to remove them and start again. I modified by ratline template and added the vertical lines, thanks to DelF for this excellent tip. Picture of the template This time I decided to add the bottom rat line, then the middle ratline and then the top ratline to ensure the shrouds were true and straight. This worked much better. I started each ratline with a half hitch which I positioned at the back of the shroud and added a touch of diluted pva, (50/50 mix, another DelF tip) when I was happy with its position. I then used clove hitch knots for the next two shroud lines and added a touch of diluted pva when I was happy with each position. Finally I stained the ratlines black. This is by far the best set of ratlines I have added to a model. Still room for some improvement

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

Hi Matt Thanks for the complement. I am mainly using tweezers which I have became quite adept at using but I do use my fingers as well, usually in combination with the tweezers.

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

I am finding adding the ratlines to the mizzen mast to be very therapeutic and it is a task I am very much enjoying at the moment. I started using the black ratline thread supplied with the kit but I found it difficult to see and adjust the clove hitch knots to get the desired tension in the ratlines. Therefore I have opted to use 0.1mm natural thread which has made the task much easier. I have the option to dye the ratlines black when the task is completed, e.g. by using Indian ink. As can been seen in the photo below I printed out a paper template for the ratline spacing. I also have a small wooden strip of the same width as a double check. I will adjust the position of the ratlines as necessary and then tighten up all the knots once I have added all the ratline lines. I will then apply a diluted pva solution to shrouds and ratlines before trimming away the excess thread and applying the dye.

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

Thank you. The Duchess is a very nice model to build

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

Another tricky rigging task completed with the addition of the catharpins and futtock staves and shrouds to the mizzen mast. As can be seen in the photo it is not the work of a master but, once again, compared with my last build it is a marked improvement. I found it better to add the catharpins either side of the mizzen mast. I found fitting the futtock stave the most complicated aspect of this task but it was not as bad as I first feared. When adding the catharpins I did experiment with using 0.5mm copper wire (as per DelF on Speedy) but I ended up using 0.5mm black thread. The futtock shrouds look OK but there is definitely room for improvement.

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

Thanks Derek. I'm slowly getting better trying to use the methods shown on MSW by better builders such as you. That is great tip on trimming, thanks for sharing. Wrapping the excess lanyard around the shroud was a challenge at times. I used a needle to help thread the lanyard end back over the top of the deadeye.

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

After many trials and tribulations over the last 7 days I have now finally completed the mizzen mast shrouds. As the two photos below will show I am no master craftsman with regards to this aspect of model ship building. This did really test my patience at times and I lost count of the number of times I had to redo various bits, adding new shroud lines, redo the lanyards, etc. I did find it very fiddling working with 3mm deadeyes but the jig I made proved to be a very useful tool in forming a nice loop, seizing and then placing the deadeye in the shroud line. The tying off of the lanyards is not still not great but, unlike previous builds, I did manage to get the final knot behind the deadeye. In summary my shroud technique is slowly improving with each new build but there is still plenty of room for improvement. Next I will look at adding the futtock stave and catharpins. I am also debating weather to add the mizzen mast ratlines before moving on to main mast shrouds and lanyards. I will redo the middle lower shroud seizing as it looks pretty awful in the picture below

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

Having spent most of this week working on the mizzen mast shrouds and lanyards I was feeling pretty pleased with myself this morning with the end result. I started to look at the ratline spacing so I could position the futtock staves. I was a bit concerned with the spacing between the shroud lines at the top. I had a look at the plan sheets to see to see if my concern was just a flight of fantasy. Looking at the plans I noted my shroud lines did not match up, it was then that I realised I had made a major mistake. I had seized the shroud lines around the bottom of the mizzen topmast instead of around the squared top of the mizzen mast. I have no idea why I had done that or why I had not noticed it sooner. With a tear in my eye and my scissors in hand I removed all the mizzen shrouds and lanyards. The mizzen mast is now devoid of all shrouds and lanyards and is ready and waiting for me to get my act together and do to the job correctly. The only positive I can take from this is that I was able to refine by technique with the first attempt.

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.