-

Posts

1,304 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MrBlueJacket

-

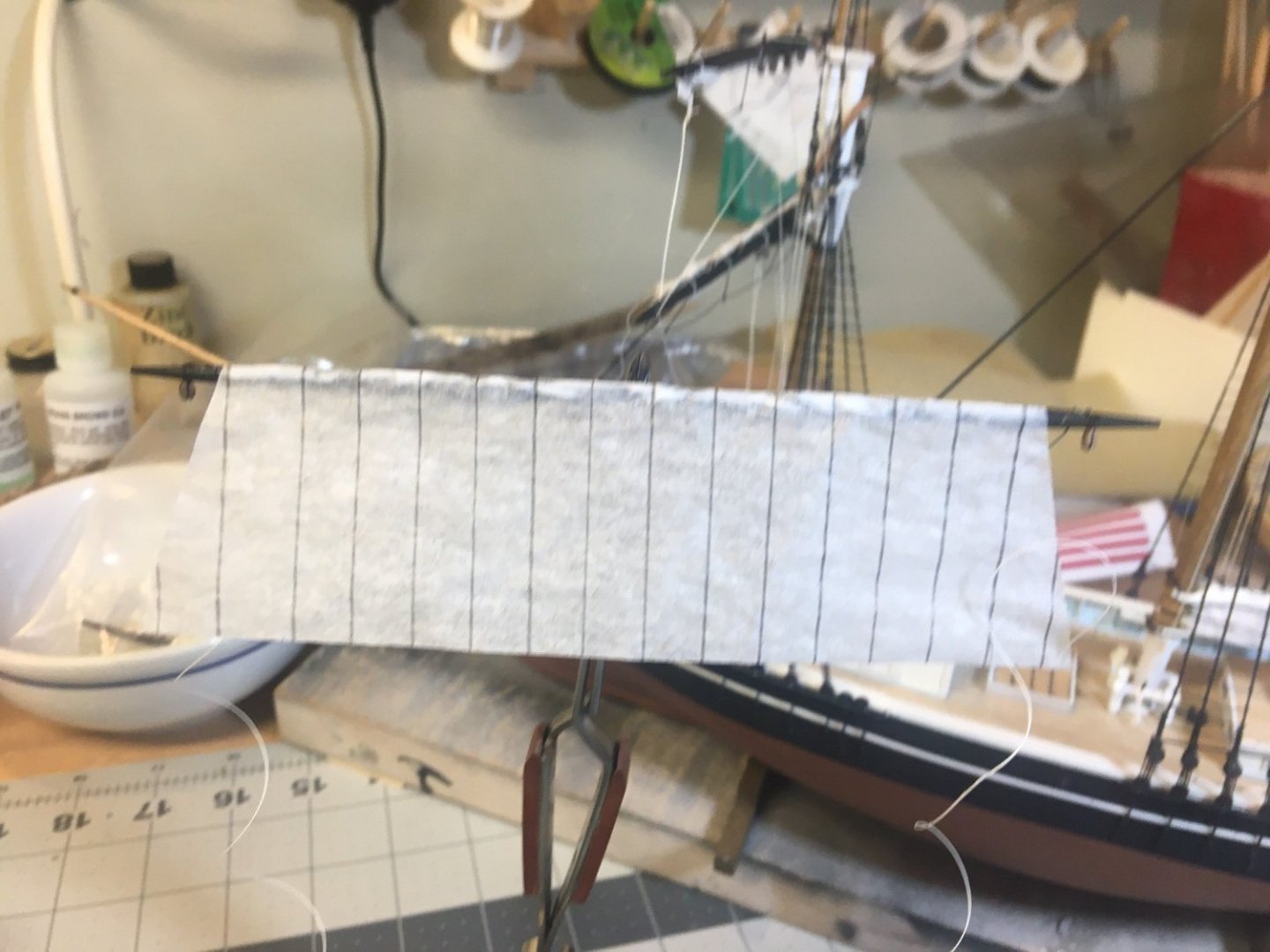

Here we have the three lower braces attached. Two more to go, then the running rigging on the bowsprit, attach 2 jib sails, and she's done.

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

The decision to make them limited edition was made by the previous owners. When I took over, they were already well into development. The idea was to honor the 150th anniversary of their battle off Cherburg, France.

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

Very nice, Dave. Your customer file now shows 10% discount on the next kit you buy from us. Nic

- 19 replies

-

- Putnam

- BlueJacket Shipcrafters

-

(and 3 more)

Tagged with:

-

Absolutely. An America kit would have either a frame set labeled A-B-C... or 1-2-3... as we still do today. The keel is labeled A 1 B 2 C 3 etc.

-

One of the most relevant reasons for the loss of solid hulls is that they are labor intensive and expensive to produce, compared with POB laser cutting. The cost of the basswood boards is also more than the cost of the sheets required to produce bulkheads. Our POF models of the America and Jefferson Davis start out as solid hulls which we then slice like a loaf of bread. that technique was invented and patented by Art Montgomery. who owned BlueJacket in the 1980's. It is very expensive, since you have the cost of a solid hull and the cost of slicing it.

-

That would be nice, but it would take hours of work that doesn't generate any revenue. With the state of the economy, it's just not practical.

-

And a long one at that. BlueJacket alone has over 80 current kits, and 100's more from the past.

-

I think you've said that before....... Nic

- 23 replies

-

- Yankee Hero

- Bluejacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Painted the inside of the cabins flat red, per the instructions. Next step is to paint the outside dark brown.

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

Yes, I make them out of .010 annealed wire. Nic

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

The pintle has a pin, the gudgeon has a hole.

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.